Environmental Risk Assessment For Cryogenic CO2 Capture Deployments

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic CO2 Capture Technology Background and Objectives

Cryogenic carbon dioxide capture technology represents a significant advancement in the field of carbon capture and storage (CCS), emerging as a response to the growing global concern over greenhouse gas emissions and climate change. This technology has evolved from early theoretical concepts in the 1970s to practical applications in the 21st century, with major developments occurring in the last two decades as climate mitigation strategies gained prominence in international policy discussions.

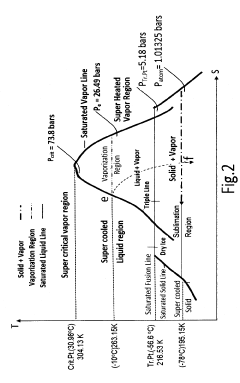

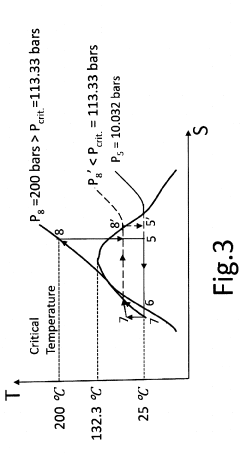

The fundamental principle of cryogenic CO2 capture involves cooling flue gases to temperatures where CO2 desublimates directly from gas to solid phase, allowing for separation from other gases. This approach offers several advantages over conventional amine-based absorption methods, including higher capture efficiency, reduced energy penalties, and minimal chemical waste generation. The technology has progressed through various iterations, from laboratory-scale experiments to pilot plant demonstrations, with each stage refining the process parameters and engineering solutions.

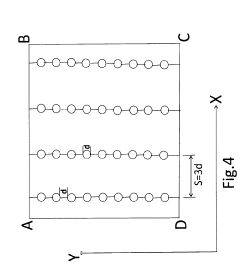

Current technological trajectories indicate a shift toward more energy-efficient designs, integration with renewable energy sources, and optimization for specific industrial applications. Research trends suggest increasing focus on process intensification, novel heat exchange mechanisms, and materials innovation to overcome the inherent energy demands of cryogenic operations. The development of anti-sublimation surfaces and advanced phase change heat transfer systems represents promising areas of recent advancement.

The primary objective of environmental risk assessment for cryogenic CO2 capture deployments is to identify, quantify, and mitigate potential hazards associated with the implementation of this technology at industrial scale. This includes evaluating risks related to the handling of cryogenic fluids, potential for CO2 leakage, energy consumption impacts, and integration challenges with existing industrial processes. Additionally, the assessment aims to establish safety protocols and operational guidelines that ensure regulatory compliance while maximizing capture efficiency.

Secondary objectives include developing standardized methodologies for risk evaluation specific to cryogenic carbon capture systems, creating comparative frameworks against alternative capture technologies, and establishing long-term monitoring strategies for environmental impacts. The ultimate goal is to facilitate the responsible deployment of cryogenic CO2 capture technology as part of a comprehensive climate change mitigation strategy, ensuring that environmental benefits are not offset by unforeseen ecological or safety risks.

As global carbon reduction targets become increasingly stringent, cryogenic CO2 capture technology stands at a critical juncture, with significant potential for widespread industrial adoption if environmental risk factors can be adequately addressed and operational reliability demonstrated at commercial scale.

The fundamental principle of cryogenic CO2 capture involves cooling flue gases to temperatures where CO2 desublimates directly from gas to solid phase, allowing for separation from other gases. This approach offers several advantages over conventional amine-based absorption methods, including higher capture efficiency, reduced energy penalties, and minimal chemical waste generation. The technology has progressed through various iterations, from laboratory-scale experiments to pilot plant demonstrations, with each stage refining the process parameters and engineering solutions.

