Liquid Nitrogen vs Air Cooled Systems: Industrial Cooling Performance

OCT 7, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Industrial Cooling Evolution and Objectives

Industrial cooling technologies have evolved significantly over the past century, transitioning from rudimentary ice-based systems to sophisticated mechanical refrigeration solutions. The early 20th century marked the beginning of modern industrial cooling with the development of vapor-compression refrigeration cycles, which laid the foundation for contemporary cooling systems. By mid-century, advancements in thermodynamics and materials science enabled more efficient and powerful cooling technologies, expanding their application across various industries.

The 1970s witnessed a paradigm shift with the introduction of liquid nitrogen as a cryogenic cooling agent, offering unprecedented low-temperature capabilities for specialized industrial processes. Concurrently, air-cooled systems continued to evolve with improvements in heat exchanger design, fan technology, and control systems, becoming more energy-efficient and environmentally friendly.

Recent decades have seen accelerated innovation driven by environmental concerns, energy efficiency requirements, and the growing demand for precise temperature control in advanced manufacturing processes. The phase-out of ozone-depleting refrigerants has pushed the industry toward natural refrigerants and alternative cooling technologies, while digitalization has enabled smart cooling systems with predictive maintenance capabilities and optimized performance.

The primary objective of modern industrial cooling technology is to achieve optimal thermal management while balancing several critical factors. These include maximizing energy efficiency to reduce operational costs and environmental impact, ensuring reliable performance under varying conditions, and meeting increasingly stringent regulatory requirements regarding refrigerants and emissions.

For liquid nitrogen versus air-cooled systems specifically, the technical objectives focus on determining the most appropriate cooling solution based on application-specific requirements. This includes analyzing temperature range capabilities, cooling speed, energy consumption patterns, installation and maintenance costs, and environmental considerations across different industrial scenarios.

The evolution trajectory suggests a future where hybrid cooling solutions may become predominant, combining the ultra-low temperature capabilities of cryogenic systems like liquid nitrogen with the operational simplicity and cost-effectiveness of air-cooled systems. Research objectives now center on developing intelligent cooling systems that can dynamically adjust cooling methods based on real-time process requirements, potentially integrating both technologies to optimize performance across varying operational conditions.

Understanding this evolutionary context is essential for evaluating the comparative performance of liquid nitrogen and air-cooled systems in contemporary industrial applications, as it provides insight into the technological capabilities, limitations, and potential future developments of these cooling methodologies.

The 1970s witnessed a paradigm shift with the introduction of liquid nitrogen as a cryogenic cooling agent, offering unprecedented low-temperature capabilities for specialized industrial processes. Concurrently, air-cooled systems continued to evolve with improvements in heat exchanger design, fan technology, and control systems, becoming more energy-efficient and environmentally friendly.

Recent decades have seen accelerated innovation driven by environmental concerns, energy efficiency requirements, and the growing demand for precise temperature control in advanced manufacturing processes. The phase-out of ozone-depleting refrigerants has pushed the industry toward natural refrigerants and alternative cooling technologies, while digitalization has enabled smart cooling systems with predictive maintenance capabilities and optimized performance.

The primary objective of modern industrial cooling technology is to achieve optimal thermal management while balancing several critical factors. These include maximizing energy efficiency to reduce operational costs and environmental impact, ensuring reliable performance under varying conditions, and meeting increasingly stringent regulatory requirements regarding refrigerants and emissions.

For liquid nitrogen versus air-cooled systems specifically, the technical objectives focus on determining the most appropriate cooling solution based on application-specific requirements. This includes analyzing temperature range capabilities, cooling speed, energy consumption patterns, installation and maintenance costs, and environmental considerations across different industrial scenarios.

The evolution trajectory suggests a future where hybrid cooling solutions may become predominant, combining the ultra-low temperature capabilities of cryogenic systems like liquid nitrogen with the operational simplicity and cost-effectiveness of air-cooled systems. Research objectives now center on developing intelligent cooling systems that can dynamically adjust cooling methods based on real-time process requirements, potentially integrating both technologies to optimize performance across varying operational conditions.

Understanding this evolutionary context is essential for evaluating the comparative performance of liquid nitrogen and air-cooled systems in contemporary industrial applications, as it provides insight into the technological capabilities, limitations, and potential future developments of these cooling methodologies.

