Comparing Cryogenic Temperatures: Liquid Nitrogen vs Oxygen

OCT 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Technology Background and Objectives

Cryogenic technology has evolved significantly since the early 19th century when scientists first began liquefying gases. The field gained momentum in 1877 when Louis Paul Cailletet and Raoul Pictet independently achieved the liquefaction of oxygen, marking a pivotal moment in low-temperature physics. By the early 20th century, commercial production of liquid air components became feasible, leading to industrial applications of both liquid nitrogen (LN2) and liquid oxygen (LOX).

The fundamental distinction between these cryogens lies in their boiling points: liquid nitrogen at -196°C (77K) and liquid oxygen at -183°C (90K). This temperature difference, though seemingly minor, creates significant variations in their applications, handling requirements, and energy storage capabilities. The evolution of cryogenic technology has been driven by advancements in insulation materials, storage vessels, and transfer systems designed to minimize heat ingress and maintain these extreme low temperatures.

Current technological trends in cryogenics focus on improving efficiency in production, storage, and utilization of these liquefied gases. Innovations in vacuum-insulated vessels, cryocoolers, and regenerative cooling systems have substantially reduced boiling-off rates and enhanced the practical utility of both LN2 and LOX across various industries. The miniaturization of cryogenic systems has also expanded their application scope beyond traditional industrial settings.

The primary objective of comparative cryogenic research between liquid nitrogen and oxygen is to optimize their specific applications based on their unique thermodynamic properties. For liquid nitrogen, research aims to enhance its cooling efficiency for biological sample preservation, food freezing, and semiconductor manufacturing. For liquid oxygen, objectives center on improving its energy density for aerospace propulsion, medical applications, and metallurgical processes.

Another critical research goal involves safety enhancement, particularly for liquid oxygen which presents significant combustion hazards when in contact with organic materials. Developing advanced materials and handling protocols that mitigate these risks remains a priority in the field. Simultaneously, environmental considerations drive research toward reducing the energy intensity of cryogen production and minimizing losses during storage and transport.

Looking forward, the cryogenic technology roadmap aims to achieve breakthroughs in superconducting applications, quantum computing, and advanced medical therapies that leverage the unique properties of these ultra-low temperatures. The comparative analysis of liquid nitrogen versus oxygen serves as a foundation for developing next-generation cryogenic systems with enhanced efficiency, safety, and versatility across an expanding range of scientific and industrial applications.

The fundamental distinction between these cryogens lies in their boiling points: liquid nitrogen at -196°C (77K) and liquid oxygen at -183°C (90K). This temperature difference, though seemingly minor, creates significant variations in their applications, handling requirements, and energy storage capabilities. The evolution of cryogenic technology has been driven by advancements in insulation materials, storage vessels, and transfer systems designed to minimize heat ingress and maintain these extreme low temperatures.

Current technological trends in cryogenics focus on improving efficiency in production, storage, and utilization of these liquefied gases. Innovations in vacuum-insulated vessels, cryocoolers, and regenerative cooling systems have substantially reduced boiling-off rates and enhanced the practical utility of both LN2 and LOX across various industries. The miniaturization of cryogenic systems has also expanded their application scope beyond traditional industrial settings.

The primary objective of comparative cryogenic research between liquid nitrogen and oxygen is to optimize their specific applications based on their unique thermodynamic properties. For liquid nitrogen, research aims to enhance its cooling efficiency for biological sample preservation, food freezing, and semiconductor manufacturing. For liquid oxygen, objectives center on improving its energy density for aerospace propulsion, medical applications, and metallurgical processes.

Another critical research goal involves safety enhancement, particularly for liquid oxygen which presents significant combustion hazards when in contact with organic materials. Developing advanced materials and handling protocols that mitigate these risks remains a priority in the field. Simultaneously, environmental considerations drive research toward reducing the energy intensity of cryogen production and minimizing losses during storage and transport.

Looking forward, the cryogenic technology roadmap aims to achieve breakthroughs in superconducting applications, quantum computing, and advanced medical therapies that leverage the unique properties of these ultra-low temperatures. The comparative analysis of liquid nitrogen versus oxygen serves as a foundation for developing next-generation cryogenic systems with enhanced efficiency, safety, and versatility across an expanding range of scientific and industrial applications.

