Energy Penalty Reduction Techniques For Cryogenic CO2 Capture

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic CO2 Capture Technology Background and Objectives

Cryogenic carbon dioxide capture technology has emerged as a promising approach for addressing the global challenge of carbon emissions reduction. The technology's development can be traced back to the early 1990s when researchers began exploring low-temperature separation methods for gas purification. Over the subsequent decades, cryogenic CO2 capture has evolved from theoretical concepts to laboratory demonstrations and pilot-scale implementations, marking significant progress in carbon capture technology.

The fundamental principle of cryogenic CO2 capture involves cooling flue gas to temperatures where CO2 desublimes directly from gas to solid phase (approximately -100°C to -135°C), allowing for physical separation from other flue gas components. This approach offers several inherent advantages, including high CO2 recovery rates (potentially exceeding 90%), production of high-purity CO2 suitable for utilization or storage, and the absence of chemical solvents that plague conventional capture methods.

Despite these advantages, the technology faces a critical challenge: high energy consumption. The substantial energy penalty associated with cooling processes has historically limited widespread commercial adoption. Current research trends are increasingly focused on developing innovative approaches to reduce this energy penalty through process optimization, heat integration, and novel equipment designs.

The evolution of cryogenic capture technology has been characterized by three distinct generations. First-generation systems employed simple direct cooling approaches with minimal heat recovery. Second-generation systems introduced more sophisticated heat exchange networks and process integration. The emerging third generation incorporates hybrid approaches, combining cryogenic processes with complementary technologies such as membrane separation or pressure swing adsorption to optimize energy efficiency.

The primary technical objective in this field is to reduce the energy penalty to below 1 GJ/tonne CO2 captured, a threshold considered economically viable for widespread implementation. Secondary objectives include enhancing operational flexibility to accommodate varying flue gas compositions, improving system reliability under industrial conditions, and reducing capital costs through equipment optimization and standardization.

Recent technological breakthroughs in advanced heat exchangers, phase change materials, and process intensification techniques have accelerated progress toward these objectives. The integration of waste heat recovery systems and the development of specialized cryogenic equipment designed specifically for CO2 capture applications represent promising pathways for further advancement.

As global climate policies increasingly mandate carbon emissions reduction, cryogenic CO2 capture technology stands at a critical juncture, with energy penalty reduction representing the key determinant of its future commercial viability and contribution to climate change mitigation efforts.

The fundamental principle of cryogenic CO2 capture involves cooling flue gas to temperatures where CO2 desublimes directly from gas to solid phase (approximately -100°C to -135°C), allowing for physical separation from other flue gas components. This approach offers several inherent advantages, including high CO2 recovery rates (potentially exceeding 90%), production of high-purity CO2 suitable for utilization or storage, and the absence of chemical solvents that plague conventional capture methods.

Despite these advantages, the technology faces a critical challenge: high energy consumption. The substantial energy penalty associated with cooling processes has historically limited widespread commercial adoption. Current research trends are increasingly focused on developing innovative approaches to reduce this energy penalty through process optimization, heat integration, and novel equipment designs.

The evolution of cryogenic capture technology has been characterized by three distinct generations. First-generation systems employed simple direct cooling approaches with minimal heat recovery. Second-generation systems introduced more sophisticated heat exchange networks and process integration. The emerging third generation incorporates hybrid approaches, combining cryogenic processes with complementary technologies such as membrane separation or pressure swing adsorption to optimize energy efficiency.

The primary technical objective in this field is to reduce the energy penalty to below 1 GJ/tonne CO2 captured, a threshold considered economically viable for widespread implementation. Secondary objectives include enhancing operational flexibility to accommodate varying flue gas compositions, improving system reliability under industrial conditions, and reducing capital costs through equipment optimization and standardization.

Recent technological breakthroughs in advanced heat exchangers, phase change materials, and process intensification techniques have accelerated progress toward these objectives. The integration of waste heat recovery systems and the development of specialized cryogenic equipment designed specifically for CO2 capture applications represent promising pathways for further advancement.

