Compare Thermopile Vs Pyroelectric Detectors in Spectroscopy

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermopile and Pyroelectric Detector Evolution and Objectives

Thermal detectors have been pivotal in the evolution of spectroscopy since the early 19th century, with thermopiles and pyroelectric detectors emerging as two dominant technologies. The thermopile detector, first conceptualized by Thomas Johann Seebeck in 1821, operates on the thermoelectric effect, converting temperature differences directly into electrical voltage. This fundamental principle has remained unchanged, though significant advancements in materials science and manufacturing techniques have dramatically improved performance parameters.

Pyroelectric detectors, by contrast, emerged later in the spectroscopy landscape, gaining prominence in the mid-20th century. These detectors function based on the pyroelectric effect, wherein certain materials generate a temporary voltage when their temperature changes. Unlike thermopiles, which respond to absolute temperature differences, pyroelectric detectors respond to temperature changes over time, making them inherently AC-coupled devices.

The technological evolution of thermopiles has been marked by several key milestones. Early thermopiles utilized metal junctions, primarily bismuth-antimony, offering modest sensitivity. The 1960s saw the introduction of semiconductor-based thermopiles, significantly enhancing detection capabilities. Modern thermopiles employ thin-film technology and MEMS (Micro-Electro-Mechanical Systems) fabrication techniques, resulting in miniaturized devices with improved thermal isolation and response characteristics.

Pyroelectric detector development has followed a parallel but distinct trajectory. Initial implementations used single-crystal materials like lithium tantalate (LiTaO₃). The 1970s and 1980s witnessed the development of ceramic pyroelectric materials, while recent decades have seen the emergence of thin-film pyroelectric materials and advanced electrode configurations, substantially improving signal-to-noise ratios and response times.

The current technological landscape shows a convergence in certain application areas but also increasing specialization. Thermopiles have evolved toward higher sensitivity and stability in continuous measurement scenarios, while pyroelectric detectors have been optimized for rapid, chopped-beam applications where their inherent AC response is advantageous.

The primary objective in comparing these technologies for spectroscopic applications is to establish clear performance boundaries and application-specific advantages. This includes quantifying sensitivity differences across various spectral regions, evaluating response time variations, assessing temperature stability characteristics, and determining noise equivalent power under different operating conditions. Additionally, this comparison aims to identify emerging hybrid approaches that might combine the strengths of both technologies.

Understanding the evolutionary paths of these detector technologies provides crucial context for evaluating their current capabilities and limitations, ultimately informing strategic decisions about their implementation in next-generation spectroscopic instruments.

Pyroelectric detectors, by contrast, emerged later in the spectroscopy landscape, gaining prominence in the mid-20th century. These detectors function based on the pyroelectric effect, wherein certain materials generate a temporary voltage when their temperature changes. Unlike thermopiles, which respond to absolute temperature differences, pyroelectric detectors respond to temperature changes over time, making them inherently AC-coupled devices.

The technological evolution of thermopiles has been marked by several key milestones. Early thermopiles utilized metal junctions, primarily bismuth-antimony, offering modest sensitivity. The 1960s saw the introduction of semiconductor-based thermopiles, significantly enhancing detection capabilities. Modern thermopiles employ thin-film technology and MEMS (Micro-Electro-Mechanical Systems) fabrication techniques, resulting in miniaturized devices with improved thermal isolation and response characteristics.

Pyroelectric detector development has followed a parallel but distinct trajectory. Initial implementations used single-crystal materials like lithium tantalate (LiTaO₃). The 1970s and 1980s witnessed the development of ceramic pyroelectric materials, while recent decades have seen the emergence of thin-film pyroelectric materials and advanced electrode configurations, substantially improving signal-to-noise ratios and response times.

The current technological landscape shows a convergence in certain application areas but also increasing specialization. Thermopiles have evolved toward higher sensitivity and stability in continuous measurement scenarios, while pyroelectric detectors have been optimized for rapid, chopped-beam applications where their inherent AC response is advantageous.

