Policy Implications For Accelerating Cryogenic Carbon Capture Pilots

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Carbon Capture Background and Objectives

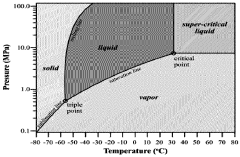

Cryogenic Carbon Capture (CCC) represents a transformative approach to addressing global carbon emissions, emerging as a promising technology in the broader carbon capture, utilization, and storage (CCUS) landscape. Developed initially in the early 2000s, CCC has evolved from theoretical concepts to laboratory demonstrations and is now poised for pilot-scale implementation. This technology operates on the principle of cooling exhaust gases to temperatures where CO2 solidifies (approximately -140°C), allowing for efficient separation from other gases with potential capture rates exceeding 95%.

The historical development of CCC has been marked by significant advancements in cryogenic engineering, materials science, and process optimization. Early research focused primarily on thermodynamic feasibility, while recent developments have addressed energy efficiency challenges and system integration complexities. The technology has progressed through laboratory validation stages and now requires policy support to accelerate pilot demonstrations that can verify commercial viability.

Current technical objectives for CCC pilot projects include demonstrating sustained operation at industrial scales, optimizing energy consumption through heat integration and recovery systems, and validating economic models under real-world conditions. These pilots aim to achieve carbon capture costs below $50 per ton of CO2, representing a significant improvement over first-generation carbon capture technologies.

The global context for CCC development is increasingly favorable, with international climate agreements driving more ambitious carbon reduction targets. The IPCC and IEA have both identified carbon capture technologies as essential components of climate mitigation strategies, particularly for hard-to-abate sectors like cement, steel, and certain chemical processes where CCC may offer unique advantages over alternative approaches.

Policy objectives for accelerating CCC pilots should focus on creating regulatory frameworks that recognize the technology's potential while addressing implementation barriers. These include establishing appropriate carbon pricing mechanisms, developing standards for captured CO2 quality and transport, and creating incentives that reflect the technology's potential climate benefits. Additionally, policies should aim to foster international collaboration on pilot projects to leverage global expertise and resources.

The technological trajectory suggests that with appropriate policy support, CCC could move from pilot demonstrations to early commercial deployment within 5-7 years, potentially becoming a mainstream carbon management solution by 2035. This timeline aligns with critical climate action windows identified in major climate assessments, underscoring the urgency of policy action to accelerate CCC development.

The historical development of CCC has been marked by significant advancements in cryogenic engineering, materials science, and process optimization. Early research focused primarily on thermodynamic feasibility, while recent developments have addressed energy efficiency challenges and system integration complexities. The technology has progressed through laboratory validation stages and now requires policy support to accelerate pilot demonstrations that can verify commercial viability.

Current technical objectives for CCC pilot projects include demonstrating sustained operation at industrial scales, optimizing energy consumption through heat integration and recovery systems, and validating economic models under real-world conditions. These pilots aim to achieve carbon capture costs below $50 per ton of CO2, representing a significant improvement over first-generation carbon capture technologies.

The global context for CCC development is increasingly favorable, with international climate agreements driving more ambitious carbon reduction targets. The IPCC and IEA have both identified carbon capture technologies as essential components of climate mitigation strategies, particularly for hard-to-abate sectors like cement, steel, and certain chemical processes where CCC may offer unique advantages over alternative approaches.

Policy objectives for accelerating CCC pilots should focus on creating regulatory frameworks that recognize the technology's potential while addressing implementation barriers. These include establishing appropriate carbon pricing mechanisms, developing standards for captured CO2 quality and transport, and creating incentives that reflect the technology's potential climate benefits. Additionally, policies should aim to foster international collaboration on pilot projects to leverage global expertise and resources.

The technological trajectory suggests that with appropriate policy support, CCC could move from pilot demonstrations to early commercial deployment within 5-7 years, potentially becoming a mainstream carbon management solution by 2035. This timeline aligns with critical climate action windows identified in major climate assessments, underscoring the urgency of policy action to accelerate CCC development.

