Cryogenic Carbon Capture For Maritime And Offshore Applications

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Carbon Capture Technology Background and Objectives

Cryogenic Carbon Capture (CCC) technology has emerged as a promising solution for reducing greenhouse gas emissions across various industries. The concept was first developed in the early 2000s as researchers sought more energy-efficient alternatives to conventional carbon capture methods. CCC operates on the principle of cooling exhaust gases to temperatures where CO2 solidifies (approximately -140°C), allowing for its physical separation from other gases, followed by pressurization and storage.

The maritime and offshore sectors represent significant contributors to global carbon emissions, accounting for approximately 2.5% of global greenhouse gas emissions according to the International Maritime Organization (IMO). With increasing regulatory pressure, including the IMO's target to reduce carbon intensity by 40% by 2030 and total annual emissions by 50% by 2050 compared to 2008 levels, these industries face urgent needs for effective carbon capture solutions.

Traditional carbon capture technologies such as amine scrubbing present significant challenges in maritime applications due to space constraints, energy requirements, and the corrosive marine environment. Cryogenic carbon capture offers potential advantages including higher capture efficiency (potentially exceeding 95%), reduced energy penalties compared to conventional methods, and the production of high-purity CO2 suitable for storage or utilization.

The technical evolution of CCC has progressed through several key phases, from laboratory-scale proof-of-concept in the early 2000s to pilot demonstrations in the 2010s. Recent advancements have focused on improving energy efficiency through heat integration, developing specialized heat exchangers resistant to fouling, and creating compact system designs suitable for the space constraints of maritime vessels and offshore platforms.

The primary technical objective for maritime CCC implementation centers on miniaturization and ruggedization of systems to withstand the harsh marine environment while maintaining high operational reliability. Secondary objectives include reducing the energy penalty to below 30% of conventional systems, developing integration strategies with existing ship power systems, and ensuring compliance with maritime safety regulations.

Current research aims to address several critical challenges, including the management of temperature fluctuations in varying operational conditions, prevention of equipment fouling from exhaust contaminants, and development of efficient heat recovery systems to minimize energy consumption. Additionally, researchers are exploring novel refrigeration cycles and working fluids specifically optimized for maritime applications.

The long-term technological goal extends beyond simple carbon capture to creating integrated systems that can utilize captured CO2 on-board or facilitate its efficient transfer to shore facilities, potentially creating new value streams that offset implementation costs while contributing to decarbonization targets for the maritime and offshore sectors.

The maritime and offshore sectors represent significant contributors to global carbon emissions, accounting for approximately 2.5% of global greenhouse gas emissions according to the International Maritime Organization (IMO). With increasing regulatory pressure, including the IMO's target to reduce carbon intensity by 40% by 2030 and total annual emissions by 50% by 2050 compared to 2008 levels, these industries face urgent needs for effective carbon capture solutions.

Traditional carbon capture technologies such as amine scrubbing present significant challenges in maritime applications due to space constraints, energy requirements, and the corrosive marine environment. Cryogenic carbon capture offers potential advantages including higher capture efficiency (potentially exceeding 95%), reduced energy penalties compared to conventional methods, and the production of high-purity CO2 suitable for storage or utilization.

The technical evolution of CCC has progressed through several key phases, from laboratory-scale proof-of-concept in the early 2000s to pilot demonstrations in the 2010s. Recent advancements have focused on improving energy efficiency through heat integration, developing specialized heat exchangers resistant to fouling, and creating compact system designs suitable for the space constraints of maritime vessels and offshore platforms.

The primary technical objective for maritime CCC implementation centers on miniaturization and ruggedization of systems to withstand the harsh marine environment while maintaining high operational reliability. Secondary objectives include reducing the energy penalty to below 30% of conventional systems, developing integration strategies with existing ship power systems, and ensuring compliance with maritime safety regulations.

Current research aims to address several critical challenges, including the management of temperature fluctuations in varying operational conditions, prevention of equipment fouling from exhaust contaminants, and development of efficient heat recovery systems to minimize energy consumption. Additionally, researchers are exploring novel refrigeration cycles and working fluids specifically optimized for maritime applications.

