How to Maximize Efficiency in Liquid Nitrogen Pump Systems

OCT 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Pump Technology Evolution and Objectives

Cryogenic pump technology has evolved significantly over the past seven decades, with liquid nitrogen pumping systems representing a critical component in various industrial applications. The journey began in the 1950s with rudimentary reciprocating pumps that suffered from poor efficiency and frequent maintenance issues due to the extreme temperature conditions. By the 1970s, centrifugal pumps adapted for cryogenic applications emerged, offering improved flow rates but still struggling with efficiency losses from heat transfer and cavitation.

The 1990s marked a significant turning point with the introduction of specialized cryogenic pump designs featuring advanced insulation techniques and materials capable of withstanding extreme temperature gradients. These innovations reduced heat ingress and improved overall system efficiency by 15-20% compared to earlier generations. The early 2000s saw the integration of computational fluid dynamics (CFD) in pump design, enabling engineers to optimize flow paths and minimize turbulence, further enhancing efficiency.

Current technological trends focus on maximizing liquid nitrogen pump efficiency through several parallel approaches. Advanced materials science has yielded new composite materials and coatings that maintain structural integrity at cryogenic temperatures while providing superior thermal insulation properties. Simultaneously, precision manufacturing techniques have improved component tolerances, reducing mechanical losses and improving volumetric efficiency.

The integration of smart sensors and real-time monitoring systems represents another significant advancement, allowing for dynamic adjustment of operating parameters based on system conditions. These systems can detect early signs of cavitation, flow irregularities, or thermal inefficiencies, enabling preventive measures before performance degradation occurs. Additionally, energy recovery systems that capture and utilize the cooling potential of vaporized nitrogen have emerged as promising efficiency enhancers.

The primary objectives for future liquid nitrogen pump technology development include achieving thermal efficiency improvements of at least 30% compared to current standards, reducing energy consumption by 25%, and extending mean time between maintenance by 40%. Additional goals focus on developing pump systems with broader operating ranges to accommodate variable flow demands without significant efficiency penalties, as well as creating more compact designs that minimize footprint while maintaining performance.

Another critical objective is the development of standardized efficiency metrics and testing protocols specifically for cryogenic pump systems, as current industrial standards often fail to address the unique challenges of extremely low-temperature operations. This standardization would enable more accurate comparison between different technologies and accelerate the adoption of truly superior solutions across industries ranging from healthcare and food processing to aerospace and semiconductor manufacturing.

The 1990s marked a significant turning point with the introduction of specialized cryogenic pump designs featuring advanced insulation techniques and materials capable of withstanding extreme temperature gradients. These innovations reduced heat ingress and improved overall system efficiency by 15-20% compared to earlier generations. The early 2000s saw the integration of computational fluid dynamics (CFD) in pump design, enabling engineers to optimize flow paths and minimize turbulence, further enhancing efficiency.

Current technological trends focus on maximizing liquid nitrogen pump efficiency through several parallel approaches. Advanced materials science has yielded new composite materials and coatings that maintain structural integrity at cryogenic temperatures while providing superior thermal insulation properties. Simultaneously, precision manufacturing techniques have improved component tolerances, reducing mechanical losses and improving volumetric efficiency.

The integration of smart sensors and real-time monitoring systems represents another significant advancement, allowing for dynamic adjustment of operating parameters based on system conditions. These systems can detect early signs of cavitation, flow irregularities, or thermal inefficiencies, enabling preventive measures before performance degradation occurs. Additionally, energy recovery systems that capture and utilize the cooling potential of vaporized nitrogen have emerged as promising efficiency enhancers.

The primary objectives for future liquid nitrogen pump technology development include achieving thermal efficiency improvements of at least 30% compared to current standards, reducing energy consumption by 25%, and extending mean time between maintenance by 40%. Additional goals focus on developing pump systems with broader operating ranges to accommodate variable flow demands without significant efficiency penalties, as well as creating more compact designs that minimize footprint while maintaining performance.

Another critical objective is the development of standardized efficiency metrics and testing protocols specifically for cryogenic pump systems, as current industrial standards often fail to address the unique challenges of extremely low-temperature operations. This standardization would enable more accurate comparison between different technologies and accelerate the adoption of truly superior solutions across industries ranging from healthcare and food processing to aerospace and semiconductor manufacturing.

