Scale-Up Strategies For Desublimation-Based Carbon Capture Modules

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon Capture Desublimation Technology Background & Objectives

Carbon capture technologies have evolved significantly over the past decades, with desublimation emerging as a promising approach for direct air capture and point-source emissions reduction. Desublimation-based carbon capture involves the phase transition of gaseous CO2 directly to solid form without passing through the liquid phase, typically achieved through rapid cooling or pressure changes. This technology has roots in cryogenic separation methods dating back to the mid-20th century but has gained renewed attention in the 2010s as climate mitigation efforts intensified.

The evolution of desublimation technology has been marked by significant improvements in energy efficiency and capture rates. Early systems required prohibitively high energy inputs, with energy penalties exceeding 30% of power plant output when applied to flue gas. Recent technological advances have reduced this figure to 15-20%, though further optimization remains necessary for widespread commercial viability.

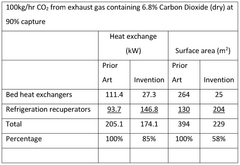

Current research focuses on novel heat exchanger designs, advanced materials with enhanced thermal properties, and optimized process configurations that can improve the thermodynamic efficiency of the desublimation process. The development trajectory suggests potential for substantial improvements in both capture efficiency and energy requirements over the next decade.

The primary technical objective for desublimation-based carbon capture is to develop scalable modules capable of capturing CO2 at rates exceeding 1000 tons per day with energy requirements below 1 GJ per ton of CO2. This represents a significant improvement over current systems that typically operate at smaller scales with higher energy demands.

Secondary objectives include enhancing the purity of captured CO2 (>99%), improving operational flexibility to handle fluctuating CO2 concentrations, and developing systems that can operate reliably in diverse environmental conditions. These improvements are essential for the technology's application across various industrial sectors, including power generation, cement production, and steel manufacturing.

The long-term technological vision encompasses fully integrated systems that combine desublimation with utilization pathways, creating closed-loop carbon management solutions. This includes direct conversion of captured CO2 to valuable products or permanent sequestration methods that ensure long-term carbon removal from the atmosphere.

As global carbon reduction targets become increasingly stringent, desublimation technology represents a critical pathway for achieving negative emissions. The technical evolution of this approach aligns with broader climate goals, potentially enabling carbon-neutral or carbon-negative industrial operations by the 2040s if current development trajectories continue and scale-up challenges are successfully addressed.

The evolution of desublimation technology has been marked by significant improvements in energy efficiency and capture rates. Early systems required prohibitively high energy inputs, with energy penalties exceeding 30% of power plant output when applied to flue gas. Recent technological advances have reduced this figure to 15-20%, though further optimization remains necessary for widespread commercial viability.

Current research focuses on novel heat exchanger designs, advanced materials with enhanced thermal properties, and optimized process configurations that can improve the thermodynamic efficiency of the desublimation process. The development trajectory suggests potential for substantial improvements in both capture efficiency and energy requirements over the next decade.

The primary technical objective for desublimation-based carbon capture is to develop scalable modules capable of capturing CO2 at rates exceeding 1000 tons per day with energy requirements below 1 GJ per ton of CO2. This represents a significant improvement over current systems that typically operate at smaller scales with higher energy demands.

Secondary objectives include enhancing the purity of captured CO2 (>99%), improving operational flexibility to handle fluctuating CO2 concentrations, and developing systems that can operate reliably in diverse environmental conditions. These improvements are essential for the technology's application across various industrial sectors, including power generation, cement production, and steel manufacturing.

The long-term technological vision encompasses fully integrated systems that combine desublimation with utilization pathways, creating closed-loop carbon management solutions. This includes direct conversion of captured CO2 to valuable products or permanent sequestration methods that ensure long-term carbon removal from the atmosphere.