The long-term technological goal extends beyond simple carbon capture to creating integrated systems that can utilize captured CO2 on-board or facilitate its efficient transfer to shore facilities, potentially creating new value streams that offset implementation costs while contributing to decarbonization targets for the maritime and offshore sectors.

Maritime Industry Demand for Carbon Capture Solutions

The maritime industry faces mounting pressure to reduce its carbon footprint amid increasingly stringent environmental regulations. The International Maritime Organization (IMO) has set ambitious targets to reduce greenhouse gas emissions from international shipping by at least 50% by 2050 compared to 2008 levels. This regulatory landscape has created substantial demand for effective carbon capture solutions specifically tailored to maritime applications.

Vessels contribute approximately 940 million tonnes of CO2 annually, representing nearly 2.5% of global greenhouse gas emissions. Without intervention, these emissions could increase by 50-250% by 2050 due to growing international trade. This trajectory has accelerated interest in carbon capture technologies among shipowners, operators, and maritime stakeholders seeking compliance solutions that maintain operational efficiency.

The maritime sector presents unique challenges for carbon capture implementation. Space constraints aboard vessels limit the feasibility of conventional carbon capture systems designed for stationary applications. Additionally, the harsh marine environment, characterized by constant motion, vibration, and salt exposure, demands robust engineering solutions. Energy efficiency remains paramount, as any carbon capture system must minimize additional fuel consumption to remain economically viable.

Port authorities and coastal communities have emerged as significant drivers of demand, implementing emissions control areas and offering incentives for cleaner shipping technologies. Major shipping companies including Maersk, MSC, and CMA CGM have announced carbon neutrality commitments, creating immediate market demand for retrofittable carbon capture solutions for existing fleets.

Offshore applications present another substantial market segment. Oil and gas platforms, which contribute significantly to maritime emissions, face similar regulatory pressures and are exploring integrated carbon capture systems. The potential for combining captured carbon with enhanced oil recovery techniques offers additional economic incentives in this sector.

Financial considerations heavily influence adoption rates. The maritime industry operates on thin profit margins, making the capital expenditure and operational costs of carbon capture systems critical factors. However, emerging carbon pricing mechanisms and emissions trading schemes are gradually improving the economic case for implementation.

Technical compatibility with existing maritime propulsion systems represents another market requirement. Solutions must integrate with both conventional marine diesel engines and emerging alternative fuels like LNG, creating demand for flexible carbon capture technologies that can adapt to the industry's transitional fuel landscape.

Vessels contribute approximately 940 million tonnes of CO2 annually, representing nearly 2.5% of global greenhouse gas emissions. Without intervention, these emissions could increase by 50-250% by 2050 due to growing international trade. This trajectory has accelerated interest in carbon capture technologies among shipowners, operators, and maritime stakeholders seeking compliance solutions that maintain operational efficiency.

The maritime sector presents unique challenges for carbon capture implementation. Space constraints aboard vessels limit the feasibility of conventional carbon capture systems designed for stationary applications. Additionally, the harsh marine environment, characterized by constant motion, vibration, and salt exposure, demands robust engineering solutions. Energy efficiency remains paramount, as any carbon capture system must minimize additional fuel consumption to remain economically viable.

Port authorities and coastal communities have emerged as significant drivers of demand, implementing emissions control areas and offering incentives for cleaner shipping technologies. Major shipping companies including Maersk, MSC, and CMA CGM have announced carbon neutrality commitments, creating immediate market demand for retrofittable carbon capture solutions for existing fleets.

Offshore applications present another substantial market segment. Oil and gas platforms, which contribute significantly to maritime emissions, face similar regulatory pressures and are exploring integrated carbon capture systems. The potential for combining captured carbon with enhanced oil recovery techniques offers additional economic incentives in this sector.

