Measuring Liquid Nitrogen's Impact on Material Brittleness

OCT 7, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Testing Background and Objectives

Cryogenic testing has evolved significantly since the early 20th century when scientists first began exploring the effects of extreme cold on material properties. The field gained substantial momentum during the Space Race era (1950s-1960s) when aerospace applications demanded materials capable of withstanding extreme temperature variations. This historical progression has established cryogenic testing as a critical discipline in materials science, with liquid nitrogen emerging as one of the most widely used cryogenic fluids due to its relatively low cost, availability, and suitable temperature range (-196°C).

The fundamental principle underlying cryogenic brittleness testing involves the examination of how materials respond to mechanical stress when subjected to extremely low temperatures. At cryogenic temperatures, many materials—particularly metals and polymers—undergo significant changes in their mechanical properties, often becoming more brittle due to reduced molecular mobility and altered crystalline structures. This phenomenon has profound implications across numerous industries, including aerospace, medical devices, energy infrastructure, and advanced manufacturing.

Current technological trends in this field are moving toward more precise measurement methodologies, real-time monitoring systems, and standardized testing protocols that can accurately quantify the relationship between temperature and brittleness across diverse material categories. The integration of digital technologies and advanced sensors has enabled more sophisticated data collection during cryogenic testing, allowing for better predictive models of material behavior under extreme conditions.

The primary objective of our technical investigation is to develop a comprehensive understanding of how liquid nitrogen exposure affects material brittleness across various substance classes, with particular emphasis on emerging composite materials and advanced alloys. We aim to establish quantifiable metrics that can accurately predict brittleness transitions and failure points when materials are subjected to cryogenic conditions.

Secondary goals include identifying optimal testing methodologies that balance precision with practical applicability, developing standardized protocols for consistent measurement across different material categories, and exploring potential mitigation strategies for brittleness-induced failures. Additionally, we seek to investigate the reversibility of cryogenic effects—determining whether materials fully recover their original properties after returning to ambient temperatures or if permanent structural changes occur.

The technological significance of this research extends beyond immediate applications, potentially informing future material development strategies and enabling more reliable performance predictions for components operating in extreme environments. By establishing clear correlations between exposure parameters (duration, temperature cycling, rate of cooling) and resultant brittleness characteristics, this investigation aims to contribute valuable insights to the broader field of materials science and cryogenic engineering.

The fundamental principle underlying cryogenic brittleness testing involves the examination of how materials respond to mechanical stress when subjected to extremely low temperatures. At cryogenic temperatures, many materials—particularly metals and polymers—undergo significant changes in their mechanical properties, often becoming more brittle due to reduced molecular mobility and altered crystalline structures. This phenomenon has profound implications across numerous industries, including aerospace, medical devices, energy infrastructure, and advanced manufacturing.

Current technological trends in this field are moving toward more precise measurement methodologies, real-time monitoring systems, and standardized testing protocols that can accurately quantify the relationship between temperature and brittleness across diverse material categories. The integration of digital technologies and advanced sensors has enabled more sophisticated data collection during cryogenic testing, allowing for better predictive models of material behavior under extreme conditions.

The primary objective of our technical investigation is to develop a comprehensive understanding of how liquid nitrogen exposure affects material brittleness across various substance classes, with particular emphasis on emerging composite materials and advanced alloys. We aim to establish quantifiable metrics that can accurately predict brittleness transitions and failure points when materials are subjected to cryogenic conditions.

Secondary goals include identifying optimal testing methodologies that balance precision with practical applicability, developing standardized protocols for consistent measurement across different material categories, and exploring potential mitigation strategies for brittleness-induced failures. Additionally, we seek to investigate the reversibility of cryogenic effects—determining whether materials fully recover their original properties after returning to ambient temperatures or if permanent structural changes occur.

The technological significance of this research extends beyond immediate applications, potentially informing future material development strategies and enabling more reliable performance predictions for components operating in extreme environments. By establishing clear correlations between exposure parameters (duration, temperature cycling, rate of cooling) and resultant brittleness characteristics, this investigation aims to contribute valuable insights to the broader field of materials science and cryogenic engineering.