Market Analysis for Efficient Liquid Nitrogen Systems

The global liquid nitrogen market is experiencing robust growth, driven primarily by expanding applications across diverse industries. The market size was valued at approximately 16.5 billion USD in 2022 and is projected to reach 25.3 billion USD by 2030, representing a compound annual growth rate of 5.5%. This growth trajectory underscores the increasing demand for efficient liquid nitrogen pump systems across various sectors.

Healthcare and pharmaceutical industries constitute the largest market segment, accounting for nearly 38% of the total market share. The critical role of liquid nitrogen in cryopreservation of biological samples, vaccines, and other medical materials has been further emphasized during recent global health challenges. Additionally, the food and beverage industry represents another significant market segment, utilizing liquid nitrogen for flash freezing, packaging, and transportation of perishable goods.

Industrial manufacturing applications, particularly in metal processing, electronics manufacturing, and rubber production, collectively account for approximately 27% of market demand. The semiconductor industry specifically has shown accelerated demand patterns, with liquid nitrogen consumption increasing at 7.2% annually due to expansion in chip manufacturing facilities globally.

Geographically, North America and Europe currently dominate the market with combined market share of 58%. However, the Asia-Pacific region is demonstrating the fastest growth rate at 6.8% annually, primarily driven by rapid industrialization in China, India, and South Korea. Emerging economies in Latin America and Africa are also showing increased adoption, albeit from a smaller base.

Market analysis reveals several key demand drivers for efficient liquid nitrogen systems. Energy efficiency ranks as the primary concern among 76% of end-users surveyed, followed by operational reliability (68%) and maintenance costs (61%). This indicates a clear market preference for pump systems that minimize energy consumption while maintaining consistent performance parameters.

Price sensitivity varies significantly across market segments. While healthcare and semiconductor industries prioritize performance and reliability over initial acquisition costs, general industrial applications demonstrate higher price elasticity. The average return on investment period expected by customers ranges from 2.5 to 4 years, depending on the application intensity and operational hours.

Customer feedback analysis indicates growing demand for integrated monitoring systems, with 82% of industrial users expressing interest in real-time efficiency tracking capabilities. Additionally, 64% of respondents identified interest in systems with variable flow capabilities to accommodate fluctuating production requirements, suggesting a market opportunity for adaptive pump technologies.

Healthcare and pharmaceutical industries constitute the largest market segment, accounting for nearly 38% of the total market share. The critical role of liquid nitrogen in cryopreservation of biological samples, vaccines, and other medical materials has been further emphasized during recent global health challenges. Additionally, the food and beverage industry represents another significant market segment, utilizing liquid nitrogen for flash freezing, packaging, and transportation of perishable goods.

Industrial manufacturing applications, particularly in metal processing, electronics manufacturing, and rubber production, collectively account for approximately 27% of market demand. The semiconductor industry specifically has shown accelerated demand patterns, with liquid nitrogen consumption increasing at 7.2% annually due to expansion in chip manufacturing facilities globally.

Geographically, North America and Europe currently dominate the market with combined market share of 58%. However, the Asia-Pacific region is demonstrating the fastest growth rate at 6.8% annually, primarily driven by rapid industrialization in China, India, and South Korea. Emerging economies in Latin America and Africa are also showing increased adoption, albeit from a smaller base.

Market analysis reveals several key demand drivers for efficient liquid nitrogen systems. Energy efficiency ranks as the primary concern among 76% of end-users surveyed, followed by operational reliability (68%) and maintenance costs (61%). This indicates a clear market preference for pump systems that minimize energy consumption while maintaining consistent performance parameters.

Price sensitivity varies significantly across market segments. While healthcare and semiconductor industries prioritize performance and reliability over initial acquisition costs, general industrial applications demonstrate higher price elasticity. The average return on investment period expected by customers ranges from 2.5 to 4 years, depending on the application intensity and operational hours.

Customer feedback analysis indicates growing demand for integrated monitoring systems, with 82% of industrial users expressing interest in real-time efficiency tracking capabilities. Additionally, 64% of respondents identified interest in systems with variable flow capabilities to accommodate fluctuating production requirements, suggesting a market opportunity for adaptive pump technologies.