Current technological trajectories indicate a shift toward more energy-efficient designs, integration with renewable energy sources, and optimization for specific industrial applications. Research trends suggest increasing focus on process intensification, novel heat exchange mechanisms, and materials innovation to overcome the inherent energy demands of cryogenic operations. The development of anti-sublimation surfaces and advanced phase change heat transfer systems represents promising areas of recent advancement.

The primary objective of environmental risk assessment for cryogenic CO2 capture deployments is to identify, quantify, and mitigate potential hazards associated with the implementation of this technology at industrial scale. This includes evaluating risks related to the handling of cryogenic fluids, potential for CO2 leakage, energy consumption impacts, and integration challenges with existing industrial processes. Additionally, the assessment aims to establish safety protocols and operational guidelines that ensure regulatory compliance while maximizing capture efficiency.

Secondary objectives include developing standardized methodologies for risk evaluation specific to cryogenic carbon capture systems, creating comparative frameworks against alternative capture technologies, and establishing long-term monitoring strategies for environmental impacts. The ultimate goal is to facilitate the responsible deployment of cryogenic CO2 capture technology as part of a comprehensive climate change mitigation strategy, ensuring that environmental benefits are not offset by unforeseen ecological or safety risks.

As global carbon reduction targets become increasingly stringent, cryogenic CO2 capture technology stands at a critical juncture, with significant potential for widespread industrial adoption if environmental risk factors can be adequately addressed and operational reliability demonstrated at commercial scale.

Market Demand Analysis for Carbon Capture Solutions

The global carbon capture market is experiencing significant growth, driven by increasing environmental regulations and corporate sustainability commitments. Current market valuations place the carbon capture and storage (CCS) sector at approximately $2.9 billion in 2022, with projections indicating growth to reach $5.6 billion by 2030, representing a compound annual growth rate of 8.5%. This growth trajectory is particularly relevant for cryogenic CO2 capture technologies, which are gaining attention for their efficiency advantages in specific applications.

Demand for carbon capture solutions is primarily driven by three key sectors: power generation, industrial processes, and direct air capture initiatives. The power generation sector, particularly coal and natural gas plants, represents the largest current market for carbon capture technologies, accounting for roughly 40% of the total addressable market. Industrial processes, including cement production, steel manufacturing, and chemical processing, constitute approximately 35% of market demand, with these hard-to-abate sectors increasingly seeking viable decarbonization pathways.

Regional analysis reveals varying levels of market maturity and demand. North America leads in carbon capture deployment, with over 40 commercial-scale projects in operation or development, followed by Europe with its ambitious climate targets under the European Green Deal. The Asia-Pacific region, particularly China and Japan, is rapidly expanding its carbon capture infrastructure, with annual investment growth exceeding 15% since 2020.

Cryogenic CO2 capture specifically addresses market needs for high-purity carbon capture in industrial applications where traditional solvent-based approaches face limitations. Market research indicates growing demand for these systems in liquefied natural gas (LNG) processing, hydrogen production, and biogas upgrading, where the ability to achieve high CO2 recovery rates (>95%) and purity (>99%) provides significant value.

Customer requirements are evolving toward solutions that offer lower energy penalties, reduced operational costs, and smaller physical footprints. Survey data from industrial operators indicates willingness to adopt carbon capture technologies when total costs fall below $50-60 per ton of CO2 captured, a threshold that cryogenic systems are approaching through technological improvements and economies of scale.

The market is also being shaped by policy incentives, with carbon pricing mechanisms, tax credits (such as the 45Q tax credit in the United States), and regulatory frameworks creating financial incentives for carbon capture adoption. These policy instruments are expected to expand the addressable market for cryogenic CO2 capture by an estimated 30% over the next five years, particularly in regions with strong climate commitments.

Demand for carbon capture solutions is primarily driven by three key sectors: power generation, industrial processes, and direct air capture initiatives. The power generation sector, particularly coal and natural gas plants, represents the largest current market for carbon capture technologies, accounting for roughly 40% of the total addressable market. Industrial processes, including cement production, steel manufacturing, and chemical processing, constitute approximately 35% of market demand, with these hard-to-abate sectors increasingly seeking viable decarbonization pathways.