As global climate policies increasingly mandate carbon emissions reduction, cryogenic CO2 capture technology stands at a critical juncture, with energy penalty reduction representing the key determinant of its future commercial viability and contribution to climate change mitigation efforts.

Market Demand Analysis for Energy-Efficient Carbon Capture

The global carbon capture market is experiencing significant growth, driven by increasing environmental regulations and corporate sustainability commitments. Current projections indicate the carbon capture and storage (CCS) market will reach approximately $7 billion by 2026, with a compound annual growth rate of 13.8% from 2021. Specifically, the cryogenic carbon capture segment is gaining traction due to its potential for higher efficiency and lower long-term operational costs compared to conventional methods.

Industrial sectors represent the primary demand drivers for energy-efficient carbon capture technologies. Power generation facilities contribute roughly 40% of global CO2 emissions, making them the largest potential market for cryogenic capture solutions. Additionally, cement production, steel manufacturing, and chemical processing industries collectively account for another 30% of industrial carbon emissions, representing substantial market opportunities.

Regulatory frameworks are increasingly favorable for carbon capture technologies. The implementation of carbon pricing mechanisms in over 45 countries has created economic incentives for emissions reduction. In the United States, the enhanced 45Q tax credit now provides up to $85 per ton for captured and sequestered CO2, significantly improving the financial viability of cryogenic capture projects.

Market analysis reveals growing interest in technologies that can reduce the energy penalty associated with carbon capture. Traditional capture methods typically impose energy penalties of 20-30%, substantially increasing operational costs. Industry stakeholders are actively seeking solutions that can reduce this penalty to below 15%, with aspirational targets of under 10% for next-generation systems.

The market for retrofit solutions is particularly robust, as existing industrial facilities seek cost-effective paths to decarbonization. Approximately 75% of potential customers express preference for technologies that can be integrated into existing infrastructure rather than requiring complete system replacements.

Regional market assessment shows varying levels of demand maturity. Europe leads in adoption readiness due to stringent emissions regulations and high carbon prices, followed by North America where tax incentives are driving interest. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with increasing government support for clean energy technologies.

End-user surveys indicate that return on investment timeline is a critical factor in technology adoption decisions. Solutions that can demonstrate payback periods under 5 years receive significantly higher consideration, highlighting the importance of reducing both capital expenditure and operational costs associated with energy penalties in cryogenic CO2 capture systems.

Industrial sectors represent the primary demand drivers for energy-efficient carbon capture technologies. Power generation facilities contribute roughly 40% of global CO2 emissions, making them the largest potential market for cryogenic capture solutions. Additionally, cement production, steel manufacturing, and chemical processing industries collectively account for another 30% of industrial carbon emissions, representing substantial market opportunities.

Regulatory frameworks are increasingly favorable for carbon capture technologies. The implementation of carbon pricing mechanisms in over 45 countries has created economic incentives for emissions reduction. In the United States, the enhanced 45Q tax credit now provides up to $85 per ton for captured and sequestered CO2, significantly improving the financial viability of cryogenic capture projects.

Market analysis reveals growing interest in technologies that can reduce the energy penalty associated with carbon capture. Traditional capture methods typically impose energy penalties of 20-30%, substantially increasing operational costs. Industry stakeholders are actively seeking solutions that can reduce this penalty to below 15%, with aspirational targets of under 10% for next-generation systems.

The market for retrofit solutions is particularly robust, as existing industrial facilities seek cost-effective paths to decarbonization. Approximately 75% of potential customers express preference for technologies that can be integrated into existing infrastructure rather than requiring complete system replacements.

Regional market assessment shows varying levels of demand maturity. Europe leads in adoption readiness due to stringent emissions regulations and high carbon prices, followed by North America where tax incentives are driving interest. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with increasing government support for clean energy technologies.

