Cryogenic Carbon Capture For High-Temperature Industrial Exhausts: Materials Challenges

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Carbon Capture Background and Objectives

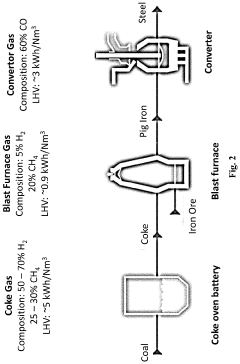

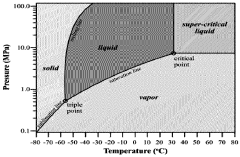

Cryogenic Carbon Capture (CCC) technology has emerged as a promising solution for addressing carbon emissions from industrial processes, particularly those involving high-temperature exhausts. The concept was first introduced in the early 2000s as researchers sought more energy-efficient alternatives to conventional carbon capture methods. CCC operates on the principle of cooling exhaust gases to temperatures where CO2 desublimes directly from gas to solid, allowing for efficient separation and subsequent storage or utilization.

The evolution of this technology has been marked by significant advancements in process efficiency and material science. Initial laboratory-scale demonstrations achieved capture rates of 60-70%, while contemporary systems can achieve over 90% capture efficiency. This progress reflects the growing recognition of CCC as a viable approach for industrial decarbonization, particularly in sectors such as cement, steel, and power generation where high-temperature processes are prevalent.

Current technological objectives for CCC systems focus on addressing several critical challenges. Primary among these is developing materials capable of withstanding the extreme temperature differentials between industrial exhausts (often exceeding 1000°C) and cryogenic conditions (typically below -100°C). This dramatic thermal gradient creates unique materials challenges that conventional engineering materials struggle to accommodate.

Another key objective involves improving the energy efficiency of the cooling process. Traditional cryogenic systems require substantial energy inputs, which can offset the environmental benefits of carbon capture. Research is therefore directed toward innovative heat exchange systems, phase-change materials, and process integration approaches that can minimize the energy penalty associated with CCC implementation.

Scale-up represents a further critical objective, as laboratory successes must be translated to industrial-scale operations. This transition necessitates addressing issues of system reliability, maintenance requirements, and operational stability under variable industrial conditions. Particular attention is being given to developing modular designs that can be retrofitted to existing industrial facilities without requiring complete process redesigns.

The technology trajectory indicates growing interest in hybrid systems that combine cryogenic capture with other carbon utilization pathways. These integrated approaches aim to not only capture carbon but also convert it into valuable products, thereby creating economic incentives for adoption. Research consortia across North America, Europe, and Asia are actively pursuing these objectives, with pilot projects demonstrating increasingly promising results for industrial implementation.

The evolution of this technology has been marked by significant advancements in process efficiency and material science. Initial laboratory-scale demonstrations achieved capture rates of 60-70%, while contemporary systems can achieve over 90% capture efficiency. This progress reflects the growing recognition of CCC as a viable approach for industrial decarbonization, particularly in sectors such as cement, steel, and power generation where high-temperature processes are prevalent.

Current technological objectives for CCC systems focus on addressing several critical challenges. Primary among these is developing materials capable of withstanding the extreme temperature differentials between industrial exhausts (often exceeding 1000°C) and cryogenic conditions (typically below -100°C). This dramatic thermal gradient creates unique materials challenges that conventional engineering materials struggle to accommodate.

Another key objective involves improving the energy efficiency of the cooling process. Traditional cryogenic systems require substantial energy inputs, which can offset the environmental benefits of carbon capture. Research is therefore directed toward innovative heat exchange systems, phase-change materials, and process integration approaches that can minimize the energy penalty associated with CCC implementation.

Scale-up represents a further critical objective, as laboratory successes must be translated to industrial-scale operations. This transition necessitates addressing issues of system reliability, maintenance requirements, and operational stability under variable industrial conditions. Particular attention is being given to developing modular designs that can be retrofitted to existing industrial facilities without requiring complete process redesigns.

