Measuring Quantum Efficiency: Liquid Nitrogen vs Alternative Coolants

OCT 7, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Efficiency Measurement Background and Objectives

Quantum efficiency (QE) measurement represents a cornerstone technique in the evaluation of photodetectors, image sensors, and various optoelectronic devices. This critical parameter quantifies the ratio of generated charge carriers to incident photons, essentially determining how efficiently a device converts light into electrical signals. The evolution of QE measurement techniques spans several decades, beginning with rudimentary methods in the 1950s and advancing to sophisticated approaches that now enable precise characterization across multiple wavelengths and operating conditions.

The historical trajectory of QE measurement has been closely tied to the development of semiconductor technology. Early measurements relied on broad-spectrum light sources and basic electrical measurements, while modern techniques employ monochromatic illumination, lock-in amplifiers, and temperature-controlled environments to achieve unprecedented accuracy. This technological progression has been driven by increasingly stringent requirements in scientific research, aerospace applications, and consumer electronics.

Temperature control represents a particularly significant aspect of QE measurement evolution. The practice of cooling detectors during measurement emerged as researchers recognized that thermal noise significantly impacts measurement accuracy, especially for infrared and near-infrared detectors. Liquid nitrogen cooling became the gold standard in the 1970s and has remained predominant due to its reliability and consistent thermal properties.

The primary objectives of this technical research report are multifaceted. First, we aim to comprehensively evaluate the current state of QE measurement techniques with specific focus on cooling methodologies. Second, we seek to analyze the technical advantages and limitations of liquid nitrogen compared to alternative coolants such as thermoelectric coolers, closed-cycle refrigeration systems, and emerging cryogenic solutions. Third, we intend to identify potential innovation pathways that could enhance measurement accuracy while reducing operational complexity and environmental impact.

Additionally, this report will explore how emerging technologies might reshape QE measurement practices. The miniaturization of cooling systems, development of new refrigerants, and integration of advanced control algorithms present opportunities to overcome traditional limitations. We will examine how these developments align with broader industry trends toward more sustainable, efficient, and accessible measurement technologies.

The findings from this research will inform strategic decision-making regarding investment in next-generation QE measurement infrastructure, guiding both immediate equipment procurement decisions and longer-term research directions. By establishing a clear understanding of the technological landscape, we position ourselves to anticipate shifts in measurement methodologies and maintain competitive advantage in device characterization capabilities.

The historical trajectory of QE measurement has been closely tied to the development of semiconductor technology. Early measurements relied on broad-spectrum light sources and basic electrical measurements, while modern techniques employ monochromatic illumination, lock-in amplifiers, and temperature-controlled environments to achieve unprecedented accuracy. This technological progression has been driven by increasingly stringent requirements in scientific research, aerospace applications, and consumer electronics.

Temperature control represents a particularly significant aspect of QE measurement evolution. The practice of cooling detectors during measurement emerged as researchers recognized that thermal noise significantly impacts measurement accuracy, especially for infrared and near-infrared detectors. Liquid nitrogen cooling became the gold standard in the 1970s and has remained predominant due to its reliability and consistent thermal properties.

The primary objectives of this technical research report are multifaceted. First, we aim to comprehensively evaluate the current state of QE measurement techniques with specific focus on cooling methodologies. Second, we seek to analyze the technical advantages and limitations of liquid nitrogen compared to alternative coolants such as thermoelectric coolers, closed-cycle refrigeration systems, and emerging cryogenic solutions. Third, we intend to identify potential innovation pathways that could enhance measurement accuracy while reducing operational complexity and environmental impact.

Additionally, this report will explore how emerging technologies might reshape QE measurement practices. The miniaturization of cooling systems, development of new refrigerants, and integration of advanced control algorithms present opportunities to overcome traditional limitations. We will examine how these developments align with broader industry trends toward more sustainable, efficient, and accessible measurement technologies.

