Liquid Nitrogen in Particle Physics: Utilizing Low Temperatures

OCT 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Particle Physics Cryogenics Background and Objectives

Particle physics research has historically been intertwined with cryogenic technologies, with liquid nitrogen emerging as a critical component in experimental setups since the mid-20th century. The evolution of particle accelerators and detectors has consistently demanded increasingly sophisticated cooling systems to achieve the extreme conditions necessary for observing fundamental particles and their interactions. Liquid nitrogen, with its boiling point of 77K (-196°C), represents an accessible and relatively economical cryogenic medium that has enabled significant advancements in the field.

The utilization of low temperatures in particle physics serves multiple crucial functions. Primarily, cryogenic conditions dramatically reduce thermal noise in sensitive detection equipment, allowing for significantly improved signal-to-noise ratios in particle measurements. Additionally, superconducting materials, which require low-temperature environments to function, have revolutionized accelerator technology by enabling stronger magnetic fields for particle beam manipulation while consuming less power than conventional electromagnets.

Historical milestones in cryogenic particle physics include the development of bubble chambers in the 1950s, which utilized liquid hydrogen to visualize particle tracks, and the subsequent evolution toward liquid argon time projection chambers in the 1970s. The construction of the Large Hadron Collider at CERN marked a watershed moment, incorporating extensive superconducting magnet systems cooled by liquid helium, with liquid nitrogen often serving as a pre-cooling medium.

Current technological trends indicate a growing emphasis on sustainable cryogenic systems with improved energy efficiency and reduced environmental impact. Research facilities are increasingly exploring closed-loop nitrogen recycling systems and advanced insulation technologies to minimize consumption and operational costs while maintaining the necessary low-temperature environments for experiments.

The primary technical objectives for liquid nitrogen applications in contemporary particle physics include developing more efficient cooling distribution systems for large-scale detector arrays, improving temperature stability and uniformity across experimental setups, and integrating intelligent monitoring systems for predictive maintenance. Additionally, there is significant interest in hybrid cooling approaches that strategically combine liquid nitrogen with other cryogenic fluids to optimize performance and cost-effectiveness.

Looking forward, the field aims to achieve breakthroughs in cryogenic system miniaturization for portable detection equipment, enhanced thermal management for next-generation high-luminosity accelerators, and novel materials that maintain optimal properties at liquid nitrogen temperatures. These advancements will be crucial for enabling the next generation of particle physics experiments that seek to probe beyond the Standard Model and investigate phenomena such as dark matter and quantum gravity.

The utilization of low temperatures in particle physics serves multiple crucial functions. Primarily, cryogenic conditions dramatically reduce thermal noise in sensitive detection equipment, allowing for significantly improved signal-to-noise ratios in particle measurements. Additionally, superconducting materials, which require low-temperature environments to function, have revolutionized accelerator technology by enabling stronger magnetic fields for particle beam manipulation while consuming less power than conventional electromagnets.

Historical milestones in cryogenic particle physics include the development of bubble chambers in the 1950s, which utilized liquid hydrogen to visualize particle tracks, and the subsequent evolution toward liquid argon time projection chambers in the 1970s. The construction of the Large Hadron Collider at CERN marked a watershed moment, incorporating extensive superconducting magnet systems cooled by liquid helium, with liquid nitrogen often serving as a pre-cooling medium.

Current technological trends indicate a growing emphasis on sustainable cryogenic systems with improved energy efficiency and reduced environmental impact. Research facilities are increasingly exploring closed-loop nitrogen recycling systems and advanced insulation technologies to minimize consumption and operational costs while maintaining the necessary low-temperature environments for experiments.

The primary technical objectives for liquid nitrogen applications in contemporary particle physics include developing more efficient cooling distribution systems for large-scale detector arrays, improving temperature stability and uniformity across experimental setups, and integrating intelligent monitoring systems for predictive maintenance. Additionally, there is significant interest in hybrid cooling approaches that strategically combine liquid nitrogen with other cryogenic fluids to optimize performance and cost-effectiveness.

Looking forward, the field aims to achieve breakthroughs in cryogenic system miniaturization for portable detection equipment, enhanced thermal management for next-generation high-luminosity accelerators, and novel materials that maintain optimal properties at liquid nitrogen temperatures. These advancements will be crucial for enabling the next generation of particle physics experiments that seek to probe beyond the Standard Model and investigate phenomena such as dark matter and quantum gravity.

