Cryogenic CO2 Capture Combined With Oxygen-Enriched Combustion Strategies

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic CO2 Capture Technology Evolution and Objectives

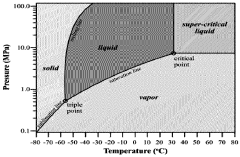

Cryogenic carbon dioxide capture technology has evolved significantly over the past several decades, transitioning from theoretical concepts to practical applications in industrial settings. Initially developed in the 1960s for natural gas processing, cryogenic separation techniques have been adapted for carbon capture purposes since the early 2000s. The fundamental principle involves cooling flue gas to temperatures where CO2 desublimes directly from gas to solid phase (approximately -78.5°C at atmospheric pressure), allowing for physical separation from other gases.

The evolution of cryogenic CO2 capture has been marked by several key technological advancements. Early systems suffered from high energy penalties and equipment fouling issues due to moisture and other impurities in flue gases. By the mid-2010s, researchers developed improved heat exchange systems and anti-sublimation coatings that significantly enhanced operational reliability and reduced energy requirements by approximately 25-30% compared to first-generation systems.

Recent innovations have focused on process integration and hybrid approaches, particularly the combination with oxygen-enriched combustion strategies. This synergistic approach leverages the advantages of both technologies: oxygen-enriched combustion produces flue gas with higher CO2 concentration (up to 80-90% compared to 12-15% in conventional combustion), which substantially improves the thermodynamic efficiency of subsequent cryogenic separation processes.

The primary objectives of current cryogenic CO2 capture research center on reducing the energy penalty associated with the cooling process, which remains the most significant barrier to widespread adoption. Specific goals include achieving energy requirements below 1 MJ/kg CO2 captured, improving heat integration with host processes, and developing materials capable of withstanding repeated thermal cycling in cryogenic environments.

Another critical objective is scaling the technology from pilot to commercial demonstration. While laboratory and small pilot plants have validated the core principles, industrial implementation requires addressing challenges related to process control, equipment reliability, and integration with existing power generation or industrial facilities. Several demonstration projects are currently underway in Europe, North America, and Asia, with capacities ranging from 5 to 50 tonnes of CO2 per day.

The integration with oxygen-enriched combustion presents specific objectives related to optimizing the oxygen concentration in combustion processes to balance NOx formation, flame stability, and downstream cryogenic separation efficiency. Research indicates that oxygen concentrations between 27-35% may represent the optimal range for most applications when considering the entire process chain efficiency.

The evolution of cryogenic CO2 capture has been marked by several key technological advancements. Early systems suffered from high energy penalties and equipment fouling issues due to moisture and other impurities in flue gases. By the mid-2010s, researchers developed improved heat exchange systems and anti-sublimation coatings that significantly enhanced operational reliability and reduced energy requirements by approximately 25-30% compared to first-generation systems.

Recent innovations have focused on process integration and hybrid approaches, particularly the combination with oxygen-enriched combustion strategies. This synergistic approach leverages the advantages of both technologies: oxygen-enriched combustion produces flue gas with higher CO2 concentration (up to 80-90% compared to 12-15% in conventional combustion), which substantially improves the thermodynamic efficiency of subsequent cryogenic separation processes.

The primary objectives of current cryogenic CO2 capture research center on reducing the energy penalty associated with the cooling process, which remains the most significant barrier to widespread adoption. Specific goals include achieving energy requirements below 1 MJ/kg CO2 captured, improving heat integration with host processes, and developing materials capable of withstanding repeated thermal cycling in cryogenic environments.

Another critical objective is scaling the technology from pilot to commercial demonstration. While laboratory and small pilot plants have validated the core principles, industrial implementation requires addressing challenges related to process control, equipment reliability, and integration with existing power generation or industrial facilities. Several demonstration projects are currently underway in Europe, North America, and Asia, with capacities ranging from 5 to 50 tonnes of CO2 per day.

