How to Optimize Liquid Nitrogen Use in Food Preservation

OCT 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Food Preservation Background and Objectives

Cryogenic food preservation represents a significant advancement in the food industry's quest for extending shelf life while maintaining product quality. The use of liquid nitrogen, with its extremely low temperature of -196°C, has revolutionized food preservation techniques since its commercial introduction in the mid-20th century. This technology evolved from traditional freezing methods, offering superior preservation capabilities through rapid freezing that minimizes cellular damage and preserves nutritional content.

The evolution of cryogenic preservation has been marked by continuous technological improvements, from basic immersion techniques to sophisticated cryogenic tunnels and spiral freezers. These advancements have enabled more precise temperature control, uniform freezing, and increased energy efficiency. The industry has witnessed a shift from batch processing to continuous flow systems, significantly enhancing production capacity and consistency.

Current trends in cryogenic food preservation focus on sustainability, efficiency optimization, and integration with other preservation technologies. The development of hybrid systems combining cryogenic freezing with modified atmosphere packaging or high-pressure processing represents the cutting edge of preservation technology. Additionally, advancements in cryogenic equipment design have led to reduced nitrogen consumption and improved thermal transfer efficiency.

The primary objective of optimizing liquid nitrogen use in food preservation is multifaceted. First, it aims to maximize preservation effectiveness while minimizing resource consumption, addressing both economic and environmental concerns. Second, it seeks to enhance product quality by preserving texture, flavor, and nutritional value through optimized freezing rates and temperature profiles. Third, it targets operational efficiency improvements through reduced processing times and increased throughput.

Another critical objective is to develop scalable solutions applicable across different food categories and production volumes. This includes creating flexible systems that can accommodate various product types and production requirements, from small-scale artisanal operations to large industrial facilities. The adaptability of cryogenic technology to diverse food matrices presents both challenges and opportunities for innovation.

The long-term technological goal extends beyond mere preservation to creating integrated food processing systems where cryogenic technology serves multiple functions, including texture modification, grinding facilitation, and packaging enhancement. This holistic approach aims to transform liquid nitrogen from a single-purpose coolant to a versatile processing tool that adds value throughout the production chain.

The evolution of cryogenic preservation has been marked by continuous technological improvements, from basic immersion techniques to sophisticated cryogenic tunnels and spiral freezers. These advancements have enabled more precise temperature control, uniform freezing, and increased energy efficiency. The industry has witnessed a shift from batch processing to continuous flow systems, significantly enhancing production capacity and consistency.

Current trends in cryogenic food preservation focus on sustainability, efficiency optimization, and integration with other preservation technologies. The development of hybrid systems combining cryogenic freezing with modified atmosphere packaging or high-pressure processing represents the cutting edge of preservation technology. Additionally, advancements in cryogenic equipment design have led to reduced nitrogen consumption and improved thermal transfer efficiency.

The primary objective of optimizing liquid nitrogen use in food preservation is multifaceted. First, it aims to maximize preservation effectiveness while minimizing resource consumption, addressing both economic and environmental concerns. Second, it seeks to enhance product quality by preserving texture, flavor, and nutritional value through optimized freezing rates and temperature profiles. Third, it targets operational efficiency improvements through reduced processing times and increased throughput.

Another critical objective is to develop scalable solutions applicable across different food categories and production volumes. This includes creating flexible systems that can accommodate various product types and production requirements, from small-scale artisanal operations to large industrial facilities. The adaptability of cryogenic technology to diverse food matrices presents both challenges and opportunities for innovation.

The long-term technological goal extends beyond mere preservation to creating integrated food processing systems where cryogenic technology serves multiple functions, including texture modification, grinding facilitation, and packaging enhancement. This holistic approach aims to transform liquid nitrogen from a single-purpose coolant to a versatile processing tool that adds value throughout the production chain.