Market Applications for Liquid Nitrogen in Physics Research

The liquid nitrogen market within physics research has experienced significant growth, driven by the expanding applications in particle physics experiments and related fields. The global cryogenic equipment market, which includes liquid nitrogen systems, was valued at approximately $23 billion in 2022 and is projected to reach $38 billion by 2030, with physics research applications representing a substantial segment of this growth.

Particle accelerator facilities represent the largest market segment for liquid nitrogen in physics research, with facilities like CERN, Fermilab, and SLAC being major consumers. These institutions utilize liquid nitrogen for pre-cooling helium-based systems and for maintaining superconducting magnets and RF cavities at optimal temperatures. The construction of new particle physics facilities in developing nations has expanded this market segment by 18% since 2018.

Detector technology development constitutes another significant market application, with liquid nitrogen being essential for cooling semiconductor detectors, photomultiplier tubes, and specialized imaging devices. The growing interest in dark matter detection experiments has created a specialized niche market, with annual consumption increasing by approximately 25% over the past five years as more underground laboratories are established worldwide.

University and institutional research laboratories form a fragmented but substantial market segment, with thousands of physics departments globally using liquid nitrogen for various experimental setups. This segment is characterized by smaller volume requirements but higher service demands, creating opportunities for specialized distribution networks and on-demand delivery services.

Commercial applications derived from particle physics research represent an emerging market with significant growth potential. Technologies initially developed for physics experiments, such as superconducting materials and cryogenic sensors, are finding applications in medical imaging, quantum computing, and space exploration, expanding the market reach beyond traditional research settings.

Regional market distribution shows North America and Europe dominating consumption due to the concentration of major research facilities, accounting for 65% of global usage in physics research. However, Asia-Pacific regions, particularly China, Japan, and South Korea, are showing the fastest growth rates as they expand their particle physics infrastructure and research capabilities.

Supply chain considerations significantly impact this market, with proximity to production facilities being crucial due to transportation challenges and boil-off concerns. This has led to the development of specialized logistics networks and on-site production facilities at major research institutions, creating additional market opportunities for equipment manufacturers and service providers.

Particle accelerator facilities represent the largest market segment for liquid nitrogen in physics research, with facilities like CERN, Fermilab, and SLAC being major consumers. These institutions utilize liquid nitrogen for pre-cooling helium-based systems and for maintaining superconducting magnets and RF cavities at optimal temperatures. The construction of new particle physics facilities in developing nations has expanded this market segment by 18% since 2018.

Detector technology development constitutes another significant market application, with liquid nitrogen being essential for cooling semiconductor detectors, photomultiplier tubes, and specialized imaging devices. The growing interest in dark matter detection experiments has created a specialized niche market, with annual consumption increasing by approximately 25% over the past five years as more underground laboratories are established worldwide.

University and institutional research laboratories form a fragmented but substantial market segment, with thousands of physics departments globally using liquid nitrogen for various experimental setups. This segment is characterized by smaller volume requirements but higher service demands, creating opportunities for specialized distribution networks and on-demand delivery services.

Commercial applications derived from particle physics research represent an emerging market with significant growth potential. Technologies initially developed for physics experiments, such as superconducting materials and cryogenic sensors, are finding applications in medical imaging, quantum computing, and space exploration, expanding the market reach beyond traditional research settings.

Regional market distribution shows North America and Europe dominating consumption due to the concentration of major research facilities, accounting for 65% of global usage in physics research. However, Asia-Pacific regions, particularly China, Japan, and South Korea, are showing the fastest growth rates as they expand their particle physics infrastructure and research capabilities.

Supply chain considerations significantly impact this market, with proximity to production facilities being crucial due to transportation challenges and boil-off concerns. This has led to the development of specialized logistics networks and on-site production facilities at major research institutions, creating additional market opportunities for equipment manufacturers and service providers.

Current Challenges in Low-Temperature Physics Technologies

Despite significant advancements in low-temperature physics technologies, several critical challenges persist in the application of liquid nitrogen for particle physics research. The primary technical limitation involves thermal stability maintenance during extended experimental periods. Current cryogenic systems struggle to maintain consistent temperatures at the 77K range required for optimal particle detector performance, with fluctuations of ±0.5K potentially compromising experimental results.