Market Demand Analysis for Advanced Cooling Solutions

The global market for advanced cooling solutions is experiencing robust growth, driven primarily by increasing demands across multiple industrial sectors. The cooling technology market, valued at approximately 11.2 billion USD in 2022, is projected to reach 18.5 billion USD by 2028, representing a compound annual growth rate of 8.7%. This growth trajectory is particularly evident in sectors requiring precise temperature control such as semiconductor manufacturing, pharmaceutical processing, and advanced materials production.

Industrial applications requiring extreme cooling capabilities have shown particularly strong demand signals. The semiconductor industry, facing challenges with heat dissipation as chip densities increase, has emerged as a primary driver for advanced cooling technologies. Market research indicates that approximately 32% of semiconductor manufacturers are actively seeking more efficient cooling solutions to address thermal management challenges in next-generation chip production.

The pharmaceutical and biotechnology sectors represent another significant market segment, with an estimated 15% annual increase in demand for cryogenic cooling systems. This growth is largely attributed to expanding requirements for biological sample preservation, vaccine storage, and specialized manufacturing processes that require ultra-low temperatures.

Energy efficiency considerations have become increasingly prominent in purchasing decisions. A recent industry survey revealed that 78% of procurement managers now consider operational efficiency and energy consumption as critical factors when evaluating cooling systems, compared to just 45% five years ago. This shift reflects broader sustainability initiatives and rising energy costs across industrial operations.

Regional analysis shows divergent market characteristics. North America and Europe demonstrate mature markets with emphasis on technology upgrades and efficiency improvements, while Asia-Pacific regions show the highest growth rates, particularly in China and India where industrial expansion is creating new demand for advanced cooling infrastructure.

The market comparison between liquid nitrogen and air-cooled systems reveals interesting dynamics. While air-cooled systems currently dominate with approximately 65% market share due to lower initial investment costs and simpler implementation, liquid nitrogen systems are gaining traction in specialized applications where extreme cooling is required. The liquid nitrogen cooling segment is growing at 12.3% annually, outpacing the broader cooling solutions market.

Customer requirements are increasingly sophisticated, with end-users demanding integrated monitoring capabilities, predictive maintenance features, and compatibility with Industry 4.0 frameworks. This evolution in customer expectations is reshaping product development roadmaps across the cooling technology industry.

Industrial applications requiring extreme cooling capabilities have shown particularly strong demand signals. The semiconductor industry, facing challenges with heat dissipation as chip densities increase, has emerged as a primary driver for advanced cooling technologies. Market research indicates that approximately 32% of semiconductor manufacturers are actively seeking more efficient cooling solutions to address thermal management challenges in next-generation chip production.

The pharmaceutical and biotechnology sectors represent another significant market segment, with an estimated 15% annual increase in demand for cryogenic cooling systems. This growth is largely attributed to expanding requirements for biological sample preservation, vaccine storage, and specialized manufacturing processes that require ultra-low temperatures.

Energy efficiency considerations have become increasingly prominent in purchasing decisions. A recent industry survey revealed that 78% of procurement managers now consider operational efficiency and energy consumption as critical factors when evaluating cooling systems, compared to just 45% five years ago. This shift reflects broader sustainability initiatives and rising energy costs across industrial operations.

Regional analysis shows divergent market characteristics. North America and Europe demonstrate mature markets with emphasis on technology upgrades and efficiency improvements, while Asia-Pacific regions show the highest growth rates, particularly in China and India where industrial expansion is creating new demand for advanced cooling infrastructure.

The market comparison between liquid nitrogen and air-cooled systems reveals interesting dynamics. While air-cooled systems currently dominate with approximately 65% market share due to lower initial investment costs and simpler implementation, liquid nitrogen systems are gaining traction in specialized applications where extreme cooling is required. The liquid nitrogen cooling segment is growing at 12.3% annually, outpacing the broader cooling solutions market.

Customer requirements are increasingly sophisticated, with end-users demanding integrated monitoring capabilities, predictive maintenance features, and compatibility with Industry 4.0 frameworks. This evolution in customer expectations is reshaping product development roadmaps across the cooling technology industry.

Current Technologies and Challenges in Industrial Cooling

Industrial cooling technologies have evolved significantly over the past decades, with two primary systems dominating the market: liquid nitrogen cooling and air-cooled systems. Each presents distinct advantages and challenges in various industrial applications. Currently, liquid nitrogen cooling systems utilize cryogenic temperatures (-196°C) to rapidly cool materials and processes, offering unparalleled cooling capacity and speed. These systems are prevalent in specialized industries such as food processing, pharmaceutical manufacturing, and advanced electronics production where extreme cooling is necessary.