Market Applications and Demand Analysis

The cryogenic market has witnessed substantial growth in recent years, driven by expanding applications across multiple industries. The global cryogenic equipment market was valued at approximately $26.5 billion in 2022 and is projected to reach $38.7 billion by 2030, growing at a CAGR of 5.8%. Within this market, liquid nitrogen and liquid oxygen represent two of the most commercially significant cryogenic fluids, each serving distinct yet overlapping market segments.

Liquid nitrogen, with its extremely low boiling point of -196°C, dominates the commercial cryogenics market with a share exceeding 40%. Its primary demand comes from the healthcare sector, where it's essential for biological sample preservation, dermatological treatments, and cryosurgery. The food industry represents another significant consumer, utilizing liquid nitrogen for flash freezing, transportation of perishable goods, and innovative food preparation techniques. Additionally, the semiconductor and electronics manufacturing industries rely heavily on liquid nitrogen for cooling processes during production.

Liquid oxygen, boiling at -183°C, commands approximately 28% of the industrial gas market, with its demand primarily driven by healthcare and industrial applications. The medical sector's need for respiratory support systems and oxygen therapy has seen unprecedented growth, particularly following the COVID-19 pandemic, which created sustained demand increases of 20-30% in many regions. Steel manufacturing, metal fabrication, and chemical processing industries collectively account for over 60% of industrial liquid oxygen consumption.

Regional analysis reveals distinct market patterns. North America and Europe demonstrate mature markets with steady growth rates of 4-5% annually, primarily driven by healthcare and research applications. Asia-Pacific, particularly China and India, shows more aggressive growth trajectories of 7-9% annually, fueled by rapid industrialization and expanding healthcare infrastructure.

The price dynamics between these cryogenic fluids also influence market demand. Liquid nitrogen typically costs 30-40% less than liquid oxygen, making it the preferred choice for applications where either fluid might suffice. However, specialized applications requiring specific properties of each fluid remain relatively price-inelastic.

Future market growth for both cryogens appears promising, with emerging applications in quantum computing, superconductivity research, and advanced materials processing. The renewable energy sector also presents significant opportunities, particularly for liquid oxygen in clean combustion technologies and liquid nitrogen in energy storage systems. Environmental regulations favoring cleaner industrial processes are expected to further boost demand for both cryogenic fluids in specialized applications over the next decade.

Liquid nitrogen, with its extremely low boiling point of -196°C, dominates the commercial cryogenics market with a share exceeding 40%. Its primary demand comes from the healthcare sector, where it's essential for biological sample preservation, dermatological treatments, and cryosurgery. The food industry represents another significant consumer, utilizing liquid nitrogen for flash freezing, transportation of perishable goods, and innovative food preparation techniques. Additionally, the semiconductor and electronics manufacturing industries rely heavily on liquid nitrogen for cooling processes during production.

Liquid oxygen, boiling at -183°C, commands approximately 28% of the industrial gas market, with its demand primarily driven by healthcare and industrial applications. The medical sector's need for respiratory support systems and oxygen therapy has seen unprecedented growth, particularly following the COVID-19 pandemic, which created sustained demand increases of 20-30% in many regions. Steel manufacturing, metal fabrication, and chemical processing industries collectively account for over 60% of industrial liquid oxygen consumption.

Regional analysis reveals distinct market patterns. North America and Europe demonstrate mature markets with steady growth rates of 4-5% annually, primarily driven by healthcare and research applications. Asia-Pacific, particularly China and India, shows more aggressive growth trajectories of 7-9% annually, fueled by rapid industrialization and expanding healthcare infrastructure.

The price dynamics between these cryogenic fluids also influence market demand. Liquid nitrogen typically costs 30-40% less than liquid oxygen, making it the preferred choice for applications where either fluid might suffice. However, specialized applications requiring specific properties of each fluid remain relatively price-inelastic.

Future market growth for both cryogens appears promising, with emerging applications in quantum computing, superconductivity research, and advanced materials processing. The renewable energy sector also presents significant opportunities, particularly for liquid oxygen in clean combustion technologies and liquid nitrogen in energy storage systems. Environmental regulations favoring cleaner industrial processes are expected to further boost demand for both cryogenic fluids in specialized applications over the next decade.