The technology trajectory indicates growing interest in hybrid systems that combine cryogenic capture with other carbon utilization pathways. These integrated approaches aim to not only capture carbon but also convert it into valuable products, thereby creating economic incentives for adoption. Research consortia across North America, Europe, and Asia are actively pursuing these objectives, with pilot projects demonstrating increasingly promising results for industrial implementation.

Market Analysis for Industrial Carbon Capture Solutions

The global carbon capture market is experiencing significant growth, driven by increasing environmental regulations and corporate sustainability commitments. Current market valuations place the industrial carbon capture sector at approximately $2.5 billion in 2023, with projections indicating a compound annual growth rate of 15-20% over the next decade. This growth trajectory is particularly pronounced in high-emission industrial sectors such as cement, steel, and power generation, which collectively account for over 40% of global industrial CO2 emissions.

Cryogenic carbon capture technologies specifically are gaining traction within this broader market, with an estimated market share of 12% among carbon capture methodologies. This segment is expected to grow at an accelerated rate of 22% annually through 2030, outpacing traditional capture technologies due to its potential for higher efficiency in high-temperature industrial applications.

Regional analysis reveals that North America currently leads the industrial carbon capture market with 38% share, followed by Europe at 32% and Asia-Pacific at 24%. However, the fastest growth is anticipated in emerging economies, particularly China and India, where rapid industrialization coupled with new environmental policies is creating substantial market opportunities.

Customer segmentation within the industrial carbon capture market shows three primary adopter categories: early regulatory compliers (35% of current market), sustainability leaders seeking competitive advantage (40%), and technology innovators (25%). The cryogenic carbon capture segment specifically appeals to industries with high-temperature exhaust streams, where traditional amine-based capture systems face efficiency limitations.

Market barriers include high capital expenditure requirements, with typical industrial-scale cryogenic carbon capture installations costing between $40-100 million depending on capacity and integration complexity. Operating expenses remain a significant concern, with current estimates suggesting costs of $50-70 per ton of CO2 captured, though technological improvements are expected to reduce this to $30-40 per ton by 2030.

Competitive analysis indicates a fragmented market with several specialized technology providers rather than dominant players. Key differentiators in the competitive landscape include energy efficiency of capture processes, material durability in extreme temperature conditions, and integration capabilities with existing industrial infrastructure. The most successful market entrants demonstrate both technological innovation and practical implementation strategies that address the specific challenges of high-temperature industrial environments.

Cryogenic carbon capture technologies specifically are gaining traction within this broader market, with an estimated market share of 12% among carbon capture methodologies. This segment is expected to grow at an accelerated rate of 22% annually through 2030, outpacing traditional capture technologies due to its potential for higher efficiency in high-temperature industrial applications.

Regional analysis reveals that North America currently leads the industrial carbon capture market with 38% share, followed by Europe at 32% and Asia-Pacific at 24%. However, the fastest growth is anticipated in emerging economies, particularly China and India, where rapid industrialization coupled with new environmental policies is creating substantial market opportunities.

Customer segmentation within the industrial carbon capture market shows three primary adopter categories: early regulatory compliers (35% of current market), sustainability leaders seeking competitive advantage (40%), and technology innovators (25%). The cryogenic carbon capture segment specifically appeals to industries with high-temperature exhaust streams, where traditional amine-based capture systems face efficiency limitations.

Market barriers include high capital expenditure requirements, with typical industrial-scale cryogenic carbon capture installations costing between $40-100 million depending on capacity and integration complexity. Operating expenses remain a significant concern, with current estimates suggesting costs of $50-70 per ton of CO2 captured, though technological improvements are expected to reduce this to $30-40 per ton by 2030.