End-user surveys indicate that return on investment timeline is a critical factor in technology adoption decisions. Solutions that can demonstrate payback periods under 5 years receive significantly higher consideration, highlighting the importance of reducing both capital expenditure and operational costs associated with energy penalties in cryogenic CO2 capture systems.

Current Status and Challenges in Cryogenic CO2 Capture

Cryogenic CO2 capture technology has emerged as a promising method for carbon capture due to its high efficiency and relatively low energy requirements compared to conventional absorption processes. Currently, the technology has advanced from laboratory-scale experiments to pilot plant demonstrations, with several industrial-scale projects under development globally. The fundamental principle involves cooling flue gas to temperatures where CO2 desublimation occurs (typically below -100°C), allowing for physical separation of solid CO2 from other gases.

Despite its potential, cryogenic CO2 capture faces significant energy penalty challenges. The primary energy consumption occurs during the cooling process, which requires substantial refrigeration power to reach cryogenic temperatures. Current systems typically exhibit energy penalties ranging from 0.7 to 1.2 MWh per ton of CO2 captured, representing a major obstacle to widespread commercial adoption.

Technical limitations include heat exchanger inefficiencies, where even state-of-the-art designs struggle to achieve optimal heat transfer at cryogenic temperatures. Frost formation on heat exchange surfaces further reduces efficiency and necessitates periodic defrosting cycles, adding operational complexity and energy costs. Additionally, the compression work required for CO2 liquefaction contributes significantly to the overall energy penalty.

Geographical distribution of research efforts shows concentration in regions with established cryogenic expertise, particularly in Europe, North America, and East Asia. Countries like Norway, Germany, the United States, China, and South Korea lead in patent filings and research publications related to cryogenic CO2 capture technologies.

Material constraints present another challenge, as conventional materials become brittle at extremely low temperatures, requiring specialized alloys that increase capital costs. The trade-off between capture rate and energy consumption remains a critical optimization problem, with current systems typically achieving 85-95% capture rates at the expense of higher energy penalties.

Process integration represents both a challenge and opportunity. While integrating cryogenic systems with existing industrial processes can reduce overall energy requirements through waste heat recovery and cold energy utilization, such integration often requires significant process redesign and capital investment.

Recent innovations have focused on hybrid systems combining cryogenic separation with other capture technologies to reduce energy penalties. These approaches include membrane-cryogenic combinations, pressure swing adsorption pre-concentration steps, and novel refrigeration cycles. However, these solutions often introduce additional complexity and have yet to demonstrate long-term reliability at industrial scale.

Despite its potential, cryogenic CO2 capture faces significant energy penalty challenges. The primary energy consumption occurs during the cooling process, which requires substantial refrigeration power to reach cryogenic temperatures. Current systems typically exhibit energy penalties ranging from 0.7 to 1.2 MWh per ton of CO2 captured, representing a major obstacle to widespread commercial adoption.

Technical limitations include heat exchanger inefficiencies, where even state-of-the-art designs struggle to achieve optimal heat transfer at cryogenic temperatures. Frost formation on heat exchange surfaces further reduces efficiency and necessitates periodic defrosting cycles, adding operational complexity and energy costs. Additionally, the compression work required for CO2 liquefaction contributes significantly to the overall energy penalty.

Geographical distribution of research efforts shows concentration in regions with established cryogenic expertise, particularly in Europe, North America, and East Asia. Countries like Norway, Germany, the United States, China, and South Korea lead in patent filings and research publications related to cryogenic CO2 capture technologies.

Material constraints present another challenge, as conventional materials become brittle at extremely low temperatures, requiring specialized alloys that increase capital costs. The trade-off between capture rate and energy consumption remains a critical optimization problem, with current systems typically achieving 85-95% capture rates at the expense of higher energy penalties.

Process integration represents both a challenge and opportunity. While integrating cryogenic systems with existing industrial processes can reduce overall energy requirements through waste heat recovery and cold energy utilization, such integration often requires significant process redesign and capital investment.

