Cryogenic Capture Pilot Data: What Operators Should Measure And Report

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Capture Technology Background and Objectives

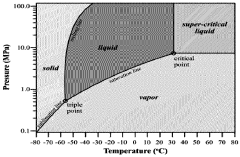

Cryogenic carbon capture (CCC) technology has emerged as a promising approach for reducing greenhouse gas emissions from industrial sources and power plants. This technology has evolved significantly over the past two decades, transitioning from theoretical concepts to laboratory demonstrations and now to pilot-scale implementations. The fundamental principle involves cooling flue gases to temperatures where CO2 solidifies (approximately -140°C), allowing for physical separation from other gases.

The evolution of cryogenic capture began in the early 2000s with basic research into phase behavior of CO2 at ultra-low temperatures. By 2010, laboratory-scale demonstrations had proven the concept's viability, achieving separation efficiencies exceeding 90%. The period between 2015 and 2020 saw significant advancements in process optimization, energy recovery systems, and materials suitable for cryogenic environments, which collectively reduced the energy penalty associated with the technology.

Current technological objectives for cryogenic capture systems focus on several key areas. Primary among these is improving energy efficiency, as the cooling process remains energy-intensive despite recent advances. Engineers aim to reduce the specific energy consumption below 1 MWh per ton of CO2 captured, which would make the technology competitive with alternative capture methods. Another critical objective is scaling the technology to handle industrial-scale gas volumes while maintaining performance metrics.

Process reliability represents another significant goal, as cryogenic systems must operate continuously in demanding industrial environments. This includes developing robust solutions for managing frost formation, preventing equipment fouling, and ensuring consistent performance across variable input conditions. Additionally, there are objectives related to reducing capital costs through innovative equipment design and standardization of components.

The integration of cryogenic capture with existing industrial processes presents unique challenges that current research aims to address. This includes developing flexible systems that can accommodate fluctuations in flue gas composition and flow rates, as well as optimizing heat integration with host facilities to maximize overall efficiency.

Data collection and analysis from pilot operations has become increasingly important, with objectives centered on establishing standardized measurement protocols and key performance indicators. These metrics are essential for comparing different technological implementations and guiding future development. The industry is working toward consensus on which operational parameters are most critical to measure and report, including energy consumption profiles, capture rates under varying conditions, and long-term reliability indicators.

The evolution of cryogenic capture began in the early 2000s with basic research into phase behavior of CO2 at ultra-low temperatures. By 2010, laboratory-scale demonstrations had proven the concept's viability, achieving separation efficiencies exceeding 90%. The period between 2015 and 2020 saw significant advancements in process optimization, energy recovery systems, and materials suitable for cryogenic environments, which collectively reduced the energy penalty associated with the technology.

Current technological objectives for cryogenic capture systems focus on several key areas. Primary among these is improving energy efficiency, as the cooling process remains energy-intensive despite recent advances. Engineers aim to reduce the specific energy consumption below 1 MWh per ton of CO2 captured, which would make the technology competitive with alternative capture methods. Another critical objective is scaling the technology to handle industrial-scale gas volumes while maintaining performance metrics.

Process reliability represents another significant goal, as cryogenic systems must operate continuously in demanding industrial environments. This includes developing robust solutions for managing frost formation, preventing equipment fouling, and ensuring consistent performance across variable input conditions. Additionally, there are objectives related to reducing capital costs through innovative equipment design and standardization of components.

The integration of cryogenic capture with existing industrial processes presents unique challenges that current research aims to address. This includes developing flexible systems that can accommodate fluctuations in flue gas composition and flow rates, as well as optimizing heat integration with host facilities to maximize overall efficiency.

Data collection and analysis from pilot operations has become increasingly important, with objectives centered on establishing standardized measurement protocols and key performance indicators. These metrics are essential for comparing different technological implementations and guiding future development. The industry is working toward consensus on which operational parameters are most critical to measure and report, including energy consumption profiles, capture rates under varying conditions, and long-term reliability indicators.