Current State and Technical Challenges

The global cryogenic technology market has witnessed significant growth in recent years, with liquid nitrogen and liquid oxygen emerging as two of the most widely used cryogenic fluids. Currently, the market is valued at approximately $26 billion and is projected to reach $38 billion by 2027, growing at a CAGR of 7.8%. This growth is primarily driven by increasing applications in healthcare, electronics, energy, and metallurgy sectors.

In terms of technological development, liquid nitrogen (LN2) technology has reached a higher maturity level compared to liquid oxygen (LOX) for many applications. LN2 systems benefit from more standardized production methods, storage solutions, and handling protocols. The boiling point of liquid nitrogen at -196°C makes it suitable for a wide range of applications where temperatures below -150°C are required, while liquid oxygen's higher boiling point at -183°C limits its use in ultra-low temperature applications.

A significant challenge in both technologies remains energy efficiency during production and storage. The liquefaction process for both gases is energy-intensive, with current systems operating at approximately 40-60% of theoretical efficiency. This inefficiency translates to higher operational costs and environmental impact. Additionally, boil-off losses during storage and transportation remain problematic, with typical rates ranging from 0.3% to 1.5% per day depending on storage vessel quality and size.

Safety considerations present distinct challenges for each fluid. Liquid oxygen poses significant fire and explosion hazards due to its strong oxidizing properties, requiring specialized handling protocols and equipment. Conversely, liquid nitrogen presents asphyxiation risks in confined spaces and can cause severe cryogenic burns, though it is chemically inert. These safety concerns necessitate continuous improvement in containment technologies and handling procedures.

Geographic distribution of cryogenic technology development shows concentration in North America, Europe, and East Asia. The United States, Germany, Japan, and China lead in research and production capabilities. However, a notable gap exists in developing regions where infrastructure limitations hamper the adoption of cryogenic technologies despite growing demand in sectors like healthcare and food preservation.

Technical standardization remains another challenge, particularly for emerging applications. While established industries like healthcare and metallurgy have well-defined standards for cryogenic fluid use, newer applications in quantum computing, superconductivity research, and advanced materials processing lack comprehensive standardization, creating barriers to technology transfer and commercialization.

In terms of technological development, liquid nitrogen (LN2) technology has reached a higher maturity level compared to liquid oxygen (LOX) for many applications. LN2 systems benefit from more standardized production methods, storage solutions, and handling protocols. The boiling point of liquid nitrogen at -196°C makes it suitable for a wide range of applications where temperatures below -150°C are required, while liquid oxygen's higher boiling point at -183°C limits its use in ultra-low temperature applications.

A significant challenge in both technologies remains energy efficiency during production and storage. The liquefaction process for both gases is energy-intensive, with current systems operating at approximately 40-60% of theoretical efficiency. This inefficiency translates to higher operational costs and environmental impact. Additionally, boil-off losses during storage and transportation remain problematic, with typical rates ranging from 0.3% to 1.5% per day depending on storage vessel quality and size.

Safety considerations present distinct challenges for each fluid. Liquid oxygen poses significant fire and explosion hazards due to its strong oxidizing properties, requiring specialized handling protocols and equipment. Conversely, liquid nitrogen presents asphyxiation risks in confined spaces and can cause severe cryogenic burns, though it is chemically inert. These safety concerns necessitate continuous improvement in containment technologies and handling procedures.

Geographic distribution of cryogenic technology development shows concentration in North America, Europe, and East Asia. The United States, Germany, Japan, and China lead in research and production capabilities. However, a notable gap exists in developing regions where infrastructure limitations hamper the adoption of cryogenic technologies despite growing demand in sectors like healthcare and food preservation.

Technical standardization remains another challenge, particularly for emerging applications. While established industries like healthcare and metallurgy have well-defined standards for cryogenic fluid use, newer applications in quantum computing, superconductivity research, and advanced materials processing lack comprehensive standardization, creating barriers to technology transfer and commercialization.