The primary objective in comparing these technologies for spectroscopic applications is to establish clear performance boundaries and application-specific advantages. This includes quantifying sensitivity differences across various spectral regions, evaluating response time variations, assessing temperature stability characteristics, and determining noise equivalent power under different operating conditions. Additionally, this comparison aims to identify emerging hybrid approaches that might combine the strengths of both technologies.

Understanding the evolutionary paths of these detector technologies provides crucial context for evaluating their current capabilities and limitations, ultimately informing strategic decisions about their implementation in next-generation spectroscopic instruments.

Spectroscopy Market Demand Analysis

The global spectroscopy market has been experiencing robust growth, driven by increasing applications across various industries including pharmaceuticals, biotechnology, food and beverage, environmental testing, and academic research. The market was valued at approximately 13.2 billion USD in 2021 and is projected to reach 20.5 billion USD by 2028, growing at a CAGR of 6.7% during the forecast period.

Infrared spectroscopy, where both thermopile and pyroelectric detectors play crucial roles, represents a significant segment of this market. The demand for these detection technologies is particularly strong in pharmaceutical quality control, environmental monitoring, and industrial process control applications, where precise molecular identification and quantification are essential.

Thermopile detectors are witnessing increased demand in portable and handheld spectroscopic devices due to their stability, reliability, and ability to operate without cooling systems. The growing need for field-deployable analytical instruments in environmental monitoring and food safety has created a substantial market opportunity for thermopile-based spectrometers. Their lower cost compared to cooled detectors makes them attractive for budget-conscious market segments.

Pyroelectric detectors, meanwhile, are experiencing heightened demand in applications requiring higher sensitivity and faster response times. The pharmaceutical industry, in particular, has shown strong interest in pyroelectric-based systems for quality control processes where rapid analysis is critical. The market for these detectors is also expanding in security and defense applications, where quick identification of substances is paramount.

Regional analysis indicates that North America currently holds the largest market share for advanced spectroscopic technologies, followed by Europe. However, the Asia-Pacific region is demonstrating the fastest growth rate, driven by expanding industrial infrastructure, increasing research activities, and growing awareness about quality control in manufacturing processes.

End-user trends reveal a shift toward more compact, user-friendly spectroscopic instruments that can be operated by personnel with minimal technical training. This has created a specific demand for both detector types in simplified, application-specific instruments rather than complex laboratory equipment.

The COVID-19 pandemic has further accelerated market growth by highlighting the importance of rapid analytical techniques in healthcare and pharmaceutical research. Both detector technologies have benefited from this trend, with increased adoption in virus detection and vaccine development applications.

Industry forecasts suggest that the demand for higher performance-to-cost ratio in spectroscopic instruments will continue to drive innovation in both thermopile and pyroelectric detector technologies, with particular emphasis on improving sensitivity, reducing size, and enhancing integration capabilities with other analytical systems.

Infrared spectroscopy, where both thermopile and pyroelectric detectors play crucial roles, represents a significant segment of this market. The demand for these detection technologies is particularly strong in pharmaceutical quality control, environmental monitoring, and industrial process control applications, where precise molecular identification and quantification are essential.

Thermopile detectors are witnessing increased demand in portable and handheld spectroscopic devices due to their stability, reliability, and ability to operate without cooling systems. The growing need for field-deployable analytical instruments in environmental monitoring and food safety has created a substantial market opportunity for thermopile-based spectrometers. Their lower cost compared to cooled detectors makes them attractive for budget-conscious market segments.

Pyroelectric detectors, meanwhile, are experiencing heightened demand in applications requiring higher sensitivity and faster response times. The pharmaceutical industry, in particular, has shown strong interest in pyroelectric-based systems for quality control processes where rapid analysis is critical. The market for these detectors is also expanding in security and defense applications, where quick identification of substances is paramount.