Competitive analysis indicates a fragmented market with several specialized technology providers rather than dominant players. Key differentiators in the competitive landscape include energy efficiency of capture processes, material durability in extreme temperature conditions, and integration capabilities with existing industrial infrastructure. The most successful market entrants demonstrate both technological innovation and practical implementation strategies that address the specific challenges of high-temperature industrial environments.

Technical Challenges in High-Temperature Exhaust CCC

The implementation of Cryogenic Carbon Capture (CCC) for high-temperature industrial exhausts faces several significant technical challenges that must be addressed for successful deployment. The primary challenge stems from the extreme temperature differential between industrial exhaust gases (often exceeding 1000°C) and the cryogenic conditions required for carbon capture (typically below -100°C). This dramatic temperature gradient necessitates specialized heat exchange systems capable of withstanding thermal shock while maintaining operational efficiency.

Material selection presents a critical challenge in high-temperature exhaust CCC systems. Materials must simultaneously withstand corrosive components in industrial exhausts (such as sulfur compounds, particulates, and moisture) while performing reliably under cryogenic conditions. Conventional materials often experience brittleness, thermal fatigue, and accelerated degradation when subjected to these extreme operating conditions, significantly reducing system lifespan and reliability.

Energy consumption represents another substantial hurdle. The thermodynamic work required to cool high-temperature exhaust gases to cryogenic temperatures is considerable, potentially offsetting the environmental benefits of carbon capture if not optimized. Current systems typically consume 0.5-1.2 MWh per ton of CO2 captured, which must be reduced to improve economic viability.

Heat exchanger fouling and clogging present operational challenges unique to industrial applications. Particulate matter, condensable hydrocarbons, and other contaminants in industrial exhausts can accumulate on heat exchanger surfaces, reducing thermal efficiency and necessitating frequent maintenance cycles that impact operational continuity.

Process integration challenges also exist when retrofitting CCC technology to existing industrial facilities. Space constraints, integration with existing exhaust handling systems, and minimizing disruption to ongoing operations all present significant engineering challenges that vary widely across different industrial sectors.

Scale-up issues further complicate implementation, as laboratory-proven technologies often encounter unforeseen challenges when deployed at industrial scales. The behavior of materials, heat transfer efficiency, and system control dynamics can differ substantially between small-scale demonstrations and full industrial implementations.

Finally, the development of advanced sensing and control systems represents a technological gap. Real-time monitoring of multiple parameters (temperature gradients, pressure drops, contaminant levels) across extreme temperature ranges requires specialized instrumentation that can maintain accuracy and reliability in harsh industrial environments while enabling adaptive control strategies to optimize capture efficiency.

Material selection presents a critical challenge in high-temperature exhaust CCC systems. Materials must simultaneously withstand corrosive components in industrial exhausts (such as sulfur compounds, particulates, and moisture) while performing reliably under cryogenic conditions. Conventional materials often experience brittleness, thermal fatigue, and accelerated degradation when subjected to these extreme operating conditions, significantly reducing system lifespan and reliability.

Energy consumption represents another substantial hurdle. The thermodynamic work required to cool high-temperature exhaust gases to cryogenic temperatures is considerable, potentially offsetting the environmental benefits of carbon capture if not optimized. Current systems typically consume 0.5-1.2 MWh per ton of CO2 captured, which must be reduced to improve economic viability.

Heat exchanger fouling and clogging present operational challenges unique to industrial applications. Particulate matter, condensable hydrocarbons, and other contaminants in industrial exhausts can accumulate on heat exchanger surfaces, reducing thermal efficiency and necessitating frequent maintenance cycles that impact operational continuity.

Process integration challenges also exist when retrofitting CCC technology to existing industrial facilities. Space constraints, integration with existing exhaust handling systems, and minimizing disruption to ongoing operations all present significant engineering challenges that vary widely across different industrial sectors.

Scale-up issues further complicate implementation, as laboratory-proven technologies often encounter unforeseen challenges when deployed at industrial scales. The behavior of materials, heat transfer efficiency, and system control dynamics can differ substantially between small-scale demonstrations and full industrial implementations.