Recent innovations have focused on hybrid systems combining cryogenic separation with other capture technologies to reduce energy penalties. These approaches include membrane-cryogenic combinations, pressure swing adsorption pre-concentration steps, and novel refrigeration cycles. However, these solutions often introduce additional complexity and have yet to demonstrate long-term reliability at industrial scale.

Current Energy Penalty Reduction Solutions and Approaches

01 Energy efficiency improvements in cryogenic CO2 capture systems

Various technological advancements have been developed to reduce the energy penalty associated with cryogenic CO2 capture systems. These include optimized heat integration, improved refrigeration cycles, and enhanced heat exchanger designs that minimize energy consumption during the cooling and separation processes. By implementing these efficiency improvements, the overall energy penalty of cryogenic CO2 capture can be significantly reduced while maintaining high capture rates.- Energy optimization in cryogenic CO2 capture systems: Cryogenic CO2 capture systems can be optimized to reduce energy penalties through various techniques including heat integration, process optimization, and advanced control strategies. These systems utilize the phase change properties of CO2 at low temperatures to separate it from other gases. By implementing energy recovery mechanisms and optimizing operating parameters, the overall energy consumption can be significantly reduced while maintaining high capture efficiency.

- Novel cryogenic separation technologies: Innovative cryogenic separation technologies have been developed to address energy penalties in CO2 capture. These include advanced desublimation techniques, hybrid separation processes combining cryogenic methods with other capture technologies, and specialized equipment designs that enhance heat transfer and separation efficiency. These novel approaches can significantly reduce the energy requirements compared to conventional cryogenic separation methods.

- Heat integration and energy recovery systems: Heat integration and energy recovery systems play a crucial role in minimizing energy penalties in cryogenic CO2 capture. By recovering cold energy from the liquefied CO2 stream and utilizing it elsewhere in the process, overall energy consumption can be reduced. Advanced heat exchanger designs, multi-stage compression with intercooling, and waste heat utilization strategies contribute to improved energy efficiency in these systems.

- Process control and optimization strategies: Advanced process control and optimization strategies are employed to minimize energy penalties in cryogenic CO2 capture systems. These include real-time monitoring and adjustment of operating parameters, predictive modeling to anticipate system behavior, and adaptive control algorithms that respond to changing conditions. By maintaining optimal operating conditions and preventing inefficiencies, these strategies can significantly reduce the energy requirements of cryogenic capture processes.

- Integration with industrial processes and renewable energy: Integration of cryogenic CO2 capture systems with industrial processes and renewable energy sources can help offset energy penalties. By utilizing waste heat or cold from adjacent industrial processes, or by powering the capture system with renewable energy, the net energy penalty can be reduced. Additionally, the captured CO2 can be utilized in various applications such as enhanced oil recovery, chemical production, or food processing, creating value streams that help compensate for the energy costs of capture.

02 Integration of waste heat recovery in cryogenic capture processes

Waste heat recovery systems can be integrated into cryogenic CO2 capture processes to utilize thermal energy that would otherwise be lost. These systems capture and repurpose waste heat from various process streams to provide energy for other parts of the capture system, such as for regeneration or preheating. This integration significantly reduces the external energy requirements and overall energy penalty of the cryogenic capture process.Expand Specific Solutions03 Novel refrigeration cycles for reduced energy consumption

Innovative refrigeration cycles specifically designed for cryogenic CO2 capture can substantially reduce the energy penalty. These include multi-stage compression systems, mixed refrigerant cycles, and cascade refrigeration processes that are optimized for the temperature ranges required in CO2 capture. By employing these novel refrigeration approaches, the energy required for cooling and liquefaction of CO2 can be minimized compared to conventional refrigeration methods.Expand Specific Solutions04 Process integration with industrial systems to reduce net energy penalty