Regional analysis indicates that North America currently holds the largest market share for advanced spectroscopic technologies, followed by Europe. However, the Asia-Pacific region is demonstrating the fastest growth rate, driven by expanding industrial infrastructure, increasing research activities, and growing awareness about quality control in manufacturing processes.

End-user trends reveal a shift toward more compact, user-friendly spectroscopic instruments that can be operated by personnel with minimal technical training. This has created a specific demand for both detector types in simplified, application-specific instruments rather than complex laboratory equipment.

The COVID-19 pandemic has further accelerated market growth by highlighting the importance of rapid analytical techniques in healthcare and pharmaceutical research. Both detector technologies have benefited from this trend, with increased adoption in virus detection and vaccine development applications.

Industry forecasts suggest that the demand for higher performance-to-cost ratio in spectroscopic instruments will continue to drive innovation in both thermopile and pyroelectric detector technologies, with particular emphasis on improving sensitivity, reducing size, and enhancing integration capabilities with other analytical systems.

Current Technical Limitations and Challenges

Despite the widespread application of thermopile and pyroelectric detectors in spectroscopy, both technologies face significant limitations that impact their performance and applicability. Thermopile detectors, while offering excellent stability and DC response capabilities, suffer from relatively slow response times typically in the range of 10-100 milliseconds. This temporal limitation restricts their utility in applications requiring rapid signal acquisition or high-frequency modulation.

The sensitivity of thermopile detectors presents another challenge, as they generally exhibit lower responsivity compared to pyroelectric alternatives, particularly in the absence of optical concentration elements. This reduced sensitivity necessitates additional signal amplification, potentially introducing noise and compromising measurement accuracy in low-signal environments.

Thermal management represents a critical challenge for thermopile technology. These detectors are susceptible to ambient temperature fluctuations, requiring sophisticated temperature compensation mechanisms to maintain measurement stability. Without proper thermal isolation, environmental variations can induce significant measurement drift, undermining long-term reliability.

Pyroelectric detectors, while offering superior sensitivity and faster response times (typically 1-10 milliseconds), face their own set of limitations. Most notably, they fundamentally cannot measure constant radiation, requiring chopped or modulated input signals. This operational constraint necessitates additional mechanical components like choppers, increasing system complexity and potential points of failure.

The pyroelectric materials themselves present challenges, with many exhibiting temperature-dependent performance characteristics that can compromise measurement consistency across varying environmental conditions. Material aging effects can also gradually alter detector response characteristics over time, necessitating more frequent recalibration.

Microphonic sensitivity represents another significant challenge for pyroelectric technology. These detectors can generate spurious signals in response to mechanical vibration or acoustic noise, potentially contaminating spectroscopic measurements in industrial or field environments where vibration isolation is impractical.

Both detector types face manufacturing challenges related to miniaturization and integration with modern microelectronics. As spectroscopic applications increasingly demand smaller form factors and lower power consumption, the thermal isolation requirements of these detectors can conflict with size reduction goals. This tension between thermal performance and miniaturization represents a fundamental engineering challenge.

Cost considerations also present limitations, particularly for high-performance variants of both technologies. Specialized materials, precision manufacturing processes, and complex signal processing requirements contribute to higher costs that may restrict adoption in cost-sensitive applications or emerging markets.

The sensitivity of thermopile detectors presents another challenge, as they generally exhibit lower responsivity compared to pyroelectric alternatives, particularly in the absence of optical concentration elements. This reduced sensitivity necessitates additional signal amplification, potentially introducing noise and compromising measurement accuracy in low-signal environments.

Thermal management represents a critical challenge for thermopile technology. These detectors are susceptible to ambient temperature fluctuations, requiring sophisticated temperature compensation mechanisms to maintain measurement stability. Without proper thermal isolation, environmental variations can induce significant measurement drift, undermining long-term reliability.