Market Analysis for Carbon Capture Technologies

The global carbon capture and storage (CCS) market is experiencing significant growth, driven by increasing environmental concerns and stringent emission regulations. As of 2023, the market was valued at approximately $7.3 billion, with projections indicating a compound annual growth rate (CAGR) of 19.2% through 2030, potentially reaching $35.6 billion by the end of the decade. This growth trajectory is particularly relevant for cryogenic carbon capture technologies, which represent an emerging segment within the broader CCS landscape.

Cryogenic carbon capture specifically addresses a critical market need for technologies capable of capturing carbon dioxide from industrial point sources with high efficiency and relatively lower energy penalties compared to conventional methods. The market demand for this technology is concentrated in energy-intensive industries including power generation, cement production, steel manufacturing, and chemical processing, which collectively account for over 70% of global industrial CO2 emissions.

Regional analysis reveals varying market dynamics for carbon capture technologies. North America currently leads the market with approximately 35% share, driven by favorable policy frameworks in the United States, including the expanded 45Q tax credits which now offer up to $85 per ton for carbon sequestration. The European market follows closely at 30% market share, bolstered by the EU Emissions Trading System and the European Green Deal's ambitious climate targets.

The Asia-Pacific region represents the fastest-growing market for carbon capture technologies, with China and India making substantial investments in pilot projects and research initiatives. This growth is fueled by rapid industrialization coupled with increasing environmental commitments, particularly China's pledge to achieve carbon neutrality by 2060.

Market segmentation analysis indicates that post-combustion capture currently dominates with 65% of market share, while pre-combustion and oxy-fuel combustion technologies account for 25% and 10% respectively. Cryogenic carbon capture, as an emerging technology, is positioned to disrupt this distribution due to its potential for higher capture rates and applicability across diverse industrial settings.

Customer demand patterns show increasing interest from both public and private sectors. Government entities are primarily motivated by climate commitments and regulatory compliance, while private industry adoption is driven by a combination of regulatory pressure, carbon pricing mechanisms, and growing corporate sustainability initiatives. The willingness to pay for carbon capture solutions correlates strongly with regional carbon prices, which range from $5-10 per ton in emerging markets to $50-100 per ton in more mature carbon markets.

Cryogenic carbon capture specifically addresses a critical market need for technologies capable of capturing carbon dioxide from industrial point sources with high efficiency and relatively lower energy penalties compared to conventional methods. The market demand for this technology is concentrated in energy-intensive industries including power generation, cement production, steel manufacturing, and chemical processing, which collectively account for over 70% of global industrial CO2 emissions.

Regional analysis reveals varying market dynamics for carbon capture technologies. North America currently leads the market with approximately 35% share, driven by favorable policy frameworks in the United States, including the expanded 45Q tax credits which now offer up to $85 per ton for carbon sequestration. The European market follows closely at 30% market share, bolstered by the EU Emissions Trading System and the European Green Deal's ambitious climate targets.

The Asia-Pacific region represents the fastest-growing market for carbon capture technologies, with China and India making substantial investments in pilot projects and research initiatives. This growth is fueled by rapid industrialization coupled with increasing environmental commitments, particularly China's pledge to achieve carbon neutrality by 2060.

Market segmentation analysis indicates that post-combustion capture currently dominates with 65% of market share, while pre-combustion and oxy-fuel combustion technologies account for 25% and 10% respectively. Cryogenic carbon capture, as an emerging technology, is positioned to disrupt this distribution due to its potential for higher capture rates and applicability across diverse industrial settings.

Customer demand patterns show increasing interest from both public and private sectors. Government entities are primarily motivated by climate commitments and regulatory compliance, while private industry adoption is driven by a combination of regulatory pressure, carbon pricing mechanisms, and growing corporate sustainability initiatives. The willingness to pay for carbon capture solutions correlates strongly with regional carbon prices, which range from $5-10 per ton in emerging markets to $50-100 per ton in more mature carbon markets.