Current Challenges in LN2 Pump Technology

Liquid nitrogen (LN2) pump systems face several significant technical challenges that limit their efficiency and operational reliability. The primary issue stems from the extreme cryogenic temperatures (-196°C) at which these systems operate, causing conventional materials to become brittle and prone to failure. This temperature differential also creates substantial thermal stress at connection points between ambient and cryogenic components, leading to frequent seal failures and system leakage.

Heat infiltration represents another major challenge, as even minimal heat ingress causes nitrogen vaporization, resulting in cavitation within pump mechanisms. This phenomenon not only reduces pumping efficiency but also accelerates mechanical wear and can trigger system instability. Current insulation technologies struggle to provide adequate thermal isolation without adding excessive bulk or weight to the system.

Power consumption efficiency remains suboptimal in existing LN2 pump designs. Many systems require significant energy input relative to their effective output, particularly during startup phases when thermal stabilization is occurring. This inefficiency is compounded by the need for redundant safety systems and backup mechanisms, which add complexity and further energy demands.

Maintenance requirements present ongoing operational challenges. The specialized nature of cryogenic equipment necessitates highly trained technicians, while the frequent need to warm systems to ambient temperature for repairs results in substantial downtime and nitrogen loss. Current designs often prioritize reliability over serviceability, making component replacement difficult and time-consuming.

Control system limitations also impact efficiency, as many existing pump systems lack sophisticated monitoring capabilities for real-time flow optimization. The rapid response needed to address fluctuations in cryogenic fluid behavior requires advanced sensors capable of functioning reliably at extreme temperatures—technology that remains underdeveloped.

Material compatibility issues persist despite advances in cryogenic-rated components. Standard lubricants solidify at LN2 temperatures, necessitating specialized formulations that often deliver suboptimal performance. Similarly, electronic control components must be carefully isolated from cryogenic environments, creating design constraints that limit integration possibilities.

Scalability challenges emerge when attempting to optimize systems across different capacity requirements. Small-scale laboratory pumps and industrial-scale systems face fundamentally different engineering constraints, with few design principles transferring effectively between applications. This has resulted in market fragmentation and limited standardization, hindering broader technological advancement in the field.

Heat infiltration represents another major challenge, as even minimal heat ingress causes nitrogen vaporization, resulting in cavitation within pump mechanisms. This phenomenon not only reduces pumping efficiency but also accelerates mechanical wear and can trigger system instability. Current insulation technologies struggle to provide adequate thermal isolation without adding excessive bulk or weight to the system.

Power consumption efficiency remains suboptimal in existing LN2 pump designs. Many systems require significant energy input relative to their effective output, particularly during startup phases when thermal stabilization is occurring. This inefficiency is compounded by the need for redundant safety systems and backup mechanisms, which add complexity and further energy demands.

Maintenance requirements present ongoing operational challenges. The specialized nature of cryogenic equipment necessitates highly trained technicians, while the frequent need to warm systems to ambient temperature for repairs results in substantial downtime and nitrogen loss. Current designs often prioritize reliability over serviceability, making component replacement difficult and time-consuming.

Control system limitations also impact efficiency, as many existing pump systems lack sophisticated monitoring capabilities for real-time flow optimization. The rapid response needed to address fluctuations in cryogenic fluid behavior requires advanced sensors capable of functioning reliably at extreme temperatures—technology that remains underdeveloped.

Material compatibility issues persist despite advances in cryogenic-rated components. Standard lubricants solidify at LN2 temperatures, necessitating specialized formulations that often deliver suboptimal performance. Similarly, electronic control components must be carefully isolated from cryogenic environments, creating design constraints that limit integration possibilities.

Scalability challenges emerge when attempting to optimize systems across different capacity requirements. Small-scale laboratory pumps and industrial-scale systems face fundamentally different engineering constraints, with few design principles transferring effectively between applications. This has resulted in market fragmentation and limited standardization, hindering broader technological advancement in the field.