Pyroelectric detectors, while offering superior sensitivity and faster response times (typically 1-10 milliseconds), face their own set of limitations. Most notably, they fundamentally cannot measure constant radiation, requiring chopped or modulated input signals. This operational constraint necessitates additional mechanical components like choppers, increasing system complexity and potential points of failure.

The pyroelectric materials themselves present challenges, with many exhibiting temperature-dependent performance characteristics that can compromise measurement consistency across varying environmental conditions. Material aging effects can also gradually alter detector response characteristics over time, necessitating more frequent recalibration.

Microphonic sensitivity represents another significant challenge for pyroelectric technology. These detectors can generate spurious signals in response to mechanical vibration or acoustic noise, potentially contaminating spectroscopic measurements in industrial or field environments where vibration isolation is impractical.

Both detector types face manufacturing challenges related to miniaturization and integration with modern microelectronics. As spectroscopic applications increasingly demand smaller form factors and lower power consumption, the thermal isolation requirements of these detectors can conflict with size reduction goals. This tension between thermal performance and miniaturization represents a fundamental engineering challenge.

Cost considerations also present limitations, particularly for high-performance variants of both technologies. Specialized materials, precision manufacturing processes, and complex signal processing requirements contribute to higher costs that may restrict adoption in cost-sensitive applications or emerging markets.

Comparative Analysis of Detection Methodologies

01 Thermopile detector design and performance characteristics

Thermopile detectors utilize the Seebeck effect to convert thermal energy into electrical signals. Their performance is characterized by high sensitivity, stability, and wide spectral response. Design improvements include optimized thermal isolation structures, enhanced absorber materials, and specialized junction configurations that increase temperature differentials. These detectors typically offer better signal-to-noise ratios at room temperature compared to other thermal detectors, making them suitable for applications requiring precise temperature measurements without cooling systems.- Thermopile detector design and performance characteristics: Thermopile detectors utilize the Seebeck effect to convert thermal energy into electrical signals. Their performance is characterized by high sensitivity, stability, and wide spectral response. Design improvements focus on optimizing the thermoelectric materials, junction configurations, and thermal isolation to enhance signal-to-noise ratio. Advanced thermopile designs incorporate multiple thermocouples in series to amplify output voltage and improve detection capabilities across various temperature ranges.

- Pyroelectric detector materials and sensitivity enhancements: Pyroelectric detectors operate based on temperature-dependent spontaneous polarization changes in certain materials. Performance improvements involve developing specialized materials with higher pyroelectric coefficients and lower dielectric constants. Common materials include lithium tantalate, lead zirconate titanate (PZT), and modified barium strontium titanate. Sensitivity enhancements are achieved through material doping, thin-film fabrication techniques, and optimized electrode configurations that maximize charge collection efficiency.

- Comparative performance between thermopile and pyroelectric technologies: Thermopile and pyroelectric detectors exhibit distinct performance characteristics suited for different applications. Thermopiles offer continuous DC response, higher temperature stability, and no need for optical choppers, but generally have slower response times. Pyroelectric detectors provide faster response to radiation changes, higher sensitivity for transient signals, and better performance in room-temperature operations. Selection between these technologies depends on specific requirements for response time, frequency range, operating temperature, and power consumption.

- Integration and packaging techniques for improved detection: Advanced integration and packaging techniques significantly enhance detector performance. These include vacuum packaging to reduce thermal conductance losses, specialized substrate materials for thermal isolation, and integrated optical elements like filters and concentrators. MEMS-based fabrication enables miniaturization while maintaining or improving sensitivity. Hermetic sealing protects sensitive elements from environmental factors, while innovative heat sink designs and thermal management strategies optimize temperature stability and response characteristics.