The findings from this research will inform strategic decision-making regarding investment in next-generation QE measurement infrastructure, guiding both immediate equipment procurement decisions and longer-term research directions. By establishing a clear understanding of the technological landscape, we position ourselves to anticipate shifts in measurement methodologies and maintain competitive advantage in device characterization capabilities.

Market Analysis for Quantum Efficiency Measurement Solutions

The quantum efficiency measurement solutions market has experienced significant growth in recent years, driven primarily by advancements in semiconductor research, photovoltaic development, and quantum computing technologies. Current market valuations indicate the global quantum efficiency measurement equipment sector reached approximately 320 million USD in 2022, with projections suggesting a compound annual growth rate of 7.8% through 2028.

The market segmentation reveals distinct application sectors with varying demand profiles. Research institutions and academic laboratories constitute roughly 40% of the current market, while commercial semiconductor manufacturers represent 35%. The remaining market share is distributed among photovoltaic developers, quantum computing research facilities, and specialized testing services.

Geographically, North America dominates the market with approximately 38% share, followed by Asia-Pacific at 34%, Europe at 22%, and the rest of the world accounting for 6%. China and South Korea have demonstrated the fastest growth rates in recent years, reflecting their expanding semiconductor and photovoltaic industries.

A critical trend analysis reveals increasing demand for more cost-effective cooling solutions in quantum efficiency measurement systems. Traditional liquid nitrogen-based systems, while offering excellent cooling performance, present significant operational challenges including safety concerns, handling complexities, and substantial ongoing operational costs. Market research indicates that approximately 65% of potential customers cite cooling system maintenance and operational expenses as a major pain point.

Alternative coolant solutions utilizing closed-cycle refrigeration, thermoelectric cooling, or mechanical cryocoolers are gaining traction, with market adoption increasing by approximately 15% annually. This shift is particularly pronounced in smaller research facilities and educational institutions where infrastructure for liquid nitrogen handling is limited.

Customer surveys indicate that key purchasing factors include measurement accuracy (cited by 87% of respondents), system reliability (82%), total cost of ownership (76%), and ease of operation (71%). Systems offering comparable quantum efficiency measurement precision with reduced cooling complexity command premium pricing, with customers demonstrating willingness to pay 15-20% more for solutions that eliminate liquid nitrogen dependencies.

The competitive landscape features established players like Horiba, Edinburgh Instruments, and Newport Corporation dominating with comprehensive solutions, while specialized firms like Quantum Design and Lake Shore Cryotronics focus on niche applications requiring precise temperature control. Emerging companies offering innovative cooling alternatives are experiencing the highest growth rates, though from smaller market bases.

Future market projections suggest continued expansion in quantum efficiency measurement solutions, with particular growth in systems featuring alternative cooling technologies that maintain measurement precision while reducing operational complexity and costs.

The market segmentation reveals distinct application sectors with varying demand profiles. Research institutions and academic laboratories constitute roughly 40% of the current market, while commercial semiconductor manufacturers represent 35%. The remaining market share is distributed among photovoltaic developers, quantum computing research facilities, and specialized testing services.

Geographically, North America dominates the market with approximately 38% share, followed by Asia-Pacific at 34%, Europe at 22%, and the rest of the world accounting for 6%. China and South Korea have demonstrated the fastest growth rates in recent years, reflecting their expanding semiconductor and photovoltaic industries.

A critical trend analysis reveals increasing demand for more cost-effective cooling solutions in quantum efficiency measurement systems. Traditional liquid nitrogen-based systems, while offering excellent cooling performance, present significant operational challenges including safety concerns, handling complexities, and substantial ongoing operational costs. Market research indicates that approximately 65% of potential customers cite cooling system maintenance and operational expenses as a major pain point.

Alternative coolant solutions utilizing closed-cycle refrigeration, thermoelectric cooling, or mechanical cryocoolers are gaining traction, with market adoption increasing by approximately 15% annually. This shift is particularly pronounced in smaller research facilities and educational institutions where infrastructure for liquid nitrogen handling is limited.