Integrating cryogenic CO2 capture systems with existing industrial processes can leverage synergies to reduce the overall energy penalty. This includes utilizing available cold energy from LNG regasification, integrating with air separation units, or coupling with other industrial processes that have excess cooling capacity. Such integration approaches can significantly reduce the net energy requirements for CO2 capture by sharing energy resources across processes.Expand Specific Solutions05 Advanced materials and equipment design for energy-efficient separation

The development of advanced materials and equipment designs specifically for cryogenic conditions can improve the energy efficiency of CO2 capture. These include specialized heat exchanger materials with enhanced thermal conductivity, novel insulation materials to reduce heat losses, and optimized separation vessel designs. These advancements in materials and equipment design contribute to reducing the overall energy penalty associated with cryogenic CO2 capture systems.Expand Specific Solutions

Key Industry Players in Cryogenic CO2 Capture Technology

The cryogenic CO2 capture technology market is in a growth phase, characterized by increasing investments and research activities aimed at reducing energy penalties. The global market size for carbon capture technologies is expanding rapidly, driven by climate change mitigation efforts and regulatory pressures. Technologically, the field shows varying maturity levels, with companies like Air Liquide and China Petroleum & Chemical Corp. leading commercial implementations, while research institutions such as Huaneng Clean Energy Research Institute and CSIC focus on fundamental innovations. Academic-industrial partnerships involving universities like Nanyang Technological University and Ohio State University are accelerating technology transfer. Energy companies including CHN ENERGY and Phillips 66 are investing in pilot projects to validate energy-efficient capture methods, positioning themselves for future market growth as efficiency improvements make the technology more economically viable.

Air Liquide SA

Technical Solution: Air Liquide has developed advanced cryogenic CO2 capture systems utilizing their proprietary Cryocap™ technology. This process separates CO2 through a combination of cryogenic distillation and membrane separation, achieving capture rates of over 90% while reducing energy penalties by approximately 30% compared to conventional amine-based systems. Their approach involves cooling flue gas to temperatures around -120°C to solidify CO2 directly, bypassing the energy-intensive regeneration step found in solvent-based systems. Air Liquide has implemented phase-change optimization techniques that recover cold energy through heat exchangers, significantly reducing the overall energy consumption. The company has successfully deployed this technology at industrial scale in hydrogen production facilities, demonstrating its commercial viability with energy penalties as low as 0.2-0.3 GJ/ton CO2 captured.

Strengths: Exceptionally high CO2 purity (>99.5%) making it suitable for industrial applications requiring high-grade CO2; significant operational experience in cryogenic systems; established global infrastructure for implementation. Weaknesses: Higher initial capital investment compared to conventional technologies; requires significant cooling infrastructure; optimal performance limited to high-concentration CO2 streams.

The Ohio State University

Technical Solution: Ohio State University has developed the CEPACS (Cryogenic Energy-efficient Process for Advanced Carbon Separation) technology, focusing specifically on reducing energy penalties in cryogenic CO2 capture. Their approach utilizes a novel staged compression and cooling system with intermediate separation steps, achieving energy reductions of up to 35% compared to conventional single-stage cryogenic processes. The CEPACS system incorporates proprietary phase-change heat exchangers that maximize energy recovery during the CO2 desublimation and melting processes. A key innovation is their dual-temperature separation technique that operates at different cryogenic temperature levels optimized for specific gas compositions, allowing for more efficient separation with lower overall energy input. The research team has demonstrated energy penalties as low as 0.7 GJ/ton CO2 in laboratory-scale testing, with theoretical models suggesting potential for further reduction to 0.5 GJ/ton with advanced heat integration. Their system also incorporates innovative frost management techniques to address solid CO2 deposition challenges that typically increase energy consumption in cryogenic systems.

Strengths: Highly adaptable to various flue gas compositions; excellent energy integration design minimizing external energy requirements; produces high-purity CO2 (>99%) suitable for various applications. Weaknesses: Limited large-scale demonstration data; higher capital costs than conventional technologies; requires specialized materials for cryogenic operation that may impact maintenance costs.