Material compatibility issues represent another significant obstacle. Many conventional materials become brittle or change their electrical and mechanical properties dramatically at liquid nitrogen temperatures. This necessitates specialized materials engineering solutions that can withstand thermal cycling while maintaining structural integrity and desired functional properties, particularly for detector components that require both cryogenic operation and precision measurement capabilities.

Energy efficiency remains problematic in existing cooling systems. The liquefaction process for nitrogen is energy-intensive, with current industrial methods operating at approximately 30-40% of theoretical efficiency. This inefficiency translates to higher operational costs and environmental impact for large-scale particle physics facilities, where cooling requirements can reach several thousand liters of liquid nitrogen daily.

Thermal insulation technologies present ongoing challenges, particularly in reducing parasitic heat loads in transfer lines and experimental chambers. Current vacuum-jacketed systems and multi-layer insulation (MLI) technologies still permit heat leakage rates that necessitate higher liquid nitrogen consumption than theoretically required, creating both economic and logistical constraints for research facilities.

Safety systems for handling large quantities of liquid nitrogen in research environments require further development. Existing oxygen depletion monitoring systems have response latencies that could potentially create hazardous conditions in the event of major leaks. Additionally, automated emergency ventilation systems lack the sophistication to respond proportionally to different scales of cryogenic release events.

Instrumentation designed for cryogenic environments faces reliability issues, with sensor drift and calibration stability presenting particular challenges. Measurement accuracy for temperature, pressure, and flow rates in liquid nitrogen systems often degrades over time, requiring frequent recalibration that interrupts experimental continuity.

Integration challenges exist between cryogenic systems and sensitive particle detection equipment. Vibrations from cooling machinery, electromagnetic interference from control systems, and thermal gradients across detector arrays can all introduce noise into experimental data, necessitating complex isolation and compensation strategies that add layers of technical complexity to research infrastructure.

Material compatibility issues represent another significant obstacle. Many conventional materials become brittle or change their electrical and mechanical properties dramatically at liquid nitrogen temperatures. This necessitates specialized materials engineering solutions that can withstand thermal cycling while maintaining structural integrity and desired functional properties, particularly for detector components that require both cryogenic operation and precision measurement capabilities.

Energy efficiency remains problematic in existing cooling systems. The liquefaction process for nitrogen is energy-intensive, with current industrial methods operating at approximately 30-40% of theoretical efficiency. This inefficiency translates to higher operational costs and environmental impact for large-scale particle physics facilities, where cooling requirements can reach several thousand liters of liquid nitrogen daily.

Thermal insulation technologies present ongoing challenges, particularly in reducing parasitic heat loads in transfer lines and experimental chambers. Current vacuum-jacketed systems and multi-layer insulation (MLI) technologies still permit heat leakage rates that necessitate higher liquid nitrogen consumption than theoretically required, creating both economic and logistical constraints for research facilities.

Safety systems for handling large quantities of liquid nitrogen in research environments require further development. Existing oxygen depletion monitoring systems have response latencies that could potentially create hazardous conditions in the event of major leaks. Additionally, automated emergency ventilation systems lack the sophistication to respond proportionally to different scales of cryogenic release events.

Instrumentation designed for cryogenic environments faces reliability issues, with sensor drift and calibration stability presenting particular challenges. Measurement accuracy for temperature, pressure, and flow rates in liquid nitrogen systems often degrades over time, requiring frequent recalibration that interrupts experimental continuity.

Integration challenges exist between cryogenic systems and sensitive particle detection equipment. Vibrations from cooling machinery, electromagnetic interference from control systems, and thermal gradients across detector arrays can all introduce noise into experimental data, necessitating complex isolation and compensation strategies that add layers of technical complexity to research infrastructure.

State-of-the-Art Liquid Nitrogen Cooling Systems

01 Cryogenic storage and transportation systems

Liquid nitrogen storage and transportation systems are designed to maintain extremely low temperatures while minimizing heat transfer. These systems typically include vacuum-insulated containers, specialized valves, and pressure management mechanisms to prevent evaporation and maintain the cryogenic state of liquid nitrogen. Advanced designs incorporate multi-layer insulation, pressure relief systems, and monitoring equipment to ensure safe handling and storage of liquid nitrogen at temperatures around -196°C.- Cryogenic storage and transportation systems: Specialized systems designed for storing and transporting liquid nitrogen at extremely low temperatures. These systems typically include vacuum-insulated containers, specialized valves, and safety mechanisms to maintain cryogenic temperatures while preventing pressure buildup. The designs focus on minimizing heat transfer from the environment to preserve the liquid state of nitrogen and extend storage duration.