- Signal processing and noise reduction methods: Signal processing and noise reduction techniques are crucial for maximizing detector performance. These include specialized amplifier circuits designed for high impedance sensors, digital filtering algorithms to improve signal-to-noise ratio, and temperature compensation methods. Advanced techniques incorporate chopper stabilization, lock-in amplification, and adaptive filtering. Integration with application-specific integrated circuits (ASICs) enables on-chip signal conditioning, while machine learning algorithms can be employed for pattern recognition and false alarm reduction in complex detection scenarios.

02 Pyroelectric detector materials and sensitivity enhancements

Pyroelectric detectors operate based on the spontaneous polarization change in certain materials when subjected to temperature variations. Performance improvements focus on developing advanced pyroelectric materials with higher figures of merit, including lithium tantalate, modified lead zirconate titanate, and polymer-based composites. Sensitivity enhancements are achieved through material doping, crystalline orientation optimization, and electrode design modifications. These advancements result in improved responsivity, reduced noise, and faster response times for detecting rapid temperature changes.Expand Specific Solutions03 Comparative performance analysis between thermopile and pyroelectric technologies

Thermopile and pyroelectric detectors exhibit distinct performance characteristics suited for different applications. Thermopiles offer continuous DC response, higher temperature stability, and better performance in steady-state measurements, while pyroelectric detectors excel in detecting rapid temperature changes with higher sensitivity but require signal chopping for DC measurements. The selection between these technologies depends on specific application requirements including response time, operating temperature range, power consumption, and signal processing complexity. Hybrid approaches combining both technologies can leverage their complementary strengths for enhanced detection capabilities.Expand Specific Solutions04 Signal processing and noise reduction techniques

Advanced signal processing techniques significantly enhance the detection performance of both thermopile and pyroelectric sensors. These include specialized amplification circuits, digital filtering algorithms, and adaptive noise cancellation methods. Chopper stabilization techniques are particularly effective for pyroelectric detectors, while thermopiles benefit from offset compensation and drift correction algorithms. Integration of application-specific integrated circuits (ASICs) with these detectors enables on-chip signal conditioning, improving signal-to-noise ratios and detection thresholds while minimizing external interference and thermal drift effects.Expand Specific Solutions05 Packaging and integration solutions for improved performance

Detector packaging and integration approaches significantly impact overall performance metrics. Advanced vacuum packaging techniques reduce thermal conductance losses, while specialized optical windows and filters enhance spectral selectivity. Micromachined structures provide improved thermal isolation, reducing response time and increasing sensitivity. Integration with complementary sensors enables temperature compensation and multi-parameter detection capabilities. Modern MEMS fabrication techniques allow for miniaturization while maintaining or improving performance, facilitating integration into compact sensing systems with reduced power requirements.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The spectroscopy detector market is currently in a growth phase, with thermopile and pyroelectric detectors representing two competing technologies at different maturity levels. The global market is expanding steadily, driven by increasing applications in industrial process control, environmental monitoring, and medical diagnostics. Thermopile technology, championed by companies like Seiko Epson, Texas Instruments, and Nippon Ceramic, offers higher stability and wider spectral response but with slower response times. Pyroelectric detectors, advanced by Laser Point, Kipp & Zonen, and Hahn-Schickard, provide faster response and higher sensitivity but require signal chopping. Major industrial players like Robert Bosch, Philips, and Ricoh are investing in both technologies, indicating the market's strategic importance across multiple sectors as these complementary technologies continue to evolve for specialized applications.

Koninklijke Philips NV

Technical Solution: Philips has developed a hybrid spectroscopic platform that intelligently combines both thermopile and pyroelectric detector technologies to maximize performance across diverse applications. Their system employs thermopile arrays for continuous baseline measurements and absolute calibration, while simultaneously utilizing pyroelectric elements for high-sensitivity detection of rapid spectral changes. This dual-detector approach is particularly valuable in medical diagnostic applications where both steady-state and dynamic measurements provide complementary information. Philips' proprietary signal processing algorithms effectively merge data from both detector types, compensating for the limitations of each while preserving their respective advantages. The company has implemented this technology in portable spectroscopic devices that can identify multiple biomarkers in breath and bodily fluids, demonstrating superior performance compared to single-detector approaches.