Current Status and Barriers in Cryogenic Carbon Capture

Cryogenic Carbon Capture (CCC) technology has emerged as a promising solution for reducing carbon emissions across various industrial sectors. Currently, the technology has progressed beyond laboratory scale and entered early pilot demonstration phases. Several research institutions and companies have successfully demonstrated CCC at small scales, with notable examples including Sustainable Energy Solutions (SES) and their Cryogenic Carbon Capture™ process, which has shown capture rates exceeding 95% in controlled environments.

Despite these advancements, CCC technology faces significant barriers to widespread implementation. Technical challenges remain prominent, particularly in scaling up the process while maintaining energy efficiency. The cryogenic cooling required for carbon separation demands substantial energy input, which can reduce the net environmental benefit if not optimized. System integration complexities also present obstacles when retrofitting existing industrial facilities with CCC technology.

Economic barriers constitute another major impediment to CCC deployment. The capital expenditure for cryogenic equipment is considerably high, with estimates suggesting installation costs between $60-100 per ton of CO2 captured annually. Operational expenses, primarily driven by energy consumption for refrigeration processes, further increase the total cost of ownership. Without sufficient carbon pricing mechanisms or incentives, these costs make CCC less attractive compared to conventional carbon capture methods.

Regulatory uncertainty compounds these challenges. Many jurisdictions lack clear frameworks for carbon capture technologies, creating hesitation among potential investors and industrial adopters. Standards for measurement, reporting, and verification of captured carbon remain inconsistent across regions, complicating international collaboration and technology transfer.

Infrastructure limitations also constrain CCC implementation. The technology requires specialized equipment for extreme cooling, and the supply chain for these components is not yet fully developed. Additionally, once carbon is captured, comprehensive CO2 transport and storage infrastructure is necessary—a requirement that remains underdeveloped in many regions globally.

Knowledge gaps persist regarding long-term performance and reliability of CCC systems in various industrial environments. Limited operational data from extended pilot projects hampers accurate assessment of maintenance requirements and system degradation over time. This uncertainty increases perceived risk for potential adopters and investors.

International collaboration on CCC development remains fragmented, with research efforts often siloed within national boundaries. This fragmentation slows knowledge sharing and technological advancement that could otherwise accelerate the maturation of CCC technology and reduce implementation costs through standardization and economies of scale.

Despite these advancements, CCC technology faces significant barriers to widespread implementation. Technical challenges remain prominent, particularly in scaling up the process while maintaining energy efficiency. The cryogenic cooling required for carbon separation demands substantial energy input, which can reduce the net environmental benefit if not optimized. System integration complexities also present obstacles when retrofitting existing industrial facilities with CCC technology.

Economic barriers constitute another major impediment to CCC deployment. The capital expenditure for cryogenic equipment is considerably high, with estimates suggesting installation costs between $60-100 per ton of CO2 captured annually. Operational expenses, primarily driven by energy consumption for refrigeration processes, further increase the total cost of ownership. Without sufficient carbon pricing mechanisms or incentives, these costs make CCC less attractive compared to conventional carbon capture methods.

Regulatory uncertainty compounds these challenges. Many jurisdictions lack clear frameworks for carbon capture technologies, creating hesitation among potential investors and industrial adopters. Standards for measurement, reporting, and verification of captured carbon remain inconsistent across regions, complicating international collaboration and technology transfer.

Infrastructure limitations also constrain CCC implementation. The technology requires specialized equipment for extreme cooling, and the supply chain for these components is not yet fully developed. Additionally, once carbon is captured, comprehensive CO2 transport and storage infrastructure is necessary—a requirement that remains underdeveloped in many regions globally.

Knowledge gaps persist regarding long-term performance and reliability of CCC systems in various industrial environments. Limited operational data from extended pilot projects hampers accurate assessment of maintenance requirements and system degradation over time. This uncertainty increases perceived risk for potential adopters and investors.