Financial considerations heavily influence adoption rates. The maritime industry operates on thin profit margins, making the capital expenditure and operational costs of carbon capture systems critical factors. However, emerging carbon pricing mechanisms and emissions trading schemes are gradually improving the economic case for implementation.

Technical compatibility with existing maritime propulsion systems represents another market requirement. Solutions must integrate with both conventional marine diesel engines and emerging alternative fuels like LNG, creating demand for flexible carbon capture technologies that can adapt to the industry's transitional fuel landscape.

Current Status and Challenges in Offshore CCS Implementation

The implementation of Cryogenic Carbon Capture (CCC) in offshore environments currently faces significant technical and operational challenges despite its promising potential. While land-based CCC technologies have demonstrated carbon capture rates exceeding 90%, offshore applications remain largely in conceptual and early development phases. Current pilot projects primarily focus on testing the technology's adaptability to marine conditions, with only a handful of small-scale demonstrations operational worldwide.

Space constraints represent a primary challenge for offshore CCC implementation. Conventional cryogenic systems require substantial equipment footprints, including refrigeration units, separation columns, and storage facilities. On offshore platforms where space is already at a premium, integrating these systems presents significant design challenges that have not been fully resolved in existing implementations.

Energy consumption poses another critical barrier. CCC processes typically require 0.8-1.2 MWh per ton of CO2 captured, creating substantial additional power demands on offshore facilities that already operate with tight energy budgets. This challenge is compounded by the need for reliable power sources in remote marine environments where grid connections are unavailable.

The harsh marine environment introduces unique operational challenges including corrosion from saltwater exposure, structural stress from wave action, and equipment stability issues during adverse weather conditions. Current materials and designs have not been fully optimized for these conditions, resulting in reliability concerns for continuous operation.

Integration with existing offshore infrastructure presents significant engineering challenges. Most offshore platforms were not designed with carbon capture capabilities in mind, requiring complex retrofitting solutions that must address space limitations, structural loading constraints, and safety considerations unique to offshore operations.

Regulatory frameworks for offshore CCC remain underdeveloped globally. While some regions have established guidelines for land-based carbon capture, specific regulations for maritime and offshore applications are still evolving, creating uncertainty for implementation and compliance requirements.

Transportation and storage logistics represent another major hurdle. Once CO2 is captured offshore, it must be either stored locally in sub-seabed formations or transported to shore facilities. Current transportation methods, including pipeline networks and specialized vessels, remain limited in capacity and geographical coverage, creating bottlenecks in the CCC value chain.

Economic viability remains perhaps the most significant challenge, with current offshore CCC implementations estimated to cost 30-50% more than equivalent land-based systems due to the additional engineering requirements, materials specifications, and operational complexities of marine environments.

Space constraints represent a primary challenge for offshore CCC implementation. Conventional cryogenic systems require substantial equipment footprints, including refrigeration units, separation columns, and storage facilities. On offshore platforms where space is already at a premium, integrating these systems presents significant design challenges that have not been fully resolved in existing implementations.

Energy consumption poses another critical barrier. CCC processes typically require 0.8-1.2 MWh per ton of CO2 captured, creating substantial additional power demands on offshore facilities that already operate with tight energy budgets. This challenge is compounded by the need for reliable power sources in remote marine environments where grid connections are unavailable.

The harsh marine environment introduces unique operational challenges including corrosion from saltwater exposure, structural stress from wave action, and equipment stability issues during adverse weather conditions. Current materials and designs have not been fully optimized for these conditions, resulting in reliability concerns for continuous operation.

Integration with existing offshore infrastructure presents significant engineering challenges. Most offshore platforms were not designed with carbon capture capabilities in mind, requiring complex retrofitting solutions that must address space limitations, structural loading constraints, and safety considerations unique to offshore operations.

Regulatory frameworks for offshore CCC remain underdeveloped globally. While some regions have established guidelines for land-based carbon capture, specific regulations for maritime and offshore applications are still evolving, creating uncertainty for implementation and compliance requirements.