The integration with oxygen-enriched combustion presents specific objectives related to optimizing the oxygen concentration in combustion processes to balance NOx formation, flame stability, and downstream cryogenic separation efficiency. Research indicates that oxygen concentrations between 27-35% may represent the optimal range for most applications when considering the entire process chain efficiency.

Market Demand for Carbon Capture Solutions

The global carbon capture market is experiencing unprecedented growth, driven by increasing environmental concerns and stringent regulatory frameworks aimed at reducing greenhouse gas emissions. Current market valuations indicate that the carbon capture, utilization, and storage (CCUS) sector reached approximately 3.5 billion USD in 2022, with projections suggesting a compound annual growth rate exceeding 15% through 2030. This rapid expansion reflects the urgent need for effective carbon management solutions across multiple industries.

Industrial sectors, particularly power generation, cement manufacturing, steel production, and chemical processing, represent the primary demand drivers for advanced carbon capture technologies. These industries collectively account for over 60% of global CO2 emissions, creating substantial market opportunities for innovative capture methodologies. The integration of cryogenic CO2 capture with oxygen-enriched combustion strategies addresses specific needs within these high-emission sectors, where conventional capture technologies face efficiency and cost limitations.

Geographically, market demand shows significant regional variations. North America and Europe currently lead in carbon capture implementation, supported by well-established regulatory frameworks and carbon pricing mechanisms. However, the Asia-Pacific region, particularly China and India, demonstrates the highest growth potential due to their expanding industrial bases and increasing commitment to emissions reduction targets. These emerging markets are actively seeking cost-effective solutions that can be deployed at scale.

From an economic perspective, the demand for carbon capture solutions is increasingly influenced by carbon pricing mechanisms. Regions with carbon taxes or cap-and-trade systems exceeding 50 USD per ton of CO2 create favorable market conditions for cryogenic capture technologies, which offer competitive cost profiles at scale. Additionally, the potential for revenue generation through carbon utilization pathways enhances the economic attractiveness of these systems.

The market also shows growing demand for integrated solutions that address multiple environmental challenges simultaneously. The oxygen-enriched combustion component of cryogenic CO2 capture systems responds to this trend by offering improved combustion efficiency alongside carbon capture capabilities. This dual-benefit approach resonates with industrial operators seeking to optimize operational costs while meeting emissions targets.

Looking forward, market analysts anticipate accelerated demand growth as carbon neutrality commitments expand globally. The International Energy Agency estimates that carbon capture capacity must increase by more than 20 times current levels by 2050 to meet climate goals, representing a substantial market opportunity for advanced technologies like cryogenic capture systems. This projected growth is further supported by increasing government investments in clean energy infrastructure and carbon management technologies.

Industrial sectors, particularly power generation, cement manufacturing, steel production, and chemical processing, represent the primary demand drivers for advanced carbon capture technologies. These industries collectively account for over 60% of global CO2 emissions, creating substantial market opportunities for innovative capture methodologies. The integration of cryogenic CO2 capture with oxygen-enriched combustion strategies addresses specific needs within these high-emission sectors, where conventional capture technologies face efficiency and cost limitations.

Geographically, market demand shows significant regional variations. North America and Europe currently lead in carbon capture implementation, supported by well-established regulatory frameworks and carbon pricing mechanisms. However, the Asia-Pacific region, particularly China and India, demonstrates the highest growth potential due to their expanding industrial bases and increasing commitment to emissions reduction targets. These emerging markets are actively seeking cost-effective solutions that can be deployed at scale.

From an economic perspective, the demand for carbon capture solutions is increasingly influenced by carbon pricing mechanisms. Regions with carbon taxes or cap-and-trade systems exceeding 50 USD per ton of CO2 create favorable market conditions for cryogenic capture technologies, which offer competitive cost profiles at scale. Additionally, the potential for revenue generation through carbon utilization pathways enhances the economic attractiveness of these systems.

The market also shows growing demand for integrated solutions that address multiple environmental challenges simultaneously. The oxygen-enriched combustion component of cryogenic CO2 capture systems responds to this trend by offering improved combustion efficiency alongside carbon capture capabilities. This dual-benefit approach resonates with industrial operators seeking to optimize operational costs while meeting emissions targets.