Market Analysis of Liquid Nitrogen Food Preservation

The global market for liquid nitrogen in food preservation has experienced significant growth over the past decade, driven by increasing demand for frozen and convenience foods. The market size was valued at approximately $12.7 billion in 2022 and is projected to reach $18.5 billion by 2028, growing at a CAGR of 6.4% during the forecast period. This growth trajectory reflects the expanding applications of liquid nitrogen across various food preservation segments.

North America currently dominates the market with a 35% share, followed by Europe at 28% and Asia-Pacific at 25%. The Asia-Pacific region is expected to witness the fastest growth due to rapid industrialization, increasing disposable incomes, and changing food consumption patterns in countries like China and India. Latin America and the Middle East & Africa regions collectively account for the remaining 12% of the market.

The food and beverage industry represents the largest end-user segment, accounting for approximately 65% of liquid nitrogen consumption in preservation applications. Within this segment, frozen foods constitute the largest application area (40%), followed by dairy products (25%), beverages (20%), and other food items (15%). The pharmaceutical industry is another significant consumer, utilizing liquid nitrogen for preserving biological samples and medications.

Consumer preferences are increasingly shifting toward minimally processed foods with extended shelf life and preserved nutritional value. This trend has bolstered the adoption of cryogenic freezing using liquid nitrogen, as it offers superior quality retention compared to conventional freezing methods. Market research indicates that 78% of consumers are willing to pay premium prices for foods that maintain better texture, flavor, and nutritional content.

Supply chain dynamics play a crucial role in market development. The cost of liquid nitrogen varies significantly by region, ranging from $0.08 to $0.25 per liter, depending on production capacity, transportation infrastructure, and energy costs. Regions with established industrial gas infrastructure enjoy competitive advantages in terms of pricing and availability.

Regulatory frameworks governing food safety and handling of cryogenic substances significantly impact market dynamics. Stringent regulations in developed markets necessitate substantial investments in safety equipment and training, creating entry barriers for smaller players. Conversely, emerging markets with evolving regulatory landscapes present opportunities for market expansion, albeit with challenges related to standardization and compliance.

The competitive landscape features both global industrial gas giants and regional specialists. Major players include Air Liquide, Linde plc, Air Products, and Messer Group, collectively controlling approximately 70% of the global market. These companies are increasingly focusing on developing energy-efficient production methods and innovative delivery systems to optimize liquid nitrogen use in food preservation applications.

North America currently dominates the market with a 35% share, followed by Europe at 28% and Asia-Pacific at 25%. The Asia-Pacific region is expected to witness the fastest growth due to rapid industrialization, increasing disposable incomes, and changing food consumption patterns in countries like China and India. Latin America and the Middle East & Africa regions collectively account for the remaining 12% of the market.

The food and beverage industry represents the largest end-user segment, accounting for approximately 65% of liquid nitrogen consumption in preservation applications. Within this segment, frozen foods constitute the largest application area (40%), followed by dairy products (25%), beverages (20%), and other food items (15%). The pharmaceutical industry is another significant consumer, utilizing liquid nitrogen for preserving biological samples and medications.

Consumer preferences are increasingly shifting toward minimally processed foods with extended shelf life and preserved nutritional value. This trend has bolstered the adoption of cryogenic freezing using liquid nitrogen, as it offers superior quality retention compared to conventional freezing methods. Market research indicates that 78% of consumers are willing to pay premium prices for foods that maintain better texture, flavor, and nutritional content.

Supply chain dynamics play a crucial role in market development. The cost of liquid nitrogen varies significantly by region, ranging from $0.08 to $0.25 per liter, depending on production capacity, transportation infrastructure, and energy costs. Regions with established industrial gas infrastructure enjoy competitive advantages in terms of pricing and availability.

Regulatory frameworks governing food safety and handling of cryogenic substances significantly impact market dynamics. Stringent regulations in developed markets necessitate substantial investments in safety equipment and training, creating entry barriers for smaller players. Conversely, emerging markets with evolving regulatory landscapes present opportunities for market expansion, albeit with challenges related to standardization and compliance.