Market Demand Analysis for Cryogenic Carbon Capture

The global carbon capture market is experiencing significant growth, driven by increasing regulatory pressures and corporate sustainability commitments. Current market projections indicate the carbon capture, utilization, and storage (CCUS) market will reach approximately $7 billion by 2030, with cryogenic carbon capture technologies potentially capturing 15-20% of this expanding market. This growth trajectory is supported by major climate policies such as the European Green Deal and the U.S. Inflation Reduction Act, which provide substantial financial incentives for carbon capture implementation.

Cryogenic carbon capture technologies are gaining particular attention due to their versatility across multiple industrial sectors. Heavy industries including cement, steel, and power generation represent the primary demand drivers, collectively accounting for over 60% of global industrial carbon emissions. These sectors face mounting pressure to decarbonize while maintaining operational efficiency, creating an urgent market need for scalable carbon capture solutions.

Market research indicates that facility operators across these industries are increasingly seeking comprehensive operational data from pilot installations to justify large-scale investments. Specifically, there is high demand for standardized measurement protocols and reporting frameworks that can accurately demonstrate the technology's performance under various industrial conditions.

The geographical distribution of market demand shows concentration in regions with both high industrial activity and strong climate policies. North America, Western Europe, and parts of Asia-Pacific (particularly China, Japan, and South Korea) represent the most immediate market opportunities, with combined potential deployment capacity exceeding 500 million tons of CO2 annually by 2035.

Stakeholder interviews reveal that potential adopters prioritize five key performance indicators when evaluating cryogenic carbon capture technologies: capture efficiency rates, energy consumption metrics, operational reliability data, integration complexity assessments, and comprehensive cost structures including both capital and operational expenditures. The market currently lacks standardized reporting on these metrics, creating significant information asymmetry between technology providers and potential adopters.

Financial analysis of the market indicates that the total addressable market for cryogenic carbon capture could reach $12-15 billion by 2040, assuming continued policy support and technology cost reductions. Early movers who can demonstrate proven performance through well-documented pilot projects stand to capture premium pricing and establish dominant market positions as the technology moves toward mainstream adoption.

Cryogenic carbon capture technologies are gaining particular attention due to their versatility across multiple industrial sectors. Heavy industries including cement, steel, and power generation represent the primary demand drivers, collectively accounting for over 60% of global industrial carbon emissions. These sectors face mounting pressure to decarbonize while maintaining operational efficiency, creating an urgent market need for scalable carbon capture solutions.

Market research indicates that facility operators across these industries are increasingly seeking comprehensive operational data from pilot installations to justify large-scale investments. Specifically, there is high demand for standardized measurement protocols and reporting frameworks that can accurately demonstrate the technology's performance under various industrial conditions.

The geographical distribution of market demand shows concentration in regions with both high industrial activity and strong climate policies. North America, Western Europe, and parts of Asia-Pacific (particularly China, Japan, and South Korea) represent the most immediate market opportunities, with combined potential deployment capacity exceeding 500 million tons of CO2 annually by 2035.

Stakeholder interviews reveal that potential adopters prioritize five key performance indicators when evaluating cryogenic carbon capture technologies: capture efficiency rates, energy consumption metrics, operational reliability data, integration complexity assessments, and comprehensive cost structures including both capital and operational expenditures. The market currently lacks standardized reporting on these metrics, creating significant information asymmetry between technology providers and potential adopters.

Financial analysis of the market indicates that the total addressable market for cryogenic carbon capture could reach $12-15 billion by 2040, assuming continued policy support and technology cost reductions. Early movers who can demonstrate proven performance through well-documented pilot projects stand to capture premium pricing and establish dominant market positions as the technology moves toward mainstream adoption.

Current Technical Challenges in Cryogenic Capture Systems

Cryogenic carbon capture (CCC) systems face several significant technical challenges that impede widespread commercial deployment. The primary challenge lies in energy efficiency, as the deep refrigeration processes required for CO2 solidification consume substantial power, often offsetting the environmental benefits of carbon capture. Current systems typically require 0.8-1.2 MWh per ton of CO2 captured, which remains economically prohibitive for many industrial applications.