Critical Patents and Innovations in Cryogenic Efficiency

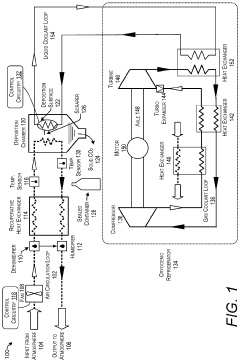

Method for the capture of carbon dioxide through cryogenically processing gaseous emissions from fossil-fuel power generation

PatentActiveUS9995530B2

Innovation

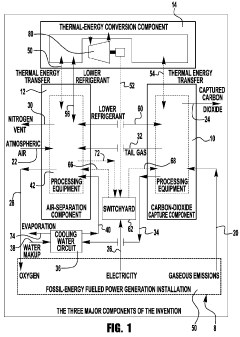

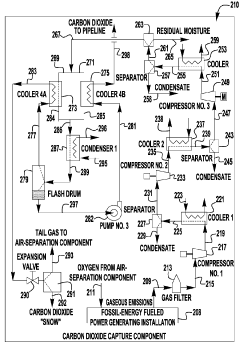

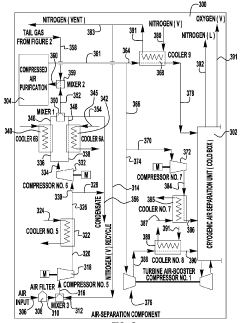

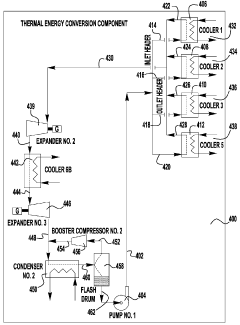

- A system comprising three interrelated components: Carbon-Dioxide Capture, Air-Separation, and Thermal-Energy Conversion components, which compress gases, separate air, and convert low-temperature thermal energy into electricity, respectively, to reduce external electricity consumption and enhance CO2 capture as a high-purity, high-pressure supercritical fluid for pipeline transport.

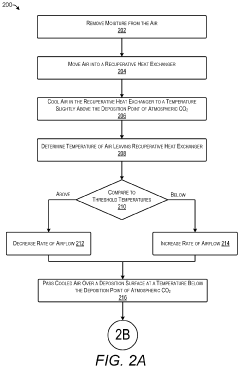

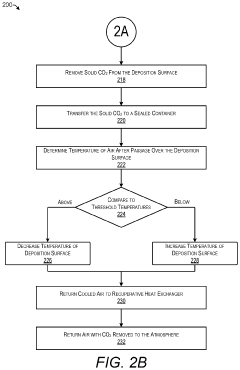

Cryogenic removal of carbon dioxide from the atmosphere

PatentPendingUS20230314070A1

Innovation

- The CryoDAC system freezes CO2 out of air without liquifying other components, using a recuperative heat exchanger to pre-cool air and a deposition chamber to solidify CO2, which is then collected and sequestered, with a cryogenic refrigerator optionally used to achieve low temperatures, optimizing energy use by recycling cooling air.

Regulatory Framework and Carbon Pricing Implications

The regulatory landscape surrounding carbon capture technologies, particularly cryogenic CO2 capture, has evolved significantly in recent years as governments worldwide intensify efforts to combat climate change. Carbon pricing mechanisms, including carbon taxes and emissions trading systems (ETS), have emerged as primary policy instruments driving the adoption of carbon capture technologies. Currently, over 40 countries have implemented some form of carbon pricing, with prices ranging from less than $1 to more than $130 per ton of CO2 equivalent.