International collaboration on CCC development remains fragmented, with research efforts often siloed within national boundaries. This fragmentation slows knowledge sharing and technological advancement that could otherwise accelerate the maturation of CCC technology and reduce implementation costs through standardization and economies of scale.

Existing Pilot Implementation Approaches

01 Cryogenic carbon capture process fundamentals

Cryogenic carbon capture involves cooling flue gas to temperatures where CO2 desublimes (transitions directly from gas to solid), allowing for separation from other gases. This process typically operates at temperatures below -100°C and can achieve high CO2 capture rates (>90%). The technology offers advantages including lower energy requirements compared to conventional amine-based capture methods and produces a high-purity CO2 stream suitable for storage or utilization.- Cryogenic carbon capture process fundamentals: Cryogenic carbon capture involves cooling flue gas to temperatures where CO2 desublimes (transitions directly from gas to solid), allowing for separation from other gases. This process typically operates at temperatures below -100°C and can achieve high CO2 capture rates (>90%). The technology offers advantages including lower energy requirements compared to conventional methods, minimal water usage, and the ability to capture other pollutants simultaneously.

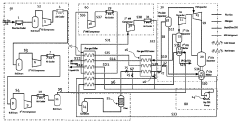

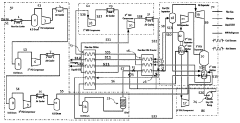

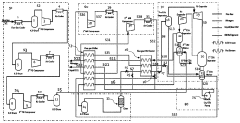

- Equipment and system design for cryogenic carbon capture: Specialized equipment designs are essential for efficient cryogenic carbon capture, including heat exchangers that maximize energy recovery, desublimation chambers where CO2 solidifies, and refrigeration systems that provide the necessary cooling. These systems often incorporate multi-stage cooling processes, pressure control mechanisms, and specialized materials that can withstand extreme cold temperatures while maintaining structural integrity and operational efficiency.

- Energy optimization in cryogenic carbon capture: Energy efficiency is critical in cryogenic carbon capture systems, achieved through heat integration techniques, waste heat recovery, and advanced refrigeration cycles. Innovations include using expansion turbines to recover energy during gas expansion, multi-stage compression with intercooling, and utilizing waste cold energy from industrial processes or LNG regasification. These optimizations significantly reduce the energy penalty associated with carbon capture, making the process more economically viable.

- Integration with industrial processes and power plants: Cryogenic carbon capture systems can be integrated with various industrial processes including power generation, cement production, and steel manufacturing. Integration strategies focus on utilizing waste heat streams, optimizing process configurations, and developing modular designs that can be retrofitted to existing facilities. This integration enables efficient carbon capture while minimizing disruption to the primary industrial processes and potentially providing additional benefits such as coproduction of liquid nitrogen or purified CO2 for industrial use.

- Post-capture CO2 handling and utilization: After cryogenic capture, solid CO2 can be processed for various applications including enhanced oil recovery, conversion to valuable chemicals, or permanent geological storage. The captured CO2 must be pressurized, purified, and transported efficiently. Innovations in this area include developing pipeline infrastructure for CO2 transport, methods for converting CO2 to fuels or chemicals using renewable energy, and techniques for monitoring long-term geological storage to ensure environmental safety and carbon permanence.

02 Equipment and system design for cryogenic carbon capture

Specialized equipment designs for cryogenic carbon capture include heat exchangers, desublimation chambers, and refrigeration systems. These systems often incorporate multi-stage cooling processes to improve energy efficiency and reduce operational costs. Innovations in system design focus on optimizing heat integration, minimizing pressure drops, and developing specialized materials that can withstand cryogenic temperatures while maintaining structural integrity and performance.Expand Specific Solutions03 Energy efficiency improvements in cryogenic carbon capture