Looking forward, market analysts anticipate accelerated demand growth as carbon neutrality commitments expand globally. The International Energy Agency estimates that carbon capture capacity must increase by more than 20 times current levels by 2050 to meet climate goals, representing a substantial market opportunity for advanced technologies like cryogenic capture systems. This projected growth is further supported by increasing government investments in clean energy infrastructure and carbon management technologies.

Global Status and Technical Barriers in Cryogenic Carbon Capture

Cryogenic carbon capture (CCC) technology has emerged as a promising approach for CO2 emission reduction globally. Currently, the United States leads research efforts with significant projects at Brigham Young University and the Pacific Northwest National Laboratory. The European Union follows closely, with notable advancements in countries like Germany and Norway focusing on integration with existing power plants. China has recently accelerated its research programs, particularly in coal-fired power plant applications, while Japan focuses on combining CCC with liquefied natural gas processes.

Despite global progress, several technical barriers impede widespread implementation of cryogenic carbon capture systems. The primary challenge remains high energy consumption, with current systems requiring 0.8-1.2 MWh per ton of CO2 captured, significantly higher than the theoretical minimum. This energy penalty reduces overall plant efficiency by approximately 15-25%, creating economic feasibility concerns for commercial deployment.

Heat exchanger efficiency presents another critical barrier. Current cryogenic systems struggle with heat transfer effectiveness at the ultra-low temperatures required (-100°C to -140°C), leading to substantial energy losses. Material limitations compound this issue, as conventional materials become brittle and lose structural integrity under cryogenic conditions, necessitating expensive specialty alloys that increase capital costs by 30-40%.

Process integration challenges also persist when combining cryogenic capture with oxygen-enriched combustion strategies. The temperature differential between combustion zones (>1000°C) and capture systems (<-100°C) creates significant thermodynamic inefficiencies. Current heat recovery systems capture only 50-60% of available thermal energy, leaving substantial room for improvement.

Frost formation and solid handling represent operational barriers that reduce system reliability. CO2 desublimation creates solid particles that can damage equipment and block flow paths, while moisture in flue gas forms ice crystals that reduce heat transfer efficiency by up to 40% within 72 hours of operation. Current defrosting cycles consume additional energy and reduce overall capture rates.

Scale-up challenges remain significant, with most successful demonstrations limited to capacities below 10 tons of CO2 per day. Industrial applications would require systems handling hundreds or thousands of tons daily, introducing complex fluid dynamics and thermal management issues not present in laboratory-scale systems.

The economic viability threshold for widespread adoption is estimated at $40-50 per ton of CO2 captured, while current cryogenic systems operate at $70-90 per ton, highlighting the need for technological breakthroughs to bridge this gap.

Despite global progress, several technical barriers impede widespread implementation of cryogenic carbon capture systems. The primary challenge remains high energy consumption, with current systems requiring 0.8-1.2 MWh per ton of CO2 captured, significantly higher than the theoretical minimum. This energy penalty reduces overall plant efficiency by approximately 15-25%, creating economic feasibility concerns for commercial deployment.

Heat exchanger efficiency presents another critical barrier. Current cryogenic systems struggle with heat transfer effectiveness at the ultra-low temperatures required (-100°C to -140°C), leading to substantial energy losses. Material limitations compound this issue, as conventional materials become brittle and lose structural integrity under cryogenic conditions, necessitating expensive specialty alloys that increase capital costs by 30-40%.

Process integration challenges also persist when combining cryogenic capture with oxygen-enriched combustion strategies. The temperature differential between combustion zones (>1000°C) and capture systems (<-100°C) creates significant thermodynamic inefficiencies. Current heat recovery systems capture only 50-60% of available thermal energy, leaving substantial room for improvement.

Frost formation and solid handling represent operational barriers that reduce system reliability. CO2 desublimation creates solid particles that can damage equipment and block flow paths, while moisture in flue gas forms ice crystals that reduce heat transfer efficiency by up to 40% within 72 hours of operation. Current defrosting cycles consume additional energy and reduce overall capture rates.