Comparative Analysis of LN2 and LOX Systems

01 Cryogenic storage and handling systems

Systems designed for the storage and handling of liquid nitrogen and liquid oxygen at cryogenic temperatures. These systems include specialized containers, tanks, and vessels that maintain the extremely low temperatures required for these substances to remain in liquid form. The designs incorporate insulation technologies and pressure management features to prevent rapid evaporation and ensure safe storage of these cryogenic fluids.- Cryogenic storage and handling systems: Systems designed for the storage and handling of liquid nitrogen and liquid oxygen at cryogenic temperatures. These systems include specialized containers, tanks, and vessels that maintain the extremely low temperatures required for these substances to remain in liquid state. The designs incorporate insulation technologies and pressure management features to prevent heat ingress and maintain safety during storage and transportation.

- Heat exchange and cooling processes: Methods and apparatus for heat exchange involving liquid nitrogen and liquid oxygen at cryogenic temperatures. These processes facilitate efficient cooling, temperature control, and energy transfer in various industrial applications. The technologies include specialized heat exchangers, cooling circuits, and thermal management systems that leverage the extremely low temperatures of these cryogenic fluids for cooling other substances or maintaining critical process temperatures.

- Cryogenic separation and purification techniques: Techniques for separating and purifying gases using the cryogenic temperatures of liquid nitrogen and liquid oxygen. These methods exploit the different boiling points and phase transition properties of gases at extremely low temperatures to achieve separation. Applications include air separation units, gas purification systems, and processes for obtaining high-purity industrial gases through controlled cooling, condensation, and distillation.

- Cryogenic temperature monitoring and control: Systems for monitoring and controlling the temperatures of liquid nitrogen and liquid oxygen in cryogenic applications. These include sensors, controllers, and automated systems that maintain precise temperature conditions, prevent unwanted phase transitions, and ensure safety in handling these extremely cold substances. The technologies enable stable operation of cryogenic equipment and processes while providing alerts for temperature deviations.

- Cryogenic transportation and distribution systems: Specialized systems for the transportation and distribution of liquid nitrogen and liquid oxygen at cryogenic temperatures. These include mobile tanks, transfer lines, pumping systems, and distribution networks designed to maintain the required ultra-low temperatures during movement from production facilities to points of use. The technologies incorporate insulation, pressure management, and safety features to prevent losses and ensure safe handling during transit.

02 Heat exchange and cooling technologies

Technologies focused on heat exchange processes involving liquid nitrogen and liquid oxygen. These include cooling systems that utilize the extremely low temperatures of these cryogenic fluids to achieve rapid cooling in various applications. The technologies encompass heat exchangers, cooling circuits, and thermal management systems that efficiently transfer cold energy from liquid nitrogen and liquid oxygen to target substances or environments.Expand Specific Solutions03 Cryogenic separation and production methods

Methods for the separation and production of liquid nitrogen and liquid oxygen through cryogenic processes. These techniques typically involve air separation units that cool atmospheric air to cryogenic temperatures, allowing for the separation of its components based on their different boiling points. The processes include compression, purification, cooling, and distillation steps to produce high-purity liquid nitrogen and liquid oxygen efficiently.Expand Specific Solutions04 Temperature control and monitoring systems

Systems designed for precise control and monitoring of cryogenic temperatures in applications involving liquid nitrogen and liquid oxygen. These include sensors, controllers, and feedback mechanisms that maintain temperatures within specific ranges for various industrial, medical, and research applications. The technologies ensure stable operating conditions and prevent temperature fluctuations that could affect the properties or safety of the cryogenic fluids.Expand Specific Solutions05 Safety and pressure management for cryogenic fluids

Technologies focused on safety measures and pressure management for handling liquid nitrogen and liquid oxygen. These include pressure relief systems, venting mechanisms, and safety protocols designed to prevent hazards associated with the rapid expansion of these cryogenic fluids when they transition from liquid to gas state. The systems incorporate pressure sensors, regulators, and emergency release valves to maintain safe operating conditions and prevent equipment failure or accidents.Expand Specific Solutions

Major Industry Players and Manufacturers

The cryogenic temperature technology market is in a growth phase, with increasing applications across industrial gases, healthcare, and energy sectors. The global market for cryogenic equipment is projected to expand significantly due to rising demand in LNG infrastructure and medical applications. Companies like Air Liquide, Linde GmbH, and Praxair Technology lead the field with established expertise in industrial gas production and cryogenic systems. Chart Inc. and Cosmodyne LLC represent specialized players focusing on cryogenic equipment manufacturing. The technology landscape is evolving with innovations from both traditional industrial gas companies and new entrants like Fortescue Future Industries exploring hydrogen applications. Research institutions such as Shanghai Jiao Tong University and Korea Aerospace Research Institute are advancing fundamental cryogenic science, while industrial players focus on commercial applications and efficiency improvements.