Market Analysis for Cryogenic Material Testing

The global market for cryogenic material testing equipment and services is experiencing robust growth, driven by increasing demand across multiple industries including aerospace, automotive, energy, and medical devices. Current market valuation stands at approximately 3.2 billion USD with a compound annual growth rate of 5.7% projected through 2028. This growth trajectory is primarily fueled by stringent safety standards in critical applications where material failure at extremely low temperatures could lead to catastrophic consequences.

The aerospace sector represents the largest market segment, accounting for nearly 32% of the total market share. This dominance stems from the industry's need to ensure material integrity for components exposed to the extreme temperature variations encountered during flight, particularly in space applications where temperatures can plummet to near absolute zero. The automotive industry follows closely behind at 24%, with particular emphasis on testing for electric vehicle battery systems that must maintain structural integrity in cold-weather conditions.

Regional analysis reveals North America as the leading market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (25%). The Asia-Pacific region, however, is demonstrating the fastest growth rate at 7.3% annually, primarily driven by China's expanding aerospace and automotive manufacturing sectors. This regional distribution reflects the concentration of high-tech manufacturing and research facilities in developed economies, though emerging markets are gradually increasing their market presence.

Key customer segments include material science research institutions, manufacturing quality control departments, and third-party testing laboratories. The latter category has shown particularly strong growth as companies increasingly outsource specialized testing requirements rather than maintaining in-house capabilities. This trend has created opportunities for testing service providers who can offer comprehensive cryogenic testing solutions.

Pricing analysis indicates that advanced cryogenic material testing systems command premium prices ranging from 75,000 to 350,000 USD depending on testing capabilities, precision, and automation features. The consumables market, particularly liquid nitrogen supply systems, represents a significant recurring revenue stream estimated at 780 million USD annually.

Market challenges include the high initial investment required for testing equipment, specialized operator training needs, and safety concerns associated with handling cryogenic materials. Additionally, the market faces pressure from alternative testing methodologies that simulate extreme conditions without requiring actual cryogenic environments, though these alternatives currently lack the reliability and regulatory acceptance of traditional cryogenic testing.

Customer demand increasingly focuses on integrated testing solutions that combine material brittleness assessment with other property evaluations, creating opportunities for comprehensive testing platforms that can analyze multiple material characteristics simultaneously under cryogenic conditions.

The aerospace sector represents the largest market segment, accounting for nearly 32% of the total market share. This dominance stems from the industry's need to ensure material integrity for components exposed to the extreme temperature variations encountered during flight, particularly in space applications where temperatures can plummet to near absolute zero. The automotive industry follows closely behind at 24%, with particular emphasis on testing for electric vehicle battery systems that must maintain structural integrity in cold-weather conditions.

Regional analysis reveals North America as the leading market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (25%). The Asia-Pacific region, however, is demonstrating the fastest growth rate at 7.3% annually, primarily driven by China's expanding aerospace and automotive manufacturing sectors. This regional distribution reflects the concentration of high-tech manufacturing and research facilities in developed economies, though emerging markets are gradually increasing their market presence.

Key customer segments include material science research institutions, manufacturing quality control departments, and third-party testing laboratories. The latter category has shown particularly strong growth as companies increasingly outsource specialized testing requirements rather than maintaining in-house capabilities. This trend has created opportunities for testing service providers who can offer comprehensive cryogenic testing solutions.

Pricing analysis indicates that advanced cryogenic material testing systems command premium prices ranging from 75,000 to 350,000 USD depending on testing capabilities, precision, and automation features. The consumables market, particularly liquid nitrogen supply systems, represents a significant recurring revenue stream estimated at 780 million USD annually.

Market challenges include the high initial investment required for testing equipment, specialized operator training needs, and safety concerns associated with handling cryogenic materials. Additionally, the market faces pressure from alternative testing methodologies that simulate extreme conditions without requiring actual cryogenic environments, though these alternatives currently lack the reliability and regulatory acceptance of traditional cryogenic testing.

Customer demand increasingly focuses on integrated testing solutions that combine material brittleness assessment with other property evaluations, creating opportunities for comprehensive testing platforms that can analyze multiple material characteristics simultaneously under cryogenic conditions.

Current Challenges in Liquid Nitrogen Brittleness Assessment

Despite significant advancements in cryogenic testing methodologies, the accurate measurement and quantification of liquid nitrogen's impact on material brittleness faces several persistent challenges. The primary difficulty lies in standardization across different material types, as various substances exhibit dramatically different responses to extreme cold. This inconsistency makes it difficult to establish universal testing protocols that can be reliably applied across industries ranging from aerospace to medical device manufacturing.