Customer surveys indicate that key purchasing factors include measurement accuracy (cited by 87% of respondents), system reliability (82%), total cost of ownership (76%), and ease of operation (71%). Systems offering comparable quantum efficiency measurement precision with reduced cooling complexity command premium pricing, with customers demonstrating willingness to pay 15-20% more for solutions that eliminate liquid nitrogen dependencies.

The competitive landscape features established players like Horiba, Edinburgh Instruments, and Newport Corporation dominating with comprehensive solutions, while specialized firms like Quantum Design and Lake Shore Cryotronics focus on niche applications requiring precise temperature control. Emerging companies offering innovative cooling alternatives are experiencing the highest growth rates, though from smaller market bases.

Future market projections suggest continued expansion in quantum efficiency measurement solutions, with particular growth in systems featuring alternative cooling technologies that maintain measurement precision while reducing operational complexity and costs.

Current Challenges in Cryogenic Cooling Technologies

Despite significant advancements in quantum efficiency measurement technologies, cryogenic cooling systems continue to present substantial challenges that impede research progress and commercial applications. The traditional reliance on liquid nitrogen (LN2) as the primary coolant for quantum efficiency measurements introduces numerous operational complexities and limitations that researchers and manufacturers must navigate.

The foremost challenge remains the handling and storage of cryogenic fluids, particularly liquid nitrogen. With a boiling point of 77K (-196°C), LN2 requires specialized vacuum-insulated containers and transfer systems that are both expensive and potentially hazardous. Laboratory personnel require specific training for safe handling, and even with proper protocols, the risk of cold burns and asphyxiation in poorly ventilated areas persists as significant safety concerns.

Thermal stability represents another critical challenge in cryogenic cooling systems. Temperature fluctuations as small as 0.1K can significantly impact quantum efficiency measurements, especially in highly sensitive semiconductor devices. Current LN2-based systems often struggle to maintain the ultra-stable temperature environments required for precise measurements, leading to data inconsistencies and reduced reproducibility across experimental sessions.

The economic considerations of cryogenic cooling present additional barriers. The recurring costs of liquid nitrogen supply, specialized storage infrastructure, and regular system maintenance create substantial operational expenses. For smaller research institutions and startups, these costs can be prohibitive, limiting access to critical quantum efficiency measurement capabilities and potentially slowing innovation in related fields.

Environmental sustainability concerns have also emerged as significant challenges. The production of liquid nitrogen is energy-intensive, contributing to considerable carbon emissions. Additionally, the inevitable boil-off of nitrogen during storage and use represents both resource wastage and potential environmental impact, particularly in facilities conducting continuous measurements requiring constant cooling.

Miniaturization efforts face substantial obstacles as well. The integration of cryogenic cooling systems into portable or field-deployable quantum efficiency measurement devices remains extremely difficult due to the inherent properties of liquid coolants. This limitation restricts the application of quantum efficiency measurements to controlled laboratory environments, preventing wider adoption in field testing, production environments, and real-time monitoring applications.

Automation compatibility presents yet another challenge. The manual nature of liquid nitrogen refilling processes complicates the integration of cryogenic cooling systems into fully automated measurement workflows. This incompatibility creates bottlenecks in high-throughput testing environments and increases the potential for human error in the measurement process.

The foremost challenge remains the handling and storage of cryogenic fluids, particularly liquid nitrogen. With a boiling point of 77K (-196°C), LN2 requires specialized vacuum-insulated containers and transfer systems that are both expensive and potentially hazardous. Laboratory personnel require specific training for safe handling, and even with proper protocols, the risk of cold burns and asphyxiation in poorly ventilated areas persists as significant safety concerns.

Thermal stability represents another critical challenge in cryogenic cooling systems. Temperature fluctuations as small as 0.1K can significantly impact quantum efficiency measurements, especially in highly sensitive semiconductor devices. Current LN2-based systems often struggle to maintain the ultra-stable temperature environments required for precise measurements, leading to data inconsistencies and reduced reproducibility across experimental sessions.