Scale-up challenges remain significant, with most successful demonstrations limited to capacities below 10 tons of CO2 per day. Industrial applications would require systems handling hundreds or thousands of tons daily, introducing complex fluid dynamics and thermal management issues not present in laboratory-scale systems.

The economic viability threshold for widespread adoption is estimated at $40-50 per ton of CO2 captured, while current cryogenic systems operate at $70-90 per ton, highlighting the need for technological breakthroughs to bridge this gap.

Current Cryogenic CO2 Capture and Oxygen-Enriched Combustion Methods

01 Cryogenic CO2 capture systems and methods

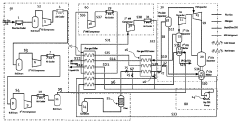

Cryogenic methods for capturing carbon dioxide involve cooling flue gas to temperatures where CO2 freezes or condenses, allowing for separation from other gases. These systems typically include heat exchangers, condensers, and separation chambers that operate at very low temperatures. The cryogenic approach offers high purity CO2 capture and can be energy-efficient when integrated with proper heat recovery systems. This method is particularly effective for high-concentration CO2 streams and can achieve capture rates exceeding 90%.- Cryogenic CO2 capture systems and methods: Cryogenic methods for capturing CO2 involve cooling flue gas to temperatures where CO2 freezes or condenses, allowing for separation from other gases. These systems typically include heat exchangers, condensers, and separation units that operate at very low temperatures. The cryogenic approach offers high purity CO2 capture and can be energy-efficient when integrated with proper heat recovery systems. This method is particularly effective for high-concentration CO2 streams and can achieve capture rates exceeding 90%.

- Oxygen-enriched combustion for enhanced CO2 capture: Oxygen-enriched combustion involves increasing the oxygen concentration in the combustion air, resulting in flue gas with higher CO2 concentration and reduced nitrogen content. This approach simplifies downstream CO2 capture by producing a more concentrated CO2 stream. The technology typically employs air separation units to produce oxygen-enriched air or pure oxygen for combustion processes. When combined with appropriate capture technologies, oxygen-enriched combustion can significantly reduce the energy penalty associated with CO2 separation.

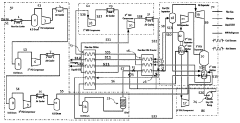

- Integration of cryogenic capture with oxy-fuel systems: The integration of cryogenic CO2 capture with oxygen-enriched combustion creates synergistic benefits. The higher CO2 concentration from oxy-fuel combustion makes cryogenic separation more efficient, while waste cold from cryogenic processes can be utilized in oxygen production. These integrated systems often include heat integration networks, energy recovery units, and optimized process control strategies. The combined approach can achieve higher overall efficiency than either technology alone, with potential for near-zero emissions from power generation and industrial processes.

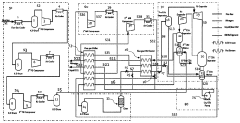

- Process optimization and energy efficiency improvements: Various techniques are employed to optimize the energy efficiency of combined cryogenic and oxygen-enriched CO2 capture systems. These include advanced heat integration, pressure swing operations, multi-stage compression with intercooling, and waste heat recovery. Process optimization strategies focus on minimizing the energy penalty associated with CO2 capture while maximizing capture efficiency. Advanced control systems and modeling approaches help balance the trade-offs between capture rate, energy consumption, and operational stability across varying load conditions.

- Novel equipment designs and system configurations: Innovative equipment designs and system configurations enhance the performance of combined cryogenic and oxygen-enriched CO2 capture systems. These include specialized heat exchangers for cryogenic service, advanced air separation units, novel contactor designs, and integrated compression systems. Some configurations incorporate membrane separation, adsorption processes, or chemical absorption as pre-treatment or polishing steps. These novel designs aim to reduce capital costs, improve operational flexibility, and enhance overall system reliability while maintaining high CO2 capture rates.