Regional analysis reveals varying levels of market maturity and demand. North America leads in carbon capture deployment, with over 40 commercial-scale projects in operation or development, followed by Europe with its ambitious climate targets under the European Green Deal. The Asia-Pacific region, particularly China and Japan, is rapidly expanding its carbon capture infrastructure, with annual investment growth exceeding 15% since 2020.

Cryogenic CO2 capture specifically addresses market needs for high-purity carbon capture in industrial applications where traditional solvent-based approaches face limitations. Market research indicates growing demand for these systems in liquefied natural gas (LNG) processing, hydrogen production, and biogas upgrading, where the ability to achieve high CO2 recovery rates (>95%) and purity (>99%) provides significant value.

Customer requirements are evolving toward solutions that offer lower energy penalties, reduced operational costs, and smaller physical footprints. Survey data from industrial operators indicates willingness to adopt carbon capture technologies when total costs fall below $50-60 per ton of CO2 captured, a threshold that cryogenic systems are approaching through technological improvements and economies of scale.

The market is also being shaped by policy incentives, with carbon pricing mechanisms, tax credits (such as the 45Q tax credit in the United States), and regulatory frameworks creating financial incentives for carbon capture adoption. These policy instruments are expected to expand the addressable market for cryogenic CO2 capture by an estimated 30% over the next five years, particularly in regions with strong climate commitments.

Current Status and Challenges in Cryogenic CO2 Capture

Cryogenic CO2 capture technology has emerged as a promising approach for carbon capture, utilizing low-temperature processes to separate CO2 from various gas streams. Currently, this technology has advanced beyond laboratory scale to pilot demonstrations, with several companies implementing small to medium-scale installations. Notable implementations include Sustainable Energy Solutions' Cryogenic Carbon Capture™ process and Air Liquide's cryogenic distillation systems, which have demonstrated capture efficiencies exceeding 90% in controlled environments.

Despite these advancements, cryogenic CO2 capture faces significant technical challenges. The primary obstacle remains the high energy consumption required for cooling processes, with current systems demanding 1.5-2.5 MJ/kg CO2 captured. This energy intensity makes large-scale deployment economically challenging compared to conventional amine-based systems. Additionally, the formation of solid CO2 (dry ice) during the process creates operational difficulties including potential blockages in heat exchangers and transport systems.

Material limitations present another substantial challenge. Equipment must withstand extreme temperature cycling between ambient and cryogenic conditions (-100°C to -150°C), leading to thermal stress and potential structural failures. Current materials exhibit degradation under these conditions, necessitating frequent maintenance and replacement, which increases operational costs and reduces system reliability.

Internationally, research efforts are concentrated in North America, Europe, and East Asia, with the United States, Norway, and China leading development initiatives. Academic institutions like Carnegie Mellon University and ETH Zurich have established dedicated research programs, while industrial players such as Air Products and Linde Engineering are advancing proprietary technologies. However, standardization of performance metrics and testing protocols remains inconsistent across regions, complicating comparative assessments.

The integration of cryogenic systems with existing industrial infrastructure presents significant engineering challenges. Retrofitting facilities requires substantial modifications to accommodate the cryogenic equipment's footprint and safety requirements. Furthermore, the intermittent nature of renewable energy sources complicates the operation of energy-intensive cryogenic systems, as they typically require stable power supplies for optimal performance.

Environmental risk assessment for these deployments is still in nascent stages, with limited comprehensive studies on potential refrigerant leakage impacts, safety protocols for handling cryogenic materials, and life-cycle environmental footprints. Regulatory frameworks specifically addressing cryogenic carbon capture technologies remain underdeveloped in most jurisdictions, creating uncertainty for potential adopters and investors.