The European Union's Emissions Trading System (EU ETS) represents one of the most mature carbon markets, with carbon prices reaching record levels of €90 per ton in 2022. This pricing trajectory creates a favorable economic environment for cryogenic CO2 capture technologies, especially as they achieve energy penalty reductions that improve their cost-effectiveness. Similarly, the United States has introduced the 45Q tax credit, which was enhanced under the Inflation Reduction Act to provide up to $85 per ton for CO2 captured and sequestered, significantly improving the financial viability of cryogenic capture systems.

Regulatory frameworks are increasingly incorporating technology-neutral performance standards rather than prescriptive requirements. This shift benefits innovative approaches like advanced cryogenic capture methods that can demonstrate superior energy efficiency. The International Organization for Standardization (ISO) has developed standards for quantifying and reporting greenhouse gas emissions reductions, providing a consistent framework for evaluating the performance of various capture technologies.

Energy efficiency regulations intersect with carbon capture requirements in many jurisdictions. For instance, the EU's Industrial Emissions Directive mandates the use of Best Available Techniques (BAT), which increasingly incorporate energy efficiency considerations that favor lower-penalty capture technologies. This regulatory convergence creates additional incentives for reducing the energy penalties associated with cryogenic CO2 capture.

The implementation of border carbon adjustment mechanisms, such as the EU's Carbon Border Adjustment Mechanism (CBAM), is creating global ripple effects that extend carbon pricing pressures beyond national borders. These mechanisms are likely to accelerate the adoption of energy-efficient capture technologies in export-oriented industries, particularly in regions without domestic carbon pricing. As these regulatory frameworks mature, they will increasingly reward technologies that minimize energy penalties while maximizing capture rates.

Looking forward, regulatory trends indicate a move toward lifecycle carbon accounting and full-chain emissions responsibility, which will further emphasize the importance of energy-efficient capture technologies. The integration of these regulatory frameworks with sustainable finance taxonomies is also creating new funding pathways for technologies that can demonstrate superior energy performance in carbon capture applications.

The European Union's Emissions Trading System (EU ETS) represents one of the most mature carbon markets, with carbon prices reaching record levels of €90 per ton in 2022. This pricing trajectory creates a favorable economic environment for cryogenic CO2 capture technologies, especially as they achieve energy penalty reductions that improve their cost-effectiveness. Similarly, the United States has introduced the 45Q tax credit, which was enhanced under the Inflation Reduction Act to provide up to $85 per ton for CO2 captured and sequestered, significantly improving the financial viability of cryogenic capture systems.

Regulatory frameworks are increasingly incorporating technology-neutral performance standards rather than prescriptive requirements. This shift benefits innovative approaches like advanced cryogenic capture methods that can demonstrate superior energy efficiency. The International Organization for Standardization (ISO) has developed standards for quantifying and reporting greenhouse gas emissions reductions, providing a consistent framework for evaluating the performance of various capture technologies.

Energy efficiency regulations intersect with carbon capture requirements in many jurisdictions. For instance, the EU's Industrial Emissions Directive mandates the use of Best Available Techniques (BAT), which increasingly incorporate energy efficiency considerations that favor lower-penalty capture technologies. This regulatory convergence creates additional incentives for reducing the energy penalties associated with cryogenic CO2 capture.

The implementation of border carbon adjustment mechanisms, such as the EU's Carbon Border Adjustment Mechanism (CBAM), is creating global ripple effects that extend carbon pricing pressures beyond national borders. These mechanisms are likely to accelerate the adoption of energy-efficient capture technologies in export-oriented industries, particularly in regions without domestic carbon pricing. As these regulatory frameworks mature, they will increasingly reward technologies that minimize energy penalties while maximizing capture rates.

Looking forward, regulatory trends indicate a move toward lifecycle carbon accounting and full-chain emissions responsibility, which will further emphasize the importance of energy-efficient capture technologies. The integration of these regulatory frameworks with sustainable finance taxonomies is also creating new funding pathways for technologies that can demonstrate superior energy performance in carbon capture applications.