Finally, the development of advanced sensing and control systems represents a technological gap. Real-time monitoring of multiple parameters (temperature gradients, pressure drops, contaminant levels) across extreme temperature ranges requires specialized instrumentation that can maintain accuracy and reliability in harsh industrial environments while enabling adaptive control strategies to optimize capture efficiency.

Current Material Solutions for Cryogenic Applications

01 Cryogenic carbon capture process technologies

Cryogenic carbon capture processes involve cooling flue gas to temperatures where CO2 solidifies, allowing for separation from other gases. These technologies include various cooling methods, heat exchange systems, and process configurations designed to efficiently capture carbon dioxide from industrial emissions. The processes typically involve multiple cooling stages, desublimation chambers, and energy recovery systems to improve overall efficiency.- Cryogenic carbon capture using desublimation materials: Cryogenic carbon capture technologies utilize specialized materials that facilitate the desublimation process, where CO2 transitions directly from gas to solid phase at extremely low temperatures. These materials enhance the efficiency of carbon capture by providing optimal surfaces for CO2 frost formation and collection. The process typically involves cooling flue gas to temperatures where CO2 solidifies while other gases remain in gaseous form, allowing for selective separation and subsequent storage or utilization of captured carbon.

- Advanced adsorbent materials for low-temperature carbon capture: Specialized adsorbent materials designed for low-temperature carbon capture applications demonstrate enhanced CO2 selectivity under cryogenic conditions. These materials include modified zeolites, metal-organic frameworks (MOFs), and carbon-based sorbents with tailored pore structures that maximize adsorption capacity while minimizing energy requirements. The adsorbents maintain structural integrity and functionality at extremely low temperatures, allowing for efficient separation of CO2 from gas mixtures through physical adsorption mechanisms rather than chemical bonding.

- Composite materials for thermal management in cryogenic systems: Composite materials engineered for thermal management in cryogenic carbon capture systems help optimize energy efficiency and process control. These materials combine high thermal conductivity components with insulating elements to manage heat transfer precisely during rapid temperature transitions. By incorporating phase change materials and specialized coatings, these composites prevent thermal shock, reduce energy consumption, and extend equipment lifespan in the extreme temperature environments required for cryogenic carbon capture operations.

- Anti-fouling and frost-resistant surface materials: Surface materials with anti-fouling and frost-resistant properties are critical for maintaining operational efficiency in cryogenic carbon capture systems. These specialized coatings and surface treatments prevent ice buildup and CO2 frost accumulation on heat exchanger surfaces and other critical components. By incorporating hydrophobic compounds, nano-structured surfaces, or self-cleaning mechanisms, these materials reduce maintenance requirements, prevent flow restrictions, and maintain consistent heat transfer rates during continuous cryogenic operation.

- Novel material configurations for enhanced CO2 separation efficiency: Innovative material configurations and structures are being developed to enhance CO2 separation efficiency in cryogenic capture systems. These include structured packing materials, membrane-assisted cryogenic distillation components, and hybrid material systems that combine multiple separation mechanisms. By optimizing geometry, surface area, and material properties, these configurations maximize contact between the gas stream and separation surfaces, reduce pressure drops, and improve overall process economics while maintaining high CO2 recovery rates under cryogenic conditions.