Strengths: Combines advantages of both technologies; versatile across multiple application scenarios; excellent performance-to-cost ratio for complex analytical tasks. Weaknesses: Increased system complexity; requires sophisticated calibration and signal processing; larger form factor than single-detector solutions.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has engineered advanced integrated circuit solutions specifically designed to optimize the performance of both thermopile and pyroelectric detectors in spectroscopic applications. Their technology includes specialized analog front-end processors that provide adaptive gain control, temperature compensation, and noise filtering tailored to the unique characteristics of each detector type. TI's solutions feature programmable signal conditioning pathways that can be dynamically reconfigured based on environmental conditions and measurement requirements, maximizing detector performance across varying scenarios. The company has developed ultra-low-power readout architectures that enable continuous spectroscopic monitoring in battery-powered and energy-harvesting applications, extending operational lifetimes by orders of magnitude compared to conventional approaches. Their integrated systems include embedded machine learning capabilities that can identify specific spectral signatures directly at the sensor level, reducing data transmission requirements and enabling real-time decision making.

Strengths: Industry-leading power efficiency; exceptional signal processing capabilities; highly configurable to optimize for specific application requirements. Weaknesses: Requires significant expertise to fully utilize advanced features; higher initial implementation complexity; optimal performance depends on proper system integration.

Key Patents and Innovations in IR Detector Technology

Thermal sensor combination

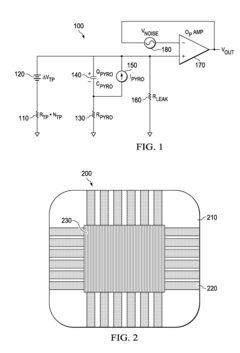

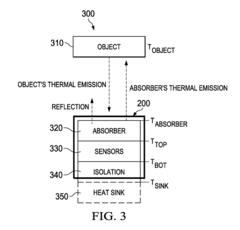

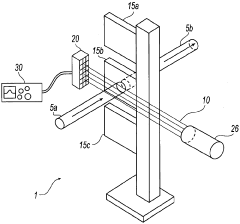

PatentActiveUS20170153146A1

Innovation

- A microelectronic device combining thermopile and pyroelectric sensors with a thermal isolation membrane and heat sink, where the thermopile elements are thermally coupled to both the heat absorber and sink, and pyroelectric elements are used to stabilize the voltage response, achieving similar temperature response coefficients and improved signal-to-noise ratio.

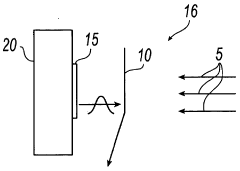

Photoacoustic joulemeter utilizing beam deflection technique

PatentWO2009023173A1

Innovation

- A photoacoustic joulemeter utilizing the photothermal deflection technique with multiple parallel probe beams to detect changes in the refractive index of a medium adjacent to the absorptive surface, allowing for real-time, non-destructive measurement of laser properties like spot size, beam profile, and total energy without significantly absorbing or splitting the laser beam.

Performance Metrics and Benchmarking Standards

Establishing standardized performance metrics for thermal detectors in spectroscopy is essential for objective comparison between thermopile and pyroelectric technologies. The industry has developed several key benchmarking parameters that serve as evaluation criteria for these detector types across various spectroscopic applications.

Responsivity, measured in V/W, represents the output voltage generated per watt of incident radiation and serves as a primary performance indicator. Thermopiles typically offer responsivity values ranging from 30-300 V/W, while pyroelectric detectors demonstrate higher values between 100-1500 V/W, making pyroelectric detectors generally more sensitive to small radiation changes.