Techno-Economic Assessment of Cryogenic Capture Systems

The techno-economic assessment of cryogenic CO2 capture systems reveals significant economic considerations that must be balanced against technical performance. Capital expenditure (CAPEX) for these systems typically ranges from $60-120 million for industrial-scale implementations, with the cryogenic heat exchangers and refrigeration units constituting approximately 40-50% of total equipment costs. The economy of scale is particularly pronounced, with unit costs decreasing by approximately 15-20% when capacity doubles.

Operating expenditure (OPEX) is dominated by energy consumption, which accounts for 60-75% of annual operating costs. Current cryogenic systems require 0.8-1.2 MWh per ton of CO2 captured, translating to $30-45 per ton at average industrial electricity rates. Maintenance costs add another 3-5% of CAPEX annually, primarily for refrigeration system components and heat exchanger cleaning to prevent frost accumulation.

The levelized cost of CO2 capture (LCCC) for cryogenic systems currently ranges from $45-70 per ton, positioning them competitively against amine-based systems in specific applications, particularly where waste cold energy can be integrated. Sensitivity analysis indicates that electricity prices have the most significant impact on economic viability, with a 10% increase in electricity costs raising the LCCC by approximately 6-8%.

Integration opportunities present substantial economic advantages. Facilities with available waste cold energy, such as LNG terminals or air separation units, can reduce energy requirements by 20-35%, lowering the LCCC by $10-15 per ton. Similarly, integration with renewable energy sources can mitigate both costs and emissions, though intermittency challenges must be addressed through thermal storage systems.

Payback periods for cryogenic capture investments typically range from 5-8 years under current carbon pricing schemes. However, this varies significantly based on regional carbon policies and available incentives. Markets with carbon prices exceeding $50 per ton offer more favorable economics, potentially reducing payback periods to 3-5 years.

Future cost reduction pathways primarily involve advanced heat integration techniques, which modeling suggests could reduce energy consumption by 15-25%, and novel refrigeration cycles that may offer 10-15% efficiency improvements. Material innovations in heat exchanger design could further reduce CAPEX by 10-20% while improving thermal performance. These combined advancements could potentially reduce the LCCC to $35-50 per ton by 2030, significantly enhancing commercial viability across broader applications.

Operating expenditure (OPEX) is dominated by energy consumption, which accounts for 60-75% of annual operating costs. Current cryogenic systems require 0.8-1.2 MWh per ton of CO2 captured, translating to $30-45 per ton at average industrial electricity rates. Maintenance costs add another 3-5% of CAPEX annually, primarily for refrigeration system components and heat exchanger cleaning to prevent frost accumulation.

The levelized cost of CO2 capture (LCCC) for cryogenic systems currently ranges from $45-70 per ton, positioning them competitively against amine-based systems in specific applications, particularly where waste cold energy can be integrated. Sensitivity analysis indicates that electricity prices have the most significant impact on economic viability, with a 10% increase in electricity costs raising the LCCC by approximately 6-8%.

Integration opportunities present substantial economic advantages. Facilities with available waste cold energy, such as LNG terminals or air separation units, can reduce energy requirements by 20-35%, lowering the LCCC by $10-15 per ton. Similarly, integration with renewable energy sources can mitigate both costs and emissions, though intermittency challenges must be addressed through thermal storage systems.

Payback periods for cryogenic capture investments typically range from 5-8 years under current carbon pricing schemes. However, this varies significantly based on regional carbon policies and available incentives. Markets with carbon prices exceeding $50 per ton offer more favorable economics, potentially reducing payback periods to 3-5 years.

Future cost reduction pathways primarily involve advanced heat integration techniques, which modeling suggests could reduce energy consumption by 15-25%, and novel refrigeration cycles that may offer 10-15% efficiency improvements. Material innovations in heat exchanger design could further reduce CAPEX by 10-20% while improving thermal performance. These combined advancements could potentially reduce the LCCC to $35-50 per ton by 2030, significantly enhancing commercial viability across broader applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!