State-of-the-Art LN2 Pump Efficiency Solutions

01 Pump design optimization for liquid nitrogen systems

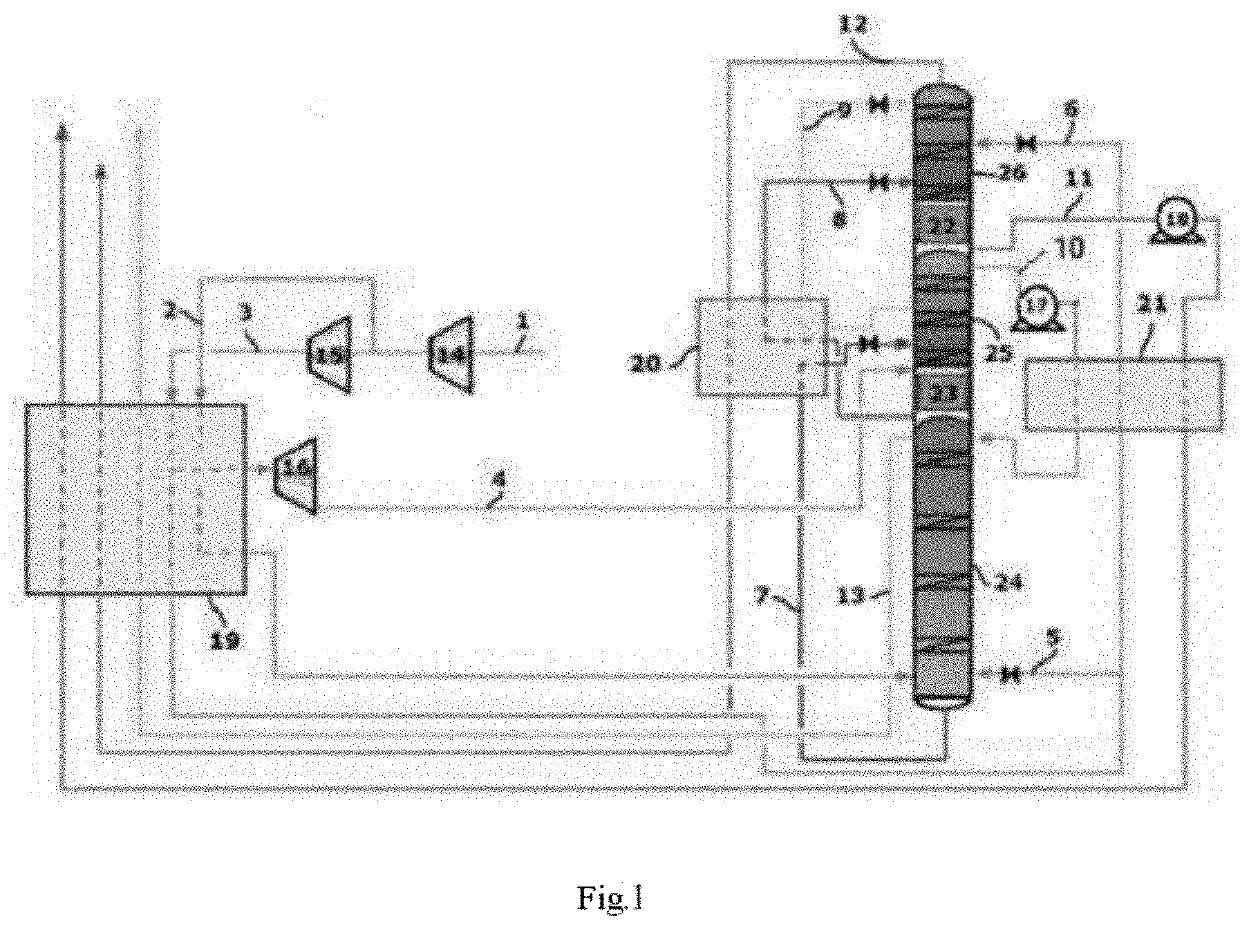

Optimizing the design of pumps specifically for liquid nitrogen applications can significantly improve efficiency. This includes specialized impeller designs, appropriate materials selection for cryogenic temperatures, and optimized flow path geometries. These design improvements help reduce energy losses and increase the overall efficiency of liquid nitrogen pumping systems.- Pump design optimization for cryogenic applications: Specialized pump designs for liquid nitrogen applications focus on optimizing efficiency through improved impeller geometry, reduced friction, and enhanced thermal insulation. These designs minimize heat transfer to the cryogenic fluid, reduce vapor formation, and maintain stable flow characteristics. Advanced materials and precision engineering help overcome the challenges of handling extremely low-temperature fluids while maximizing energy efficiency and operational reliability.