Despite these advancements, cryogenic CO2 capture faces significant technical challenges. The primary obstacle remains the high energy consumption required for cooling processes, with current systems demanding 1.5-2.5 MJ/kg CO2 captured. This energy intensity makes large-scale deployment economically challenging compared to conventional amine-based systems. Additionally, the formation of solid CO2 (dry ice) during the process creates operational difficulties including potential blockages in heat exchangers and transport systems.

Material limitations present another substantial challenge. Equipment must withstand extreme temperature cycling between ambient and cryogenic conditions (-100°C to -150°C), leading to thermal stress and potential structural failures. Current materials exhibit degradation under these conditions, necessitating frequent maintenance and replacement, which increases operational costs and reduces system reliability.

Internationally, research efforts are concentrated in North America, Europe, and East Asia, with the United States, Norway, and China leading development initiatives. Academic institutions like Carnegie Mellon University and ETH Zurich have established dedicated research programs, while industrial players such as Air Products and Linde Engineering are advancing proprietary technologies. However, standardization of performance metrics and testing protocols remains inconsistent across regions, complicating comparative assessments.

The integration of cryogenic systems with existing industrial infrastructure presents significant engineering challenges. Retrofitting facilities requires substantial modifications to accommodate the cryogenic equipment's footprint and safety requirements. Furthermore, the intermittent nature of renewable energy sources complicates the operation of energy-intensive cryogenic systems, as they typically require stable power supplies for optimal performance.

Environmental risk assessment for these deployments is still in nascent stages, with limited comprehensive studies on potential refrigerant leakage impacts, safety protocols for handling cryogenic materials, and life-cycle environmental footprints. Regulatory frameworks specifically addressing cryogenic carbon capture technologies remain underdeveloped in most jurisdictions, creating uncertainty for potential adopters and investors.

Current Environmental Risk Assessment Methodologies

01 Leakage and release risks in cryogenic CO2 capture systems

Cryogenic CO2 capture systems pose potential environmental risks related to CO2 leakage and accidental releases. These risks include atmospheric contamination, localized high CO2 concentrations that can affect air quality, and potential hazards to nearby ecosystems and personnel. The cryogenic nature of these systems adds additional risk factors due to the extremely low temperatures involved, which can cause rapid expansion of CO2 if containment is compromised.- Leakage and release risks in cryogenic CO2 capture systems: Cryogenic CO2 capture systems face potential environmental risks related to CO2 leakage and accidental releases. These risks include atmospheric contamination, localized high CO2 concentrations that can affect air quality, and potential hazards to nearby ecosystems and personnel. The cryogenic nature of these systems adds additional risk factors due to the extremely low temperatures involved, which can cause rapid expansion of CO2 if containment is breached, potentially leading to asphyxiation hazards in enclosed spaces.

- Energy consumption and carbon footprint concerns: The energy requirements for cryogenic CO2 capture present significant environmental considerations. The cooling processes necessary to reach cryogenic temperatures demand substantial energy inputs, which may generate additional greenhouse gas emissions if powered by fossil fuels. This creates a potential efficiency paradox where the carbon footprint of the capture process itself must be carefully balanced against the environmental benefits of removing CO2. Advanced systems incorporate energy recovery mechanisms and integration with renewable energy sources to mitigate these concerns.

- Handling and storage of captured CO2: Environmental risks associated with the handling and storage of captured CO2 include potential for ground contamination, water table impacts, and long-term geological stability concerns. Once captured through cryogenic processes, the CO2 must be safely transported and stored, typically in geological formations. Monitoring systems are essential to detect any migration of stored CO2 that could affect groundwater quality or surface ecosystems. The transportation infrastructure also presents potential points of failure that require risk assessment and mitigation strategies.

- Chemical additives and refrigerant impacts: Cryogenic CO2 capture systems often utilize chemical additives and refrigerants that carry their own environmental risks. These substances may include potential ozone-depleting compounds, greenhouse gases with high global warming potential, or chemicals that pose toxicity concerns if released. The selection of environmentally benign refrigerants and process chemicals is critical to minimize secondary environmental impacts. Proper containment, handling protocols, and emergency response procedures are necessary to manage these chemical-related risks.