Temperature gradient control presents another significant obstacle. When materials are immersed in liquid nitrogen (-196°C), achieving uniform cooling throughout the specimen remains problematic, particularly for larger or geometrically complex samples. These uneven temperature distributions can lead to internal stresses that confound brittleness measurements, making it difficult to distinguish between actual material properties and testing artifacts.

The transient nature of the testing environment further complicates assessment procedures. As samples are removed from liquid nitrogen for testing, they immediately begin warming, creating a narrow testing window that demands precise timing and handling. This rapid temperature change introduces variables that can significantly impact measurement accuracy and reproducibility, especially for high-precision applications.

Current instrumentation also faces limitations when operating at cryogenic temperatures. Many conventional sensors and measurement devices lose accuracy or fail entirely at extreme cold, necessitating specialized equipment that is often expensive and requires significant expertise to operate correctly. The development of sensors that maintain calibration and performance at cryogenic temperatures remains an active research challenge.

Data interpretation presents additional complexity, as the relationship between measured parameters (such as impact energy absorption or fracture toughness) and actual material performance in real-world cryogenic applications is not always straightforward. Correlating laboratory measurements with in-service performance requires sophisticated modeling that accounts for loading conditions, exposure duration, and environmental factors beyond temperature alone.

Microstructural analysis at cryogenic temperatures presents unique challenges as well. Traditional metallographic techniques often cannot be applied while materials remain at liquid nitrogen temperatures, forcing researchers to rely on post-warming examinations that may not fully capture the material state during actual cryogenic exposure.

Finally, there exists a significant gap in standardized testing methodologies specifically designed for cryogenic brittleness assessment. While standards like ASTM D746 and ISO 812 provide some guidance, they often fail to address the full complexity of material behavior at liquid nitrogen temperatures, particularly for newer composite materials and advanced alloys being developed for extreme environment applications.

Temperature gradient control presents another significant obstacle. When materials are immersed in liquid nitrogen (-196°C), achieving uniform cooling throughout the specimen remains problematic, particularly for larger or geometrically complex samples. These uneven temperature distributions can lead to internal stresses that confound brittleness measurements, making it difficult to distinguish between actual material properties and testing artifacts.

The transient nature of the testing environment further complicates assessment procedures. As samples are removed from liquid nitrogen for testing, they immediately begin warming, creating a narrow testing window that demands precise timing and handling. This rapid temperature change introduces variables that can significantly impact measurement accuracy and reproducibility, especially for high-precision applications.

Current instrumentation also faces limitations when operating at cryogenic temperatures. Many conventional sensors and measurement devices lose accuracy or fail entirely at extreme cold, necessitating specialized equipment that is often expensive and requires significant expertise to operate correctly. The development of sensors that maintain calibration and performance at cryogenic temperatures remains an active research challenge.

Data interpretation presents additional complexity, as the relationship between measured parameters (such as impact energy absorption or fracture toughness) and actual material performance in real-world cryogenic applications is not always straightforward. Correlating laboratory measurements with in-service performance requires sophisticated modeling that accounts for loading conditions, exposure duration, and environmental factors beyond temperature alone.

Microstructural analysis at cryogenic temperatures presents unique challenges as well. Traditional metallographic techniques often cannot be applied while materials remain at liquid nitrogen temperatures, forcing researchers to rely on post-warming examinations that may not fully capture the material state during actual cryogenic exposure.

Finally, there exists a significant gap in standardized testing methodologies specifically designed for cryogenic brittleness assessment. While standards like ASTM D746 and ISO 812 provide some guidance, they often fail to address the full complexity of material behavior at liquid nitrogen temperatures, particularly for newer composite materials and advanced alloys being developed for extreme environment applications.