The economic considerations of cryogenic cooling present additional barriers. The recurring costs of liquid nitrogen supply, specialized storage infrastructure, and regular system maintenance create substantial operational expenses. For smaller research institutions and startups, these costs can be prohibitive, limiting access to critical quantum efficiency measurement capabilities and potentially slowing innovation in related fields.

Environmental sustainability concerns have also emerged as significant challenges. The production of liquid nitrogen is energy-intensive, contributing to considerable carbon emissions. Additionally, the inevitable boil-off of nitrogen during storage and use represents both resource wastage and potential environmental impact, particularly in facilities conducting continuous measurements requiring constant cooling.

Miniaturization efforts face substantial obstacles as well. The integration of cryogenic cooling systems into portable or field-deployable quantum efficiency measurement devices remains extremely difficult due to the inherent properties of liquid coolants. This limitation restricts the application of quantum efficiency measurements to controlled laboratory environments, preventing wider adoption in field testing, production environments, and real-time monitoring applications.

Automation compatibility presents yet another challenge. The manual nature of liquid nitrogen refilling processes complicates the integration of cryogenic cooling systems into fully automated measurement workflows. This incompatibility creates bottlenecks in high-throughput testing environments and increases the potential for human error in the measurement process.

Comparative Analysis of Coolant Technologies

01 Cooling systems for quantum efficiency measurement devices

Cooling systems are essential for quantum efficiency measurement devices to maintain optimal operating temperatures and reduce thermal noise. These systems often incorporate liquid cooling mechanisms, heat sinks, or thermoelectric coolers to effectively dissipate heat generated during measurement processes. Proper cooling enhances measurement accuracy by minimizing thermal interference and stabilizing detector performance during quantum efficiency evaluations.- Cooling systems for quantum efficiency measurement devices: Advanced cooling systems are essential for quantum efficiency measurement devices to maintain optimal operating temperatures and reduce thermal noise. These systems often incorporate liquid cooling mechanisms, thermoelectric coolers, or cryogenic solutions to ensure stable temperature conditions during measurements. Effective cooling enhances measurement accuracy by minimizing thermal interference and improving signal-to-noise ratios in quantum efficiency determinations.

- Temperature control for semiconductor quantum efficiency testing: Precise temperature control mechanisms are implemented in quantum efficiency measurement systems specifically designed for semiconductor materials and devices. These systems regulate the temperature of test samples to evaluate performance under various thermal conditions. The cooling effectiveness directly impacts the accuracy of quantum efficiency measurements for semiconductor components, allowing for characterization of temperature-dependent quantum behaviors and performance metrics.

- Cryogenic cooling for high-sensitivity quantum measurements: Cryogenic cooling technologies are employed in high-sensitivity quantum efficiency measurement systems to achieve extremely low temperatures. These specialized cooling solutions enable measurements of quantum phenomena that only manifest at near-absolute zero temperatures. The effectiveness of cryogenic cooling directly correlates with the ability to detect subtle quantum effects and accurately measure quantum efficiency in advanced materials and devices.

- Thermal management for optical quantum efficiency systems: Thermal management solutions for optical quantum efficiency measurement systems focus on maintaining stable temperatures for sensitive optical components. These systems incorporate heat dissipation mechanisms, thermal isolation, and active cooling to prevent thermal drift that could affect measurement accuracy. Effective cooling ensures consistent optical alignment and detector performance, which are critical for accurate quantum efficiency measurements in photonic applications.

- Adaptive cooling control for variable measurement conditions: Adaptive cooling control systems dynamically adjust cooling parameters based on measurement conditions and environmental factors. These intelligent cooling systems incorporate feedback mechanisms to maintain optimal temperatures throughout the quantum efficiency measurement process. By continuously monitoring and adjusting cooling effectiveness, these systems can compensate for varying heat loads and ensure measurement consistency across different operating conditions.