02 Oxygen-enriched combustion for enhanced CO2 capture

Oxygen-enriched combustion involves increasing the oxygen concentration in the combustion air, resulting in flue gas with higher CO2 concentration and reduced nitrogen content. This approach simplifies downstream CO2 capture by producing a more concentrated CO2 stream. The technology typically employs air separation units to produce oxygen-enriched air or pure oxygen for combustion processes. By reducing the volume of flue gas and increasing CO2 concentration, this method significantly improves the efficiency of subsequent capture systems and reduces overall energy requirements.Expand Specific Solutions03 Integration of cryogenic systems with oxy-fuel combustion

The combination of cryogenic CO2 capture with oxygen-enriched combustion creates synergistic benefits. The air separation unit used for producing oxygen for combustion can share cooling infrastructure with the cryogenic CO2 capture system, improving overall energy efficiency. This integrated approach allows for heat integration between processes, reducing the energy penalty associated with both technologies when operated separately. The system design typically includes specialized heat exchangers, phase separators, and compression equipment optimized for the combined process flow.Expand Specific Solutions04 Process control and optimization for combined systems

Advanced control systems are essential for managing the complex integration of cryogenic CO2 capture with oxygen-enriched combustion. These control systems monitor and adjust operating parameters such as temperature, pressure, flow rates, and oxygen concentration to maintain optimal performance. Machine learning algorithms and predictive models can be employed to anticipate system behavior and make proactive adjustments. Energy recovery and heat integration are carefully managed to minimize overall energy consumption while maintaining capture efficiency and product purity.Expand Specific Solutions05 Novel equipment designs for integrated capture systems

Specialized equipment designs have been developed for the combined cryogenic CO2 capture and oxygen-enriched combustion systems. These include multi-stage heat exchangers that maximize energy recovery, novel separation vessels that enhance phase separation at cryogenic temperatures, and compact integration modules that reduce footprint and capital costs. Some designs incorporate membrane technology to assist with gas separation before or after cryogenic processing. These equipment innovations focus on improving efficiency, reducing size, and enhancing reliability of the integrated capture system.Expand Specific Solutions

Leading Companies and Research Institutions in Carbon Capture

Cryogenic CO2 Capture Combined With Oxygen-Enriched Combustion Strategies is currently in an early commercial development phase, with a growing market expected to reach significant scale as carbon capture technologies become essential for climate goals. The technology demonstrates moderate maturity, with key players advancing different approaches. Air Liquide SA and Southwest Research Institute lead in industrial applications, while academic institutions like Xi'an Jiaotong University and Huazhong University of Science & Technology contribute fundamental research. Companies such as IFP Energies Nouvelles, Sustainable Energy Solutions, and Global Thermostat are developing proprietary systems, while Chinese entities including Huaneng Clean Energy Research Institute and State Power Investment Corporation are investing heavily in demonstration projects. The competitive landscape shows a mix of established industrial gas companies, specialized technology developers, and research institutions working to optimize efficiency and reduce implementation costs.

Air Liquide SA

Technical Solution: Air Liquide has developed an integrated cryogenic CO2 capture system that leverages their expertise in industrial gas separation. Their technology utilizes a multi-stage cooling process where flue gas is progressively cooled to temperatures below -100°C, causing CO2 to desublimate directly from gas to solid phase. This is combined with their proprietary oxygen-enriched combustion technology that increases oxygen concentration in the combustion air to 30-40%, significantly enhancing combustion efficiency and CO2 concentration in flue gas. The system incorporates heat integration networks that recover cold energy from the captured solid CO2 during regasification, reducing the overall energy penalty. Their Cryocap™ technology has demonstrated capture rates exceeding 90% in industrial applications while producing high-purity CO2 (>99.9%) suitable for utilization or storage. The technology has been successfully implemented in several industrial facilities, including a large-scale demonstration at a hydrogen production unit that captures 100,000 tons of CO2 annually.