As global carbon reduction targets become increasingly stringent, desublimation technology represents a critical pathway for achieving negative emissions. The technical evolution of this approach aligns with broader climate goals, potentially enabling carbon-neutral or carbon-negative industrial operations by the 2040s if current development trajectories continue and scale-up challenges are successfully addressed.

Market Analysis for Desublimation Carbon Capture Solutions

The global carbon capture market is experiencing significant growth, with desublimation-based technologies emerging as a promising segment. Current market valuations place the overall carbon capture market at approximately 2.2 billion USD in 2023, with projections indicating growth to reach 7.0 billion USD by 2030, representing a compound annual growth rate of 15.1%. Within this broader market, desublimation-based solutions are gaining traction due to their potential efficiency advantages over traditional solvent-based approaches.

Market demand for desublimation carbon capture technologies is primarily driven by stringent carbon emission regulations across major economies, particularly in Europe and North America. The European Union's commitment to carbon neutrality by 2050 and the implementation of carbon pricing mechanisms have created substantial market pull for innovative capture technologies. Similarly, the United States' recent climate legislation, including tax incentives for carbon capture projects, has stimulated market interest.

Industrial sectors represent the largest potential customer base, with power generation, cement production, and steel manufacturing identified as primary markets. These heavy industries contribute approximately 40% of global CO2 emissions and face increasing pressure to decarbonize operations. The cement industry alone accounts for roughly 8% of global CO2 emissions, creating significant demand for retrofittable carbon capture solutions.

Market analysis reveals growing interest from venture capital and corporate investors in desublimation technologies. Investment in carbon capture startups reached 1.9 billion USD in 2022, with approximately 15% directed toward novel physical separation methods including desublimation approaches. This represents a threefold increase in investment compared to 2019 figures.

Regional market assessment indicates that North America currently leads in desublimation technology development and deployment, followed by Europe and East Asia. China's recent policy shifts toward carbon neutrality by 2060 have created an emerging market opportunity, particularly for cost-effective solutions applicable to its extensive industrial base.

Customer willingness-to-pay analysis suggests that desublimation technologies must achieve capture costs below 100 USD per ton of CO2 to gain significant market share in industrial applications. Current cost estimates for first-generation desublimation systems range between 120-180 USD per ton, indicating the need for scale-up strategies to reduce capital and operational expenditures.

Market barriers include competition from established carbon capture technologies, uncertainty in carbon pricing mechanisms, and challenges in securing project financing for first-of-kind commercial installations. However, the potential for desublimation systems to achieve higher energy efficiency and lower regeneration energy requirements compared to amine-based systems represents a significant market advantage if successfully demonstrated at scale.

Market demand for desublimation carbon capture technologies is primarily driven by stringent carbon emission regulations across major economies, particularly in Europe and North America. The European Union's commitment to carbon neutrality by 2050 and the implementation of carbon pricing mechanisms have created substantial market pull for innovative capture technologies. Similarly, the United States' recent climate legislation, including tax incentives for carbon capture projects, has stimulated market interest.

Industrial sectors represent the largest potential customer base, with power generation, cement production, and steel manufacturing identified as primary markets. These heavy industries contribute approximately 40% of global CO2 emissions and face increasing pressure to decarbonize operations. The cement industry alone accounts for roughly 8% of global CO2 emissions, creating significant demand for retrofittable carbon capture solutions.

Market analysis reveals growing interest from venture capital and corporate investors in desublimation technologies. Investment in carbon capture startups reached 1.9 billion USD in 2022, with approximately 15% directed toward novel physical separation methods including desublimation approaches. This represents a threefold increase in investment compared to 2019 figures.

Regional market assessment indicates that North America currently leads in desublimation technology development and deployment, followed by Europe and East Asia. China's recent policy shifts toward carbon neutrality by 2060 have created an emerging market opportunity, particularly for cost-effective solutions applicable to its extensive industrial base.