- Thermal insulation and heat management systems: Effective thermal insulation is critical for liquid nitrogen pump efficiency. Advanced insulation techniques prevent ambient heat from warming the cryogenic fluid, which would cause vaporization and reduce pumping efficiency. These systems incorporate vacuum-jacketed components, multi-layer insulation materials, and strategic heat shields. Proper heat management reduces nitrogen boil-off, minimizes energy losses, and extends equipment lifespan while maintaining consistent pump performance.

- Integrated monitoring and control systems: Smart monitoring and control systems significantly improve liquid nitrogen pump efficiency by continuously optimizing operational parameters. These systems incorporate sensors for temperature, pressure, flow rate, and vibration monitoring. Advanced algorithms adjust pump speed, valve positions, and cooling cycles in real-time to maintain optimal efficiency across varying load conditions. Automated fault detection and predictive maintenance capabilities reduce downtime and prevent efficiency losses from developing problems.

- Energy recovery and recirculation technologies: Energy recovery systems capture and reuse cold energy from liquid nitrogen processes, significantly improving overall system efficiency. These technologies include heat exchangers that pre-cool incoming nitrogen with the cold from vaporized nitrogen, expansion energy recovery systems, and closed-loop recirculation designs. By harnessing otherwise wasted energy, these systems reduce power consumption, lower operating costs, and improve the environmental footprint of liquid nitrogen operations.

- Multi-stage pumping and pressure optimization: Multi-stage pumping configurations enhance liquid nitrogen system efficiency by distributing the pressure increase across several stages. This approach reduces mechanical stress, minimizes heat generation, and allows for intercooling between stages. Pressure optimization techniques ensure that each component operates at its most efficient point, preventing energy waste from over-pressurization or flow restrictions. These systems often incorporate variable frequency drives to match pump output precisely to system requirements.

02 Thermal insulation and heat exchange management

Effective thermal insulation and heat exchange management are crucial for maintaining efficiency in liquid nitrogen pump systems. This involves minimizing heat ingress through advanced insulation materials, optimized vacuum spaces, and strategic placement of components. Proper heat exchange management reduces nitrogen boil-off and maintains the liquid state, thereby improving overall system efficiency.Expand Specific Solutions03 Control systems and automation for efficiency optimization

Advanced control systems and automation technologies can significantly enhance the efficiency of liquid nitrogen pump systems. These include intelligent flow control, pressure monitoring, variable speed drives, and automated operational adjustments based on real-time conditions. Such systems optimize energy consumption and maintain optimal operating parameters under varying load conditions.Expand Specific Solutions04 Energy recovery and recycling systems

Energy recovery and recycling systems capture and reuse energy that would otherwise be lost in liquid nitrogen pumping operations. These include pressure energy recovery devices, cold energy utilization systems, and gas recapture technologies. By recovering and reusing energy, these systems significantly improve the overall efficiency of liquid nitrogen pump operations.Expand Specific Solutions05 Novel pump configurations and multi-stage systems

Innovative pump configurations and multi-stage systems offer improved efficiency for liquid nitrogen applications. These include specialized centrifugal designs, submerged pump arrangements, and cascaded pumping systems. Such configurations optimize performance across varying pressure requirements and flow conditions, resulting in higher overall system efficiency and reduced energy consumption.Expand Specific Solutions

Leading Manufacturers and Industry Competition

The liquid nitrogen pump systems market is currently in a growth phase, characterized by increasing demand across industrial gas, healthcare, and energy sectors. The market size is estimated to be expanding at a CAGR of 4-5%, driven by applications in cryogenics, food processing, and medical equipment. Technologically, the field shows varying maturity levels, with established players like Air Liquide, Linde GmbH, and Air Products & Chemicals leading innovation in efficiency optimization. Emerging competitors such as Jereh Group and Nitricity are introducing disruptive technologies focused on energy efficiency and digital control systems. The competitive landscape features traditional industrial gas giants alongside specialized equipment manufacturers like Flowtech and Pfeiffer Vacuum, creating a dynamic environment where efficiency improvements represent the primary competitive advantage.