Air-cooled systems, conversely, operate through heat exchange with ambient air, typically employing fans or blowers to enhance heat dissipation. These systems are more commonly found in general manufacturing, HVAC applications, and data centers due to their lower operational complexity and maintenance requirements. Recent technological advancements have improved their efficiency through enhanced heat exchanger designs and intelligent control systems.

The industrial cooling market faces several significant challenges. Energy consumption remains a primary concern, with cooling systems often accounting for 30-40% of industrial energy usage. Liquid nitrogen systems, while offering superior cooling performance, require substantial energy for nitrogen production and liquefaction. Air-cooled systems struggle with efficiency limitations in high-ambient temperature environments and space constraints in dense industrial settings.

Environmental considerations present another major challenge. Traditional cooling systems often utilize refrigerants with high global warming potential (GWP). While liquid nitrogen itself has zero GWP, its production process can be carbon-intensive depending on the energy source. Regulatory pressures worldwide are pushing industries toward more sustainable cooling solutions, driving innovation in both technologies.

Scalability challenges differ between the systems. Liquid nitrogen cooling requires specialized infrastructure for storage, transport, and handling, limiting its scalability in some applications. Air-cooled systems, while more easily scalable, face diminishing returns in cooling efficiency as system size increases, particularly in confined spaces with limited airflow.

Cost structures vary significantly between technologies. Liquid nitrogen systems typically involve lower initial capital expenditure but higher operational costs due to continuous nitrogen supply requirements. Air-cooled systems generally require higher upfront investment in equipment but may offer lower long-term operational expenses, particularly in regions with moderate climates and affordable electricity.

Integration with existing industrial processes presents technical challenges for both cooling methods. Liquid nitrogen systems require careful material selection to withstand cryogenic temperatures and specialized safety protocols. Air-cooled systems must overcome issues related to dust accumulation, airflow restrictions, and noise limitations in industrial environments.

Air-cooled systems, conversely, operate through heat exchange with ambient air, typically employing fans or blowers to enhance heat dissipation. These systems are more commonly found in general manufacturing, HVAC applications, and data centers due to their lower operational complexity and maintenance requirements. Recent technological advancements have improved their efficiency through enhanced heat exchanger designs and intelligent control systems.

The industrial cooling market faces several significant challenges. Energy consumption remains a primary concern, with cooling systems often accounting for 30-40% of industrial energy usage. Liquid nitrogen systems, while offering superior cooling performance, require substantial energy for nitrogen production and liquefaction. Air-cooled systems struggle with efficiency limitations in high-ambient temperature environments and space constraints in dense industrial settings.

Environmental considerations present another major challenge. Traditional cooling systems often utilize refrigerants with high global warming potential (GWP). While liquid nitrogen itself has zero GWP, its production process can be carbon-intensive depending on the energy source. Regulatory pressures worldwide are pushing industries toward more sustainable cooling solutions, driving innovation in both technologies.

Scalability challenges differ between the systems. Liquid nitrogen cooling requires specialized infrastructure for storage, transport, and handling, limiting its scalability in some applications. Air-cooled systems, while more easily scalable, face diminishing returns in cooling efficiency as system size increases, particularly in confined spaces with limited airflow.

Cost structures vary significantly between technologies. Liquid nitrogen systems typically involve lower initial capital expenditure but higher operational costs due to continuous nitrogen supply requirements. Air-cooled systems generally require higher upfront investment in equipment but may offer lower long-term operational expenses, particularly in regions with moderate climates and affordable electricity.

Integration with existing industrial processes presents technical challenges for both cooling methods. Liquid nitrogen systems require careful material selection to withstand cryogenic temperatures and specialized safety protocols. Air-cooled systems must overcome issues related to dust accumulation, airflow restrictions, and noise limitations in industrial environments.