Transportation and storage logistics represent another major hurdle. Once CO2 is captured offshore, it must be either stored locally in sub-seabed formations or transported to shore facilities. Current transportation methods, including pipeline networks and specialized vessels, remain limited in capacity and geographical coverage, creating bottlenecks in the CCC value chain.

Economic viability remains perhaps the most significant challenge, with current offshore CCC implementations estimated to cost 30-50% more than equivalent land-based systems due to the additional engineering requirements, materials specifications, and operational complexities of marine environments.

Existing Cryogenic Carbon Capture Solutions for Marine Applications

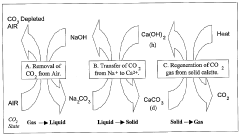

01 Cryogenic carbon capture process fundamentals

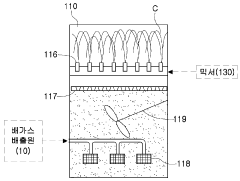

Cryogenic carbon capture involves cooling flue gas to very low temperatures where CO2 desublimes (transitions directly from gas to solid), allowing for separation from other gases. This process typically operates at temperatures below -100°C and can achieve high capture efficiencies (>90%). The technology offers advantages including lower energy requirements compared to some conventional methods, high purity of captured CO2, and the ability to handle various gas streams with different CO2 concentrations.- Cryogenic carbon capture process fundamentals: Cryogenic carbon capture involves cooling flue gas to very low temperatures where CO2 desublimes (transitions directly from gas to solid). This process allows for the separation and capture of carbon dioxide from emission streams with high efficiency. The technology typically involves cooling stages, solid CO2 formation, and subsequent processing of the captured carbon. This approach offers advantages in energy efficiency and capture rates compared to conventional methods.

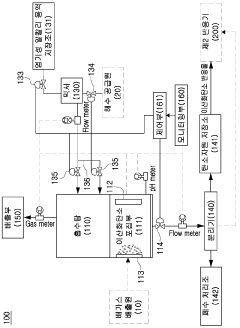

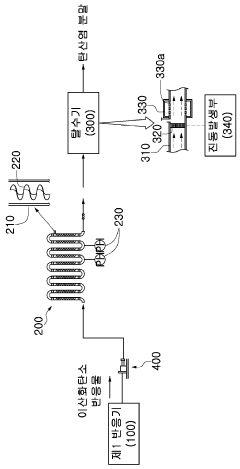

- Equipment and apparatus for cryogenic carbon capture: Specialized equipment is essential for implementing cryogenic carbon capture systems. This includes heat exchangers, desublimation chambers, refrigeration units, and solid handling systems. The apparatus is designed to efficiently cool gas streams, separate solid CO2, and manage the thermal energy requirements of the process. Innovations in equipment design focus on improving heat transfer efficiency, reducing energy consumption, and enhancing the reliability of solid CO2 handling mechanisms.

- Energy optimization in cryogenic carbon capture: Energy efficiency is critical in cryogenic carbon capture systems due to the significant cooling requirements. Innovations focus on heat integration, waste heat recovery, and optimized refrigeration cycles to reduce the overall energy penalty. Advanced approaches include cascaded cooling systems, pressure swing processes, and integration with existing power plant operations. These optimizations aim to make cryogenic carbon capture economically viable by minimizing operational costs while maintaining high capture efficiency.

- Integration with industrial processes and emissions control: Cryogenic carbon capture technologies can be integrated with various industrial processes including power generation, cement production, and steel manufacturing. The integration focuses on adapting the capture system to specific flue gas compositions and process conditions. These systems can be designed to simultaneously remove multiple pollutants alongside CO2, providing comprehensive emissions control. Integration strategies also consider space constraints, existing infrastructure, and operational flexibility requirements.

- Post-capture CO2 utilization and storage: After cryogenic capture, the concentrated CO2 can be processed for various applications including enhanced oil recovery, conversion to valuable chemicals, or permanent geological storage. The high purity of cryogenically captured CO2 makes it suitable for direct utilization in industrial processes. Technologies for compression, transportation, and injection of the captured CO2 are essential components of the complete carbon capture and storage chain. Innovations in this area focus on reducing costs and ensuring long-term stability of stored carbon.