Strengths: Produces extremely high-purity CO2 without chemical solvents; leverages Air Liquide's extensive industrial gas expertise; demonstrated at commercial scale; integrates well with existing oxygen production infrastructure. Weaknesses: Higher capital costs compared to conventional amine-based systems; significant energy requirements for cryogenic cooling; challenges in handling moisture in flue gas that can cause equipment fouling.

IFP Energies Nouvelles

Technical Solution: IFP Energies Nouvelles has developed a hybrid cryogenic CO2 capture system called CryoCap that combines membrane pre-separation with cryogenic distillation. The process first uses selective membranes to increase CO2 concentration from typical 12-15% to over 50%, significantly reducing the downstream cooling load. The concentrated stream then enters a cryogenic processing unit where it's cooled in stages to approximately -120°C, allowing CO2 to be separated as a liquid or solid phase. This system is integrated with their oxygen-enriched combustion technology that utilizes specialized burners capable of operating with oxygen concentrations up to 40% while maintaining flame stability and minimizing NOx formation. The technology incorporates advanced heat exchangers that recover up to 85% of the cold energy, substantially reducing the process energy penalty. IFP has demonstrated this technology at pilot scale (capturing 1-2 tons CO2/day) and shown that it can achieve capture rates exceeding 95% while producing CO2 with purity suitable for enhanced oil recovery or food-grade applications. Their economic analyses indicate a potential reduction in capture costs of 25-30% compared to conventional amine scrubbing when integrated with oxygen-enriched combustion.

Strengths: Hybrid approach reduces energy requirements compared to pure cryogenic systems; membrane pre-concentration enhances efficiency; produces high-purity CO2; avoids chemical solvents and associated environmental issues. Weaknesses: Limited large-scale demonstration experience; membrane components may require periodic replacement; system complexity requires sophisticated control systems; higher capital costs than conventional approaches.

Key Patents and Technical Innovations in Cryogenic Separation

A new flue gas co2 capture process using the cryogenic method

PatentPendingCA3171526A1

Innovation

- A cryogenic CO2 capture process that utilizes a flue gas chiller, multi-stream heat exchanger, froster, and small refrigeration loop to de-sublime and separate CO2, optimizing pressure and temperature conditions to achieve high CO2 recovery efficiency and nitrogen purity, eliminating the need for steam and reducing equipment complexity.

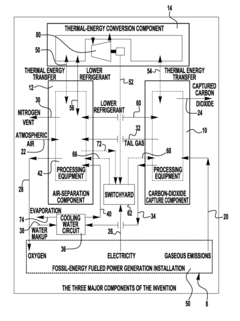

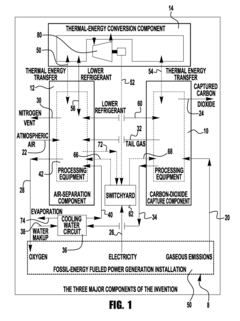

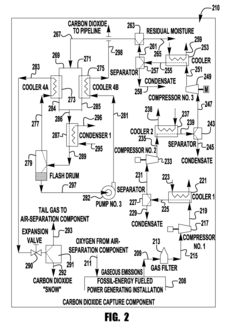

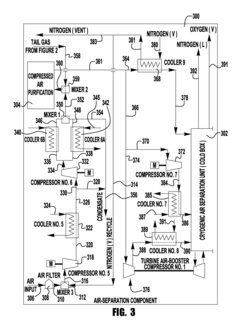

Method for the capture of carbon dioxide through cryogenically processing gaseous emissions from fossil-fuel power generation

PatentActiveUS20170241707A1

Innovation

- A system comprising three interrelated components: Carbon-Dioxide Capture, Air-Separation, and Thermal-Energy Conversion components, which compress gases, separate air, and convert low-temperature thermal energy into electricity, respectively, to reduce external electricity consumption and enhance CO2 capture as a high-purity, high-pressure supercritical fluid for transport or sequestration.

Energy Efficiency Analysis and Optimization Strategies

The energy efficiency of cryogenic CO2 capture systems integrated with oxygen-enriched combustion presents significant opportunities for optimization. Current systems typically consume between 0.7-1.2 MWh per ton of CO2 captured, with the cryogenic separation process accounting for approximately 60-70% of this energy demand. The thermodynamic analysis reveals that the primary energy penalties occur during the gas cooling and phase separation stages, where temperature gradients and heat exchange inefficiencies create substantial exergy losses.