Temperature control presents another critical challenge, as cryogenic systems must maintain precise temperature gradients throughout the capture process. Even minor fluctuations can significantly reduce capture efficiency or cause system failures. Operators struggle with maintaining stable conditions during load variations, particularly in industrial settings where energy inputs may fluctuate based on production demands.

Material limitations constitute a substantial barrier, as components must withstand extreme temperature cycling between ambient and cryogenic conditions (-140°C and below). This thermal cycling accelerates material fatigue and can lead to premature equipment failure. Current materials science has not yet delivered cost-effective solutions that combine thermal resilience with the necessary mechanical properties for long-term operation.

Process integration challenges are evident in pilot implementations, where cryogenic capture systems must interface with existing industrial processes without disrupting core operations. The heat exchange requirements and physical footprint of cryogenic equipment often necessitate significant modifications to existing facilities, increasing implementation costs and complexity.

Scaling issues persist as laboratory successes have proven difficult to translate to industrial-scale operations. The physics of heat transfer and fluid dynamics change significantly at larger scales, requiring redesigned components and control systems. Most current pilot projects operate at capacities below 100 tons of CO2 per day, far from the thousands of tons required for major industrial applications.

Instrumentation and monitoring systems face unique challenges in cryogenic environments, as conventional sensors often fail or provide inaccurate readings at extremely low temperatures. This creates significant data gaps in operational monitoring, complicating both process optimization and safety management.

Defrosting and solid CO2 handling remain problematic, as ice formation on heat exchange surfaces reduces efficiency and requires periodic system shutdown for defrosting. Current solutions for handling the solid CO2 product after capture are largely manual and difficult to automate, creating operational bottlenecks in continuous processing systems.

Temperature control presents another critical challenge, as cryogenic systems must maintain precise temperature gradients throughout the capture process. Even minor fluctuations can significantly reduce capture efficiency or cause system failures. Operators struggle with maintaining stable conditions during load variations, particularly in industrial settings where energy inputs may fluctuate based on production demands.

Material limitations constitute a substantial barrier, as components must withstand extreme temperature cycling between ambient and cryogenic conditions (-140°C and below). This thermal cycling accelerates material fatigue and can lead to premature equipment failure. Current materials science has not yet delivered cost-effective solutions that combine thermal resilience with the necessary mechanical properties for long-term operation.

Process integration challenges are evident in pilot implementations, where cryogenic capture systems must interface with existing industrial processes without disrupting core operations. The heat exchange requirements and physical footprint of cryogenic equipment often necessitate significant modifications to existing facilities, increasing implementation costs and complexity.

Scaling issues persist as laboratory successes have proven difficult to translate to industrial-scale operations. The physics of heat transfer and fluid dynamics change significantly at larger scales, requiring redesigned components and control systems. Most current pilot projects operate at capacities below 100 tons of CO2 per day, far from the thousands of tons required for major industrial applications.

Instrumentation and monitoring systems face unique challenges in cryogenic environments, as conventional sensors often fail or provide inaccurate readings at extremely low temperatures. This creates significant data gaps in operational monitoring, complicating both process optimization and safety management.

Defrosting and solid CO2 handling remain problematic, as ice formation on heat exchange surfaces reduces efficiency and requires periodic system shutdown for defrosting. Current solutions for handling the solid CO2 product after capture are largely manual and difficult to automate, creating operational bottlenecks in continuous processing systems.

Current Measurement Protocols and Data Collection Methods

01 Cryogenic carbon capture measurement systems

Systems for measuring and reporting data related to cryogenic carbon capture processes. These systems monitor parameters such as temperature, pressure, and flow rates during the capture of carbon dioxide at extremely low temperatures. The measurement systems provide real-time data on capture efficiency and process performance, enabling optimization of the cryogenic capture process and ensuring compliance with environmental regulations.- Cryogenic carbon capture measurement systems: Systems for measuring and monitoring carbon capture processes under cryogenic conditions. These systems include sensors and instruments that can operate at extremely low temperatures to accurately measure parameters such as temperature, pressure, flow rates, and composition of gases during the carbon capture process. The data collected helps optimize the efficiency of cryogenic carbon capture operations and ensures compliance with environmental regulations.