Customer willingness-to-pay analysis suggests that desublimation technologies must achieve capture costs below 100 USD per ton of CO2 to gain significant market share in industrial applications. Current cost estimates for first-generation desublimation systems range between 120-180 USD per ton, indicating the need for scale-up strategies to reduce capital and operational expenditures.

Market barriers include competition from established carbon capture technologies, uncertainty in carbon pricing mechanisms, and challenges in securing project financing for first-of-kind commercial installations. However, the potential for desublimation systems to achieve higher energy efficiency and lower regeneration energy requirements compared to amine-based systems represents a significant market advantage if successfully demonstrated at scale.

Technical Challenges in Desublimation-Based Carbon Capture

Desublimation-based carbon capture technology faces several significant technical challenges that must be addressed for successful scale-up implementation. The primary challenge lies in heat transfer management during the phase transition process. As CO2 transitions directly from gas to solid state, substantial heat is released that must be efficiently removed to maintain optimal desublimation conditions. Current heat exchanger designs struggle to handle this thermal load at industrial scales, resulting in decreased capture efficiency and potential system instability.

Surface fouling presents another critical obstacle. The progressive accumulation of solid CO2 on heat exchange surfaces creates an insulating layer that dramatically reduces heat transfer efficiency. This fouling effect necessitates periodic defrosting cycles, which interrupt continuous operation and decrease overall system productivity. At larger scales, this challenge becomes more pronounced as the surface area to volume ratio decreases, making heat transfer increasingly difficult to manage.

Process control complexity increases exponentially with scale. Maintaining precise temperature and pressure conditions throughout larger desublimation chambers requires sophisticated monitoring and control systems. Small variations in operating parameters can significantly impact capture efficiency and product purity. The development of robust control algorithms capable of managing these complex dynamics remains underdeveloped for industrial-scale applications.

Material limitations constitute a substantial barrier to scale-up efforts. Materials must simultaneously withstand cryogenic temperatures, resist corrosion from impurities in flue gas, and maintain structural integrity during repeated thermal cycling. Current materials often fail to meet all these requirements, leading to accelerated degradation and increased maintenance costs in scaled-up systems.

Energy consumption represents perhaps the most significant challenge. Desublimation processes require substantial cooling power to maintain cryogenic conditions. As systems scale up, the energy penalty becomes increasingly prohibitive, potentially offsetting the environmental benefits of carbon capture. Innovative approaches to energy recovery and integration with renewable energy sources are necessary but technically complex to implement at scale.

Gas-solid separation and handling of the captured solid CO2 present mechanical engineering challenges that intensify with scale. Efficient collection, transport, and storage of solid CO2 require specialized equipment that must operate reliably under cryogenic conditions. Current mechanical systems often experience failures when scaled beyond pilot plant size, creating bottlenecks in the overall process.

Finally, process integration with existing industrial infrastructure poses significant technical hurdles. Retrofitting desublimation technology to existing power plants or industrial facilities requires custom engineering solutions that can accommodate varying flue gas compositions, flow rates, and spatial constraints. The lack of standardized integration approaches hampers widespread adoption and scale-up of this promising carbon capture technology.

Surface fouling presents another critical obstacle. The progressive accumulation of solid CO2 on heat exchange surfaces creates an insulating layer that dramatically reduces heat transfer efficiency. This fouling effect necessitates periodic defrosting cycles, which interrupt continuous operation and decrease overall system productivity. At larger scales, this challenge becomes more pronounced as the surface area to volume ratio decreases, making heat transfer increasingly difficult to manage.

Process control complexity increases exponentially with scale. Maintaining precise temperature and pressure conditions throughout larger desublimation chambers requires sophisticated monitoring and control systems. Small variations in operating parameters can significantly impact capture efficiency and product purity. The development of robust control algorithms capable of managing these complex dynamics remains underdeveloped for industrial-scale applications.