When combined with oxygen-enriched combustion, the overall system demonstrates improved capture rates of 85-95% compared to conventional approaches, but introduces additional energy requirements for oxygen production. Modern air separation units consume approximately 0.2-0.3 kWh per kg of oxygen produced, creating a trade-off between enhanced combustion efficiency and increased auxiliary power demands.

Process integration strategies have demonstrated potential energy savings of 15-30% through heat recovery networks that utilize waste cold energy from the cryogenic CO2 liquefaction process. The implementation of multi-stage compression with intercooling has shown to reduce compression work by up to 25% compared to single-stage alternatives, while advanced heat exchanger designs with enhanced surface geometries have improved heat transfer coefficients by 30-40%.

Optimization modeling using pinch analysis and exergy-based methodologies identifies key intervention points within the integrated process. The most promising approaches include variable oxygen enrichment levels (20-40% oxygen concentration) tailored to specific fuel characteristics, and dynamic operation of the cryogenic separation unit in response to fluctuating load conditions.

Recent pilot demonstrations have achieved energy consumption reductions of 18-22% through the implementation of advanced control systems that optimize the cryogenic temperature profile based on feed gas composition. Additionally, novel process configurations incorporating partial condensation and distillation columns have shown potential to reduce separation energy requirements by up to 25% while maintaining product purity specifications above 99%.

Future optimization pathways include the development of novel working fluids for refrigeration cycles with improved thermodynamic properties, membrane-assisted cryogenic separation to reduce the cooling load, and advanced materials with enhanced thermal conductivity for heat exchanger applications. Economic analysis indicates that these optimization strategies could reduce the energy penalty cost by $15-25 per ton of CO2 captured, significantly improving the commercial viability of integrated cryogenic capture systems.

When combined with oxygen-enriched combustion, the overall system demonstrates improved capture rates of 85-95% compared to conventional approaches, but introduces additional energy requirements for oxygen production. Modern air separation units consume approximately 0.2-0.3 kWh per kg of oxygen produced, creating a trade-off between enhanced combustion efficiency and increased auxiliary power demands.

Process integration strategies have demonstrated potential energy savings of 15-30% through heat recovery networks that utilize waste cold energy from the cryogenic CO2 liquefaction process. The implementation of multi-stage compression with intercooling has shown to reduce compression work by up to 25% compared to single-stage alternatives, while advanced heat exchanger designs with enhanced surface geometries have improved heat transfer coefficients by 30-40%.

Optimization modeling using pinch analysis and exergy-based methodologies identifies key intervention points within the integrated process. The most promising approaches include variable oxygen enrichment levels (20-40% oxygen concentration) tailored to specific fuel characteristics, and dynamic operation of the cryogenic separation unit in response to fluctuating load conditions.

Recent pilot demonstrations have achieved energy consumption reductions of 18-22% through the implementation of advanced control systems that optimize the cryogenic temperature profile based on feed gas composition. Additionally, novel process configurations incorporating partial condensation and distillation columns have shown potential to reduce separation energy requirements by up to 25% while maintaining product purity specifications above 99%.

Future optimization pathways include the development of novel working fluids for refrigeration cycles with improved thermodynamic properties, membrane-assisted cryogenic separation to reduce the cooling load, and advanced materials with enhanced thermal conductivity for heat exchanger applications. Economic analysis indicates that these optimization strategies could reduce the energy penalty cost by $15-25 per ton of CO2 captured, significantly improving the commercial viability of integrated cryogenic capture systems.

Environmental Impact and Regulatory Compliance Framework

The implementation of Cryogenic CO2 Capture Combined with Oxygen-Enriched Combustion Strategies presents significant environmental implications that must be carefully evaluated against evolving regulatory frameworks. These technologies collectively offer substantial potential for reducing greenhouse gas emissions, particularly in energy-intensive industries where conventional carbon capture methods prove economically challenging.