Established Protocols for Liquid Nitrogen Embrittlement Testing

01 Mechanisms of liquid nitrogen induced brittleness

Liquid nitrogen can cause materials to become brittle due to the extreme low temperatures (-196°C) that significantly reduce molecular mobility. This phenomenon affects various materials differently, with metals and polymers experiencing a ductile-to-brittle transition when cooled to cryogenic temperatures. The brittleness occurs because the thermal energy becomes insufficient for molecules to overcome energy barriers for plastic deformation, resulting in crack propagation rather than material yielding under stress.- Mechanisms of liquid nitrogen induced brittleness: Liquid nitrogen can cause materials to become brittle due to the extremely low temperatures (-196°C) that reduce molecular mobility and change mechanical properties. This cryogenic embrittlement occurs as materials transition from ductile to brittle behavior, with reduced impact resistance and increased susceptibility to fracture. The rapid cooling can also create thermal stresses that contribute to material failure, particularly in metals and polymers that experience significant changes in their crystalline structure at low temperatures.

- Material selection for cryogenic applications: Selecting appropriate materials for liquid nitrogen environments is critical to prevent brittleness-related failures. Certain materials like austenitic stainless steels, aluminum alloys, and specially formulated polymers maintain better ductility at cryogenic temperatures. These materials typically have specific microstructural characteristics that resist the transition to brittle behavior. Testing protocols have been developed to evaluate material performance under liquid nitrogen conditions, ensuring safety and reliability in cryogenic applications.

- Cryogenic treatment processes: Controlled exposure to liquid nitrogen can be used as a beneficial treatment process for certain materials. These cryogenic treatments can improve wear resistance, dimensional stability, and stress relief in metals. The process typically involves slowly cooling materials to liquid nitrogen temperatures, holding them at that temperature for a specified period, and then gradually warming them back to ambient conditions. This controlled process helps minimize thermal shock while achieving desired material property modifications.

- Protective measures against liquid nitrogen brittleness: Various protective measures can be implemented to mitigate the effects of liquid nitrogen brittleness. These include applying specialized coatings that provide thermal insulation, using composite materials with improved low-temperature properties, implementing design modifications that accommodate thermal contraction, and developing handling procedures that minimize thermal shock. Proper insulation systems and gradual cooling techniques help prevent sudden temperature changes that could lead to brittleness-related failures.

- Testing and analysis methods for cryogenic brittleness: Specialized testing and analysis methods have been developed to evaluate material behavior under liquid nitrogen conditions. These include impact testing at cryogenic temperatures, fracture toughness assessments, thermal cycling tests, and advanced microscopy techniques to observe microstructural changes. Computational models can also predict how materials will respond to extreme cold, helping engineers select appropriate materials and design components that can withstand liquid nitrogen environments without experiencing catastrophic brittle failure.

02 Material selection for cryogenic applications

Selecting appropriate materials for use in liquid nitrogen environments is critical to prevent brittle failure. Certain materials like austenitic stainless steels, aluminum alloys, and specially formulated polymers maintain better ductility at cryogenic temperatures. These materials are engineered with specific microstructures and compositions that resist the embrittlement effects of extreme cold, making them suitable for applications where exposure to liquid nitrogen is expected.Expand Specific Solutions03 Testing methods for cryogenic brittleness

Various testing methodologies have been developed to evaluate material performance under liquid nitrogen conditions. These include impact testing (Charpy and Izod), tensile testing at cryogenic temperatures, and fracture toughness assessments. These tests help engineers understand how materials will behave when subjected to mechanical stress in extremely cold environments, allowing for proper material selection and design considerations for cryogenic applications.Expand Specific Solutions04 Design considerations for cryogenic equipment

Equipment designed for use with liquid nitrogen requires special considerations to account for material brittleness. This includes avoiding sharp corners and stress concentrations, incorporating expansion joints to accommodate thermal contraction, using appropriate insulation techniques, and implementing safety factors in structural calculations. Proper design can mitigate the risks associated with brittle fracture in components exposed to cryogenic temperatures.Expand Specific Solutions05 Surface treatments and coatings for cryogenic protection

Various surface treatments and specialized coatings have been developed to enhance material performance in liquid nitrogen environments. These include nitriding, carburizing, and the application of composite coatings that can improve wear resistance and reduce brittleness at cryogenic temperatures. These treatments modify the surface properties of materials to better withstand the extreme conditions associated with liquid nitrogen exposure while maintaining structural integrity.Expand Specific Solutions