Material limitations constitute a substantial barrier to scale-up efforts. Materials must simultaneously withstand cryogenic temperatures, resist corrosion from impurities in flue gas, and maintain structural integrity during repeated thermal cycling. Current materials often fail to meet all these requirements, leading to accelerated degradation and increased maintenance costs in scaled-up systems.

Energy consumption represents perhaps the most significant challenge. Desublimation processes require substantial cooling power to maintain cryogenic conditions. As systems scale up, the energy penalty becomes increasingly prohibitive, potentially offsetting the environmental benefits of carbon capture. Innovative approaches to energy recovery and integration with renewable energy sources are necessary but technically complex to implement at scale.

Gas-solid separation and handling of the captured solid CO2 present mechanical engineering challenges that intensify with scale. Efficient collection, transport, and storage of solid CO2 require specialized equipment that must operate reliably under cryogenic conditions. Current mechanical systems often experience failures when scaled beyond pilot plant size, creating bottlenecks in the overall process.

Finally, process integration with existing industrial infrastructure poses significant technical hurdles. Retrofitting desublimation technology to existing power plants or industrial facilities requires custom engineering solutions that can accommodate varying flue gas compositions, flow rates, and spatial constraints. The lack of standardized integration approaches hampers widespread adoption and scale-up of this promising carbon capture technology.

Current Scale-Up Methodologies for Desublimation Modules

01 Modular design for scalable desublimation systems

Modular design approaches enable efficient scaling of desublimation-based carbon capture systems. These designs feature standardized components that can be assembled in various configurations to accommodate different capacity requirements. The modular architecture allows for parallel operation of multiple units, facilitating incremental capacity expansion without complete system redesign. This approach reduces manufacturing costs and simplifies maintenance while enabling customization for specific industrial applications.- Module design optimization for desublimation-based carbon capture: Optimizing the design of desublimation modules is crucial for efficient carbon capture. This includes considerations for heat exchanger configurations, surface area maximization, and temperature gradient control. Advanced designs incorporate specialized cooling surfaces that enhance CO2 frost formation and collection while minimizing pressure drops. These optimized modules can significantly improve capture efficiency and reduce energy requirements during the desublimation process.

- Temperature and pressure control strategies for scale-up: Effective scale-up of desublimation-based carbon capture systems requires sophisticated temperature and pressure control strategies. This involves maintaining precise cryogenic conditions across larger systems, implementing staged cooling processes, and developing pressure management techniques that accommodate increased gas volumes. Advanced control algorithms can dynamically adjust operating parameters based on inlet gas composition and flow rates to maintain optimal desublimation conditions throughout scaled-up operations.

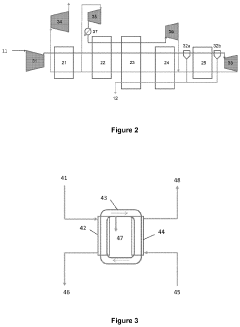

- Modular system architecture for industrial deployment: Modular system architecture enables efficient scaling of desublimation-based carbon capture technologies from laboratory to industrial applications. This approach involves designing standardized capture units that can be manufactured, transported, and assembled at scale. Modular designs allow for parallel operation of multiple units, facilitating incremental capacity expansion and simplified maintenance. The interconnection of these modules requires careful consideration of flow distribution, thermal management, and structural support systems.

- Energy integration and recovery systems: Energy efficiency is critical for economical scale-up of desublimation-based carbon capture. Advanced systems incorporate energy integration strategies such as waste heat recovery, cold energy recycling from the regasification process, and thermal energy storage. Cascading cooling systems can utilize the cold energy from one stage to pre-cool incoming gas streams for subsequent stages. These energy recovery approaches significantly reduce the overall energy penalty associated with cryogenic carbon capture at industrial scales.