The competitive landscape features both global industrial gas giants and regional specialists. Major players include Air Liquide, Linde plc, Air Products, and Messer Group, collectively controlling approximately 70% of the global market. These companies are increasingly focusing on developing energy-efficient production methods and innovative delivery systems to optimize liquid nitrogen use in food preservation applications.

Current Challenges in Liquid Nitrogen Preservation Technology

Despite significant advancements in liquid nitrogen preservation technology, several critical challenges continue to impede optimal utilization in food preservation applications. The foremost challenge remains the high energy consumption associated with liquid nitrogen production and storage. The cryogenic liquefaction process requires substantial energy input, with current systems operating at approximately 40-50% of theoretical efficiency, resulting in considerable operational costs and environmental impact.

Temperature control precision presents another significant hurdle. Maintaining consistent ultra-low temperatures throughout the preservation process is technically demanding, with fluctuations as small as 2-3°C potentially compromising food quality. Current monitoring systems often lack the responsiveness needed for real-time adjustments, particularly during the critical rapid freezing phase.

Safety concerns constitute a persistent challenge in liquid nitrogen handling. The risk of cryogenic burns, asphyxiation in confined spaces, and pressure build-up in storage vessels necessitates rigorous safety protocols that many food processing facilities struggle to implement effectively. The absence of standardized safety frameworks specific to food industry applications compounds this issue.

Distribution infrastructure limitations significantly constrain widespread adoption. The specialized vacuum-insulated transport vessels required for liquid nitrogen delivery are costly and subject to boil-off losses of 0.5-1.5% daily. In regions with underdeveloped cold chain logistics, these challenges become particularly pronounced, limiting technology penetration in emerging markets.

Economic barriers remain substantial, with initial capital investment for cryogenic equipment ranging from $50,000 to several million dollars depending on scale. The return on investment timeline often extends beyond 3-5 years, deterring small and medium-sized food processors from adoption despite potential long-term benefits.

Technical expertise deficiency represents an often-overlooked challenge. The specialized knowledge required for optimal liquid nitrogen system operation and maintenance is not widely available in the food industry workforce. Training programs specifically tailored for food preservation applications remain limited, creating operational inefficiencies and potential safety risks.

Regulatory frameworks across different jurisdictions exhibit inconsistencies in addressing liquid nitrogen use in food processing. This regulatory uncertainty creates compliance challenges for companies operating across multiple markets and potentially inhibits innovation in application methodologies.

Sustainability concerns are increasingly prominent, with the carbon footprint of liquid nitrogen production becoming a consideration for environmentally conscious consumers and businesses. Current production methods generate approximately 0.8-1.2 kg of CO₂ equivalent per kilogram of liquid nitrogen, presenting challenges for companies with carbon reduction targets.

Temperature control precision presents another significant hurdle. Maintaining consistent ultra-low temperatures throughout the preservation process is technically demanding, with fluctuations as small as 2-3°C potentially compromising food quality. Current monitoring systems often lack the responsiveness needed for real-time adjustments, particularly during the critical rapid freezing phase.

Safety concerns constitute a persistent challenge in liquid nitrogen handling. The risk of cryogenic burns, asphyxiation in confined spaces, and pressure build-up in storage vessels necessitates rigorous safety protocols that many food processing facilities struggle to implement effectively. The absence of standardized safety frameworks specific to food industry applications compounds this issue.

Distribution infrastructure limitations significantly constrain widespread adoption. The specialized vacuum-insulated transport vessels required for liquid nitrogen delivery are costly and subject to boil-off losses of 0.5-1.5% daily. In regions with underdeveloped cold chain logistics, these challenges become particularly pronounced, limiting technology penetration in emerging markets.