Leading Organizations in Cryogenic Testing Industry

The liquid nitrogen material brittleness testing market is in a growth phase, with increasing applications across automotive, aerospace, and manufacturing sectors. The market is estimated to reach approximately $300-350 million by 2025, driven by rising demand for cryogenic material testing. Technologically, the field shows moderate maturity with established players like Robert Bosch GmbH and Honda Motor Co. leading industrial applications, while research institutions such as Naval Research Laboratory and China University of Mining & Technology advance fundamental understanding. Educational institutions collaborate with companies like Timken Co. and NTN Corp. to develop standardized testing protocols. Specialized companies including Expanite A/S and Sanyo Special Steel are developing niche applications for cryogenic brittleness testing, particularly in high-performance materials and specialized steel products.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has developed a sophisticated multi-parameter testing system for evaluating liquid nitrogen's impact on material brittleness, particularly for automotive and industrial components. Their approach integrates high-precision strain measurement during cryogenic exposure with advanced digital image correlation techniques to map strain fields across test specimens. Bosch's methodology includes cyclic thermal loading between ambient and cryogenic temperatures to evaluate fatigue behavior under repeated thermal shock conditions. They've implemented automated testing systems that can simultaneously evaluate multiple material samples under identical cryogenic conditions, ensuring statistical reliability. Their research has particularly focused on the embrittlement of precision components in fuel injection systems and sensors that may be exposed to extreme temperature variations. Bosch has also developed specialized non-destructive evaluation techniques using ultrasonic wave propagation characteristics to detect embrittlement without damaging components.

Strengths: Highly automated and repeatable testing procedures; excellent correlation between laboratory tests and real-world component performance; comprehensive material database spanning metals, polymers, and composites. Weaknesses: Testing protocols primarily optimized for automotive applications; significant investment required in specialized cryogenic testing infrastructure.

BP Exploration Operating Co. Ltd.

Technical Solution: BP Exploration has developed comprehensive testing protocols for measuring liquid nitrogen's impact on material brittleness specifically for oil and gas infrastructure components. Their methodology incorporates full-scale component testing under simulated service conditions while exposed to cryogenic temperatures. BP has pioneered the use of fiber optic sensing systems embedded within test specimens to provide real-time strain measurements during cryogenic exposure, offering unprecedented insight into material behavior during cooling and warming cycles. Their research has established correlations between material composition, processing history, and susceptibility to liquid nitrogen embrittlement for pipeline steels and elastomeric sealing materials. BP's approach includes accelerated aging protocols that simulate years of service followed by cryogenic exposure to evaluate long-term material degradation effects. They've also developed specialized non-destructive evaluation techniques using phased array ultrasonics to detect embrittlement in field components without requiring sample extraction.

Strengths: Testing methodologies directly applicable to real-world oil and gas infrastructure; excellent correlation between laboratory tests and field performance; comprehensive understanding of combined effects of mechanical stress and cryogenic temperatures. Weaknesses: Testing protocols primarily optimized for specific oil and gas applications; significant investment in specialized large-scale testing facilities required.

Key Technologies for Measuring Low-Temperature Material Properties

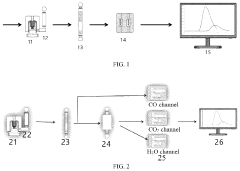

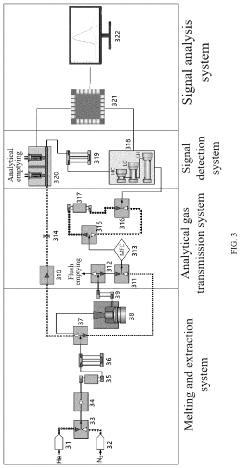

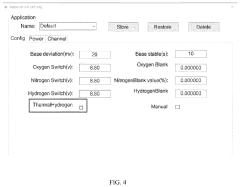

Combined oxygen, nitrogen and hydrogen joint determination device and method based on thermal conductivity-infrared technique

PatentActiveUS11971349B1

Innovation

- A combined oxygen, nitrogen, and hydrogen joint determination device and method utilizing both thermal conductivity and infrared techniques, where a melting and extraction system, analytical gas transmission system, and signal detection system are integrated to allow switching between different gas paths, enabling the use of both IR absorption and TC methods on a single device for various determination modes, using high-purity He or N2 as carrier gases to selectively determine oxygen, nitrogen, and hydrogen based on their concentrations.