Current environmental impact assessments indicate that cryogenic CO2 capture systems can achieve carbon capture rates exceeding 90% when optimally designed and operated. When combined with oxygen-enriched combustion, these systems demonstrate enhanced efficiency profiles with reduced NOx emissions compared to conventional combustion processes. The concentrated CO2 streams produced facilitate more economical capture and subsequent utilization or storage.

Regulatory compliance requirements for these technologies vary significantly across jurisdictions but generally follow increasingly stringent carbon reduction mandates. The European Union's Emissions Trading System (EU ETS) and the recent updates to the Industrial Emissions Directive specifically address carbon capture technologies, establishing performance benchmarks that favor high-efficiency systems like cryogenic capture. Similarly, the United States EPA's New Source Performance Standards (NSPS) and Clean Air Act provisions are evolving to incorporate carbon capture requirements for certain industrial categories.

Life cycle assessment studies reveal important considerations regarding the environmental footprint of cryogenic systems. While operational carbon capture benefits are substantial, the energy requirements for cryogenic cooling and oxygen production represent significant environmental considerations. Recent technological improvements have reduced these energy penalties by approximately 15-20% compared to early implementations, though further optimization remains necessary to achieve full environmental benefits.

Compliance pathways for industrial adopters typically involve phased implementation strategies aligned with regulatory timelines. The most progressive regulatory frameworks, such as those in Canada and Norway, have established carbon pricing mechanisms that effectively incentivize adoption of advanced capture technologies when prices exceed $50-70 per ton of CO2. These economic signals, combined with technology-specific incentives, create viable compliance pathways for industrial operators.

Future regulatory developments are trending toward performance-based standards rather than technology prescriptions, potentially benefiting cryogenic capture systems due to their high capture efficiency. The International Organization for Standardization (ISO) is currently developing standardized methodologies for evaluating carbon capture technologies (ISO 27919 series), which will likely influence future regulatory approaches and technology selection criteria across multiple jurisdictions.

Current environmental impact assessments indicate that cryogenic CO2 capture systems can achieve carbon capture rates exceeding 90% when optimally designed and operated. When combined with oxygen-enriched combustion, these systems demonstrate enhanced efficiency profiles with reduced NOx emissions compared to conventional combustion processes. The concentrated CO2 streams produced facilitate more economical capture and subsequent utilization or storage.

Regulatory compliance requirements for these technologies vary significantly across jurisdictions but generally follow increasingly stringent carbon reduction mandates. The European Union's Emissions Trading System (EU ETS) and the recent updates to the Industrial Emissions Directive specifically address carbon capture technologies, establishing performance benchmarks that favor high-efficiency systems like cryogenic capture. Similarly, the United States EPA's New Source Performance Standards (NSPS) and Clean Air Act provisions are evolving to incorporate carbon capture requirements for certain industrial categories.

Life cycle assessment studies reveal important considerations regarding the environmental footprint of cryogenic systems. While operational carbon capture benefits are substantial, the energy requirements for cryogenic cooling and oxygen production represent significant environmental considerations. Recent technological improvements have reduced these energy penalties by approximately 15-20% compared to early implementations, though further optimization remains necessary to achieve full environmental benefits.

Compliance pathways for industrial adopters typically involve phased implementation strategies aligned with regulatory timelines. The most progressive regulatory frameworks, such as those in Canada and Norway, have established carbon pricing mechanisms that effectively incentivize adoption of advanced capture technologies when prices exceed $50-70 per ton of CO2. These economic signals, combined with technology-specific incentives, create viable compliance pathways for industrial operators.

Future regulatory developments are trending toward performance-based standards rather than technology prescriptions, potentially benefiting cryogenic capture systems due to their high capture efficiency. The International Organization for Standardization (ISO) is currently developing standardized methodologies for evaluating carbon capture technologies (ISO 27919 series), which will likely influence future regulatory approaches and technology selection criteria across multiple jurisdictions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!