Economic barriers remain substantial, with initial capital investment for cryogenic equipment ranging from $50,000 to several million dollars depending on scale. The return on investment timeline often extends beyond 3-5 years, deterring small and medium-sized food processors from adoption despite potential long-term benefits.

Technical expertise deficiency represents an often-overlooked challenge. The specialized knowledge required for optimal liquid nitrogen system operation and maintenance is not widely available in the food industry workforce. Training programs specifically tailored for food preservation applications remain limited, creating operational inefficiencies and potential safety risks.

Regulatory frameworks across different jurisdictions exhibit inconsistencies in addressing liquid nitrogen use in food processing. This regulatory uncertainty creates compliance challenges for companies operating across multiple markets and potentially inhibits innovation in application methodologies.

Sustainability concerns are increasingly prominent, with the carbon footprint of liquid nitrogen production becoming a consideration for environmentally conscious consumers and businesses. Current production methods generate approximately 0.8-1.2 kg of CO₂ equivalent per kilogram of liquid nitrogen, presenting challenges for companies with carbon reduction targets.

Current Liquid Nitrogen Optimization Techniques

01 Storage and transportation systems for liquid nitrogen

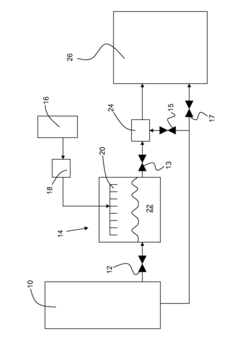

Optimized storage and transportation systems for liquid nitrogen involve specialized containers and vessels designed to minimize evaporation and maintain cryogenic temperatures. These systems incorporate vacuum insulation technology, pressure regulation mechanisms, and efficient transfer methods to ensure safe handling and reduced losses during storage and transport. Advanced monitoring systems are integrated to track temperature, pressure, and liquid levels for improved safety and efficiency.- Storage and transportation systems for liquid nitrogen: Various systems have been developed for the efficient storage and transportation of liquid nitrogen. These systems include specialized containers, vessels, and tanks designed to maintain the cryogenic temperatures required for liquid nitrogen. The designs focus on minimizing heat transfer, preventing evaporation, and ensuring safety during handling and transport. Advanced insulation techniques and pressure management systems are incorporated to optimize the storage efficiency and extend holding times.

- Cooling and refrigeration applications: Liquid nitrogen is widely used in cooling and refrigeration applications due to its extremely low temperature. Optimization techniques in this area focus on improving heat exchange efficiency, controlling cooling rates, and developing specialized equipment for specific cooling needs. These innovations include advanced heat exchangers, temperature control systems, and methods to maximize cooling capacity while minimizing liquid nitrogen consumption. Applications range from industrial freezing processes to medical sample preservation and superconductivity research.

- Energy efficiency and consumption reduction: Significant research has been conducted on optimizing the energy efficiency of liquid nitrogen systems and reducing overall consumption. These innovations include improved production methods, recovery systems that capture and reuse nitrogen gas, and advanced monitoring technologies that prevent waste. Energy-efficient liquefaction processes and intelligent control systems help minimize the power required for producing and maintaining liquid nitrogen, resulting in more sustainable and cost-effective operations.

- Safety systems and handling protocols: Safety is a critical aspect of liquid nitrogen optimization, given its hazardous properties. Innovations in this category include automated safety systems, specialized handling equipment, and advanced monitoring technologies to prevent accidents. These developments focus on minimizing risks associated with pressure buildup, oxygen displacement, and extreme cold exposure. Improved venting systems, personal protective equipment, and emergency response protocols have been designed to ensure safe handling and usage of liquid nitrogen in various applications.

- Industrial process applications and optimization: Liquid nitrogen is extensively used in various industrial processes, and optimization efforts focus on improving its application efficiency in specific industries. These include metal processing, food freezing, pharmaceutical manufacturing, and electronics production. Innovations in this area involve specialized delivery systems, precise temperature control mechanisms, and application-specific equipment designed to maximize the benefits of liquid nitrogen while minimizing consumption. Advanced process integration techniques help synchronize liquid nitrogen usage with production requirements for optimal results.