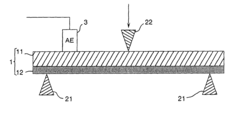

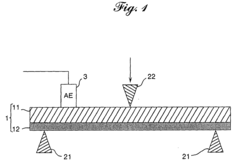

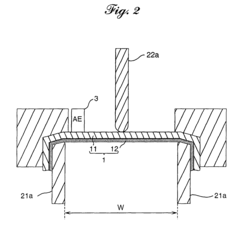

Method of rating brittleness of coating substance and device for implementing the brittleness rating method

PatentInactiveUS20040045357A1

Innovation

- A brittleness rating method involving deformation of a test film piece laminated with a coating substance using a compression transverse test device, detecting acoustic emissions to quantify brittleness, and a device comprising a deforming mechanism, acoustic emission sensor, and rating system for precise brittleness assessment.

Safety Standards for Cryogenic Testing Procedures

The establishment of comprehensive safety standards for cryogenic testing procedures is paramount when measuring liquid nitrogen's impact on material brittleness. Current international standards, such as ISO 21013 and ASTM G86, provide foundational guidelines for handling cryogenic materials, but specific protocols for brittleness testing require additional considerations. These standards must address the extreme temperature differentials (ambient to -196°C) that create significant safety hazards for both personnel and equipment.

Personal protective equipment requirements constitute a critical component of these safety standards. Operators must utilize insulated gloves, face shields, and specialized cryogenic aprons to prevent cold burns and tissue damage. The standards should specify minimum insulation ratings and material compositions suitable for prolonged exposure to liquid nitrogen environments. Additionally, closed-toe footwear with impermeable uppers is essential to prevent pooling of cryogenic liquids around vulnerable extremities.

Laboratory ventilation specifications represent another crucial safety consideration. Liquid nitrogen rapidly expands to gas form at room temperature, potentially displacing oxygen in confined spaces. Safety standards must mandate minimum air exchange rates (typically 6-10 air changes per hour), oxygen monitoring systems with audible alarms set to trigger at oxygen levels below 19.5%, and emergency ventilation protocols. These requirements should scale according to the laboratory volume and quantity of liquid nitrogen utilized.

Equipment certification and maintenance protocols ensure testing apparatus can withstand repeated thermal cycling. Standards should require regular inspection of seals, connections, and structural components for microfractures that might develop under cryogenic stress. Documentation of these inspections must be maintained according to established record-keeping procedures, with clear criteria for equipment retirement when integrity becomes compromised.

Emergency response procedures form the final critical element of comprehensive safety standards. These include detailed protocols for addressing liquid nitrogen spills, oxygen depletion scenarios, and cryogenic burns. Standards should mandate regular drills, accessible emergency equipment (including specialized first aid supplies for cryogenic injuries), and clear evacuation routes. Communication systems must remain functional in emergency scenarios, with backup protocols established for power failure situations.

Implementation of these safety standards requires regular training and certification of personnel involved in cryogenic testing. Documentation of this training should be maintained and periodically audited to ensure compliance. As research methodologies evolve, these standards must undergo regular review and updating to incorporate new safety technologies and address emerging risks in the measurement of material brittleness under liquid nitrogen conditions.

Personal protective equipment requirements constitute a critical component of these safety standards. Operators must utilize insulated gloves, face shields, and specialized cryogenic aprons to prevent cold burns and tissue damage. The standards should specify minimum insulation ratings and material compositions suitable for prolonged exposure to liquid nitrogen environments. Additionally, closed-toe footwear with impermeable uppers is essential to prevent pooling of cryogenic liquids around vulnerable extremities.

Laboratory ventilation specifications represent another crucial safety consideration. Liquid nitrogen rapidly expands to gas form at room temperature, potentially displacing oxygen in confined spaces. Safety standards must mandate minimum air exchange rates (typically 6-10 air changes per hour), oxygen monitoring systems with audible alarms set to trigger at oxygen levels below 19.5%, and emergency ventilation protocols. These requirements should scale according to the laboratory volume and quantity of liquid nitrogen utilized.

Equipment certification and maintenance protocols ensure testing apparatus can withstand repeated thermal cycling. Standards should require regular inspection of seals, connections, and structural components for microfractures that might develop under cryogenic stress. Documentation of these inspections must be maintained according to established record-keeping procedures, with clear criteria for equipment retirement when integrity becomes compromised.