02 Heat exchange systems for cryogenic carbon capture

Advanced heat exchange systems are critical for energy efficiency in cryogenic carbon capture. These systems typically employ multi-stage heat exchangers to recover cold energy from the process, reducing overall energy consumption. Innovations include specialized heat exchanger designs that minimize temperature differences, prevent frost formation, and optimize heat transfer coefficients. Some systems incorporate phase change materials or utilize waste heat from other industrial processes to further improve efficiency.Expand Specific Solutions03 CO2 solidification and handling techniques

Specialized techniques for handling solid CO2 are essential in cryogenic carbon capture systems. These include controlled desublimation chambers where CO2 forms as solid particles, mechanical separation systems to collect the solid CO2, and equipment for processing the solid CO2 into forms suitable for transport or storage. Some systems employ cyclonic separators, electrostatic precipitators, or specialized filters to efficiently collect solid CO2 particles from the gas stream. Advanced systems may include continuous solid handling capabilities to avoid process interruptions.Expand Specific Solutions04 Integration with industrial processes

Cryogenic carbon capture systems can be integrated with various industrial processes including power plants, cement production, and steel manufacturing. Integration approaches focus on optimizing energy use by utilizing waste heat or cold from the host process, minimizing additional energy requirements. Some designs incorporate the cryogenic system directly into the industrial process flow, while others operate as end-of-pipe solutions. Advanced integration strategies may include using captured CO2 for industrial applications or enhanced oil recovery, creating additional value streams.Expand Specific Solutions05 Energy optimization and efficiency improvements

Energy optimization is crucial for making cryogenic carbon capture economically viable. Innovations include advanced refrigeration cycles, pressure swing processes, and hybrid systems that combine cryogenic separation with other capture technologies. Some approaches utilize renewable energy sources or off-peak electricity to power the energy-intensive cooling processes. Process intensification techniques, such as novel contactor designs and optimized phase transition control, can significantly reduce energy consumption. Computational modeling and advanced control systems help optimize operating parameters in real-time.Expand Specific Solutions

Leading Companies and Research Institutions in Maritime CCS

The maritime cryogenic carbon capture (CCC) technology market is in its early growth phase, characterized by increasing R&D investments and emerging commercial applications. The global market is projected to expand significantly as maritime emissions regulations tighten, with potential to reach several billion dollars by 2030. Technologically, CCC for maritime applications is advancing from laboratory to demonstration phase, with key players showing varying levels of maturity. Leading companies like TotalEnergies OneTech, Equinor Energy, and CNOOC are developing proprietary solutions, while shipbuilding specialists Hudong-Zhonghua and Dalian Shipbuilding are integrating these systems into vessel designs. Academic institutions including Politecnico di Milano, California Institute of Technology, and Dalian Maritime University are driving fundamental research, creating a competitive landscape balanced between energy majors, specialized engineering firms, and research organizations.

TotalEnergies OneTech SAS

Technical Solution: TotalEnergies has developed a comprehensive Cryogenic Carbon Capture (CCC) solution optimized for both maritime vessels and offshore production facilities. Their system employs a proprietary multi-phase cooling process that progressively reduces exhaust gas temperature to approximately -135°C, enabling efficient CO2 solidification and separation. The technology features advanced heat integration that recovers cold energy from the regasification of LNG used as fuel, significantly reducing the overall energy penalty of the capture process. TotalEnergies' maritime CCC implementation includes specialized vibration-resistant components designed to maintain performance under varying sea conditions and vessel movements. For offshore applications, their system incorporates modular units that can be retrofitted to existing platforms with minimal disruption to operations. The company has developed an integrated logistics approach for handling captured CO2, including temporary onboard storage solutions and transfer systems compatible with supply vessels. Pilot installations have demonstrated capture rates exceeding 90% with energy consumption approximately 25% lower than conventional amine-based systems, while maintaining a compact footprint suitable for space-constrained marine environments.