Recent advancements focus on improving the energy efficiency of cryogenic carbon capture systems through heat recovery techniques, process optimization, and integration with existing power plants. Innovations include staged cooling processes, waste heat utilization, and novel refrigeration cycles. These improvements aim to reduce the parasitic energy load of carbon capture, making the technology more economically viable for large-scale implementation in industrial settings.Expand Specific Solutions04 Integration with industrial processes and power generation

Cryogenic carbon capture technologies can be integrated with various industrial processes including power generation, cement production, and steel manufacturing. Integration strategies focus on utilizing waste heat from industrial processes to offset energy requirements for the capture system, optimizing process configurations to minimize efficiency losses, and developing modular designs that can be retrofitted to existing facilities with minimal disruption to operations.Expand Specific Solutions05 Post-capture CO2 handling and utilization

After cryogenic capture, the solid CO2 can be pressurized and warmed to produce liquid or supercritical CO2 for transport and storage. Innovations in this area include methods for CO2 purification, compression techniques optimized for solid-derived CO2, and integration with carbon utilization pathways. Technologies focus on minimizing energy requirements for phase transitions while maintaining high purity levels required for geological storage or industrial applications such as enhanced oil recovery, chemical manufacturing, or conversion to value-added products.Expand Specific Solutions

Leading Organizations in Cryogenic Carbon Capture

Cryogenic Carbon Capture (CCC) technology is currently in an early commercialization phase, with market growth accelerating as climate policies drive demand for carbon reduction solutions. The global carbon capture market, valued at approximately $2 billion, is projected to expand significantly with increasing policy support. Technologically, CCC shows promising maturity levels with academic institutions (Tianjin University, Zhejiang University, Columbia University, West Virginia University) leading fundamental research while industrial players (Nuovo Pignone Tecnologie, Huaneng Clean Energy Research Institute, Shanghai Power Equipment Research Institute) focus on pilot implementation and scaling. Research collaborations between Global Thermostat Operations, Saudi Aramco, and Industrial Technology Research Institute demonstrate growing commercial interest. Policy acceleration is critical to bridge the valley between laboratory success and industrial deployment, particularly for addressing cost barriers and regulatory frameworks.

The Trustees of Columbia University in The City of New York

Technical Solution: Columbia University has developed an innovative Cryogenic Carbon Capture (CCC) technology called "CryoSep" through their Carbon Management Research Initiative. Their approach utilizes a staged refrigeration process that progressively cools flue gas to temperatures around -120°C, causing CO2 to desublimate while other gases remain in vapor phase. The university's research team has created advanced heat exchanger designs that minimize temperature gradients and energy losses during the cooling process, achieving energy requirements approximately 35% lower than first-generation cryogenic systems. Their pilot system incorporates thermal energy storage using phase-change materials to manage intermittent operation and grid integration challenges. Columbia's technology features a novel defrosting cycle that maintains continuous operation without significant downtime, addressing a key operational challenge in cryogenic systems. The university has conducted extensive testing with various flue gas compositions, demonstrating robust performance across different industrial applications including cement production and power generation. Their research includes comprehensive techno-economic analysis showing potential capture costs of $40-60 per ton when fully scaled and integrated with industrial waste heat recovery systems.

Strengths: Highly efficient heat exchanger design reduces energy requirements; thermal storage integration enables flexible operation with renewable energy sources; extensive academic research backing with peer-reviewed validation; adaptable to various industrial applications beyond power generation. Weaknesses: Limited commercial-scale demonstration experience compared to industry players; technology transfer and commercialization pathways still developing; higher capital costs than conventional capture technologies; requires specialized expertise for operation and maintenance.

C2F, Inc.