02 Liquid nitrogen cooling and refrigeration applications

Liquid nitrogen is utilized in various cooling and refrigeration applications where its extremely low temperature properties are optimized for maximum efficiency. These applications include food freezing, biological sample preservation, and industrial cooling processes. Optimization involves controlled release mechanisms, heat exchange systems, and temperature gradient management to achieve precise cooling rates while minimizing nitrogen consumption. Advanced designs incorporate recirculation systems to capture and reuse nitrogen gas.Expand Specific Solutions03 Energy efficiency improvements in liquid nitrogen systems

Energy efficiency in liquid nitrogen systems is achieved through optimized production, liquefaction, and utilization processes. These improvements include enhanced heat exchangers, advanced insulation materials, and regenerative cooling cycles that recover cold energy. Waste heat recovery systems and integrated process control algorithms help minimize energy consumption during nitrogen production and use. Optimization techniques focus on reducing power requirements while maintaining or improving system performance.Expand Specific Solutions04 Liquid nitrogen spray and treatment technologies

Liquid nitrogen spray and treatment technologies are optimized for various industrial and medical applications. These include precision spray nozzles, controlled delivery systems, and specialized applicators designed for surface treatment, cryotherapy, and material processing. Optimization focuses on spray pattern uniformity, droplet size control, and application rate precision to achieve desired treatment effects while minimizing nitrogen consumption. Advanced systems incorporate feedback mechanisms to adjust spray parameters based on treatment results.Expand Specific Solutions05 Safety and monitoring systems for liquid nitrogen handling

Safety and monitoring systems for liquid nitrogen handling are designed to prevent accidents and ensure proper operation. These include oxygen level monitors, pressure relief systems, automated shutdown mechanisms, and personal protective equipment. Optimization involves integrating sensors and alarms that provide real-time data on critical parameters, implementing redundant safety features, and developing intelligent control systems that can predict and prevent potential hazards. Training protocols and handling procedures are also optimized to minimize risk during liquid nitrogen operations.Expand Specific Solutions

Leading Companies in Cryogenic Preservation Industry

The liquid nitrogen food preservation market is in a growth phase, with increasing demand driven by the need for efficient cold chain solutions. The global market size is expanding due to rising processed food consumption and extended shelf-life requirements. Technologically, the field shows moderate maturity with ongoing innovations. Air Liquide SA and Air Liquide France Industries SA lead as industrial gas suppliers with established cryogenic expertise. Food industry players like Frito-Lay, Nisshin OilliO Group, and Toyo Seikan are implementing advanced preservation techniques. Research institutions including Zhejiang University, University of Florida, and CNRS contribute to technological advancement through fundamental research. The competitive landscape features collaboration between gas suppliers, equipment manufacturers like SANYO Electric, and food processors to optimize nitrogen utilization and reduce costs.

Air Liquide SA

Technical Solution: Air Liquide has developed comprehensive liquid nitrogen (LN2) food preservation systems utilizing cryogenic freezing technology. Their solutions include the Aligal™ freezing systems that precisely control temperature during the freezing process to maintain food quality. The company employs tunnel freezers with optimized LN2 injection systems that reduce nitrogen consumption by up to 15% compared to conventional methods. Their advanced nozzle design ensures even distribution of liquid nitrogen throughout the freezing chamber, minimizing wastage while maximizing cooling efficiency. Air Liquide has also pioneered closed-loop nitrogen recovery systems that capture and recycle nitrogen vapor, reducing overall consumption by approximately 20-30%. Their smart monitoring systems continuously adjust nitrogen flow based on product load and temperature requirements, further optimizing usage patterns and reducing waste.