- Data reporting and analytics for cryogenic processes: Methods and systems for collecting, analyzing, and reporting data from cryogenic capture operations. These solutions include software platforms that process raw measurement data into actionable insights, generate automated reports, and provide visualization tools for monitoring performance metrics. The reporting systems help operators track capture efficiency, energy consumption, and other key performance indicators to optimize cryogenic capture operations.

- Real-time monitoring and control systems for cryogenic applications: Technologies for real-time monitoring and control of cryogenic capture processes. These systems integrate sensors, controllers, and communication networks to provide continuous feedback on process conditions and enable automated adjustments to maintain optimal performance. Real-time monitoring helps detect anomalies quickly, prevent equipment failures, and ensure safe operation of cryogenic capture facilities.

- Mobile and remote cryogenic data collection solutions: Portable and remote systems for collecting data from cryogenic capture operations in various locations. These solutions include mobile measurement devices, wireless sensors, and cloud-based data management platforms that enable monitoring of distributed capture sites. The technologies allow for efficient data collection from remote or difficult-to-access locations and facilitate centralized management of multiple cryogenic capture installations.

- Integration of cryogenic capture data with environmental compliance systems: Methods and systems for integrating cryogenic capture measurement data with environmental compliance and reporting frameworks. These solutions automate the collection and formatting of data required for regulatory reporting, carbon credit verification, and sustainability disclosures. The integration helps organizations demonstrate compliance with emissions regulations, validate carbon offset claims, and quantify the environmental benefits of their cryogenic capture operations.

02 Data reporting and visualization for cryogenic processes

Methods and systems for reporting and visualizing data collected from cryogenic capture operations. These technologies include dashboards, automated reporting tools, and visualization interfaces that transform complex measurement data into actionable insights. The reporting systems enable operators to monitor capture performance, identify trends, and make data-driven decisions to improve operational efficiency and reduce environmental impact.Expand Specific Solutions03 Sensor networks for cryogenic environments

Specialized sensor networks designed to function reliably in extreme cold environments associated with cryogenic capture processes. These networks include temperature sensors, pressure transducers, flow meters, and composition analyzers that can withstand cryogenic conditions while maintaining measurement accuracy. The sensor systems provide comprehensive data collection capabilities essential for monitoring and controlling cryogenic capture operations.Expand Specific Solutions04 Cryogenic capture efficiency calculation methods

Algorithms and methodologies for calculating and reporting the efficiency of cryogenic capture processes. These methods process measurement data to determine key performance indicators such as capture rate, energy consumption per unit captured, and purity of captured substances. The calculation methods enable standardized reporting of capture performance and facilitate comparison between different capture technologies and operational parameters.Expand Specific Solutions05 Integration of cryogenic capture data with broader monitoring systems

Technologies that integrate cryogenic capture measurement and reporting with broader industrial monitoring and control systems. These integration approaches enable cryogenic capture data to be incorporated into facility-wide management systems, emissions reporting platforms, and regulatory compliance frameworks. The integrated systems provide a comprehensive view of how cryogenic capture operations affect overall facility performance and environmental impact.Expand Specific Solutions

Leading Companies and Research Institutions in Cryogenic Capture

Cryogenic capture technology is currently in an early growth phase, with increasing interest driven by carbon capture and storage applications. The market size is expanding, projected to reach significant scale as environmental regulations tighten globally. Technologically, the field shows varying maturity levels across players. Boeing, Lockheed Martin, and Honeywell lead with advanced aerospace cryogenic expertise, while State Grid Corporation of China and Air Liquide demonstrate strong industrial-scale implementation capabilities. Research institutions like China Electric Power Research Institute and Montana Instruments contribute specialized knowledge in measurement protocols. The competitive landscape is diversifying as companies from energy, aerospace, and industrial gas sectors converge, with measurement standardization becoming a critical differentiator for pilot project success.