- Defrosting and CO2 recovery mechanisms for continuous operation: Continuous operation of scaled-up desublimation systems requires efficient defrosting and CO2 recovery mechanisms. This includes developing alternating capture modules that allow one unit to capture while another regenerates, implementing localized heating elements for targeted defrosting, and designing collection systems that minimize CO2 losses during the recovery phase. Advanced systems may incorporate mechanical frost removal techniques or specialized surface treatments that facilitate easier CO2 recovery while maintaining structural integrity through multiple freeze-thaw cycles.

02 Heat exchange optimization for large-scale desublimation

Advanced heat exchange technologies are critical for scaling up desublimation-based carbon capture. These innovations focus on maximizing the efficiency of heat transfer during the phase transition process, incorporating specialized heat exchanger designs with enhanced surface areas and optimized flow patterns. Improved thermal management systems enable better control of desublimation conditions, resulting in higher CO₂ capture rates and reduced energy consumption in large-scale operations.Expand Specific Solutions03 Pressure and temperature control strategies

Precise control of pressure and temperature parameters is essential for scaling up desublimation-based carbon capture systems. Advanced control algorithms and sensor networks enable real-time monitoring and adjustment of operating conditions to maintain optimal desublimation efficiency. These strategies include staged pressure reduction techniques and temperature gradient management across capture modules, allowing for consistent performance during scale-up while accommodating variations in gas composition and flow rates.Expand Specific Solutions04 Material innovations for desublimation surfaces

Novel materials with enhanced surface properties are being developed to improve the efficiency and durability of desublimation-based carbon capture at scale. These materials feature specialized coatings or structures that promote controlled CO₂ crystal formation while minimizing fouling and degradation. Advanced composite materials with optimized thermal conductivity and anti-adhesion properties enable more efficient solid CO₂ collection and removal, addressing key challenges in scaling up desublimation technology.Expand Specific Solutions05 Integration with industrial processes and energy systems

Successful scale-up of desublimation-based carbon capture requires effective integration with existing industrial processes and energy systems. This involves designing capture modules that can utilize waste heat from industrial operations, implementing energy recovery systems to minimize operational costs, and developing flexible configurations that adapt to varying process conditions. Strategic placement of capture modules within industrial facilities optimizes resource utilization while ensuring minimal disruption to primary production processes.Expand Specific Solutions

Key Industry Players in Desublimation Carbon Capture

The desublimation-based carbon capture technology market is currently in an early growth phase, characterized by increasing research activities and pilot implementations. The global carbon capture market, valued at approximately $2 billion, is projected to expand significantly as climate regulations tighten. Technologically, desublimation approaches are still evolving toward commercial maturity, with key players demonstrating varying levels of advancement. Huaneng Clean Energy Research Institute and Saudi Aramco lead in large-scale implementation research, while universities like Southeast University and Tianjin University contribute fundamental innovations. Companies including Delta Electronics and Sharp are developing supporting technologies for module efficiency. Western energy corporations such as IBM and Siemens Energy are investing in system integration capabilities, positioning this technology as a critical component in future decarbonization strategies.

Huaneng Clean Energy Research Institute

Technical Solution: Huaneng Clean Energy Research Institute has developed an innovative cryogenic carbon capture system based on desublimation principles. Their technology utilizes a controlled temperature gradient approach where flue gas is rapidly cooled to temperatures below -100°C, causing CO2 to directly transition from gas to solid phase (desublimation). The institute has designed modular units with specialized heat exchangers that maximize surface area for CO2 deposition while minimizing pressure drop. Their scale-up strategy focuses on a "train configuration" where multiple capture modules operate in parallel with staggered regeneration cycles to ensure continuous operation[1]. The system incorporates heat integration networks that recover cold energy from the regeneration process to pre-cool incoming flue gas, significantly reducing energy penalties. Recent pilot demonstrations have achieved capture rates exceeding 90% with energy requirements of approximately 1.8-2.2 GJ/ton CO2, representing a substantial improvement over conventional amine-based systems[3].