Strengths: Industry-leading nitrogen recovery systems that significantly reduce consumption costs; proprietary nozzle technology that ensures even distribution and efficient usage; comprehensive monitoring systems that optimize nitrogen flow in real-time. Weaknesses: Higher initial capital investment compared to traditional freezing methods; requires specialized technical expertise for maintenance and operation; system optimization depends on consistent production volumes.

Shanghai Origincell Biological Cryo Equipment Co. Ltd.

Technical Solution: Shanghai Origincell has pioneered advanced liquid nitrogen preservation systems specifically optimized for food applications. Their technology employs a multi-stage cooling approach that gradually reduces product temperature, minimizing thermal shock while optimizing nitrogen efficiency. The company's proprietary "CryoSmart" system incorporates precision sensors that monitor product core temperatures and automatically adjust nitrogen flow rates, reducing consumption by up to 25% compared to fixed-flow systems. Their equipment features specialized spray nozzles that create ultra-fine nitrogen mist, increasing surface contact and cooling efficiency while minimizing usage. Origincell has also developed hybrid systems that combine mechanical pre-cooling with liquid nitrogen finishing stages, reducing overall LN2 requirements by approximately 30-40%. Their latest innovations include AI-driven predictive algorithms that learn from operational patterns to further optimize nitrogen dispensing based on specific food product characteristics.

Strengths: Highly efficient multi-stage cooling technology that significantly reduces nitrogen consumption; intelligent control systems that automatically optimize usage based on product requirements; specialized nozzle design that maximizes cooling efficiency. Weaknesses: Limited global service network compared to international competitors; higher initial investment costs; requires consistent production volumes to achieve maximum efficiency benefits.

Key Patents and Innovations in Cryogenic Preservation

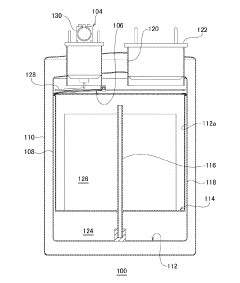

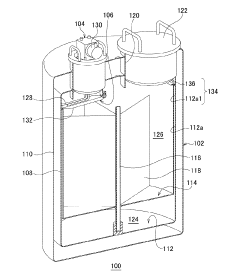

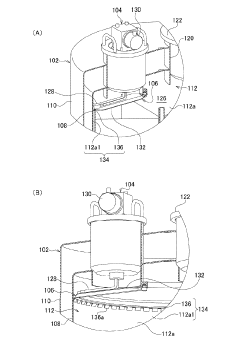

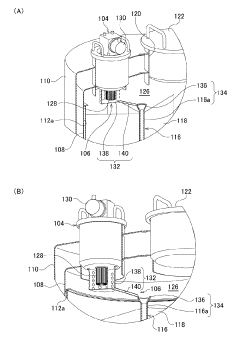

Preservation device

PatentActiveJP2018077011A

Innovation

- A storage device design with a refrigerator integrated within the gas phase, incorporating a guide section to direct condensed liquid nitrogen back to the liquid phase, and a splash control mechanism to prevent contamination, while maintaining uniform temperature distribution.

Method and system for treating food items with an additive and liquid nitrogen

PatentInactiveUS8470383B2

Innovation

- A method involving the use of liquid nitrogen combined with a solid antimicrobial additive, where the additive is sprayed onto the liquid nitrogen to form discrete particles, which are then mixed and introduced into food processing equipment to provide both cooling and sanitizing effects, thereby addressing the limitations of existing refrigeration and sanitization methods.

Safety Standards and Regulatory Compliance

The regulatory landscape governing liquid nitrogen use in food preservation is complex and multifaceted, requiring strict adherence to various safety standards. In the United States, the Occupational Safety and Health Administration (OSHA) has established comprehensive guidelines for handling cryogenic liquids, including liquid nitrogen. These regulations mandate proper ventilation systems, personal protective equipment (PPE), and regular safety training for personnel. The Food and Drug Administration (FDA) further regulates liquid nitrogen in food applications, particularly focusing on direct food contact scenarios and potential contamination risks.