Montana Instruments Corporation

Technical Solution: Montana Instruments Corporation has developed comprehensive cryogenic capture systems with integrated measurement and reporting capabilities specifically designed for research applications. Their technology focuses on closed-cycle cryostats that eliminate the need for liquid helium while providing precise temperature control down to 4K. Their systems incorporate multiple measurement sensors including temperature monitors with sub-millikelvin resolution, vibration analysis tools, and vacuum quality sensors. The company's CryoStation platform features automated data logging protocols that capture critical operational parameters such as cool-down rates, temperature stability, and system efficiency metrics. Montana Instruments has implemented standardized reporting formats that allow operators to document cryogenic performance consistently across different experimental setups, facilitating better comparison of results across research institutions.

Strengths: Highly integrated measurement systems with automated data collection capabilities; specialized expertise in research-grade cryogenic environments; systems designed specifically for optical and quantum applications. Weaknesses: Solutions primarily focused on laboratory research rather than industrial-scale applications; higher cost compared to conventional cryogenic systems; requires specialized training for optimal operation.

Asymptote Ltd.

Technical Solution: Asymptote Ltd. has pioneered advanced cryogenic capture technology specifically for biological materials preservation. Their systems incorporate sophisticated measurement protocols designed to monitor critical parameters during the freezing process. The company's VIA Freeze platform utilizes proprietary algorithms to control cooling rates with precision of ±0.1°C/min while simultaneously capturing temperature gradient data across samples. Their technology includes integrated sensors that monitor nucleation events, thermal profiles, and phase transitions during the preservation process. Asymptote's systems automatically generate comprehensive reports including cooling curves, hold times at critical temperatures, and thermal history of samples. The company has developed specialized software that analyzes captured data to identify potential issues in the preservation protocol and recommend process improvements for operators.

Strengths: Specialized expertise in biological material preservation; highly precise temperature control systems; advanced data analytics for process optimization. Weaknesses: Limited application outside biological preservation; systems require significant technical expertise to fully utilize advanced features; higher initial investment compared to conventional freezing systems.

Key Performance Indicators and Measurement Standards

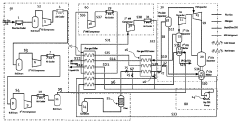

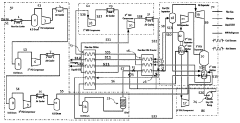

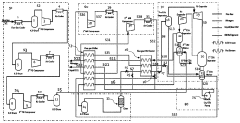

A new flue gas co2 capture process using the cryogenic method

PatentPendingCA3171526A1

Innovation

- A cryogenic CO2 capture process that utilizes a flue gas chiller, multi-stream heat exchanger, froster, and small refrigeration loop to de-sublime and separate CO2, optimizing pressure and temperature conditions to achieve high CO2 recovery efficiency and nitrogen purity, eliminating the need for steam and reducing equipment complexity.

Device and method for monitoring the temperature of a cryogenically preserved biological sample

PatentActiveEP3448154A1

Innovation

- A device with a sample container and a separate chamber filled with an indicator substance that changes state at temperatures between -10 °C and -140 °C, allowing for detection of temperature exceedances by measuring the decrease in the indicator substance, which can be easily integrated into cryogenic containers and monitored visually or automatically.

Regulatory Compliance and Reporting Requirements

Cryogenic carbon capture (CCC) operations are subject to a complex web of regulatory frameworks that vary significantly across jurisdictions. Operators must navigate federal, state, and local regulations governing carbon capture, storage, and transportation activities. At the federal level in the United States, the Environmental Protection Agency (EPA) has established reporting requirements under the Greenhouse Gas Reporting Program (GHGRP), which mandates detailed documentation of capture efficiency, volumes captured, and ultimate disposition of carbon dioxide.