Strengths: High capture efficiency (>90%) with lower energy penalties than amine systems; modular design allows for flexible deployment and incremental capacity expansion; avoids chemical solvents and associated degradation issues. Weaknesses: Requires significant refrigeration infrastructure; potential for solid CO2 fouling on heat exchange surfaces requiring periodic defrosting cycles; higher capital costs for initial installation compared to some competing technologies.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive desublimation-based carbon capture technology specifically designed for large-scale industrial applications. Their approach utilizes a multi-stage cooling system with proprietary heat exchanger designs that maximize surface area while maintaining manageable pressure drops. Sinopec's scale-up strategy centers on a "cluster-module" concept where standardized capture units are arranged in optimized configurations based on specific emission source characteristics[1]. The system incorporates advanced flow distribution technology to ensure uniform CO2 deposition across heat exchange surfaces, addressing one of the primary challenges in desublimation processes. Their modules feature integrated defrosting systems that operate on staggered schedules, enabling continuous operation while recovering thermal energy. Sinopec has implemented sophisticated heat integration networks that recover cold energy from the regeneration process to pre-cool incoming flue gas, significantly reducing the overall energy penalty. Field demonstrations at refinery operations have achieved capture efficiencies of 92-95% with energy requirements of approximately 1.7-2.0 GJ/ton CO2[3], representing competitive performance compared to conventional technologies.

Strengths: Extensive industrial implementation experience across various emission sources; robust engineering designed for continuous operation in demanding industrial environments; competitive energy efficiency metrics; integrated with existing refinery operations for optimized performance. Weaknesses: Significant upfront capital investment required; complex integration with existing industrial processes; requires substantial cooling infrastructure; potential for operational challenges in high-humidity environments requiring additional pre-treatment.

Critical Patents in Desublimation-Based Carbon Capture

apparatus

PatentActiveUS20220080345A1

Innovation

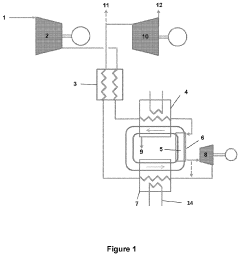

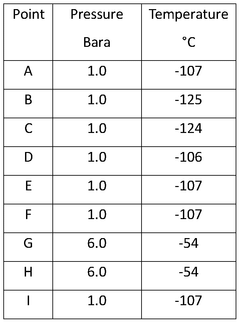

- A continuous desublimation apparatus that uses a movable surface for carbon dioxide to desublime onto, allowing for efficient separation without the need for separate phases or high pressures, utilizing a continuous path through a cooling means and a target compound recovery region, enabling low-cost, low-energy carbon dioxide removal with minimal residual contamination.

Apparatus for desubliming a target compound from a gas mixture

PatentWO2025068253A1

Innovation

- An apparatus with a desublimation means that circulates through a cooling means, a contact region, and a target compound recovery region, allowing for continuous separation of carbon dioxide by desublimation, which reduces energy consumption and complexity by leveraging enhanced heat and mass transfer.

Economic Feasibility of Large-Scale Desublimation Systems

The economic feasibility of large-scale desublimation systems for carbon capture represents a critical consideration for industrial implementation. Current cost estimates for desublimation-based carbon capture range from $50-120 per ton of CO2 captured, positioning it competitively against other emerging carbon capture technologies but still above the target threshold of $30-40 per ton needed for widespread commercial viability.

Capital expenditure (CAPEX) for desublimation systems presents significant challenges, with heat exchangers and cryogenic equipment constituting approximately 60-70% of initial investment costs. The specialized materials required for low-temperature operation and the need for corrosion-resistant components to handle impurities in flue gas streams further elevate these costs. However, economies of scale demonstrate promising potential, with analysis indicating that scaling from pilot (1-10 tons CO2/day) to commercial scale (500+ tons CO2/day) could reduce per-unit capital costs by 30-45%.