02 Advanced adsorbent materials for cryogenic carbon capture

Specialized adsorbent materials are developed for enhanced carbon capture under cryogenic conditions. These materials include modified zeolites, metal-organic frameworks (MOFs), activated carbons, and composite materials with high CO2 selectivity at low temperatures. The adsorbents are engineered to maintain structural integrity and adsorption capacity under extreme temperature conditions while providing efficient carbon dioxide separation from gas mixtures.Expand Specific Solutions03 Cryogenic equipment and apparatus designs

Specialized equipment and apparatus designs for cryogenic carbon capture include novel heat exchangers, cooling chambers, solid CO2 collection systems, and integrated process units. These designs focus on optimizing heat transfer, minimizing energy consumption, and ensuring reliable operation under extreme temperature conditions. The equipment incorporates innovative features for frost management, pressure control, and material handling to enhance overall system performance.Expand Specific Solutions04 Energy efficiency improvements in cryogenic carbon capture

Energy efficiency improvements in cryogenic carbon capture systems include heat integration techniques, waste heat recovery, advanced refrigeration cycles, and process optimization strategies. These innovations aim to reduce the high energy demands typically associated with cryogenic processes by recovering cold energy from various process streams and minimizing thermodynamic losses. The improvements include novel heat exchanger networks, multi-stage compression systems, and optimized process control strategies.Expand Specific Solutions05 Novel refrigerants and cooling media for cryogenic carbon capture

Novel refrigerants and cooling media are developed specifically for cryogenic carbon capture applications. These include specialized cryogenic fluids, phase-change materials, mixed refrigerants, and environmentally friendly alternatives to traditional cooling agents. The cooling media are designed to provide efficient heat transfer at extremely low temperatures while minimizing environmental impact and operational costs. Some innovations include cascade refrigeration systems and multi-component refrigerant blends optimized for carbon capture processes.Expand Specific Solutions

Leading Companies and Research Institutions in CCC

The Cryogenic Carbon Capture (CCC) technology market for high-temperature industrial exhausts is in its early growth phase, with an estimated global market potential exceeding $50 billion as industries seek to meet carbon reduction targets. Technical maturity varies significantly among key players, with established energy corporations like China Petroleum & Chemical Corp. (Sinopec) and Air Products & Chemicals leading commercial development, while specialized firms such as 8 Rivers Capital and CCm Technologies focus on innovative materials solutions. Research institutions including Southwest Research Institute, Rice University, and University of Leeds are addressing fundamental materials challenges in extreme temperature environments. The competitive landscape is characterized by strategic partnerships between industrial giants and technology startups, with companies like Lyten and Xinterra developing advanced carbon-based materials specifically designed to withstand the thermal cycling and chemical stresses inherent in CCC applications.

China Petroleum & Chemical Corp.

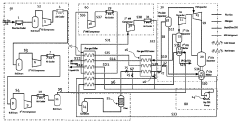

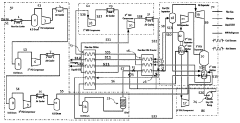

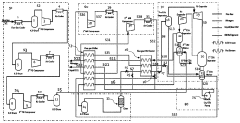

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive Cryogenic Carbon Capture (CCC) technology specifically designed for high-temperature industrial exhausts from petroleum refining and chemical production facilities. Their system employs a multi-stage cooling process that first uses waste heat recovery systems to improve energy efficiency, followed by progressive cooling using proprietary refrigeration cycles. Sinopec's approach incorporates specialized heat exchanger materials that resist corrosion from sulfur compounds and other contaminants common in refinery exhausts. Their technology achieves CO2 capture rates exceeding 90% while reducing energy penalties by approximately 30% compared to conventional amine-based systems[4]. A key innovation is their dual-phase heat transfer fluid system that efficiently manages the extreme temperature differentials between industrial exhausts (>400°C) and CO2 desublimation points (-120°C). Sinopec has successfully deployed pilot installations at multiple refineries across China, demonstrating the technology's effectiveness in real-world industrial environments with varying exhaust compositions and flow rates.