Strengths: Versatile design applicable to both vessels and offshore platforms; excellent energy efficiency through LNG cold energy recovery; comprehensive CO2 handling and logistics solutions. Weaknesses: Significant upfront capital costs; complex installation requiring specialized expertise; performance optimization still needed for smaller vessels and varying operational profiles.

Equinor Energy AS

Technical Solution: Equinor has developed an innovative Cryogenic Carbon Capture (CCC) solution specifically designed for offshore platforms and floating production vessels. Their system employs a cascade refrigeration cycle using environmentally friendly refrigerants to progressively cool exhaust gases to approximately -120°C, at which point CO2 solidifies and can be separated. Equinor's technology features a patented heat integration network that recovers waste heat from various offshore processes to reduce the energy penalty associated with cryogenic cooling. The company has engineered their CCC system to operate reliably under dynamic conditions, including varying platform motions and changing production rates. Their offshore implementation includes specialized CO2 handling and temporary storage solutions that maintain the captured carbon in liquid form at moderate pressure, facilitating easier transport via existing offshore pipeline infrastructure or shuttle tankers. Equinor has successfully tested this technology on North Sea platforms, demonstrating capture rates of approximately 95% with energy consumption approximately 25% lower than conventional post-combustion capture methods.

Strengths: Excellent integration with existing offshore energy systems; advanced heat recovery mechanisms reducing operational costs; flexible storage and transport options for captured CO2. Weaknesses: Significant footprint requirements challenging for space-limited offshore installations; complex refrigeration systems requiring specialized maintenance; sensitivity to ambient temperature variations in different operating environments.

Key Technical Innovations in Low-Temperature Carbon Sequestration

Carbon dioxide capture and mitigation of carbon dioxide emissions

PatentWO2005108297A2

Innovation

- The methods involve dissolving magnesium-bearing silicates in acidic solutions, neutralizing to precipitate magnesium components, and carbonating them to bind CO2, with additional steps for recovering ammonia and acid through thermal decomposition or electrodialysis, and using sorbents like activated carbon and alkaline solutions to capture CO2 from the air, followed by regeneration and storage.

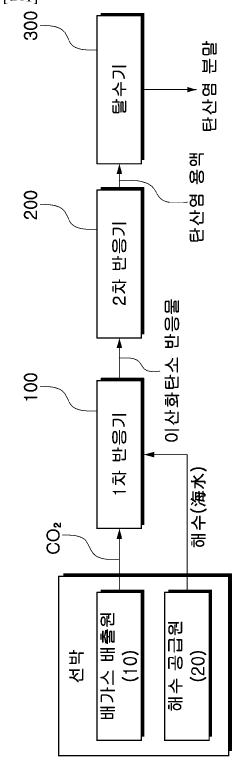

Carbon dioxide capture and carbon resource utilization system, for ship, using seawater and flue gas

PatentWO2023210875A1

Innovation

- A carbon dioxide capture and carbon resource recovery system using a basic alkaline mixture containing seawater, which sprays a basic alkaline solution into ship exhaust gases to capture CO2, followed by conversion into carbonate minerals in a compact reactor configuration, including a first reactor for separation and storage, and a second reactor for precipitation and dehydration.

Regulatory Framework for Maritime Emissions and Carbon Capture

The maritime industry faces increasingly stringent environmental regulations aimed at reducing greenhouse gas emissions, particularly carbon dioxide. The International Maritime Organization (IMO) has established ambitious targets through its Initial GHG Strategy, mandating a reduction of carbon intensity by at least 40% by 2030 and pursuing efforts towards 70% by 2050, compared to 2008 levels. Additionally, the IMO aims for a 50% reduction in total annual GHG emissions by 2050, with a vision of phasing them out entirely.

These regulations have catalyzed interest in carbon capture technologies for maritime applications, with cryogenic carbon capture emerging as a promising solution. The European Union's Emissions Trading System (EU ETS) has recently expanded to include maritime transport, requiring shipping companies to purchase carbon allowances for their emissions. This regulatory pressure creates a direct financial incentive for implementing carbon capture technologies aboard vessels.