European regulations, primarily through the European Food Safety Authority (EFSA), impose additional requirements concerning the purity of liquid nitrogen used in food preservation. The EU Regulation 852/2004 on food hygiene specifically addresses cryogenic freezing processes, requiring documented hazard analysis and critical control points (HACCP) implementation. These standards are more stringent than their American counterparts, particularly regarding documentation and traceability requirements.

The International Organization for Standardization (ISO) provides globally recognized standards for cryogenic equipment design and operation. ISO 21009-1:2008 specifically addresses insulated vessels for liquid nitrogen, establishing minimum safety requirements for containers used in food preservation applications. Compliance with these standards is increasingly becoming a prerequisite for international trade in preserved food products.

Risk assessment protocols represent another critical component of regulatory compliance. The American Society of Mechanical Engineers (ASME) and the Compressed Gas Association (CGA) have developed specific guidelines for risk assessment in cryogenic applications, including P-8 Standard for Safe Practices in Oxygen-Enriched Atmospheres and SB-2 Oxygen-Deficient Atmospheres. These protocols help identify potential hazards associated with liquid nitrogen use and establish mitigation strategies.

Worker safety regulations are particularly stringent, given the significant hazards associated with liquid nitrogen handling. These include the risk of cryogenic burns, asphyxiation in confined spaces, and potential explosion hazards from pressure buildup. Training requirements typically include emergency response procedures, first aid for cryogenic injuries, and proper equipment operation protocols. Documentation of this training is mandatory in most jurisdictions.

Environmental regulations also impact liquid nitrogen use in food preservation. While liquid nitrogen itself is environmentally benign, the energy consumption associated with its production has carbon footprint implications. Several jurisdictions now require carbon footprint reporting for industrial processes, including cryogenic food preservation. Companies optimizing liquid nitrogen use must therefore consider both direct compliance requirements and broader environmental sustainability standards.

European regulations, primarily through the European Food Safety Authority (EFSA), impose additional requirements concerning the purity of liquid nitrogen used in food preservation. The EU Regulation 852/2004 on food hygiene specifically addresses cryogenic freezing processes, requiring documented hazard analysis and critical control points (HACCP) implementation. These standards are more stringent than their American counterparts, particularly regarding documentation and traceability requirements.

The International Organization for Standardization (ISO) provides globally recognized standards for cryogenic equipment design and operation. ISO 21009-1:2008 specifically addresses insulated vessels for liquid nitrogen, establishing minimum safety requirements for containers used in food preservation applications. Compliance with these standards is increasingly becoming a prerequisite for international trade in preserved food products.

Risk assessment protocols represent another critical component of regulatory compliance. The American Society of Mechanical Engineers (ASME) and the Compressed Gas Association (CGA) have developed specific guidelines for risk assessment in cryogenic applications, including P-8 Standard for Safe Practices in Oxygen-Enriched Atmospheres and SB-2 Oxygen-Deficient Atmospheres. These protocols help identify potential hazards associated with liquid nitrogen use and establish mitigation strategies.

Worker safety regulations are particularly stringent, given the significant hazards associated with liquid nitrogen handling. These include the risk of cryogenic burns, asphyxiation in confined spaces, and potential explosion hazards from pressure buildup. Training requirements typically include emergency response procedures, first aid for cryogenic injuries, and proper equipment operation protocols. Documentation of this training is mandatory in most jurisdictions.

Environmental regulations also impact liquid nitrogen use in food preservation. While liquid nitrogen itself is environmentally benign, the energy consumption associated with its production has carbon footprint implications. Several jurisdictions now require carbon footprint reporting for industrial processes, including cryogenic food preservation. Companies optimizing liquid nitrogen use must therefore consider both direct compliance requirements and broader environmental sustainability standards.