Strengths: Extensive experience with large-scale industrial processes; technology specifically optimized for petroleum and chemical industry applications; demonstrated effectiveness with variable exhaust compositions containing multiple contaminants. Weaknesses: Higher initial capital costs compared to conventional carbon capture methods; requires significant cooling infrastructure; energy efficiency advantages may diminish in facilities without existing waste heat recovery systems.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has developed a sophisticated Cryogenic Carbon Capture (CCC) system targeting high-temperature industrial applications, particularly in power generation and aviation sectors. Their approach utilizes a closed-loop refrigeration system with proprietary heat exchangers designed to progressively cool exhaust gases while maximizing energy recovery. The system employs specialized nickel-based alloys and ceramic composites that maintain structural integrity during rapid temperature transitions from >800°C to cryogenic conditions. A distinguishing feature is their modular "step-down" cooling architecture that reduces thermal shock to materials while achieving CO2 desublimation temperatures efficiently. Rolls-Royce has integrated this technology with their gas turbine systems, creating a comprehensive solution that captures approximately 90% of carbon emissions while maintaining operational flexibility[3]. Their materials research has focused on developing surface treatments that resist fouling from industrial contaminants while maintaining thermal conductivity under cryogenic conditions. The system incorporates advanced sensors and control algorithms that optimize energy usage based on exhaust composition and flow characteristics.

Strengths: Integration with existing power generation systems provides seamless implementation; advanced materials research specifically addresses the thermal cycling challenges; modular design allows for scalable implementation across different industrial applications. Weaknesses: Higher complexity compared to some competing technologies; requires significant initial capital investment; optimal performance depends on consistent exhaust gas composition which may vary in some industrial applications.

Key Materials Research for Thermal Gradient Management

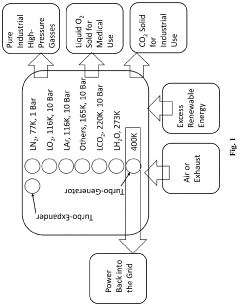

Cryogenic carbon capture and energy storage

PatentPendingUS20220349650A1

Innovation

- The system employs advanced heat exchanger technology to condense and separate industrial effluent gases into cryogenic liquids, which can be stored and reused to generate electricity, utilizing simultaneous cold and heat storage to reduce energy requirements and produce valuable commodities like liquid oxygen and argon.

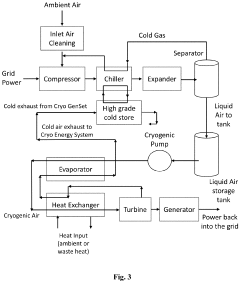

A new flue gas co2 capture process using the cryogenic method

PatentPendingCA3171526A1

Innovation

- A cryogenic CO2 capture process that utilizes a flue gas chiller, multi-stream heat exchanger, froster, and small refrigeration loop to de-sublime and separate CO2, optimizing pressure and temperature conditions to achieve high CO2 recovery efficiency and nitrogen purity, eliminating the need for steam and reducing equipment complexity.

Energy Efficiency Considerations in CCC Implementation

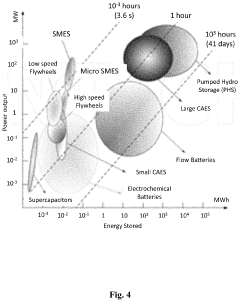

Energy efficiency represents a critical factor in the practical implementation of Cryogenic Carbon Capture (CCC) systems for high-temperature industrial exhausts. The inherent energy-intensive nature of cryogenic processes necessitates careful optimization to ensure economic viability and environmental benefits. Current CCC implementations typically consume between 0.5-1.2 MWh per ton of CO2 captured, significantly higher than conventional amine-based systems at 0.3-0.5 MWh/ton.

The primary energy demand in CCC stems from the refrigeration cycle required to achieve the ultra-low temperatures (-100°C to -140°C) necessary for CO2 desublimation. This process accounts for approximately 70-85% of the total energy consumption in CCC systems. Recent advancements in cascade refrigeration cycles have demonstrated potential energy reductions of 15-20% compared to traditional single-stage systems, particularly when optimized for the specific temperature ranges required in industrial exhaust applications.