The Clean Air Act also imposes specific monitoring, reporting, and verification (MRV) protocols that cryogenic capture facilities must adhere to. These include continuous emissions monitoring systems (CEMS) for tracking capture rates and potential leakage points. Additionally, the Department of Energy (DOE) has established technical reporting standards for pilot projects receiving federal funding, requiring quarterly performance metrics and annual comprehensive assessments.

International frameworks such as the ISO 14064 standard provide guidelines for quantification and reporting of greenhouse gas emissions and removals, which are increasingly being adopted as baseline requirements for carbon capture operations. The EU Emissions Trading System (EU ETS) imposes particularly stringent monitoring and reporting obligations for facilities operating within its jurisdiction.

For underground storage components of cryogenic capture systems, operators must comply with Underground Injection Control (UIC) Class VI well regulations, which include extensive monitoring requirements for potential migration of CO2 and impacts on underground sources of drinking water. These regulations necessitate regular reporting of pressure, temperature, and chemical composition data from monitoring wells.

Financial reporting requirements add another layer of complexity, particularly for publicly traded companies implementing cryogenic capture technologies. The Securities and Exchange Commission's (SEC) recent climate disclosure rules require detailed reporting on climate-related risks and greenhouse gas emissions, including those mitigated through carbon capture operations.

Operators should establish comprehensive data management systems capable of tracking all required parameters and generating automated compliance reports. This includes implementing quality assurance/quality control (QA/QC) procedures that meet regulatory standards for data integrity and validation. Third-party verification of reported data is increasingly becoming mandatory under various regulatory schemes, requiring operators to budget for independent assessment of their monitoring and reporting processes.

Staying current with evolving regulatory requirements presents a significant challenge, as frameworks continue to develop in response to technological advancements and climate policy shifts. Operators should maintain active engagement with regulatory agencies and industry associations to anticipate and prepare for compliance changes that may impact cryogenic capture operations.

The Clean Air Act also imposes specific monitoring, reporting, and verification (MRV) protocols that cryogenic capture facilities must adhere to. These include continuous emissions monitoring systems (CEMS) for tracking capture rates and potential leakage points. Additionally, the Department of Energy (DOE) has established technical reporting standards for pilot projects receiving federal funding, requiring quarterly performance metrics and annual comprehensive assessments.

International frameworks such as the ISO 14064 standard provide guidelines for quantification and reporting of greenhouse gas emissions and removals, which are increasingly being adopted as baseline requirements for carbon capture operations. The EU Emissions Trading System (EU ETS) imposes particularly stringent monitoring and reporting obligations for facilities operating within its jurisdiction.

For underground storage components of cryogenic capture systems, operators must comply with Underground Injection Control (UIC) Class VI well regulations, which include extensive monitoring requirements for potential migration of CO2 and impacts on underground sources of drinking water. These regulations necessitate regular reporting of pressure, temperature, and chemical composition data from monitoring wells.

Financial reporting requirements add another layer of complexity, particularly for publicly traded companies implementing cryogenic capture technologies. The Securities and Exchange Commission's (SEC) recent climate disclosure rules require detailed reporting on climate-related risks and greenhouse gas emissions, including those mitigated through carbon capture operations.

Operators should establish comprehensive data management systems capable of tracking all required parameters and generating automated compliance reports. This includes implementing quality assurance/quality control (QA/QC) procedures that meet regulatory standards for data integrity and validation. Third-party verification of reported data is increasingly becoming mandatory under various regulatory schemes, requiring operators to budget for independent assessment of their monitoring and reporting processes.

Staying current with evolving regulatory requirements presents a significant challenge, as frameworks continue to develop in response to technological advancements and climate policy shifts. Operators should maintain active engagement with regulatory agencies and industry associations to anticipate and prepare for compliance changes that may impact cryogenic capture operations.