The MARPOL Annex VI framework, which governs air pollution from ships, continues to evolve with increasingly strict limits on sulfur oxides, nitrogen oxides, and particulate matter. These regulations complement carbon reduction efforts, as integrated systems must address multiple pollutants simultaneously.

Regional regulations add another layer of complexity. Emission Control Areas (ECAs) in North America, the Baltic Sea, and the North Sea impose stricter emission standards. The California Air Resources Board (CARB) has implemented its own vessel requirements, while China has established domestic emission control areas in its major ports.

For offshore applications, regulatory frameworks vary significantly by jurisdiction. The United States Bureau of Ocean Energy Management (BOEM) and Bureau of Safety and Environmental Enforcement (BSEE) oversee emissions from offshore platforms in U.S. waters, while similar bodies exist in other major offshore energy-producing regions.

Financial mechanisms supporting carbon capture implementation include carbon pricing schemes, green shipping incentives, and sustainable finance initiatives. The Poseidon Principles provide a framework for financial institutions to assess and disclose the climate alignment of their shipping portfolios, potentially facilitating investment in carbon capture technologies.

Certification and compliance verification systems are being developed specifically for maritime carbon capture. Classification societies like DNV GL and Lloyd's Register are establishing guidelines for the installation, operation, and maintenance of carbon capture systems on vessels, ensuring they meet safety and performance standards while achieving regulatory compliance.

These regulations have catalyzed interest in carbon capture technologies for maritime applications, with cryogenic carbon capture emerging as a promising solution. The European Union's Emissions Trading System (EU ETS) has recently expanded to include maritime transport, requiring shipping companies to purchase carbon allowances for their emissions. This regulatory pressure creates a direct financial incentive for implementing carbon capture technologies aboard vessels.

The MARPOL Annex VI framework, which governs air pollution from ships, continues to evolve with increasingly strict limits on sulfur oxides, nitrogen oxides, and particulate matter. These regulations complement carbon reduction efforts, as integrated systems must address multiple pollutants simultaneously.

Regional regulations add another layer of complexity. Emission Control Areas (ECAs) in North America, the Baltic Sea, and the North Sea impose stricter emission standards. The California Air Resources Board (CARB) has implemented its own vessel requirements, while China has established domestic emission control areas in its major ports.

For offshore applications, regulatory frameworks vary significantly by jurisdiction. The United States Bureau of Ocean Energy Management (BOEM) and Bureau of Safety and Environmental Enforcement (BSEE) oversee emissions from offshore platforms in U.S. waters, while similar bodies exist in other major offshore energy-producing regions.

Financial mechanisms supporting carbon capture implementation include carbon pricing schemes, green shipping incentives, and sustainable finance initiatives. The Poseidon Principles provide a framework for financial institutions to assess and disclose the climate alignment of their shipping portfolios, potentially facilitating investment in carbon capture technologies.

Certification and compliance verification systems are being developed specifically for maritime carbon capture. Classification societies like DNV GL and Lloyd's Register are establishing guidelines for the installation, operation, and maintenance of carbon capture systems on vessels, ensuring they meet safety and performance standards while achieving regulatory compliance.

Energy Integration and Efficiency Considerations for Shipboard CCS

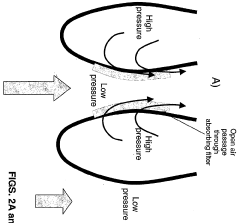

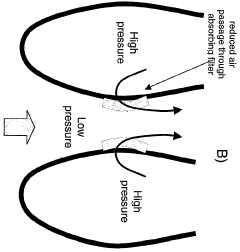

Implementing Cryogenic Carbon Capture (CCC) systems on maritime vessels presents unique energy integration challenges that must be addressed to ensure operational viability. The cryogenic processes involved in carbon capture require significant energy inputs, potentially increasing the vessel's overall energy consumption by 15-30% depending on system design and capture efficiency targets. This energy penalty necessitates careful integration with existing shipboard systems to minimize operational costs and environmental impact.