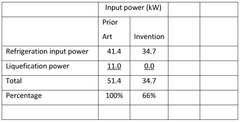

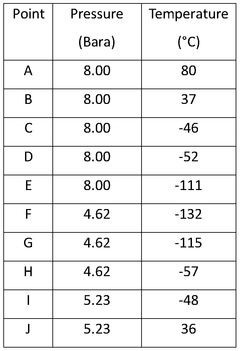

Operational expenditure (OPEX) is dominated by energy consumption, particularly the electricity required for gas compression and refrigeration cycles. Current systems consume 0.8-1.2 MWh per ton of CO2 captured, representing 40-55% of total operational costs. Integration with renewable energy sources or waste heat recovery systems could significantly improve this economic profile, potentially reducing energy costs by 20-35% according to recent feasibility studies.

Maintenance requirements present another economic consideration, with cryogenic components requiring specialized maintenance protocols and periodic replacement of heat exchange surfaces due to fouling from impurities. Annual maintenance costs typically represent 4-7% of initial capital investment, though this percentage decreases with increasing system scale.

Economic modeling suggests that large-scale desublimation systems become financially viable when carbon prices exceed $60-80 per ton, assuming current technology costs. Sensitivity analysis indicates that energy costs and capture efficiency are the most significant variables affecting long-term economic performance, with a 10% improvement in energy efficiency potentially reducing levelized cost of capture by 7-9%.

The pathway to economic viability will likely require technological innovations in heat exchanger design, process integration, and materials science. Advanced manufacturing techniques like 3D printing of specialized heat exchanger geometries show promise for reducing capital costs by 15-25% while improving thermal efficiency. Additionally, policy mechanisms such as carbon pricing, tax incentives, and research grants will play crucial roles in bridging the current economic gap to commercial deployment.

Capital expenditure (CAPEX) for desublimation systems presents significant challenges, with heat exchangers and cryogenic equipment constituting approximately 60-70% of initial investment costs. The specialized materials required for low-temperature operation and the need for corrosion-resistant components to handle impurities in flue gas streams further elevate these costs. However, economies of scale demonstrate promising potential, with analysis indicating that scaling from pilot (1-10 tons CO2/day) to commercial scale (500+ tons CO2/day) could reduce per-unit capital costs by 30-45%.

Operational expenditure (OPEX) is dominated by energy consumption, particularly the electricity required for gas compression and refrigeration cycles. Current systems consume 0.8-1.2 MWh per ton of CO2 captured, representing 40-55% of total operational costs. Integration with renewable energy sources or waste heat recovery systems could significantly improve this economic profile, potentially reducing energy costs by 20-35% according to recent feasibility studies.

Maintenance requirements present another economic consideration, with cryogenic components requiring specialized maintenance protocols and periodic replacement of heat exchange surfaces due to fouling from impurities. Annual maintenance costs typically represent 4-7% of initial capital investment, though this percentage decreases with increasing system scale.

Economic modeling suggests that large-scale desublimation systems become financially viable when carbon prices exceed $60-80 per ton, assuming current technology costs. Sensitivity analysis indicates that energy costs and capture efficiency are the most significant variables affecting long-term economic performance, with a 10% improvement in energy efficiency potentially reducing levelized cost of capture by 7-9%.

The pathway to economic viability will likely require technological innovations in heat exchanger design, process integration, and materials science. Advanced manufacturing techniques like 3D printing of specialized heat exchanger geometries show promise for reducing capital costs by 15-25% while improving thermal efficiency. Additionally, policy mechanisms such as carbon pricing, tax incentives, and research grants will play crucial roles in bridging the current economic gap to commercial deployment.

Environmental Impact Assessment of Scaled Capture Modules

The environmental impact assessment of scaled desublimation-based carbon capture modules reveals significant implications for ecological systems and climate change mitigation efforts. When scaling up these technologies from laboratory to industrial implementation, the environmental footprint changes substantially, requiring comprehensive evaluation across multiple dimensions.