Comparative Analysis of Liquid Nitrogen and Air Cooled Systems

01 Liquid nitrogen cooling system design

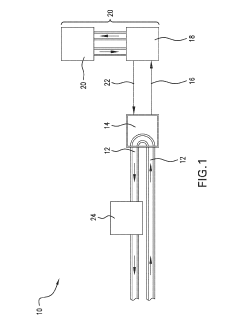

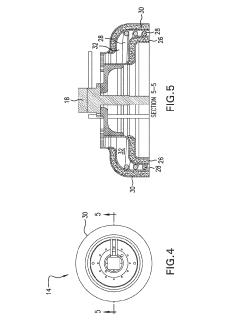

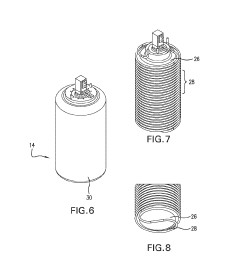

Liquid nitrogen cooling systems utilize the extremely low temperature of liquid nitrogen to achieve rapid and efficient cooling. These systems typically include specialized components such as cryogenic storage tanks, insulated transfer lines, and heat exchangers designed to handle the extreme cold. The cooling performance is characterized by very low temperature capabilities, rapid cooling rates, and high thermal efficiency. These systems are particularly effective for applications requiring temperatures well below what conventional cooling methods can achieve.- Liquid nitrogen cooling systems: Liquid nitrogen cooling systems utilize the extremely low temperature of liquid nitrogen to provide efficient cooling. These systems are particularly effective for applications requiring rapid cooling or very low temperatures. The liquid nitrogen absorbs heat as it transitions from liquid to gas, providing significant cooling capacity. These systems often include specialized components for handling cryogenic temperatures and managing the phase change process safely and efficiently.

- Air-cooled heat dissipation systems: Air-cooled systems use ambient air as the primary cooling medium. These systems typically employ fans or blowers to force air across heat exchangers or heat sinks to dissipate heat. The design often includes optimized airflow paths, fin structures, and fan configurations to maximize cooling efficiency while minimizing noise and power consumption. Air-cooled systems are widely used due to their simplicity, reliability, and lower maintenance requirements compared to liquid-based cooling systems.

- Hybrid and combined cooling approaches: Hybrid cooling systems combine multiple cooling technologies to achieve optimal performance. These systems may integrate liquid nitrogen with air cooling, or combine other cooling methods such as thermoelectric cooling, phase change materials, or refrigeration cycles. The hybrid approach allows for better temperature control, improved energy efficiency, and adaptability to varying cooling demands. These systems often include sophisticated control mechanisms to manage the transition between different cooling modes based on operational requirements.

- Cooling performance enhancement techniques: Various techniques can be employed to enhance cooling performance in both liquid nitrogen and air-cooled systems. These include optimized heat exchanger designs, improved thermal interface materials, enhanced surface treatments for better heat transfer, and advanced flow management. Other approaches involve the use of phase change materials, heat pipes, or microchannels to improve heat dissipation efficiency. These enhancements can significantly improve cooling capacity, reduce temperature gradients, and increase overall system performance.

- Control systems for cooling performance optimization: Advanced control systems play a crucial role in optimizing cooling performance. These systems employ sensors, controllers, and algorithms to monitor operating conditions and adjust cooling parameters accordingly. Features may include variable speed fans, adaptive flow control for liquid nitrogen, temperature-based operation modes, and predictive cooling based on load forecasting. Smart control systems can significantly improve energy efficiency, extend component life, and ensure consistent cooling performance across varying operational conditions.

02 Air-cooled system configurations

Air-cooled systems rely on ambient air as the primary heat transfer medium. These systems typically incorporate fans or blowers to force air across heat exchangers or finned surfaces. The cooling performance depends on factors such as airflow rate, heat exchanger design, and ambient air conditions. Air-cooled systems offer advantages including simplicity, lower maintenance requirements, and elimination of water consumption. Various design configurations can be implemented to optimize cooling efficiency based on specific application requirements.Expand Specific Solutions03 Hybrid and combined cooling approaches

Hybrid cooling systems integrate multiple cooling technologies to leverage the advantages of each method. These systems may combine liquid nitrogen with air cooling or incorporate other cooling media to achieve optimal performance across varying operating conditions. The integration allows for enhanced cooling efficiency, improved temperature control, and greater operational flexibility. Such combined approaches can provide backup cooling capabilities, energy optimization, and adaptability to changing thermal loads or environmental conditions.Expand Specific Solutions04 Cooling performance enhancement techniques

Various techniques can be employed to enhance the cooling performance of both liquid nitrogen and air-cooled systems. These include optimized heat exchanger designs, improved airflow management, enhanced surface treatments for better heat transfer, and advanced control algorithms. Additional performance enhancements may involve phase-change materials, thermal storage solutions, or specialized component configurations. These techniques aim to maximize cooling efficiency, reduce energy consumption, and improve overall system reliability under various operating conditions.Expand Specific Solutions05 Cooling system monitoring and control