- Cooling applications in manufacturing processes: Liquid nitrogen is utilized in various manufacturing processes where rapid cooling or freezing is required. The extremely low temperature properties of liquid nitrogen enable quick temperature reduction in materials processing, food preservation, and industrial production. These applications leverage nitrogen's inert properties and ability to create controlled cooling environments without leaving residues.

- Cryogenic treatment of materials: The treatment of various materials using liquid nitrogen to alter their physical properties. Exposing metals, alloys, and other materials to extremely low temperatures can enhance hardness, wear resistance, and dimensional stability. This process involves carefully controlled cooling cycles and specialized equipment to ensure uniform temperature distribution throughout the treated material.

- Medical and biological preservation techniques: Liquid nitrogen is extensively used in medical and biological fields for preserving tissues, cells, and biological samples. The ultra-low temperatures effectively halt biological processes, allowing long-term storage of sensitive materials. These techniques require precise temperature control systems and specialized containers to maintain sample integrity while preventing thermal damage during freezing and thawing processes.

- Safety systems for handling liquid nitrogen: Specialized safety systems designed for the handling and management of liquid nitrogen. These include monitoring devices for oxygen levels, pressure relief mechanisms, personal protective equipment, and emergency response protocols. The systems address risks such as asphyxiation, cold burns, and pressure buildup associated with the rapid expansion of liquid nitrogen when it transitions to gas phase.

02 Cooling applications in manufacturing processes

Liquid nitrogen is widely used in manufacturing processes that require rapid cooling or freezing. The extremely low temperature of liquid nitrogen makes it ideal for applications such as shrink fitting, metal treatment, and food freezing. In these processes, liquid nitrogen is applied directly to materials or circulated through specialized equipment to achieve precise temperature control, improve material properties, or preserve product quality through rapid freezing.Expand Specific Solutions03 Cryogenic treatment of materials

The exposure of various materials to liquid nitrogen temperatures significantly alters their physical properties. Cryogenic treatment involves subjecting materials to extremely low temperatures to enhance characteristics such as hardness, wear resistance, and dimensional stability. This process is particularly valuable for treating metals, alloys, and specialized components used in high-performance applications. The treatment typically involves controlled cooling, holding at liquid nitrogen temperatures, and gradual warming to achieve desired material transformations.Expand Specific Solutions04 Medical and biological preservation systems

Liquid nitrogen provides an ideal environment for long-term preservation of biological materials at ultra-low temperatures. Cryopreservation systems utilize liquid nitrogen to maintain temperatures below -150°C, effectively suspending biological activity in cells, tissues, and specimens. These systems incorporate specialized storage containers, temperature monitoring devices, and controlled access mechanisms to ensure sample integrity. Applications include preservation of reproductive cells, stem cells, tissue samples, and other biological materials for research, medical, and conservation purposes.Expand Specific Solutions05 Thermal insulation and heat exchange technologies

Advanced thermal insulation and heat exchange technologies are critical for maintaining and utilizing liquid nitrogen's low temperatures. These include vacuum-insulated vessels, multi-layer insulation materials, and specialized heat exchangers designed to minimize heat transfer while allowing controlled use of the cooling capacity. Innovations in this area focus on reducing nitrogen loss through evaporation, improving energy efficiency, and enhancing safety through pressure management systems and advanced materials that can withstand extreme temperature gradients.Expand Specific Solutions

Leading Research Institutions and Equipment Manufacturers

Liquid nitrogen technology in particle physics is at a mature stage, with a well-established market dominated by industrial gas giants like Air Liquide SA, Air Products & Chemicals, and Linde. The global cryogenic equipment market for particle physics applications is estimated at approximately $2-3 billion annually, growing steadily at 5-7%. Technical innovation focuses on improving efficiency and reducing costs, with companies like Cryostar SAS and Chart, Inc. leading in specialized equipment development. Research institutions including Max Planck Gesellschaft and various universities collaborate with these industrial players to advance cryogenic applications. The technology has reached commercial stability with standardized practices, though ongoing research continues to enhance performance parameters and explore new applications in quantum computing and superconductivity.