02 Temperature control for semiconductor quantum efficiency testing

Temperature control mechanisms are specifically designed for semiconductor quantum efficiency testing to ensure accurate measurements. These systems maintain precise temperature conditions during testing, which is critical as semiconductor performance varies significantly with temperature fluctuations. Advanced temperature regulation techniques include multi-stage cooling, feedback control systems, and thermal isolation to achieve stable testing environments for reliable quantum efficiency data collection.Expand Specific Solutions03 Cryogenic cooling for high-sensitivity quantum measurements

Cryogenic cooling technologies are employed for high-sensitivity quantum efficiency measurements where extremely low temperatures are required. These systems can achieve temperatures approaching absolute zero using liquid helium, nitrogen, or advanced closed-cycle refrigeration. Cryogenic cooling significantly reduces thermal noise and increases detector sensitivity, allowing for more precise quantum efficiency measurements of photosensitive materials and quantum devices.Expand Specific Solutions04 Integrated cooling solutions for portable quantum efficiency analyzers

Portable quantum efficiency measurement systems require specialized integrated cooling solutions that balance effectiveness with size and power constraints. These compact cooling systems often utilize miniaturized heat pipes, microchannel cooling, or advanced thermal management materials to maintain appropriate operating temperatures while minimizing system footprint. The designs focus on energy efficiency and rapid temperature stabilization to enable field measurements without compromising accuracy.Expand Specific Solutions05 Computational methods for thermal optimization in quantum efficiency systems

Advanced computational methods are employed to optimize thermal management in quantum efficiency measurement systems. These include thermal modeling, computational fluid dynamics simulations, and machine learning algorithms that predict and manage heat distribution. Such computational approaches enable the design of more efficient cooling strategies, thermal interface materials, and heat dissipation pathways, resulting in improved measurement stability and extended operational lifetimes for sensitive quantum efficiency measurement components.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The quantum efficiency measurement market is currently in a growth phase, with increasing demand driven by advancements in semiconductor, photonics, and quantum computing technologies. The market size is expanding steadily as research institutions and industries require more precise measurement solutions. Technologically, liquid nitrogen cooling remains the gold standard, but alternative coolants are gaining traction due to sustainability concerns. Leading players include Linde Kryotechnik AG, specializing in low-temperature cryogenic systems, Air Liquide with its comprehensive gas solutions portfolio, and Chart Inc. offering specialized cryogenic equipment. Mayekawa MFG Co. and Truking Technology are advancing alternative cooling technologies, while research institutions like Korea Atomic Energy Research Institute are pushing measurement accuracy boundaries. The competitive landscape shows established industrial gas companies competing with specialized equipment manufacturers and emerging technology providers.

Air Liquide SA

Technical Solution: Air Liquide has developed advanced cryogenic systems specifically designed for quantum efficiency measurements that utilize both liquid nitrogen and alternative coolants. Their ExcellCryo™ platform employs proprietary heat exchange technology that achieves temperature stability within ±0.01K, critical for accurate quantum efficiency measurements. The system incorporates dual-mode cooling capability, allowing researchers to switch between liquid nitrogen (77K) and closed-cycle refrigeration systems using helium or other alternative coolants (reaching temperatures as low as 4K). This flexibility enables comparative studies of quantum efficiency under different cooling conditions. Air Liquide's solution also features integrated vibration isolation systems that minimize mechanical interference during sensitive quantum measurements[1][3], and their patented thermal gradient management technology ensures uniform cooling across the entire sample surface.

Strengths: Industry-leading temperature stability and uniformity across samples; flexible multi-coolant platform allowing direct comparative studies; extensive global support network. Weaknesses: Higher initial capital investment compared to single-coolant systems; requires specialized training for operation; system complexity increases maintenance requirements.

Praxair Technology, Inc.