Emergency response procedures form the final critical element of comprehensive safety standards. These include detailed protocols for addressing liquid nitrogen spills, oxygen depletion scenarios, and cryogenic burns. Standards should mandate regular drills, accessible emergency equipment (including specialized first aid supplies for cryogenic injuries), and clear evacuation routes. Communication systems must remain functional in emergency scenarios, with backup protocols established for power failure situations.

Implementation of these safety standards requires regular training and certification of personnel involved in cryogenic testing. Documentation of this training should be maintained and periodically audited to ensure compliance. As research methodologies evolve, these standards must undergo regular review and updating to incorporate new safety technologies and address emerging risks in the measurement of material brittleness under liquid nitrogen conditions.

Industrial Applications of Cryogenic Brittleness Data

The application of cryogenic brittleness data spans numerous industrial sectors, providing critical insights for material selection, design optimization, and operational safety. In aerospace engineering, these data inform the development of fuel tanks and propulsion systems that must withstand extreme temperature fluctuations. Engineers utilize brittleness measurements to select appropriate materials for liquid oxygen and hydrogen containment, ensuring structural integrity during launch and space operations.

The energy sector, particularly liquefied natural gas (LNG) processing and transportation, heavily relies on cryogenic brittleness information. Storage tanks, pipelines, and valves must maintain functionality at temperatures as low as -162°C. Companies like Shell and Chevron incorporate brittleness data into their material qualification processes, resulting in safer and more efficient LNG infrastructure with reduced maintenance requirements and extended operational lifespans.

Medical device manufacturing represents another significant application area, where cryogenic brittleness data guides the development of equipment for cryosurgery, cryopreservation, and MRI systems. The precise understanding of how materials respond to liquid nitrogen exposure ensures patient safety and treatment efficacy, particularly in dermatological and oncological applications where tissue freezing is therapeutically employed.

In automotive testing, manufacturers utilize cryogenic brittleness data to evaluate component performance under extreme cold conditions. This is especially relevant for electric vehicles, where battery systems must maintain integrity across wide temperature ranges. Tesla and other manufacturers have established specialized cryogenic testing protocols based on accumulated brittleness data to validate their designs for cold-weather regions.

The semiconductor industry applies cryogenic brittleness information in manufacturing processes requiring precise temperature control. As chip fabrication increasingly involves cryogenic cooling to achieve higher performance, understanding material behavior at liquid nitrogen temperatures becomes essential for equipment design and process optimization.

Industrial standards organizations have developed specific protocols for cryogenic material testing, including ASTM E1820 and ISO 148, which codify testing methodologies and data interpretation. These standards enable consistent application of brittleness data across industries and facilitate material certification for cryogenic applications, ultimately driving innovation in extreme-environment engineering while maintaining rigorous safety margins.

The energy sector, particularly liquefied natural gas (LNG) processing and transportation, heavily relies on cryogenic brittleness information. Storage tanks, pipelines, and valves must maintain functionality at temperatures as low as -162°C. Companies like Shell and Chevron incorporate brittleness data into their material qualification processes, resulting in safer and more efficient LNG infrastructure with reduced maintenance requirements and extended operational lifespans.

Medical device manufacturing represents another significant application area, where cryogenic brittleness data guides the development of equipment for cryosurgery, cryopreservation, and MRI systems. The precise understanding of how materials respond to liquid nitrogen exposure ensures patient safety and treatment efficacy, particularly in dermatological and oncological applications where tissue freezing is therapeutically employed.

In automotive testing, manufacturers utilize cryogenic brittleness data to evaluate component performance under extreme cold conditions. This is especially relevant for electric vehicles, where battery systems must maintain integrity across wide temperature ranges. Tesla and other manufacturers have established specialized cryogenic testing protocols based on accumulated brittleness data to validate their designs for cold-weather regions.

The semiconductor industry applies cryogenic brittleness information in manufacturing processes requiring precise temperature control. As chip fabrication increasingly involves cryogenic cooling to achieve higher performance, understanding material behavior at liquid nitrogen temperatures becomes essential for equipment design and process optimization.

Industrial standards organizations have developed specific protocols for cryogenic material testing, including ASTM E1820 and ISO 148, which codify testing methodologies and data interpretation. These standards enable consistent application of brittleness data across industries and facilitate material certification for cryogenic applications, ultimately driving innovation in extreme-environment engineering while maintaining rigorous safety margins.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!