Technical Solution: C2F, Inc. has developed a proprietary Cryogenic Carbon Capture (CCC) technology that freezes and separates CO2 from flue gas streams at temperatures below -140°C. Their process involves cooling the flue gas in stages, causing CO2 to desublimate directly from gas to solid while other gases remain in vapor form. The technology achieves over 95% carbon capture efficiency while requiring approximately 30-40% less energy than conventional amine-based systems. C2F has demonstrated their technology at small pilot scales (1-5 MWe equivalent) and is currently working on scaling to larger demonstration projects (10-25 MWe). Their approach integrates waste heat recovery systems and proprietary heat exchangers to maximize energy efficiency throughout the capture process. The company has also developed specialized anti-fouling mechanisms to prevent ice buildup on critical components, addressing a common challenge in cryogenic systems.

Strengths: Lower energy penalty compared to conventional technologies; high capture efficiency (>95%); potential for integration with existing power plants without major modifications; produces high-purity CO2 suitable for utilization or storage. Weaknesses: Requires significant refrigeration infrastructure; higher capital costs for initial deployment; technology still needs demonstration at commercial scale; sensitive to moisture content in flue gas requiring effective pre-treatment systems.

Key Patents and Technical Innovations

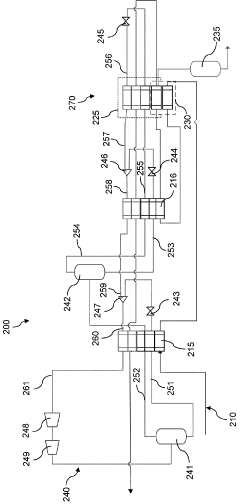

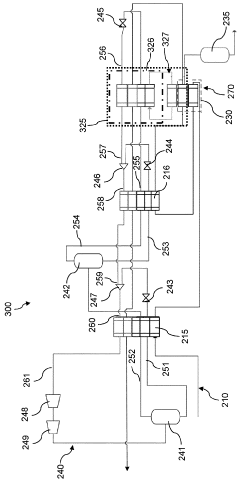

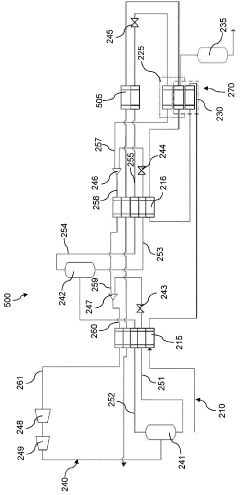

A new flue gas co2 capture process using the cryogenic method

PatentPendingCA3171526A1

Innovation

- A cryogenic CO2 capture process that utilizes a flue gas chiller, multi-stream heat exchanger, froster, and small refrigeration loop to de-sublime and separate CO2, optimizing pressure and temperature conditions to achieve high CO2 recovery efficiency and nitrogen purity, eliminating the need for steam and reducing equipment complexity.

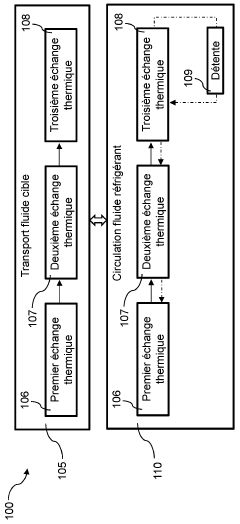

Device and method for cryogenic capture of carbon dioxide contained in a target fluid stream

PatentWO2024003285A1

Innovation

- A device and method for cryogenic capture of carbon dioxide using a closed circuit with multiple heat exchangers and a refrigerant fluid mixture of hydrocarbons (methane, ethane, propane, isobutane, and n-butane) that allows for pre-cooling and anti-sublimation without liquid condensation, optimizing heat exchanges and reducing energy costs.

Regulatory Framework and Policy Landscape

The global regulatory landscape for carbon capture technologies is undergoing significant transformation as governments recognize the urgent need to address climate change. Current regulatory frameworks for Cryogenic Carbon Capture (CCC) vary substantially across regions, creating a complex environment for technology developers and potential adopters. In the United States, the EPA's Clean Air Act provides some oversight for carbon capture projects, while the Department of Energy offers various funding mechanisms for pilot demonstrations through programs like the Carbon Capture Demonstration Projects.