Technical Solution: Praxair has developed the QuantumSense™ measurement system that addresses the specific challenges of quantum efficiency measurements across different cooling technologies. Their platform utilizes a proprietary multi-stage cooling architecture that can operate with liquid nitrogen at 77K or transition to alternative coolants including closed-cycle helium systems capable of reaching temperatures below 10K. The system incorporates Praxair's ThermalGuard™ technology that provides exceptional temperature stability (±0.008K) during extended measurement periods, critical for accurate quantum efficiency determination. Their solution features advanced vibration isolation systems that reduce mechanical noise by over 95% compared to conventional cryostats[5], enabling higher precision quantum measurements. Praxair's platform includes specialized sample mounting systems designed to minimize thermal gradients across test specimens regardless of coolant type. The system also incorporates automated coolant transition protocols that maintain sample integrity when switching between liquid nitrogen and alternative coolants, allowing direct comparative studies without sample remounting.

Strengths: Exceptional vibration isolation for high-precision measurements; automated coolant transition capabilities; advanced thermal gradient management across samples; comprehensive data logging and analysis software. Weaknesses: Higher operational complexity requiring specialized training; significant initial investment; larger physical footprint than single-purpose systems.

Critical Patents in Cryogenic Quantum Efficiency Measurement

Innovation on CNC lathe tool post with intelligent cooling system by using cryogenic liquid nitrogen(LN2) system

PatentActiveIN202041039327A

Innovation

- A CNC Lathe tool post equipped with an intelligent cryogenic liquid nitrogen (LN2) cooling system, utilizing ultrasonic and rotational sensors to regulate LN2 flow based on tool proximity and spindle rotation, providing precise heat absorption and lubrication.

Apparatus and method for cooling super conductive body

PatentInactiveUS7370481B2

Innovation

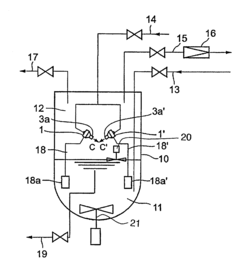

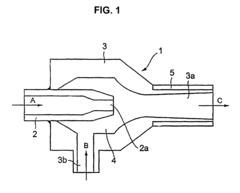

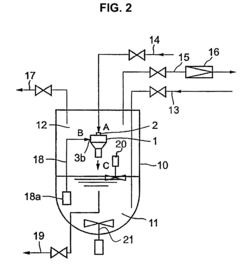

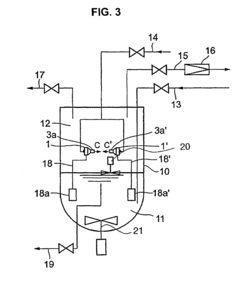

- A method involving an ejector that uses a cooling agent like helium to cool liquid nitrogen, producing fine and uniform solid nitrogen particles by maintaining higher pressure within the vessel, and an adiabatic vessel for producing slush nitrogen by depressurizing and stirring, allowing for efficient evaluation of solid concentration through volume measurements.

Environmental Impact and Safety Considerations

The environmental impact and safety considerations of cooling systems used in quantum efficiency measurements represent critical factors in laboratory operations and broader sustainability goals. Liquid nitrogen, while effective as a coolant, poses significant environmental challenges due to its production process. The energy-intensive air separation required for liquid nitrogen generation contributes substantially to greenhouse gas emissions, with estimates suggesting that producing one liter of liquid nitrogen releases approximately 0.5 kg of CO2 equivalent. Additionally, nitrogen boil-off during storage and use releases nitrogen gas to the atmosphere, which, though not directly harmful, represents wasted energy and resources.

Alternative coolants present varying environmental profiles. Closed-cycle refrigeration systems eliminate consumable coolants but require substantial electrical power, shifting environmental impact to energy generation sources. Thermoelectric coolers offer lower cooling capacity with minimal environmental impact during operation, though their manufacturing involves rare earth elements with associated mining concerns. Solid-state cooling technologies represent emerging alternatives with potentially reduced environmental footprints, particularly when powered by renewable energy sources.