- Monitoring and risk mitigation technologies: Advanced monitoring systems and risk mitigation technologies are essential components of environmentally responsible cryogenic CO2 capture implementations. These include continuous emission monitoring systems, leak detection technologies, automated shutdown protocols, and environmental impact assessment frameworks. Real-time data collection allows for early detection of potential issues before they develop into significant environmental hazards. Integrated safety systems can respond automatically to detected anomalies, while comprehensive risk assessment methodologies help identify and address potential failure points before they occur.

02 Energy consumption and efficiency concerns

Cryogenic CO2 capture technologies require significant energy inputs for cooling and maintaining low temperatures, which can lead to increased fossil fuel consumption if not powered by renewable sources. This energy demand presents an environmental trade-off that must be considered when implementing these systems. Innovations focus on improving energy efficiency through heat integration, advanced refrigeration cycles, and process optimization to reduce the overall carbon footprint of the capture process.Expand Specific Solutions03 Safety measures and risk mitigation strategies

To address environmental risks associated with cryogenic CO2 capture, various safety measures and mitigation strategies have been developed. These include advanced monitoring systems for leak detection, pressure relief systems, containment designs with multiple barriers, emergency shutdown protocols, and specialized materials resistant to low-temperature embrittlement. Proper risk assessment methodologies and safety management systems are essential for minimizing potential environmental impacts.Expand Specific Solutions04 Lifecycle environmental impact assessment

Comprehensive lifecycle assessment of cryogenic CO2 capture systems evaluates their overall environmental impact beyond operational risks. This includes analysis of raw material extraction, manufacturing processes, transportation, installation, operation, maintenance, and end-of-life disposal. These assessments help identify potential environmental hotspots and guide improvements in system design and operation to minimize negative impacts while maximizing climate benefits through effective carbon capture.Expand Specific Solutions05 Integration with carbon utilization and storage systems

The environmental risk profile of cryogenic CO2 capture is influenced by how the captured CO2 is subsequently handled. Integration with carbon utilization pathways (converting CO2 into valuable products) or secure geological storage systems affects the overall environmental impact. Proper integration requires careful consideration of transportation infrastructure, injection well integrity, monitoring systems for storage sites, and potential leakage pathways to ensure long-term environmental safety and carbon sequestration effectiveness.Expand Specific Solutions

Key Industry Players in Cryogenic CO2 Capture

The environmental risk assessment for cryogenic CO2 capture deployments is currently in an early growth phase, with the market expanding as global decarbonization efforts intensify. The technology is approaching commercial maturity, with key players demonstrating varied levels of expertise. Major energy corporations like PetroChina, Shell, Saudi Aramco, and Sinopec are investing significantly in this field, leveraging their industrial infrastructure. Research institutions including Huaneng Clean Energy Research Institute, California Institute of Technology, and The Ohio State University are advancing fundamental science. Specialized technology providers such as Calix Ltd. and Calera Corp. are developing innovative capture solutions. This competitive landscape reflects a technology transitioning from research to commercial implementation, with collaborations between industry and academia accelerating development toward cost-effective, environmentally sound CO2 capture systems.

Shell-USA, Inc.

Technical Solution: Shell has developed a comprehensive environmental risk assessment framework specifically for cryogenic CO2 capture deployments. Their approach integrates multiple risk evaluation methodologies including Quantitative Risk Assessment (QRA), Hazard and Operability Study (HAZOP), and Environmental Impact Assessment (EIA) tailored for the unique challenges of cryogenic conditions. The framework addresses risks associated with the handling of cryogenic fluids at temperatures below -78.5°C, potential CO2 leakage scenarios, and material compatibility issues under extreme temperature conditions. Shell's methodology incorporates advanced dispersion modeling to predict the behavior of dense CO2 clouds in case of accidental release, considering factors such as topography, atmospheric conditions, and population density. Their risk assessment protocol also includes specialized monitoring systems with temperature-resistant sensors capable of functioning reliably in cryogenic environments, providing real-time data on system integrity and environmental parameters.