Air Liquide SA

Technical Solution: Air Liquide has developed the CryoStar® pump system specifically engineered for maximizing efficiency in liquid nitrogen applications. Their technology employs a unique combination of submerged pump designs that eliminate the need for long suction lines, reducing heat ingress and cavitation risks. The system features proprietary impeller geometries optimized through computational fluid dynamics to achieve peak efficiency at cryogenic temperatures, resulting in energy consumption reductions of up to 18% compared to conventional designs[5]. Air Liquide's pumps incorporate specialized mechanical seals with self-lubricating properties that maintain performance at extreme low temperatures while minimizing nitrogen losses. Their integrated automation platform continuously monitors over 20 operational parameters to maintain optimal efficiency, with predictive maintenance algorithms that identify potential issues before they impact performance. Additionally, Air Liquide has implemented innovative pressure management systems that maintain ideal net positive suction head conditions, allowing their pumps to operate closer to their maximum efficiency points while preventing cavitation damage that typically reduces pump lifespan and efficiency in cryogenic applications.

Strengths: Submerged pump design significantly reduces heat transfer and improves overall system efficiency; Advanced monitoring and control systems optimize performance in real-time; Extensive global service network provides reliable maintenance support. Weaknesses: System complexity requires specialized training for operators; Higher initial investment compared to standard pump systems; Customization requirements for specific applications may extend implementation timelines.

Exxonmobil Upstream Research Co.

Technical Solution: ExxonMobil has developed the CryoEfficient™ liquid nitrogen pump system designed specifically for high-throughput industrial applications. Their technology utilizes multistage centrifugal pumps with specialized impeller designs optimized through computational fluid dynamics for cryogenic service, achieving efficiency improvements of up to 22% compared to conventional designs[8]. The system incorporates proprietary thermal management techniques including strategic insulation placement and material selection that minimizes heat transfer while maintaining structural integrity at extreme temperatures. ExxonMobil's pumps feature advanced bearing systems with specialized lubricants that maintain performance characteristics across the wide temperature gradients experienced in cryogenic applications. Their integrated control platform continuously monitors system parameters including inlet conditions, pump performance curves, and downstream requirements to automatically adjust operation for maximum efficiency. Additionally, ExxonMobil has implemented innovative cavitation prevention technology that maintains optimal net positive suction head through precise pressure control, significantly extending equipment life while maintaining peak efficiency. The system also incorporates waste heat recovery mechanisms that capture and repurpose energy from the pumping process, reducing overall facility energy consumption related to nitrogen handling by approximately 15-20%[9].

Strengths: Robust design optimized for industrial-scale operations with high reliability; Advanced thermal management significantly reduces operational losses; Comprehensive monitoring system ensures consistent peak performance. Weaknesses: Significant capital investment required for implementation; System complexity necessitates specialized technical expertise for maintenance; Optimization primarily focused on large-scale applications with less flexibility for smaller operations.

Critical Patents and Innovations in Cryogenic Pumping

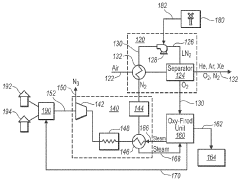

Method and apparatus for producing high-purity nitrogen and low-purity oxygen

PatentActiveUS20220090855A1

Innovation

- A three-column rectification system is introduced, featuring a high-pressure column, a medium-pressure column, and a low-pressure column, where air is cooled and processed through heat exchangers and subcoolers to separate high-purity nitrogen and low-purity oxygen simultaneously, reducing energy consumption and equipment investment.

Methods and systems for generating power from a turbine using pressurized nitrogen

PatentWO2009075897A2

Innovation

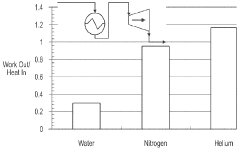

- The use of liquid nitrogen from an air separation unit, pressurized to at least 1.8 atmospheres, which is then heated and expanded in a turbine to generate power, eliminating the need for cooling towers and reducing water usage by 25-30%, while venting the expanded nitrogen to ambient air to avoid recompression inefficiencies.

Energy Conservation Strategies in Cryogenic Applications

Energy conservation in cryogenic applications represents a critical frontier in optimizing liquid nitrogen pump systems. The fundamental challenge lies in the significant energy requirements for maintaining extremely low temperatures while minimizing heat ingress. Effective insulation technologies form the cornerstone of energy conservation strategies, with vacuum-jacketed transfer lines and multi-layer insulation (MLI) demonstrating superior performance by reducing heat transfer through conduction, convection, and radiation pathways.