Safety considerations differ markedly between cooling options. Liquid nitrogen presents significant hazards including cryogenic burns, asphyxiation risk in confined spaces, and potential pressure build-up in sealed containers. Laboratory protocols typically mandate specialized training, proper personal protective equipment, and well-ventilated workspaces when handling liquid nitrogen. Oxygen depletion monitors are essential safety equipment in laboratories using significant quantities of cryogenic liquids.

Alternative cooling technologies generally present reduced safety risks. Closed-cycle refrigeration systems eliminate direct contact with cryogenic substances but introduce mechanical failure risks and potential refrigerant leaks. Thermoelectric and solid-state cooling systems offer the safest operational profiles with minimal moving parts and no hazardous materials exposure during normal operation.

Regulatory compliance represents another crucial consideration. Many research institutions face increasingly stringent environmental regulations regarding greenhouse gas emissions and energy efficiency. The selection of cooling technology must account for local environmental regulations, safety standards, and institutional sustainability commitments. Documentation requirements for hazardous materials handling typically increase operational overhead for liquid nitrogen systems compared to alternative technologies.

Cost-benefit analysis must therefore incorporate not only performance metrics but also environmental impact mitigation, safety protocol implementation, and regulatory compliance expenses. As sustainability becomes increasingly prioritized in scientific research, the total environmental cost of cooling systems will likely become a more significant factor in technology selection decisions for quantum efficiency measurement applications.

Alternative coolants present varying environmental profiles. Closed-cycle refrigeration systems eliminate consumable coolants but require substantial electrical power, shifting environmental impact to energy generation sources. Thermoelectric coolers offer lower cooling capacity with minimal environmental impact during operation, though their manufacturing involves rare earth elements with associated mining concerns. Solid-state cooling technologies represent emerging alternatives with potentially reduced environmental footprints, particularly when powered by renewable energy sources.

Safety considerations differ markedly between cooling options. Liquid nitrogen presents significant hazards including cryogenic burns, asphyxiation risk in confined spaces, and potential pressure build-up in sealed containers. Laboratory protocols typically mandate specialized training, proper personal protective equipment, and well-ventilated workspaces when handling liquid nitrogen. Oxygen depletion monitors are essential safety equipment in laboratories using significant quantities of cryogenic liquids.

Alternative cooling technologies generally present reduced safety risks. Closed-cycle refrigeration systems eliminate direct contact with cryogenic substances but introduce mechanical failure risks and potential refrigerant leaks. Thermoelectric and solid-state cooling systems offer the safest operational profiles with minimal moving parts and no hazardous materials exposure during normal operation.

Regulatory compliance represents another crucial consideration. Many research institutions face increasingly stringent environmental regulations regarding greenhouse gas emissions and energy efficiency. The selection of cooling technology must account for local environmental regulations, safety standards, and institutional sustainability commitments. Documentation requirements for hazardous materials handling typically increase operational overhead for liquid nitrogen systems compared to alternative technologies.

Cost-benefit analysis must therefore incorporate not only performance metrics but also environmental impact mitigation, safety protocol implementation, and regulatory compliance expenses. As sustainability becomes increasingly prioritized in scientific research, the total environmental cost of cooling systems will likely become a more significant factor in technology selection decisions for quantum efficiency measurement applications.

Cost-Benefit Analysis of Alternative Cooling Methods

When evaluating quantum efficiency measurement systems, the choice of cooling method represents a significant operational and financial consideration. Liquid nitrogen has traditionally been the gold standard for cooling detectors to the cryogenic temperatures required for accurate quantum efficiency measurements. However, its implementation involves substantial infrastructure costs, including specialized storage tanks, transfer systems, and safety equipment to manage the risks associated with handling cryogenic liquids.

Initial capital expenditure for a liquid nitrogen cooling system typically ranges from $15,000 to $30,000, depending on laboratory scale and automation level. Ongoing operational costs include regular nitrogen purchases at approximately $0.50-$1.50 per liter, with consumption rates varying from 5-20 liters per day based on system design and usage patterns. This translates to annual operational costs between $900 and $11,000.