Strengths: Comprehensive integration of multiple risk assessment methodologies specifically adapted for cryogenic conditions; advanced dispersion modeling capabilities; extensive industry experience in handling hazardous materials. Weaknesses: Implementation requires significant technical expertise and resources; system complexity may increase operational challenges; potential gaps in long-term environmental impact data for novel cryogenic technologies.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell Internationale Research Maatschappij has developed the CANSOLV CO2 Capture System with cryogenic components that incorporates sophisticated environmental risk assessment protocols. Their approach focuses on lifecycle environmental impact analysis, examining potential risks from construction through decommissioning phases. The system employs proprietary cryogenic distillation technology that operates at temperatures around -120°C, requiring specialized risk assessment for thermal stress on materials, potential for rapid phase transitions, and management of high-pressure CO2 streams. Their environmental risk framework includes detailed analysis of potential soil and groundwater contamination pathways from amine degradation products, atmospheric dispersion modeling for accidental releases, and ecosystem impact assessment methodologies specific to cryogenic operations. The company has developed specialized safety protocols for handling cryogenic CO2, including emergency response procedures for potential release scenarios and worker safety guidelines for extreme temperature environments.

Strengths: Extensive experience with large-scale carbon capture implementations; proprietary technology with proven track record; comprehensive lifecycle approach to risk assessment. Weaknesses: Higher implementation costs compared to conventional systems; energy penalties associated with cryogenic processes; limited public domain information on specific risk mitigation strategies.

Critical Technical Innovations in Risk Mitigation

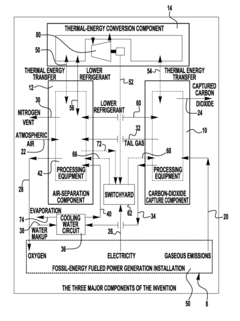

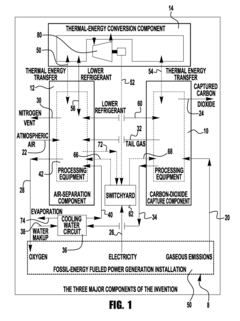

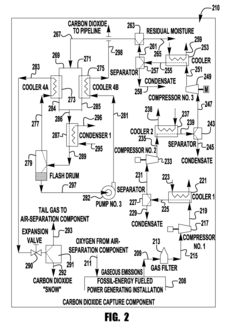

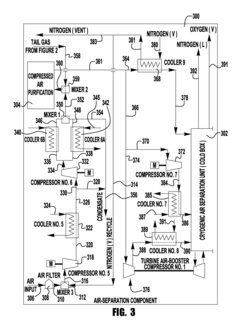

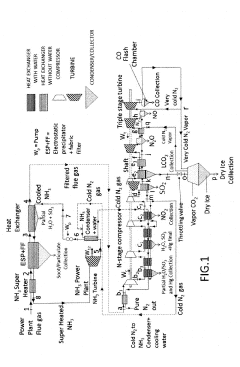

Method for the capture of carbon dioxide through cryogenically processing gaseous emissions from fossil-fuel power generation

PatentActiveUS20170241707A1

Innovation

- A system comprising three interrelated components: Carbon-Dioxide Capture, Air-Separation, and Thermal-Energy Conversion components, which compress gases, separate air, and convert low-temperature thermal energy into electricity, respectively, to reduce external electricity consumption and enhance CO2 capture as a high-purity, high-pressure supercritical fluid for transport or sequestration.

Novel and highly cost effective technology for capture of industrial emissions without reagent for clean energy and clean environment applications

PatentInactiveUS20190170436A1

Innovation

- A cryogenic technology that uses fractional condensation of flue gas components with super-cold nitrogen and an ammonia power plant to generate auxiliary power, capturing each component separately without chemicals or external cryogens, utilizing a fixed amount of water and minimizing energy consumption.