Energy recovery mechanisms represent a critical aspect of shipboard CCC implementation. Waste heat from the ship's main engines and auxiliary systems can be redirected to support the regeneration phases of the carbon capture process. Advanced heat exchangers specifically designed for marine environments can recover up to 40-60% of the thermal energy that would otherwise be lost, substantially improving the overall system efficiency.

Cold energy utilization presents another significant opportunity for efficiency improvements. The extreme cold temperatures generated during the cryogenic separation process can be harnessed for various shipboard applications, including air conditioning, refrigeration, and potentially liquefied natural gas (LNG) regasification on dual-fuel vessels. This integrated approach to energy management can offset approximately 10-25% of the CCC system's energy requirements.

Power management systems must be redesigned to accommodate the additional electrical load from CCC operations. Smart load distribution algorithms can optimize power allocation between propulsion, hotel loads, and carbon capture systems based on operational conditions and regulatory requirements in different maritime zones. Dynamic load management can reduce peak power demands by 15-20% compared to non-integrated approaches.

Space and weight constraints aboard vessels necessitate compact energy integration solutions. Modular designs that combine multiple energy recovery functions within limited footprints are emerging as preferred configurations. These integrated energy modules typically achieve 25-35% higher energy efficiency than conventional segregated systems while reducing the total installation space by up to 40%.

Operational flexibility must be maintained despite the additional energy demands. Advanced control systems utilizing predictive algorithms can anticipate changes in operational profiles and adjust the CCC system's energy consumption accordingly. This adaptive approach ensures optimal energy utilization across varying conditions, from port maneuvers to open-sea cruising, maintaining propulsion efficiency while meeting emission reduction targets.

Economic viability ultimately depends on achieving acceptable energy efficiency ratios. Current research indicates that well-integrated shipboard CCC systems can achieve net energy penalties as low as 0.8-1.2 GJ per ton of CO₂ captured, representing a significant improvement over early marine carbon capture implementations that required 2.0-2.5 GJ per ton.

Energy recovery mechanisms represent a critical aspect of shipboard CCC implementation. Waste heat from the ship's main engines and auxiliary systems can be redirected to support the regeneration phases of the carbon capture process. Advanced heat exchangers specifically designed for marine environments can recover up to 40-60% of the thermal energy that would otherwise be lost, substantially improving the overall system efficiency.

Cold energy utilization presents another significant opportunity for efficiency improvements. The extreme cold temperatures generated during the cryogenic separation process can be harnessed for various shipboard applications, including air conditioning, refrigeration, and potentially liquefied natural gas (LNG) regasification on dual-fuel vessels. This integrated approach to energy management can offset approximately 10-25% of the CCC system's energy requirements.

Power management systems must be redesigned to accommodate the additional electrical load from CCC operations. Smart load distribution algorithms can optimize power allocation between propulsion, hotel loads, and carbon capture systems based on operational conditions and regulatory requirements in different maritime zones. Dynamic load management can reduce peak power demands by 15-20% compared to non-integrated approaches.

Space and weight constraints aboard vessels necessitate compact energy integration solutions. Modular designs that combine multiple energy recovery functions within limited footprints are emerging as preferred configurations. These integrated energy modules typically achieve 25-35% higher energy efficiency than conventional segregated systems while reducing the total installation space by up to 40%.

Operational flexibility must be maintained despite the additional energy demands. Advanced control systems utilizing predictive algorithms can anticipate changes in operational profiles and adjust the CCC system's energy consumption accordingly. This adaptive approach ensures optimal energy utilization across varying conditions, from port maneuvers to open-sea cruising, maintaining propulsion efficiency while meeting emission reduction targets.

Economic viability ultimately depends on achieving acceptable energy efficiency ratios. Current research indicates that well-integrated shipboard CCC systems can achieve net energy penalties as low as 0.8-1.2 GJ per ton of CO₂ captured, representing a significant improvement over early marine carbon capture implementations that required 2.0-2.5 GJ per ton.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!