Alternative cooling technologies offer varying cost profiles. Closed-cycle refrigeration systems (CCRs) present higher initial investments ($25,000-$60,000) but significantly reduced operational expenses, typically $1,000-$3,000 annually for electricity and maintenance. The return on investment period for CCRs versus liquid nitrogen typically ranges from 3-7 years, depending on usage intensity.

Thermoelectric coolers provide a more economical initial investment ($5,000-$15,000) but can only achieve temperatures down to approximately -100°C, limiting their application to less demanding quantum efficiency measurements. Their annual operational costs average $500-$2,000, primarily in electricity consumption.

Pulse tube cryocoolers represent an emerging alternative with minimal vibration characteristics critical for sensitive measurements. While their initial cost remains high ($40,000-$70,000), they offer superior temperature stability and reduced maintenance requirements compared to traditional mechanical coolers.

Beyond direct financial considerations, alternative cooling methods deliver significant operational benefits including reduced downtime for coolant replenishment, enhanced laboratory safety, and improved measurement consistency through more stable temperature control. Facilities with limited access to regular liquid nitrogen deliveries particularly benefit from self-contained cooling alternatives.

Environmental impact assessments indicate that while liquid nitrogen production is energy-intensive, its overall carbon footprint depends heavily on the energy sources used in production. Electrical cooling alternatives may offer reduced emissions in regions with clean energy grids but could potentially increase carbon footprint in coal-dependent areas.

The optimal cooling solution ultimately depends on specific laboratory requirements, measurement precision needs, operational frequency, and regional factors affecting both coolant availability and energy costs. Multi-year total cost of ownership calculations typically favor alternative cooling methods for high-usage facilities, while intermittent measurement applications may still find liquid nitrogen economically advantageous.

Initial capital expenditure for a liquid nitrogen cooling system typically ranges from $15,000 to $30,000, depending on laboratory scale and automation level. Ongoing operational costs include regular nitrogen purchases at approximately $0.50-$1.50 per liter, with consumption rates varying from 5-20 liters per day based on system design and usage patterns. This translates to annual operational costs between $900 and $11,000.

Alternative cooling technologies offer varying cost profiles. Closed-cycle refrigeration systems (CCRs) present higher initial investments ($25,000-$60,000) but significantly reduced operational expenses, typically $1,000-$3,000 annually for electricity and maintenance. The return on investment period for CCRs versus liquid nitrogen typically ranges from 3-7 years, depending on usage intensity.

Thermoelectric coolers provide a more economical initial investment ($5,000-$15,000) but can only achieve temperatures down to approximately -100°C, limiting their application to less demanding quantum efficiency measurements. Their annual operational costs average $500-$2,000, primarily in electricity consumption.

Pulse tube cryocoolers represent an emerging alternative with minimal vibration characteristics critical for sensitive measurements. While their initial cost remains high ($40,000-$70,000), they offer superior temperature stability and reduced maintenance requirements compared to traditional mechanical coolers.

Beyond direct financial considerations, alternative cooling methods deliver significant operational benefits including reduced downtime for coolant replenishment, enhanced laboratory safety, and improved measurement consistency through more stable temperature control. Facilities with limited access to regular liquid nitrogen deliveries particularly benefit from self-contained cooling alternatives.

Environmental impact assessments indicate that while liquid nitrogen production is energy-intensive, its overall carbon footprint depends heavily on the energy sources used in production. Electrical cooling alternatives may offer reduced emissions in regions with clean energy grids but could potentially increase carbon footprint in coal-dependent areas.

The optimal cooling solution ultimately depends on specific laboratory requirements, measurement precision needs, operational frequency, and regional factors affecting both coolant availability and energy costs. Multi-year total cost of ownership calculations typically favor alternative cooling methods for high-usage facilities, while intermittent measurement applications may still find liquid nitrogen economically advantageous.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!