Regulatory Framework for Carbon Capture Deployments

The regulatory landscape for carbon capture technologies, particularly cryogenic CO2 capture systems, is complex and evolving rapidly as governments worldwide recognize the importance of carbon management in addressing climate change. Current regulatory frameworks vary significantly across jurisdictions, creating challenges for widespread deployment of these technologies.

In the United States, carbon capture deployments are primarily regulated under the Environmental Protection Agency's (EPA) Clean Air Act and Underground Injection Control Program, which establish standards for CO2 transport and storage. The 45Q tax credit provides significant financial incentives for carbon capture projects, with recent enhancements through the Inflation Reduction Act of 2022 increasing credit values to $85 per metric ton for CO2 storage.

The European Union has established the EU Emissions Trading System (EU ETS) as its primary regulatory mechanism, complemented by the CCS Directive (2009/31/EC) that provides a legal framework specifically for geological storage of CO2. The EU Innovation Fund further supports commercial demonstration of innovative low-carbon technologies, including cryogenic capture systems.

In Asia, regulatory approaches differ substantially. China has included carbon capture in its 14th Five-Year Plan and is developing provincial carbon trading markets, while Japan has focused on creating technology-specific standards through its Ministry of Economy, Trade and Industry (METI). South Korea has implemented both a national emissions trading scheme and R&D subsidies for carbon capture technologies.

International standards and protocols also influence regulatory frameworks, with the ISO/TC 265 developing standards for carbon capture, transportation, and geological storage. The London Protocol and its 2009 amendment address transboundary CO2 transport for geological storage purposes, though ratification remains incomplete.

For cryogenic CO2 capture specifically, additional regulatory considerations include safety standards for cryogenic equipment handling, risk assessment protocols for low-temperature operations, and specialized permitting requirements for facilities using cryogenic processes. These requirements often fall under industrial safety regulations rather than environmental frameworks, creating potential regulatory gaps.

Emerging regulatory trends include the development of carbon border adjustment mechanisms, lifecycle assessment requirements for captured carbon, and integration of environmental justice considerations into permitting processes. Harmonization efforts are also underway to create more consistent international standards, potentially reducing regulatory barriers to technology transfer and global deployment of cryogenic capture systems.

In the United States, carbon capture deployments are primarily regulated under the Environmental Protection Agency's (EPA) Clean Air Act and Underground Injection Control Program, which establish standards for CO2 transport and storage. The 45Q tax credit provides significant financial incentives for carbon capture projects, with recent enhancements through the Inflation Reduction Act of 2022 increasing credit values to $85 per metric ton for CO2 storage.

The European Union has established the EU Emissions Trading System (EU ETS) as its primary regulatory mechanism, complemented by the CCS Directive (2009/31/EC) that provides a legal framework specifically for geological storage of CO2. The EU Innovation Fund further supports commercial demonstration of innovative low-carbon technologies, including cryogenic capture systems.

In Asia, regulatory approaches differ substantially. China has included carbon capture in its 14th Five-Year Plan and is developing provincial carbon trading markets, while Japan has focused on creating technology-specific standards through its Ministry of Economy, Trade and Industry (METI). South Korea has implemented both a national emissions trading scheme and R&D subsidies for carbon capture technologies.

International standards and protocols also influence regulatory frameworks, with the ISO/TC 265 developing standards for carbon capture, transportation, and geological storage. The London Protocol and its 2009 amendment address transboundary CO2 transport for geological storage purposes, though ratification remains incomplete.

For cryogenic CO2 capture specifically, additional regulatory considerations include safety standards for cryogenic equipment handling, risk assessment protocols for low-temperature operations, and specialized permitting requirements for facilities using cryogenic processes. These requirements often fall under industrial safety regulations rather than environmental frameworks, creating potential regulatory gaps.