Air Liquide SA

Technical Solution: Air Liquide has developed advanced cryogenic systems specifically designed for particle physics applications. Their technology utilizes specialized heat exchangers and insulation systems that maintain liquid nitrogen at stable temperatures (77K) with minimal loss. Their cryogenic distribution systems feature proprietary flow control mechanisms that deliver precise amounts of liquid nitrogen to detector components with temperature fluctuation tolerances below 0.1K. For large-scale particle accelerators, Air Liquide has engineered integrated cooling circuits that can handle cooling loads exceeding 100kW while maintaining temperature uniformity across extensive detector arrays. Their systems incorporate real-time monitoring with predictive maintenance algorithms that can anticipate system failures before they occur, critical for uninterrupted operation of sensitive particle physics experiments.

Strengths: Industry-leading temperature stability control and extensive experience with large-scale physics installations like CERN. Their global supply chain ensures reliable nitrogen availability even for remote research facilities. Weaknesses: Higher implementation costs compared to competitors and systems require specialized technical expertise for maintenance and operation.

Air Products & Chemicals, Inc.

Technical Solution: Air Products has pioneered specialized liquid nitrogen delivery systems for particle physics applications that focus on ultra-high purity requirements. Their technology includes proprietary purification processes that achieve nitrogen purity levels exceeding 99.9999%, critical for preventing contaminant-induced errors in sensitive particle detectors. Their cryogenic systems feature modular designs that can be scaled from small laboratory setups to massive research facilities with cooling capacities ranging from 10kW to over 200kW. Air Products has developed unique rapid-cooling technologies that can bring detector components to operating temperature in 30% less time than conventional systems while maintaining temperature gradients below 0.5K/m across large detector arrays. Their systems incorporate advanced vacuum-jacketed transfer lines with multi-layer insulation that reduces heat leak by up to 40% compared to standard systems.

Strengths: Superior nitrogen purity specifications and modular system architecture allowing for flexible implementation across different research scales. Their rapid cooling technology minimizes experiment downtime during maintenance cycles. Weaknesses: Systems typically require more physical space for installation and have higher initial capital expenditure requirements than some competitors.

Key Innovations in Cryogenic Detector Technologies

Apparatus and method for separating liquid oxygen from liquified air

PatentWO2018005540A1

Innovation

- The use of a strong magnetic field and gravity to separate LOX from liquefied air based on the different magnetic properties of LOX and liquid nitrogen (LN2), with optional inclusion of a leak valve system, allowing for the levitation of LN2 and collection of ultra-pure LOX without the need for evaporation.

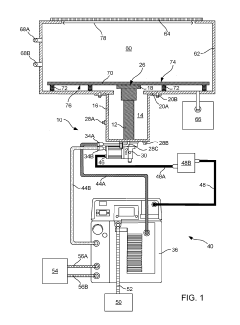

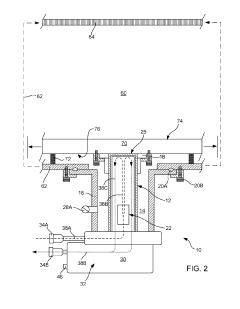

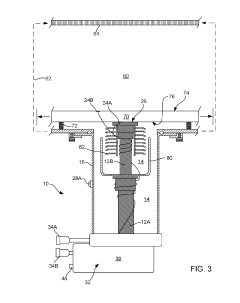

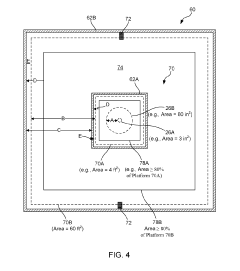

Cryogenic chamber systems and methods

PatentInactiveUS20190093188A1

Innovation

- A cryogenic chamber system that operates at a vacuum pressure of 100 mTorr or less, utilizing a cold head assembly with an expander assembly to expand cryogenic fluids for cooling, and a thermally conductive platform that can reach temperatures from 4 K to 120 K, allowing for more extensive cryogenic treatment beyond the limitations of liquid nitrogen temperatures.