The European Union has established more comprehensive frameworks through its Emissions Trading System (ETS) and the Innovation Fund, which specifically targets carbon capture technologies. These mechanisms create economic incentives for industrial facilities to implement carbon capture solutions by putting a price on carbon emissions and providing financial support for innovative projects. The EU's Taxonomy Regulation also classifies certain carbon capture activities as environmentally sustainable, potentially directing more investment toward CCC pilots.

In Asia, countries like Japan and South Korea have introduced carbon pricing mechanisms and technology-specific subsidies that could benefit CCC deployment. China's national emissions trading scheme, while currently limited in scope, represents a significant step toward creating market-based incentives for carbon capture technologies in the world's largest emitter.

Policy gaps remain significant barriers to accelerating CCC pilot projects. These include insufficient carbon pricing mechanisms in many jurisdictions, regulatory uncertainty regarding long-term storage of captured carbon, and limited harmonization of standards across borders. The absence of clear permitting pathways specifically designed for novel carbon capture technologies like CCC creates additional hurdles for project developers seeking to move from laboratory to commercial-scale demonstrations.

Recent policy developments show promising trends, including enhanced tax incentives for carbon capture in the U.S. (45Q tax credits), the EU's Carbon Border Adjustment Mechanism, and increasing international collaboration through initiatives like the Carbon Sequestration Leadership Forum. These developments signal growing recognition of the need for supportive policy frameworks to accelerate carbon capture technologies.

For CCC pilots specifically, regulatory sandboxes and technology-specific incentives represent potential policy innovations that could accelerate deployment. Creating designated regulatory pathways for novel carbon capture technologies, with streamlined permitting processes and temporary exemptions from certain requirements during the pilot phase, could significantly reduce barriers to demonstration projects while maintaining necessary environmental and safety standards.

The European Union has established more comprehensive frameworks through its Emissions Trading System (ETS) and the Innovation Fund, which specifically targets carbon capture technologies. These mechanisms create economic incentives for industrial facilities to implement carbon capture solutions by putting a price on carbon emissions and providing financial support for innovative projects. The EU's Taxonomy Regulation also classifies certain carbon capture activities as environmentally sustainable, potentially directing more investment toward CCC pilots.

In Asia, countries like Japan and South Korea have introduced carbon pricing mechanisms and technology-specific subsidies that could benefit CCC deployment. China's national emissions trading scheme, while currently limited in scope, represents a significant step toward creating market-based incentives for carbon capture technologies in the world's largest emitter.

Policy gaps remain significant barriers to accelerating CCC pilot projects. These include insufficient carbon pricing mechanisms in many jurisdictions, regulatory uncertainty regarding long-term storage of captured carbon, and limited harmonization of standards across borders. The absence of clear permitting pathways specifically designed for novel carbon capture technologies like CCC creates additional hurdles for project developers seeking to move from laboratory to commercial-scale demonstrations.

Recent policy developments show promising trends, including enhanced tax incentives for carbon capture in the U.S. (45Q tax credits), the EU's Carbon Border Adjustment Mechanism, and increasing international collaboration through initiatives like the Carbon Sequestration Leadership Forum. These developments signal growing recognition of the need for supportive policy frameworks to accelerate carbon capture technologies.

For CCC pilots specifically, regulatory sandboxes and technology-specific incentives represent potential policy innovations that could accelerate deployment. Creating designated regulatory pathways for novel carbon capture technologies, with streamlined permitting processes and temporary exemptions from certain requirements during the pilot phase, could significantly reduce barriers to demonstration projects while maintaining necessary environmental and safety standards.

Economic Incentives and Funding Mechanisms

The acceleration of Cryogenic Carbon Capture (CCC) pilot projects requires robust economic incentives and funding mechanisms to overcome the significant capital barriers associated with this emerging technology. Current estimates indicate that CCC implementation costs range between $40-70 per ton of CO2 captured, making financial viability a critical concern for potential adopters without adequate support structures.