Heat integration strategies present significant opportunities for improving CCC energy efficiency. By recovering cold energy from the liquefied gases and utilizing waste heat from industrial processes, energy consumption can be reduced by 25-30%. Advanced heat exchanger designs incorporating micro-channel technology have shown promising results in pilot installations, achieving thermal effectiveness exceeding 90% compared to conventional plate heat exchangers at 70-75%.

Material selection plays a dual role in energy efficiency considerations. Thermal insulation materials with lower thermal conductivity (below 0.02 W/m·K) can reduce parasitic heat losses by up to 40% compared to conventional insulation. Additionally, materials with higher thermal mass in strategic system components can help buffer temperature fluctuations, reducing the energy required for temperature stabilization during load variations by 10-15%.

Process integration with existing industrial systems offers further efficiency improvements. When CCC is integrated with power generation facilities, waste cold from LNG regasification, or other cryogenic processes, overall energy requirements can be reduced by 30-45%. This synergistic approach has been successfully demonstrated in several pilot projects, though scaling challenges remain for full industrial implementation.

Emerging technologies such as magnetic refrigeration and thermoelectric cooling present potential breakthrough opportunities for CCC energy efficiency. Though currently at laboratory scale, these technologies promise theoretical energy savings of 30-50% compared to vapor compression refrigeration cycles, with magnetic refrigeration systems already demonstrating coefficient of performance values 20-30% higher than conventional systems in controlled environments.

The primary energy demand in CCC stems from the refrigeration cycle required to achieve the ultra-low temperatures (-100°C to -140°C) necessary for CO2 desublimation. This process accounts for approximately 70-85% of the total energy consumption in CCC systems. Recent advancements in cascade refrigeration cycles have demonstrated potential energy reductions of 15-20% compared to traditional single-stage systems, particularly when optimized for the specific temperature ranges required in industrial exhaust applications.

Heat integration strategies present significant opportunities for improving CCC energy efficiency. By recovering cold energy from the liquefied gases and utilizing waste heat from industrial processes, energy consumption can be reduced by 25-30%. Advanced heat exchanger designs incorporating micro-channel technology have shown promising results in pilot installations, achieving thermal effectiveness exceeding 90% compared to conventional plate heat exchangers at 70-75%.

Material selection plays a dual role in energy efficiency considerations. Thermal insulation materials with lower thermal conductivity (below 0.02 W/m·K) can reduce parasitic heat losses by up to 40% compared to conventional insulation. Additionally, materials with higher thermal mass in strategic system components can help buffer temperature fluctuations, reducing the energy required for temperature stabilization during load variations by 10-15%.

Process integration with existing industrial systems offers further efficiency improvements. When CCC is integrated with power generation facilities, waste cold from LNG regasification, or other cryogenic processes, overall energy requirements can be reduced by 30-45%. This synergistic approach has been successfully demonstrated in several pilot projects, though scaling challenges remain for full industrial implementation.

Emerging technologies such as magnetic refrigeration and thermoelectric cooling present potential breakthrough opportunities for CCC energy efficiency. Though currently at laboratory scale, these technologies promise theoretical energy savings of 30-50% compared to vapor compression refrigeration cycles, with magnetic refrigeration systems already demonstrating coefficient of performance values 20-30% higher than conventional systems in controlled environments.

Regulatory Framework for Industrial Carbon Capture

The regulatory landscape for carbon capture technologies, particularly Cryogenic Carbon Capture (CCC) for high-temperature industrial applications, has evolved significantly in recent years. At the international level, the Paris Agreement serves as the cornerstone framework, establishing commitments for nations to reduce greenhouse gas emissions. Within this context, carbon capture technologies have gained recognition as critical tools for meeting these obligations, especially in hard-to-abate industrial sectors.