Noise Equivalent Power (NEP), expressed in W/√Hz, indicates the minimum detectable power per square root bandwidth. Lower NEP values signify better performance, with thermopiles achieving 0.5-5 nW/√Hz and pyroelectric detectors reaching 0.1-1 nW/√Hz, highlighting the pyroelectric advantage in detecting weak signals.

Frequency response represents another critical benchmark, with thermopiles operating optimally below 25 Hz and pyroelectric detectors functioning effectively between 0.1-1000 Hz. This difference significantly impacts their suitability for various spectroscopic techniques.

Temperature coefficient, measuring detector stability across ambient temperature variations, shows thermopiles with coefficients of 0.1-0.2%/°C compared to pyroelectric detectors' 0.5-2%/°C, indicating superior thermopile stability in fluctuating environments.

Standardized testing protocols have emerged to ensure consistent evaluation across manufacturers. These include ASTM E1543 for thermal detector calibration, ISO 21254 for laser-induced damage threshold testing, and MIL-STD-810 for environmental stress testing, providing a framework for reliable performance comparison.

Application-specific benchmarks have also been developed for specialized fields. In gas analysis spectroscopy, response time and selectivity serve as key metrics, while in thermal imaging, spatial resolution and thermal sensitivity (NETD) are prioritized. Medical diagnostic applications emphasize reproducibility and biological sample compatibility.

Recent advancements in benchmarking include real-time performance monitoring systems that track detector degradation over time and AI-assisted calibration techniques that compensate for environmental variations, ensuring more accurate comparative analysis between thermopile and pyroelectric technologies in evolving spectroscopic applications.

Responsivity, measured in V/W, represents the output voltage generated per watt of incident radiation and serves as a primary performance indicator. Thermopiles typically offer responsivity values ranging from 30-300 V/W, while pyroelectric detectors demonstrate higher values between 100-1500 V/W, making pyroelectric detectors generally more sensitive to small radiation changes.

Noise Equivalent Power (NEP), expressed in W/√Hz, indicates the minimum detectable power per square root bandwidth. Lower NEP values signify better performance, with thermopiles achieving 0.5-5 nW/√Hz and pyroelectric detectors reaching 0.1-1 nW/√Hz, highlighting the pyroelectric advantage in detecting weak signals.

Frequency response represents another critical benchmark, with thermopiles operating optimally below 25 Hz and pyroelectric detectors functioning effectively between 0.1-1000 Hz. This difference significantly impacts their suitability for various spectroscopic techniques.

Temperature coefficient, measuring detector stability across ambient temperature variations, shows thermopiles with coefficients of 0.1-0.2%/°C compared to pyroelectric detectors' 0.5-2%/°C, indicating superior thermopile stability in fluctuating environments.

Standardized testing protocols have emerged to ensure consistent evaluation across manufacturers. These include ASTM E1543 for thermal detector calibration, ISO 21254 for laser-induced damage threshold testing, and MIL-STD-810 for environmental stress testing, providing a framework for reliable performance comparison.

Application-specific benchmarks have also been developed for specialized fields. In gas analysis spectroscopy, response time and selectivity serve as key metrics, while in thermal imaging, spatial resolution and thermal sensitivity (NETD) are prioritized. Medical diagnostic applications emphasize reproducibility and biological sample compatibility.

Recent advancements in benchmarking include real-time performance monitoring systems that track detector degradation over time and AI-assisted calibration techniques that compensate for environmental variations, ensuring more accurate comparative analysis between thermopile and pyroelectric technologies in evolving spectroscopic applications.

Application-Specific Optimization Strategies

Optimizing the selection and implementation of thermal detectors in spectroscopy requires careful consideration of application-specific requirements. For high-precision laboratory spectroscopy, thermopile detectors offer superior advantages due to their exceptional DC stability and low noise characteristics. When configured with appropriate optical filters and signal processing algorithms, thermopiles can achieve detection limits in the nanowatt range, making them ideal for trace gas analysis and materials characterization applications where signal stability is paramount.