Advanced monitoring and control systems play a crucial role in optimizing cooling performance. These systems incorporate sensors, controllers, and software algorithms to continuously monitor operating parameters such as temperature, pressure, flow rates, and energy consumption. Automated control mechanisms can adjust cooling system operation in real-time to maintain desired conditions while maximizing efficiency. Predictive maintenance capabilities can identify potential issues before they affect cooling performance, while data analytics provide insights for ongoing system optimization.Expand Specific Solutions

Key Industrial Cooling System Manufacturers

The industrial cooling market is currently in a mature growth phase, with liquid nitrogen and air-cooled systems competing for dominance. The global market size is estimated to exceed $15 billion, driven by increasing demand in manufacturing, healthcare, and data centers. Technologically, liquid nitrogen systems offer superior cooling performance but with higher complexity, while air-cooled systems provide cost-effective alternatives with improving efficiency. Leading players like Air Liquide, Linde Group, and Praxair have established strong market positions through extensive R&D and global distribution networks. Emerging competitors such as NITROcrete and Mayekawa are introducing innovative solutions targeting specific industrial applications, while Chinese manufacturers like Hangzhou Oxygen Plant Group are rapidly gaining market share through cost advantages and technological improvements.

Air Liquide SA

Technical Solution: Air Liquide has developed advanced cryogenic cooling systems utilizing liquid nitrogen that operate on a closed-loop principle. Their technology employs a proprietary heat exchange mechanism where liquid nitrogen at -196°C is circulated through specialized heat exchangers, providing rapid and precise temperature control for industrial processes. The system features intelligent flow regulation that adjusts nitrogen delivery based on real-time cooling demands, optimizing consumption while maintaining target temperatures. Air Liquide's solution incorporates digital monitoring platforms that track performance metrics and enable predictive maintenance. Their cryogenic cooling technology achieves temperatures as low as -150°C with temperature stability of ±0.5°C, making it suitable for pharmaceutical manufacturing, food freezing, and semiconductor production processes requiring extreme precision[1][3].

Strengths: Superior cooling capacity with extremely low temperatures unattainable by conventional air cooling; precise temperature control (±0.5°C); rapid cooling rates; environmentally friendly with zero direct emissions. Weaknesses: Higher initial capital investment; requires specialized infrastructure for nitrogen storage and handling; potential safety concerns with nitrogen handling; ongoing operational costs for nitrogen supply.

NITROcrete LLC

Technical Solution: NITROcrete has developed a specialized liquid nitrogen cooling system specifically for concrete temperature management in construction applications. Their technology utilizes a proprietary delivery system that precisely injects liquid nitrogen directly into concrete mixers or batching systems, providing immediate and uniform cooling throughout the concrete mass. The system features automated temperature sensing and control algorithms that adjust nitrogen flow rates to achieve target concrete temperatures with ±1°C precision. NITROcrete's solution includes mobile delivery units that can be deployed to construction sites, eliminating the need for permanent cooling infrastructure. Their technology achieves cooling rates of approximately 1°C per 1kg of liquid nitrogen per cubic meter of concrete, allowing for precise temperature management even in extreme ambient conditions. The system has demonstrated the ability to reduce concrete temperatures by up to 20°C within minutes, enabling year-round concrete placement in challenging climates[6][8].

Strengths: Highly portable and adaptable to various construction sites; precise temperature control for concrete quality; eliminates need for ice or chilled water in concrete production; reduces water consumption in concrete cooling; enables concrete placement in extreme weather conditions. Weaknesses: Requires specialized training for operation; higher per-unit cooling costs compared to traditional methods for small projects; limited to concrete applications rather than general industrial cooling; requires careful safety protocols for nitrogen handling at construction sites.

Technical Innovations in Cryogenic and Air Cooling

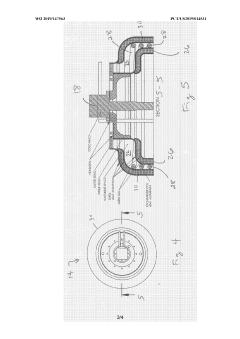

Liquid Nitrogen-Based Cooling System

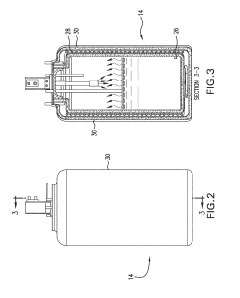

PatentActiveUS20190226745A1

Innovation

- A liquid nitrogen-based cooling system featuring a heat sink with a first vessel containing liquid nitrogen and a series of coils for heat transfer, combined with a helium-based cryo-refrigeration system to condense vaporized nitrogen back into liquid form, minimizing heat transfer from the ambient environment through a partial vacuum and insulating materials.