In the United States, the regulatory framework has been strengthened by the 45Q tax credit, which provides financial incentives for carbon capture, utilization, and storage (CCUS). Recent amendments have increased these credits to $50 per metric ton for geological storage and $35 per ton for enhanced oil recovery or utilization, making CCC implementations more economically viable. The Infrastructure Investment and Jobs Act of 2021 further allocated $12 billion for carbon capture initiatives, including demonstration projects specifically targeting industrial applications.

The European Union has implemented the Emissions Trading System (ETS) as its primary regulatory mechanism, creating a market-based approach to carbon reduction. The Innovation Fund, established under the EU ETS, provides substantial financial support for innovative low-carbon technologies, including advanced carbon capture solutions like CCC. The European Green Deal and the "Fit for 55" package have further strengthened these frameworks, setting more ambitious targets for industrial decarbonization.

In Asia, regulatory approaches vary significantly. China has incorporated carbon capture into its national climate strategy through its 14th Five-Year Plan, establishing pilot programs in key industrial regions. Japan has implemented the Carbon Recycling Roadmap, which includes specific provisions for cryogenic and other advanced capture technologies in industrial settings.

Material-specific regulations present unique considerations for CCC implementation. Safety standards for cryogenic materials and equipment are governed by frameworks such as ASME's Boiler and Pressure Vessel Code and the International Cryogenic Materials Conference standards. These regulations address the specific challenges of materials performance under extreme temperature conditions encountered in CCC systems processing high-temperature industrial exhausts.

Permitting processes for industrial CCC installations typically involve environmental impact assessments, safety reviews, and compliance with local zoning regulations. The cross-cutting nature of CCC technology often requires navigation of multiple regulatory domains, including air quality, industrial safety, and hazardous materials handling regulations.

Looking forward, regulatory frameworks are evolving toward performance-based standards rather than prescriptive requirements, allowing greater flexibility for innovative technologies like CCC. This shift presents opportunities for technology developers to demonstrate compliance through performance metrics rather than adherence to specific technical approaches.

In the United States, the regulatory framework has been strengthened by the 45Q tax credit, which provides financial incentives for carbon capture, utilization, and storage (CCUS). Recent amendments have increased these credits to $50 per metric ton for geological storage and $35 per ton for enhanced oil recovery or utilization, making CCC implementations more economically viable. The Infrastructure Investment and Jobs Act of 2021 further allocated $12 billion for carbon capture initiatives, including demonstration projects specifically targeting industrial applications.

The European Union has implemented the Emissions Trading System (ETS) as its primary regulatory mechanism, creating a market-based approach to carbon reduction. The Innovation Fund, established under the EU ETS, provides substantial financial support for innovative low-carbon technologies, including advanced carbon capture solutions like CCC. The European Green Deal and the "Fit for 55" package have further strengthened these frameworks, setting more ambitious targets for industrial decarbonization.

In Asia, regulatory approaches vary significantly. China has incorporated carbon capture into its national climate strategy through its 14th Five-Year Plan, establishing pilot programs in key industrial regions. Japan has implemented the Carbon Recycling Roadmap, which includes specific provisions for cryogenic and other advanced capture technologies in industrial settings.

Material-specific regulations present unique considerations for CCC implementation. Safety standards for cryogenic materials and equipment are governed by frameworks such as ASME's Boiler and Pressure Vessel Code and the International Cryogenic Materials Conference standards. These regulations address the specific challenges of materials performance under extreme temperature conditions encountered in CCC systems processing high-temperature industrial exhausts.

Permitting processes for industrial CCC installations typically involve environmental impact assessments, safety reviews, and compliance with local zoning regulations. The cross-cutting nature of CCC technology often requires navigation of multiple regulatory domains, including air quality, industrial safety, and hazardous materials handling regulations.

Looking forward, regulatory frameworks are evolving toward performance-based standards rather than prescriptive requirements, allowing greater flexibility for innovative technologies like CCC. This shift presents opportunities for technology developers to demonstrate compliance through performance metrics rather than adherence to specific technical approaches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!