Environmental Impact and Sustainability Considerations

The environmental impact of liquid nitrogen in food preservation extends beyond its immediate application, encompassing the entire lifecycle from production to disposal. Liquid nitrogen production is energy-intensive, requiring approximately 0.7 kWh of electricity per kilogram produced, which translates to significant carbon emissions when sourced from non-renewable energy. A medium-sized food processing facility utilizing liquid nitrogen can indirectly contribute to 150-200 tons of CO2 emissions annually through nitrogen production alone.

Nitrogen production facilities also face challenges related to water usage and potential air pollution. The air separation process used to extract nitrogen requires substantial cooling water, with larger plants consuming up to 1,000 cubic meters daily. Additionally, older production facilities may release NOx compounds during operation, contributing to air quality degradation in surrounding areas.

From a sustainability perspective, optimizing liquid nitrogen use presents several opportunities for improvement. Implementing closed-loop systems can recapture nitrogen gas after use, allowing for reconversion to liquid form with significantly less energy than initial production. Such systems have demonstrated recovery rates of 60-75% in pilot implementations, substantially reducing the environmental footprint of food preservation operations.

The transportation of liquid nitrogen also merits consideration in sustainability assessments. Traditional delivery methods involve diesel-powered tanker trucks traveling between production facilities and end users, generating approximately 62g of CO2 per ton-kilometer. On-site nitrogen generation presents an alternative that eliminates these transportation emissions, though the technology requires significant initial investment and may not be feasible for smaller operations.

Emerging technologies offer promising pathways toward more sustainable liquid nitrogen utilization. Renewable energy-powered production facilities are beginning to appear in regions with abundant solar or wind resources, potentially reducing the carbon footprint of nitrogen production by 70-90%. Additionally, advanced insulation materials and smart dispensing systems can reduce nitrogen losses during storage and application by 15-25%, addressing a significant source of waste in current preservation methods.

Regulatory frameworks are increasingly acknowledging these environmental considerations, with several countries implementing carbon pricing mechanisms that affect the economics of liquid nitrogen use. Food producers utilizing more efficient nitrogen systems may qualify for sustainability certifications or carbon credits in certain markets, creating additional incentives for optimization beyond direct cost savings.

Nitrogen production facilities also face challenges related to water usage and potential air pollution. The air separation process used to extract nitrogen requires substantial cooling water, with larger plants consuming up to 1,000 cubic meters daily. Additionally, older production facilities may release NOx compounds during operation, contributing to air quality degradation in surrounding areas.

From a sustainability perspective, optimizing liquid nitrogen use presents several opportunities for improvement. Implementing closed-loop systems can recapture nitrogen gas after use, allowing for reconversion to liquid form with significantly less energy than initial production. Such systems have demonstrated recovery rates of 60-75% in pilot implementations, substantially reducing the environmental footprint of food preservation operations.

The transportation of liquid nitrogen also merits consideration in sustainability assessments. Traditional delivery methods involve diesel-powered tanker trucks traveling between production facilities and end users, generating approximately 62g of CO2 per ton-kilometer. On-site nitrogen generation presents an alternative that eliminates these transportation emissions, though the technology requires significant initial investment and may not be feasible for smaller operations.

Emerging technologies offer promising pathways toward more sustainable liquid nitrogen utilization. Renewable energy-powered production facilities are beginning to appear in regions with abundant solar or wind resources, potentially reducing the carbon footprint of nitrogen production by 70-90%. Additionally, advanced insulation materials and smart dispensing systems can reduce nitrogen losses during storage and application by 15-25%, addressing a significant source of waste in current preservation methods.

Regulatory frameworks are increasingly acknowledging these environmental considerations, with several countries implementing carbon pricing mechanisms that affect the economics of liquid nitrogen use. Food producers utilizing more efficient nitrogen systems may qualify for sustainability certifications or carbon credits in certain markets, creating additional incentives for optimization beyond direct cost savings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!