Advanced regenerative cooling techniques offer substantial efficiency improvements by recapturing and utilizing the cooling potential of vaporized nitrogen. These systems can reduce energy consumption by 15-30% compared to conventional approaches. The implementation of variable frequency drives (VFDs) in pump motors provides precise control over operational parameters, allowing systems to operate at optimal efficiency points rather than at fixed speeds, resulting in energy savings of up to 25% in variable-load applications.

Pressure management strategies play a crucial role in energy conservation. Maintaining optimal pressure differentials throughout the system minimizes unnecessary work performed by pumps while ensuring adequate flow rates. Automated pressure control systems with real-time monitoring capabilities can dynamically adjust system parameters to maintain ideal operating conditions despite changing process requirements.

Heat exchanger optimization represents another significant opportunity for efficiency gains. Novel compact heat exchanger designs with enhanced surface geometries have demonstrated thermal efficiency improvements of 20-40% compared to traditional designs. The strategic placement of these exchangers within the system flow path maximizes their effectiveness while minimizing pressure drops.

Recovery systems for capturing and reusing cold energy from boil-off gases present compelling energy conservation opportunities. These systems can redirect the cooling potential of evaporated nitrogen to pre-cool incoming liquid or support auxiliary cooling processes, effectively recapturing what would otherwise be wasted energy.

Operational protocols and maintenance practices significantly impact energy efficiency. Regular inspection and maintenance of insulation integrity, seal performance, and system cleanliness prevent efficiency degradation over time. Implementing predictive maintenance approaches using IoT sensors and machine learning algorithms enables early detection of efficiency losses before they become significant.

Integration of digital twin technology allows for continuous simulation and optimization of system parameters under varying conditions. These virtual models enable operators to identify optimal operating regimes and anticipate the impact of process changes before implementation, reducing energy waste from suboptimal operation by up to 15% in complex systems.

Advanced regenerative cooling techniques offer substantial efficiency improvements by recapturing and utilizing the cooling potential of vaporized nitrogen. These systems can reduce energy consumption by 15-30% compared to conventional approaches. The implementation of variable frequency drives (VFDs) in pump motors provides precise control over operational parameters, allowing systems to operate at optimal efficiency points rather than at fixed speeds, resulting in energy savings of up to 25% in variable-load applications.

Pressure management strategies play a crucial role in energy conservation. Maintaining optimal pressure differentials throughout the system minimizes unnecessary work performed by pumps while ensuring adequate flow rates. Automated pressure control systems with real-time monitoring capabilities can dynamically adjust system parameters to maintain ideal operating conditions despite changing process requirements.

Heat exchanger optimization represents another significant opportunity for efficiency gains. Novel compact heat exchanger designs with enhanced surface geometries have demonstrated thermal efficiency improvements of 20-40% compared to traditional designs. The strategic placement of these exchangers within the system flow path maximizes their effectiveness while minimizing pressure drops.

Recovery systems for capturing and reusing cold energy from boil-off gases present compelling energy conservation opportunities. These systems can redirect the cooling potential of evaporated nitrogen to pre-cool incoming liquid or support auxiliary cooling processes, effectively recapturing what would otherwise be wasted energy.

Operational protocols and maintenance practices significantly impact energy efficiency. Regular inspection and maintenance of insulation integrity, seal performance, and system cleanliness prevent efficiency degradation over time. Implementing predictive maintenance approaches using IoT sensors and machine learning algorithms enables early detection of efficiency losses before they become significant.

Integration of digital twin technology allows for continuous simulation and optimization of system parameters under varying conditions. These virtual models enable operators to identify optimal operating regimes and anticipate the impact of process changes before implementation, reducing energy waste from suboptimal operation by up to 15% in complex systems.

Safety Standards and Compliance Requirements

Compliance with safety standards is paramount in liquid nitrogen pump systems due to the inherent hazards associated with cryogenic fluids. The primary regulatory frameworks governing these systems include OSHA 29 CFR 1910.103 for handling compressed gases, ASME Boiler and Pressure Vessel Code Section VIII for pressure vessels, and CGA P-12 for safe handling of cryogenic liquids. These standards establish minimum requirements for equipment design, installation, operation, and maintenance to ensure personnel safety and system integrity.