Government grants and subsidies represent the most direct approach to stimulating CCC pilot development. Countries including the United States, European Union members, and Canada have established specialized funding programs targeting carbon capture technologies, with the US Department of Energy's Carbon Capture Program allocating approximately $240 million annually to promising technologies including cryogenic approaches.

Tax incentives have emerged as powerful market-based instruments for CCC advancement. The enhanced Section 45Q tax credits in the United States now offer up to $85 per metric ton for carbon capture and sequestration, significantly improving the economic calculus for CCC implementation. Similar mechanisms in the UK, Norway, and Australia provide tax relief proportional to carbon reduction achievements.

Public-private partnerships (PPPs) offer a balanced approach to risk distribution and resource mobilization. The EU Innovation Fund exemplifies this model, combining governmental oversight with private sector expertise to accelerate commercial-scale CCC demonstrations. These partnerships typically involve cost-sharing arrangements where public entities absorb early-stage risks while private investors contribute technical expertise and operational efficiency.

Carbon pricing mechanisms, including emissions trading systems and carbon taxes, create economic incentives for CCC adoption by establishing a clear cost for carbon emissions. Regions with robust carbon pricing, such as the European Union with prices exceeding €80 per ton, provide favorable economic conditions for CCC implementation.

Green bonds and climate finance instruments represent emerging funding avenues specifically designed for environmental technologies. The Climate Bonds Initiative reports that green bond issuance reached $290 billion in 2020, with increasing allocations toward carbon capture technologies including CCC pilots.

International development finance institutions, including the World Bank and regional development banks, have established specialized climate finance facilities that can support CCC pilots in developing economies. These mechanisms often combine concessional financing with technical assistance to address both economic and knowledge barriers.

For optimal effectiveness, these economic incentives and funding mechanisms should be coordinated within comprehensive policy frameworks that address the full technology development cycle, from research through commercialization. Successful CCC acceleration will require strategic combinations of these instruments tailored to specific regional contexts and project phases.

Government grants and subsidies represent the most direct approach to stimulating CCC pilot development. Countries including the United States, European Union members, and Canada have established specialized funding programs targeting carbon capture technologies, with the US Department of Energy's Carbon Capture Program allocating approximately $240 million annually to promising technologies including cryogenic approaches.

Tax incentives have emerged as powerful market-based instruments for CCC advancement. The enhanced Section 45Q tax credits in the United States now offer up to $85 per metric ton for carbon capture and sequestration, significantly improving the economic calculus for CCC implementation. Similar mechanisms in the UK, Norway, and Australia provide tax relief proportional to carbon reduction achievements.

Public-private partnerships (PPPs) offer a balanced approach to risk distribution and resource mobilization. The EU Innovation Fund exemplifies this model, combining governmental oversight with private sector expertise to accelerate commercial-scale CCC demonstrations. These partnerships typically involve cost-sharing arrangements where public entities absorb early-stage risks while private investors contribute technical expertise and operational efficiency.

Carbon pricing mechanisms, including emissions trading systems and carbon taxes, create economic incentives for CCC adoption by establishing a clear cost for carbon emissions. Regions with robust carbon pricing, such as the European Union with prices exceeding €80 per ton, provide favorable economic conditions for CCC implementation.

Green bonds and climate finance instruments represent emerging funding avenues specifically designed for environmental technologies. The Climate Bonds Initiative reports that green bond issuance reached $290 billion in 2020, with increasing allocations toward carbon capture technologies including CCC pilots.

International development finance institutions, including the World Bank and regional development banks, have established specialized climate finance facilities that can support CCC pilots in developing economies. These mechanisms often combine concessional financing with technical assistance to address both economic and knowledge barriers.

For optimal effectiveness, these economic incentives and funding mechanisms should be coordinated within comprehensive policy frameworks that address the full technology development cycle, from research through commercialization. Successful CCC acceleration will require strategic combinations of these instruments tailored to specific regional contexts and project phases.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!