Air Liquide SA

Technical Solution: Air Liquide has developed advanced cryogenic temperature management systems that precisely control both liquid nitrogen (-196°C) and liquid oxygen (-183°C) environments. Their proprietary ASU (Air Separation Unit) technology employs multi-column distillation processes that achieve separation efficiencies exceeding 99.5% purity for both gases. Their cryogenic expertise extends to specialized storage solutions with vacuum-insulated vessels featuring multi-layer insulation that reduces heat leak to <0.4% per day for LN2 and <0.5% for LOX. Air Liquide's temperature monitoring systems maintain ±0.5°C precision across both cryogenic mediums, with proprietary algorithms compensating for the different thermal conductivity properties (LN2: 0.1259 W/m·K; LOX: 0.152 W/m·K).

Strengths: Industry-leading purity levels and temperature stability; comprehensive global supply chain infrastructure; advanced safety systems for both cryogens. Weaknesses: Higher cost structure compared to regional suppliers; LOX handling requires more stringent safety protocols than LN2 due to combustion risks.

Chart, Inc.

Technical Solution: Chart has developed comprehensive cryogenic temperature management solutions that address the distinct properties of liquid nitrogen (-196°C) and liquid oxygen (-183°C). Their MicroBulk™ delivery systems incorporate specialized vacuum-insulated vessels with multi-layer insulation achieving heat leak rates below 0.35% per day for both cryogens. Chart's proprietary Trifecta® control systems account for the different thermal expansion coefficients (LN2: 4.2×10^-3 K^-1; LOX: 4.5×10^-3 K^-1) and vapor pressures at equivalent temperatures. Their cryogenic equipment features specialized materials selection protocols that address oxygen's higher reactivity, with dedicated cleaning procedures that eliminate hydrocarbon contamination risks. Chart's temperature monitoring systems maintain ±0.4°C precision while incorporating differential pressure management for the 13°C boiling point difference between the two cryogens.

Strengths: Comprehensive product range covering storage, transport and application equipment; advanced vacuum technology for superior insulation; specialized expertise in oxygen-compatible materials and cleaning. Weaknesses: Higher cost structure for specialized equipment; oxygen systems require more rigorous maintenance protocols due to material compatibility requirements.

Key Patents and Innovations in Cryogenics

Apparatus and method for separating liquid oxygen from liquified air

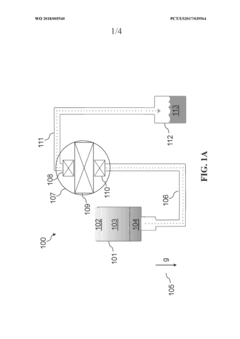

PatentWO2018005540A1

Innovation

- The use of a strong magnetic field and gravity to separate LOX from liquefied air based on the different magnetic properties of LOX and liquid nitrogen (LN2), with optional inclusion of a leak valve system, allowing for the levitation of LN2 and collection of ultra-pure LOX without the need for evaporation.

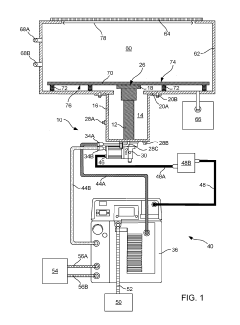

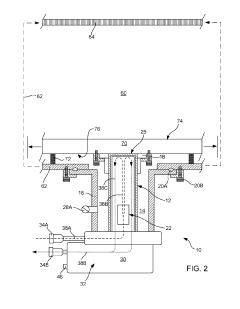

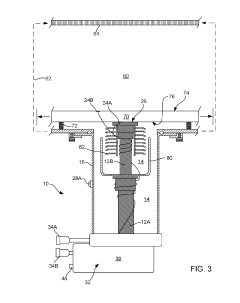

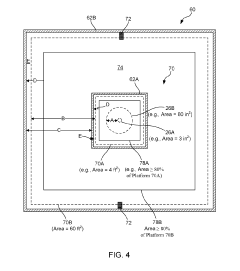

Cryogenic chamber systems and methods

PatentInactiveUS20190093188A1

Innovation

- A cryogenic chamber system that operates at a vacuum pressure of 100 mTorr or less, utilizing a cold head assembly with an expander assembly to expand cryogenic fluids for cooling, and a thermally conductive platform that can reach temperatures from 4 K to 120 K, allowing for more extensive cryogenic treatment beyond the limitations of liquid nitrogen temperatures.