Emerging regulatory trends include the development of carbon border adjustment mechanisms, lifecycle assessment requirements for captured carbon, and integration of environmental justice considerations into permitting processes. Harmonization efforts are also underway to create more consistent international standards, potentially reducing regulatory barriers to technology transfer and global deployment of cryogenic capture systems.

Socioeconomic Impact of Cryogenic CO2 Capture Implementation

The implementation of cryogenic CO2 capture technology extends far beyond environmental benefits, creating significant socioeconomic ripples across multiple sectors. Job creation represents one of the most immediate positive impacts, with new employment opportunities emerging throughout the value chain—from manufacturing specialized cryogenic equipment to facility construction, operation, and maintenance. Analysis of similar large-scale environmental technology deployments suggests that each major cryogenic CO2 capture facility could generate between 200-500 direct jobs and up to 1,500 indirect positions in supporting industries.

Economic diversification presents another substantial benefit, particularly for regions historically dependent on fossil fuel industries. Communities facing economic challenges due to the energy transition can leverage cryogenic CO2 capture implementation to develop new industrial capabilities, attracting investment and creating alternative revenue streams. This transition pathway offers a more gradual adaptation period compared to abrupt shifts away from carbon-intensive industries.

The technology also creates opportunities for industrial symbiosis, where captured CO2 becomes a valuable input for other processes. Industries such as enhanced oil recovery, food and beverage production, and synthetic fuel manufacturing can utilize the captured carbon, creating additional economic value chains. This circular economy approach maximizes resource efficiency while generating new market opportunities.

From a global competitiveness perspective, regions that develop expertise in cryogenic CO2 capture position themselves advantageously in the emerging low-carbon economy. Early adopters can export technology, expertise, and services to international markets, establishing leadership in climate solutions. Countries like Norway, Canada, and Japan have already begun strategic investments in this domain to secure future market advantages.

However, implementation challenges include significant upfront capital requirements that may strain public and private budgets. The high initial investment costs—ranging from $60-120 million for medium-scale facilities—can create financial barriers, particularly for economically disadvantaged communities. This raises equity concerns about which regions can afford to implement these technologies and potentially benefit from their economic advantages.

Energy price impacts must also be considered, as the energy-intensive nature of cryogenic processes may increase operational costs for industries and potentially affect consumer energy prices. Without careful policy design, these costs could disproportionately affect lower-income households, exacerbating energy poverty concerns in some regions.

Economic diversification presents another substantial benefit, particularly for regions historically dependent on fossil fuel industries. Communities facing economic challenges due to the energy transition can leverage cryogenic CO2 capture implementation to develop new industrial capabilities, attracting investment and creating alternative revenue streams. This transition pathway offers a more gradual adaptation period compared to abrupt shifts away from carbon-intensive industries.

The technology also creates opportunities for industrial symbiosis, where captured CO2 becomes a valuable input for other processes. Industries such as enhanced oil recovery, food and beverage production, and synthetic fuel manufacturing can utilize the captured carbon, creating additional economic value chains. This circular economy approach maximizes resource efficiency while generating new market opportunities.

From a global competitiveness perspective, regions that develop expertise in cryogenic CO2 capture position themselves advantageously in the emerging low-carbon economy. Early adopters can export technology, expertise, and services to international markets, establishing leadership in climate solutions. Countries like Norway, Canada, and Japan have already begun strategic investments in this domain to secure future market advantages.

However, implementation challenges include significant upfront capital requirements that may strain public and private budgets. The high initial investment costs—ranging from $60-120 million for medium-scale facilities—can create financial barriers, particularly for economically disadvantaged communities. This raises equity concerns about which regions can afford to implement these technologies and potentially benefit from their economic advantages.

Energy price impacts must also be considered, as the energy-intensive nature of cryogenic processes may increase operational costs for industries and potentially affect consumer energy prices. Without careful policy design, these costs could disproportionately affect lower-income households, exacerbating energy poverty concerns in some regions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!