Data Management and Integration Strategies

Effective data management and integration strategies are crucial for the successful implementation of cryogenic carbon capture (CCC) pilot projects. As these technologies generate vast amounts of operational data across multiple parameters, organizations must establish robust frameworks for data collection, storage, processing, and integration to maximize insights and operational efficiency.

The foundation of any successful CCC data management strategy begins with a centralized data architecture that can accommodate diverse data types from various measurement points. This architecture should support both structured data (sensor readings, operational parameters) and unstructured data (maintenance logs, operator observations) while maintaining data integrity and accessibility across organizational boundaries.

Real-time data processing capabilities represent a critical component for cryogenic capture operations. Implementing edge computing solutions at measurement points can enable immediate analysis of critical parameters, allowing for rapid response to operational anomalies before they escalate into system failures. This approach reduces data transmission requirements while enhancing system responsiveness.

Integration with existing plant control systems presents both opportunities and challenges. Operators should prioritize developing standardized APIs and communication protocols that facilitate seamless data exchange between cryogenic capture units and plant-wide SCADA or DCS systems. This integration enables comprehensive operational visibility and supports holistic optimization of energy consumption across interconnected processes.

Cloud-based data storage solutions offer scalability advantages for long-term data retention and analysis. However, operators must carefully balance cloud implementation with cybersecurity considerations, particularly for critical infrastructure. Hybrid approaches that maintain sensitive operational data on-premises while leveraging cloud capabilities for analytics and reporting often provide an optimal compromise.

Machine learning and advanced analytics should be incorporated into data management strategies to identify patterns and optimization opportunities that might escape traditional analysis methods. These tools can predict maintenance needs, optimize energy efficiency, and enhance carbon capture rates through continuous learning from operational data.

Data governance frameworks must establish clear protocols for data ownership, quality assurance, retention policies, and access controls. These frameworks should align with regulatory requirements while supporting operational needs and facilitating knowledge sharing across the organization and potentially with research partners or industry consortia.

Finally, visualization tools and customizable dashboards enable stakeholders at various organizational levels to interact with data in meaningful ways. Effective visualization transforms complex datasets into actionable insights, supporting both day-to-day operational decisions and strategic planning for future cryogenic capture implementations.

The foundation of any successful CCC data management strategy begins with a centralized data architecture that can accommodate diverse data types from various measurement points. This architecture should support both structured data (sensor readings, operational parameters) and unstructured data (maintenance logs, operator observations) while maintaining data integrity and accessibility across organizational boundaries.

Real-time data processing capabilities represent a critical component for cryogenic capture operations. Implementing edge computing solutions at measurement points can enable immediate analysis of critical parameters, allowing for rapid response to operational anomalies before they escalate into system failures. This approach reduces data transmission requirements while enhancing system responsiveness.

Integration with existing plant control systems presents both opportunities and challenges. Operators should prioritize developing standardized APIs and communication protocols that facilitate seamless data exchange between cryogenic capture units and plant-wide SCADA or DCS systems. This integration enables comprehensive operational visibility and supports holistic optimization of energy consumption across interconnected processes.

Cloud-based data storage solutions offer scalability advantages for long-term data retention and analysis. However, operators must carefully balance cloud implementation with cybersecurity considerations, particularly for critical infrastructure. Hybrid approaches that maintain sensitive operational data on-premises while leveraging cloud capabilities for analytics and reporting often provide an optimal compromise.

Machine learning and advanced analytics should be incorporated into data management strategies to identify patterns and optimization opportunities that might escape traditional analysis methods. These tools can predict maintenance needs, optimize energy efficiency, and enhance carbon capture rates through continuous learning from operational data.

Data governance frameworks must establish clear protocols for data ownership, quality assurance, retention policies, and access controls. These frameworks should align with regulatory requirements while supporting operational needs and facilitating knowledge sharing across the organization and potentially with research partners or industry consortia.

Finally, visualization tools and customizable dashboards enable stakeholders at various organizational levels to interact with data in meaningful ways. Effective visualization transforms complex datasets into actionable insights, supporting both day-to-day operational decisions and strategic planning for future cryogenic capture implementations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!