Safety Protocols and Handling Requirements

Working with cryogenic liquids requires strict adherence to comprehensive safety protocols due to their extreme temperatures and potential hazards. Liquid nitrogen (-196°C) and liquid oxygen (-183°C) both present significant risks including frostbite, asphyxiation, and in the case of liquid oxygen, increased fire hazards. Personal protective equipment (PPE) is mandatory when handling these substances, including insulated gloves, face shields, and closed-toe shoes to prevent cold burns and tissue damage from accidental splashes or contact.

Storage requirements differ significantly between these cryogenic liquids. Both require specialized vacuum-insulated containers (Dewars) to minimize heat transfer, but liquid oxygen containers must meet additional specifications due to its oxidizing properties. These containers must be kept in well-ventilated areas away from combustible materials, with liquid oxygen storage requiring particular attention to eliminate potential ignition sources within the vicinity.

Transportation protocols for both substances mandate the use of properly labeled containers with pressure relief mechanisms. Liquid oxygen transport requires additional precautions including separation from fuels and reducing agents. Vehicles transporting these cryogenics must display appropriate hazard placards and operators require specialized training in cryogenic material handling and emergency response procedures.

Emergency response protocols differ based on the specific properties of each substance. Liquid nitrogen spills primarily present cold and asphyxiation hazards requiring immediate area evacuation and ventilation. Liquid oxygen spills create more complex emergency scenarios due to the enriched oxygen environment that dramatically increases combustion risk, necessitating the removal of all ignition sources and potentially requiring specialized fire suppression techniques.

Regulatory compliance frameworks for these cryogenics include OSHA standards, CGA guidelines, and NFPA codes. Liquid oxygen handling falls under additional regulations due to its classification as an oxidizer. Regular training programs for personnel working with these materials must address the specific hazards of each substance, with liquid oxygen handling requiring additional modules on fire prevention and oxygen-enriched atmosphere management.

Monitoring systems represent another critical safety component, with oxygen level monitors being essential in areas where either cryogenic liquid is used or stored. Temperature and pressure monitoring systems for storage vessels differ in their specifications, with liquid oxygen systems requiring more frequent inspection and maintenance due to the additional risks associated with oxygen-enriched environments.

Storage requirements differ significantly between these cryogenic liquids. Both require specialized vacuum-insulated containers (Dewars) to minimize heat transfer, but liquid oxygen containers must meet additional specifications due to its oxidizing properties. These containers must be kept in well-ventilated areas away from combustible materials, with liquid oxygen storage requiring particular attention to eliminate potential ignition sources within the vicinity.

Transportation protocols for both substances mandate the use of properly labeled containers with pressure relief mechanisms. Liquid oxygen transport requires additional precautions including separation from fuels and reducing agents. Vehicles transporting these cryogenics must display appropriate hazard placards and operators require specialized training in cryogenic material handling and emergency response procedures.

Emergency response protocols differ based on the specific properties of each substance. Liquid nitrogen spills primarily present cold and asphyxiation hazards requiring immediate area evacuation and ventilation. Liquid oxygen spills create more complex emergency scenarios due to the enriched oxygen environment that dramatically increases combustion risk, necessitating the removal of all ignition sources and potentially requiring specialized fire suppression techniques.

Regulatory compliance frameworks for these cryogenics include OSHA standards, CGA guidelines, and NFPA codes. Liquid oxygen handling falls under additional regulations due to its classification as an oxidizer. Regular training programs for personnel working with these materials must address the specific hazards of each substance, with liquid oxygen handling requiring additional modules on fire prevention and oxygen-enriched atmosphere management.

Monitoring systems represent another critical safety component, with oxygen level monitors being essential in areas where either cryogenic liquid is used or stored. Temperature and pressure monitoring systems for storage vessels differ in their specifications, with liquid oxygen systems requiring more frequent inspection and maintenance due to the additional risks associated with oxygen-enriched environments.