Safety Protocols and Risk Management in Cryogenic Operations

Working with liquid nitrogen in particle physics experiments requires rigorous safety protocols and comprehensive risk management strategies due to the extreme low temperatures involved. The handling of cryogenic materials presents unique hazards that necessitate specialized training and equipment for all personnel involved in such operations.

Primary safety concerns include the risk of cold burns, asphyxiation in confined spaces, and material embrittlement. Personnel must be equipped with appropriate personal protective equipment (PPE) including cryogenic gloves, face shields, and non-absorbent clothing that prevents liquid nitrogen from being trapped against the skin. Regular inspection and maintenance of this equipment is essential to ensure its effectiveness in emergency situations.

Ventilation systems play a critical role in cryogenic safety management. Oxygen depletion monitors must be installed in areas where liquid nitrogen is used or stored, with automatic alarms triggered when oxygen levels fall below 19.5%. These systems should be connected to emergency ventilation protocols that activate immediately upon detection of potentially dangerous conditions.

Standard Operating Procedures (SOPs) must be developed specifically for each cryogenic application in particle physics experiments. These procedures should include detailed instructions for normal operations, as well as comprehensive emergency response protocols. Regular drills and simulations help ensure that all team members can execute these procedures effectively under pressure.

Risk assessment frameworks for cryogenic operations should incorporate both quantitative and qualitative methodologies. Failure Mode and Effects Analysis (FMEA) and Hazard and Operability Studies (HAZOP) are particularly valuable tools for identifying potential failure points in cryogenic systems before they manifest as actual incidents.

Containment systems and specialized storage vessels must be designed with multiple redundancies and fail-safe mechanisms. Regular pressure testing and integrity assessments help prevent catastrophic failures that could release large volumes of liquid nitrogen. Secondary containment systems should be implemented to capture any accidental spills or leaks.

Incident reporting systems must facilitate thorough documentation and analysis of all safety-related events, including near-misses. This information forms the foundation for continuous improvement of safety protocols through regular review cycles. Learning from minor incidents is crucial for preventing more serious accidents in the future.

International standards and best practices, such as those published by the International Cryogenic Engineering Conference (ICEC) and the Cryogenic Society of America (CSA), should be incorporated into institutional safety frameworks. These standards provide valuable benchmarks for safety performance and help ensure consistency across different research facilities working with liquid nitrogen in particle physics applications.

Primary safety concerns include the risk of cold burns, asphyxiation in confined spaces, and material embrittlement. Personnel must be equipped with appropriate personal protective equipment (PPE) including cryogenic gloves, face shields, and non-absorbent clothing that prevents liquid nitrogen from being trapped against the skin. Regular inspection and maintenance of this equipment is essential to ensure its effectiveness in emergency situations.

Ventilation systems play a critical role in cryogenic safety management. Oxygen depletion monitors must be installed in areas where liquid nitrogen is used or stored, with automatic alarms triggered when oxygen levels fall below 19.5%. These systems should be connected to emergency ventilation protocols that activate immediately upon detection of potentially dangerous conditions.

Standard Operating Procedures (SOPs) must be developed specifically for each cryogenic application in particle physics experiments. These procedures should include detailed instructions for normal operations, as well as comprehensive emergency response protocols. Regular drills and simulations help ensure that all team members can execute these procedures effectively under pressure.

Risk assessment frameworks for cryogenic operations should incorporate both quantitative and qualitative methodologies. Failure Mode and Effects Analysis (FMEA) and Hazard and Operability Studies (HAZOP) are particularly valuable tools for identifying potential failure points in cryogenic systems before they manifest as actual incidents.

Containment systems and specialized storage vessels must be designed with multiple redundancies and fail-safe mechanisms. Regular pressure testing and integrity assessments help prevent catastrophic failures that could release large volumes of liquid nitrogen. Secondary containment systems should be implemented to capture any accidental spills or leaks.

Incident reporting systems must facilitate thorough documentation and analysis of all safety-related events, including near-misses. This information forms the foundation for continuous improvement of safety protocols through regular review cycles. Learning from minor incidents is crucial for preventing more serious accidents in the future.

International standards and best practices, such as those published by the International Cryogenic Engineering Conference (ICEC) and the Cryogenic Society of America (CSA), should be incorporated into institutional safety frameworks. These standards provide valuable benchmarks for safety performance and help ensure consistency across different research facilities working with liquid nitrogen in particle physics applications.