Pyroelectric detectors, conversely, excel in dynamic measurement scenarios such as process monitoring and quality control systems. Their inherent AC response characteristic can be leveraged through modulation techniques (typically 1-20 Hz) to achieve excellent signal-to-noise ratios in environments with fluctuating background radiation. This makes them particularly valuable in industrial spectroscopy applications where rapid sample throughput and resistance to environmental variations are critical performance factors.

Temperature management strategies differ significantly between these detector types. Thermopiles benefit from thermal stabilization systems that maintain constant reference junction temperatures, while pyroelectric implementations often incorporate temperature compensation circuits to mitigate drift effects. The selection of window materials and optical coatings must also be optimized according to the specific wavelength bands of interest, with germanium, silicon, and zinc selenide offering different transmission profiles across the infrared spectrum.

Signal processing requirements present another dimension for application-specific optimization. Thermopile-based systems typically employ low-noise amplifiers with careful attention to thermal drift compensation, while pyroelectric detector circuits require specialized charge amplifiers and phase-sensitive detection schemes to maximize performance. Modern digital signal processing techniques, including adaptive filtering and machine learning algorithms, can further enhance detection capabilities for both technologies when tailored to specific application requirements.

Form factor considerations also drive optimization strategies, with miniaturized thermopile arrays enabling portable spectroscopic instruments for field applications, while pyroelectric detector configurations can be optimized for scanning systems requiring rapid response characteristics. Power consumption profiles differ substantially, with thermopiles offering advantages for battery-operated devices due to their passive operation, while pyroelectric implementations may require more sophisticated power management to support their biasing and signal conditioning requirements.

Ultimately, hybrid approaches combining both technologies may yield optimal results for complex spectroscopic applications, leveraging the complementary strengths of each detector type through multiplexed optical paths or sequential measurement strategies. Such integrated solutions represent an emerging trend in advanced spectroscopic instrumentation design, particularly for multi-gas analyzers and hyperspectral imaging systems.

Pyroelectric detectors, conversely, excel in dynamic measurement scenarios such as process monitoring and quality control systems. Their inherent AC response characteristic can be leveraged through modulation techniques (typically 1-20 Hz) to achieve excellent signal-to-noise ratios in environments with fluctuating background radiation. This makes them particularly valuable in industrial spectroscopy applications where rapid sample throughput and resistance to environmental variations are critical performance factors.

Temperature management strategies differ significantly between these detector types. Thermopiles benefit from thermal stabilization systems that maintain constant reference junction temperatures, while pyroelectric implementations often incorporate temperature compensation circuits to mitigate drift effects. The selection of window materials and optical coatings must also be optimized according to the specific wavelength bands of interest, with germanium, silicon, and zinc selenide offering different transmission profiles across the infrared spectrum.

Signal processing requirements present another dimension for application-specific optimization. Thermopile-based systems typically employ low-noise amplifiers with careful attention to thermal drift compensation, while pyroelectric detector circuits require specialized charge amplifiers and phase-sensitive detection schemes to maximize performance. Modern digital signal processing techniques, including adaptive filtering and machine learning algorithms, can further enhance detection capabilities for both technologies when tailored to specific application requirements.

Form factor considerations also drive optimization strategies, with miniaturized thermopile arrays enabling portable spectroscopic instruments for field applications, while pyroelectric detector configurations can be optimized for scanning systems requiring rapid response characteristics. Power consumption profiles differ substantially, with thermopiles offering advantages for battery-operated devices due to their passive operation, while pyroelectric implementations may require more sophisticated power management to support their biasing and signal conditioning requirements.

Ultimately, hybrid approaches combining both technologies may yield optimal results for complex spectroscopic applications, leveraging the complementary strengths of each detector type through multiplexed optical paths or sequential measurement strategies. Such integrated solutions represent an emerging trend in advanced spectroscopic instrumentation design, particularly for multi-gas analyzers and hyperspectral imaging systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!