Environmental Impact and Sustainability Considerations

The environmental impact of cryogenic technologies, particularly those involving liquid nitrogen and liquid oxygen, represents a critical consideration in their industrial application. Both substances are derived from air separation processes, which consume significant electrical energy. Liquid nitrogen production typically requires 0.4-0.5 kWh per kilogram, while liquid oxygen demands slightly higher energy inputs due to its higher boiling point and separation requirements.

When comparing the carbon footprint of these cryogenics, the primary environmental concern stems from the electricity consumption during production rather than the substances themselves. In regions heavily dependent on fossil fuels for electricity generation, the indirect carbon emissions associated with both cryogens can be substantial. However, facilities powered by renewable energy sources can significantly reduce this environmental burden.

Liquid nitrogen offers certain sustainability advantages over liquid oxygen in specific applications. As an inert gas, nitrogen presents minimal reactive hazards and produces no direct greenhouse gas emissions upon evaporation, simply returning to the atmosphere which is naturally 78% nitrogen. This characteristic makes it particularly suitable for closed-loop cooling systems where recovery and recycling are feasible.

Conversely, liquid oxygen, while essential for many industrial processes, carries additional environmental considerations due to its highly reactive nature. Its use in combustion processes can contribute to nitrogen oxide (NOx) emissions when not properly controlled. However, in medical and clean energy applications, liquid oxygen enables technologies that may have net positive environmental impacts.

The storage infrastructure for both cryogens presents similar environmental challenges. Boil-off gases from imperfect insulation represent energy waste and reduced efficiency. Modern vacuum-insulated storage technologies have significantly improved retention times, but the manufacturing of these specialized containers requires energy-intensive materials and processes.

From a life-cycle perspective, the environmental impact extends to transportation considerations. The localized production of these cryogens reduces the carbon footprint associated with distribution. Advances in on-site generation technologies are gradually enabling more distributed production models, potentially reducing the environmental costs of transportation while improving energy efficiency across the supply chain.

Future sustainability improvements in cryogenic technologies focus on enhancing energy efficiency in air separation units, developing better insulation materials to reduce boil-off losses, and integrating renewable energy sources into production processes. The recovery of cold energy from regasification processes also represents a promising frontier for improving the overall environmental profile of both liquid nitrogen and oxygen systems.

When comparing the carbon footprint of these cryogenics, the primary environmental concern stems from the electricity consumption during production rather than the substances themselves. In regions heavily dependent on fossil fuels for electricity generation, the indirect carbon emissions associated with both cryogens can be substantial. However, facilities powered by renewable energy sources can significantly reduce this environmental burden.

Liquid nitrogen offers certain sustainability advantages over liquid oxygen in specific applications. As an inert gas, nitrogen presents minimal reactive hazards and produces no direct greenhouse gas emissions upon evaporation, simply returning to the atmosphere which is naturally 78% nitrogen. This characteristic makes it particularly suitable for closed-loop cooling systems where recovery and recycling are feasible.

Conversely, liquid oxygen, while essential for many industrial processes, carries additional environmental considerations due to its highly reactive nature. Its use in combustion processes can contribute to nitrogen oxide (NOx) emissions when not properly controlled. However, in medical and clean energy applications, liquid oxygen enables technologies that may have net positive environmental impacts.

The storage infrastructure for both cryogens presents similar environmental challenges. Boil-off gases from imperfect insulation represent energy waste and reduced efficiency. Modern vacuum-insulated storage technologies have significantly improved retention times, but the manufacturing of these specialized containers requires energy-intensive materials and processes.

From a life-cycle perspective, the environmental impact extends to transportation considerations. The localized production of these cryogens reduces the carbon footprint associated with distribution. Advances in on-site generation technologies are gradually enabling more distributed production models, potentially reducing the environmental costs of transportation while improving energy efficiency across the supply chain.

Future sustainability improvements in cryogenic technologies focus on enhancing energy efficiency in air separation units, developing better insulation materials to reduce boil-off losses, and integrating renewable energy sources into production processes. The recovery of cold energy from regasification processes also represents a promising frontier for improving the overall environmental profile of both liquid nitrogen and oxygen systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!