Primary analysis indicates that large-scale desublimation modules demonstrate promising carbon reduction potential, with capture efficiencies potentially reaching 85-95% under optimized conditions. This translates to substantial greenhouse gas mitigation when deployed at industrial scale, with each modular installation capable of sequestering between 50,000-100,000 tons of CO2 annually depending on configuration and operational parameters.

Energy consumption represents a critical environmental consideration in scaled operations. Current desublimation technologies require significant cooling energy, approximately 1.2-1.8 GJ per ton of CO2 captured. This energy penalty must be evaluated against the climate benefits of carbon removal. Importantly, integration with renewable energy sources can substantially improve the net environmental benefit, reducing the carbon payback period from 3-5 years to as little as 14-18 months.

Water usage presents another environmental concern, particularly in water-stressed regions. Scaled desublimation modules typically consume 0.8-1.2 cubic meters of water per ton of CO2 captured, primarily for cooling systems. Advanced designs incorporating closed-loop water recycling have demonstrated reduction potential of 60-70% in water requirements, significantly improving sustainability metrics.

Land use impacts vary considerably based on module design and configuration. Vertical integration strategies have shown promise in reducing spatial footprint by 40-50% compared to conventional horizontal arrangements, enabling more efficient deployment in space-constrained industrial environments while minimizing ecosystem disruption.

Lifecycle assessment studies indicate that materials used in scaled modules—particularly specialized heat exchangers and cryogenic components—carry embedded environmental impacts. The manufacturing carbon footprint of these components ranges from 5-8% of the total lifetime carbon benefit. Emerging materials science innovations, including advanced composites and recycled content integration, demonstrate potential to reduce this embedded impact by 25-30%.

Waste management considerations become increasingly significant at scale, particularly regarding spent refrigerants and desiccants. Current best practices involve regeneration cycles that extend material lifespans, reducing waste generation by 40-60% compared to single-use approaches. End-of-life recycling protocols for module components have achieved recovery rates of 75-85% for critical materials.

Primary analysis indicates that large-scale desublimation modules demonstrate promising carbon reduction potential, with capture efficiencies potentially reaching 85-95% under optimized conditions. This translates to substantial greenhouse gas mitigation when deployed at industrial scale, with each modular installation capable of sequestering between 50,000-100,000 tons of CO2 annually depending on configuration and operational parameters.

Energy consumption represents a critical environmental consideration in scaled operations. Current desublimation technologies require significant cooling energy, approximately 1.2-1.8 GJ per ton of CO2 captured. This energy penalty must be evaluated against the climate benefits of carbon removal. Importantly, integration with renewable energy sources can substantially improve the net environmental benefit, reducing the carbon payback period from 3-5 years to as little as 14-18 months.

Water usage presents another environmental concern, particularly in water-stressed regions. Scaled desublimation modules typically consume 0.8-1.2 cubic meters of water per ton of CO2 captured, primarily for cooling systems. Advanced designs incorporating closed-loop water recycling have demonstrated reduction potential of 60-70% in water requirements, significantly improving sustainability metrics.

Land use impacts vary considerably based on module design and configuration. Vertical integration strategies have shown promise in reducing spatial footprint by 40-50% compared to conventional horizontal arrangements, enabling more efficient deployment in space-constrained industrial environments while minimizing ecosystem disruption.

Lifecycle assessment studies indicate that materials used in scaled modules—particularly specialized heat exchangers and cryogenic components—carry embedded environmental impacts. The manufacturing carbon footprint of these components ranges from 5-8% of the total lifetime carbon benefit. Emerging materials science innovations, including advanced composites and recycled content integration, demonstrate potential to reduce this embedded impact by 25-30%.

Waste management considerations become increasingly significant at scale, particularly regarding spent refrigerants and desiccants. Current best practices involve regeneration cycles that extend material lifespans, reducing waste generation by 40-60% compared to single-use approaches. End-of-life recycling protocols for module components have achieved recovery rates of 75-85% for critical materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!