European operations must adhere to the Pressure Equipment Directive (PED) 2014/68/EU and the ATEX Directive 2014/34/EU for equipment used in potentially explosive atmospheres. ISO 24490 specifically addresses cryogenic vessel operational requirements, while EN 13458 covers static vacuum-insulated vessels. Compliance with these standards is not optional but mandatory for legal operation in respective jurisdictions.

Risk assessment protocols form a critical component of safety compliance. HAZOP (Hazard and Operability Study) and LOPA (Layer of Protection Analysis) methodologies are widely employed to identify potential failure modes and establish appropriate safeguards. These assessments must be documented and regularly updated to reflect system modifications or operational changes.

Personal protective equipment requirements are explicitly defined in standards such as EN 511 for cold-protective gloves and ANSI Z87.1 for eye protection. Operators must be equipped with cryogenic-rated face shields, gloves, aprons, and closed-toe shoes when handling liquid nitrogen. Training programs must be implemented in accordance with OSHA 1910.38 for emergency action plans and OSHA 1910.147 for lockout/tagout procedures during maintenance activities.

Monitoring and alarm systems represent another critical safety element. Oxygen depletion monitors must be installed in enclosed spaces where nitrogen is used, with alarm thresholds typically set at 19.5% oxygen concentration per OSHA requirements. Pressure relief devices must comply with ASME Section VIII standards, with appropriate sizing calculations documented and relief valve testing schedules established.

Documentation requirements include maintaining current piping and instrumentation diagrams (P&IDs), standard operating procedures (SOPs), emergency response plans, and maintenance records. Regular compliance audits should be conducted to verify adherence to applicable standards and identify areas for improvement. Third-party certification may be required for certain components or systems, particularly those subject to pressure vessel regulations.

Efficiency optimization efforts must never compromise safety compliance. In fact, properly implemented safety systems often contribute to operational efficiency by preventing costly incidents, reducing downtime, and extending equipment life. Organizations should establish a management of change process that evaluates safety implications before implementing efficiency improvements to ensure continued regulatory compliance.

European operations must adhere to the Pressure Equipment Directive (PED) 2014/68/EU and the ATEX Directive 2014/34/EU for equipment used in potentially explosive atmospheres. ISO 24490 specifically addresses cryogenic vessel operational requirements, while EN 13458 covers static vacuum-insulated vessels. Compliance with these standards is not optional but mandatory for legal operation in respective jurisdictions.

Risk assessment protocols form a critical component of safety compliance. HAZOP (Hazard and Operability Study) and LOPA (Layer of Protection Analysis) methodologies are widely employed to identify potential failure modes and establish appropriate safeguards. These assessments must be documented and regularly updated to reflect system modifications or operational changes.

Personal protective equipment requirements are explicitly defined in standards such as EN 511 for cold-protective gloves and ANSI Z87.1 for eye protection. Operators must be equipped with cryogenic-rated face shields, gloves, aprons, and closed-toe shoes when handling liquid nitrogen. Training programs must be implemented in accordance with OSHA 1910.38 for emergency action plans and OSHA 1910.147 for lockout/tagout procedures during maintenance activities.

Monitoring and alarm systems represent another critical safety element. Oxygen depletion monitors must be installed in enclosed spaces where nitrogen is used, with alarm thresholds typically set at 19.5% oxygen concentration per OSHA requirements. Pressure relief devices must comply with ASME Section VIII standards, with appropriate sizing calculations documented and relief valve testing schedules established.

Documentation requirements include maintaining current piping and instrumentation diagrams (P&IDs), standard operating procedures (SOPs), emergency response plans, and maintenance records. Regular compliance audits should be conducted to verify adherence to applicable standards and identify areas for improvement. Third-party certification may be required for certain components or systems, particularly those subject to pressure vessel regulations.

Efficiency optimization efforts must never compromise safety compliance. In fact, properly implemented safety systems often contribute to operational efficiency by preventing costly incidents, reducing downtime, and extending equipment life. Organizations should establish a management of change process that evaluates safety implications before implementing efficiency improvements to ensure continued regulatory compliance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!