Environmental Impact and Sustainability of Cryogenic Systems

The environmental impact of cryogenic systems used in particle physics, particularly those utilizing liquid nitrogen, presents significant sustainability challenges and opportunities. These systems consume substantial energy during the production, transportation, and maintenance of cryogenic temperatures, contributing to their carbon footprint. The liquefaction process for nitrogen alone requires approximately 0.5 kWh/kg, which translates to considerable energy consumption in large-scale particle physics facilities where thousands of liters may be used daily.

Despite these energy demands, liquid nitrogen systems offer environmental advantages compared to alternative cooling technologies. With a Global Warming Potential (GWP) of zero, nitrogen presents no direct greenhouse effect when released to the atmosphere, unlike synthetic refrigerants that can have GWP values thousands of times higher than CO2. Additionally, nitrogen comprises 78% of Earth's atmosphere, making it an abundant resource with minimal extraction impact.

Modern cryogenic facilities are increasingly implementing energy recovery systems to enhance sustainability. Heat exchangers that capture and repurpose the cooling capacity of evaporating nitrogen can improve overall system efficiency by 25-40%. Some advanced facilities employ closed-loop recondensation systems that recapture gaseous nitrogen, reducing both operational costs and environmental impact through decreased production requirements.

The longevity and reliability of cryogenic equipment also contributes to sustainability profiles. Well-maintained liquid nitrogen systems in particle physics applications typically operate for 15-20 years, reducing manufacturing-related environmental impacts compared to technologies requiring more frequent replacement. However, insulation materials used in cryogenic vessels, often composed of vacuum-jacketed systems or aerogels, present end-of-life disposal challenges that must be addressed in comprehensive environmental assessments.

Safety considerations intersect with environmental concerns in cryogenic system management. Nitrogen displacement of oxygen presents both workplace hazards and potential local environmental impacts if large releases occur in confined spaces. Modern facilities mitigate these risks through oxygen monitoring systems, proper ventilation, and emergency response protocols that minimize both safety and environmental risks.

Looking forward, research into alternative insulation materials, more efficient liquefaction processes, and integration with renewable energy sources represents promising directions for improving the sustainability of cryogenic systems in particle physics. Some facilities have begun powering liquefaction plants with solar or wind energy, creating pathways toward carbon-neutral cryogenic operations that maintain the scientific benefits of low-temperature environments while minimizing environmental impact.

Despite these energy demands, liquid nitrogen systems offer environmental advantages compared to alternative cooling technologies. With a Global Warming Potential (GWP) of zero, nitrogen presents no direct greenhouse effect when released to the atmosphere, unlike synthetic refrigerants that can have GWP values thousands of times higher than CO2. Additionally, nitrogen comprises 78% of Earth's atmosphere, making it an abundant resource with minimal extraction impact.

Modern cryogenic facilities are increasingly implementing energy recovery systems to enhance sustainability. Heat exchangers that capture and repurpose the cooling capacity of evaporating nitrogen can improve overall system efficiency by 25-40%. Some advanced facilities employ closed-loop recondensation systems that recapture gaseous nitrogen, reducing both operational costs and environmental impact through decreased production requirements.

The longevity and reliability of cryogenic equipment also contributes to sustainability profiles. Well-maintained liquid nitrogen systems in particle physics applications typically operate for 15-20 years, reducing manufacturing-related environmental impacts compared to technologies requiring more frequent replacement. However, insulation materials used in cryogenic vessels, often composed of vacuum-jacketed systems or aerogels, present end-of-life disposal challenges that must be addressed in comprehensive environmental assessments.

Safety considerations intersect with environmental concerns in cryogenic system management. Nitrogen displacement of oxygen presents both workplace hazards and potential local environmental impacts if large releases occur in confined spaces. Modern facilities mitigate these risks through oxygen monitoring systems, proper ventilation, and emergency response protocols that minimize both safety and environmental risks.

Looking forward, research into alternative insulation materials, more efficient liquefaction processes, and integration with renewable energy sources represents promising directions for improving the sustainability of cryogenic systems in particle physics. Some facilities have begun powering liquefaction plants with solar or wind energy, creating pathways toward carbon-neutral cryogenic operations that maintain the scientific benefits of low-temperature environments while minimizing environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!