Liquid nitrogen-based cooling system

PatentWO2019147563A1

Innovation

- A liquid nitrogen-based cooling system featuring a heat sink with a first vessel containing liquid nitrogen and a series of coils in heat-exchanging contact, where heat is absorbed by a heat-absorbing medium and transferred to liquid nitrogen, vaporized, and then condensed back using a helium-based cryo-refrigeration system, with a partial vacuum and insulating materials to minimize ambient heat transfer.

Energy Efficiency and Sustainability Considerations

Energy efficiency represents a critical factor in the comparative analysis of liquid nitrogen and air-cooled industrial cooling systems. Liquid nitrogen systems, while offering superior cooling performance, typically require significant energy input during the nitrogen production phase. The liquefaction process demands substantial electricity consumption, with modern air separation units requiring approximately 0.4-0.7 kWh per kilogram of liquid nitrogen produced. However, once produced, liquid nitrogen cooling systems operate with minimal additional energy requirements during application, as they utilize the natural phase change properties of the cryogenic fluid.

In contrast, air-cooled systems demonstrate continuous energy consumption patterns throughout their operational lifecycle. These systems rely on compressors, fans, and pumps that draw electrical power consistently during operation. Recent industry benchmarks indicate that air-cooled systems typically consume between 0.8-1.2 kWh per ton-hour of refrigeration, with variations based on ambient conditions and system efficiency.

From a sustainability perspective, the environmental impact of both cooling technologies extends beyond direct energy consumption. Liquid nitrogen systems present a lower direct carbon footprint during operation due to zero on-site emissions, but their overall environmental impact is heavily influenced by the energy sources used in nitrogen production. When produced using renewable energy, liquid nitrogen can represent a significantly greener cooling solution with up to 70% lower lifecycle carbon emissions compared to conventional cooling methods.

Air-cooled systems face increasing scrutiny regarding refrigerant usage, particularly as global regulations phase out hydrofluorocarbons (HFCs) with high global warming potential. Modern air-cooled systems are transitioning toward natural refrigerants and low-GWP alternatives, though this transition presents technical challenges and increased costs. The refrigerant leakage risk also remains a persistent environmental concern, with average annual leakage rates in industrial systems estimated at 8-15% of total charge.

Water consumption represents another critical sustainability metric, with liquid nitrogen systems offering substantial advantages by eliminating the need for cooling water. Traditional air-cooled systems with supplemental water cooling can consume 2-4 gallons of water per ton-hour of cooling, while liquid nitrogen systems require virtually no water during operation, an increasingly valuable attribute in water-stressed regions.

Lifecycle assessment studies indicate that the sustainability equation between these technologies is highly context-dependent, influenced by factors including operational scale, duty cycle, local energy mix, and system lifespan. Recent industry trends show increasing adoption of hybrid solutions that leverage the advantages of both technologies while mitigating their respective environmental drawbacks.

In contrast, air-cooled systems demonstrate continuous energy consumption patterns throughout their operational lifecycle. These systems rely on compressors, fans, and pumps that draw electrical power consistently during operation. Recent industry benchmarks indicate that air-cooled systems typically consume between 0.8-1.2 kWh per ton-hour of refrigeration, with variations based on ambient conditions and system efficiency.

From a sustainability perspective, the environmental impact of both cooling technologies extends beyond direct energy consumption. Liquid nitrogen systems present a lower direct carbon footprint during operation due to zero on-site emissions, but their overall environmental impact is heavily influenced by the energy sources used in nitrogen production. When produced using renewable energy, liquid nitrogen can represent a significantly greener cooling solution with up to 70% lower lifecycle carbon emissions compared to conventional cooling methods.

Air-cooled systems face increasing scrutiny regarding refrigerant usage, particularly as global regulations phase out hydrofluorocarbons (HFCs) with high global warming potential. Modern air-cooled systems are transitioning toward natural refrigerants and low-GWP alternatives, though this transition presents technical challenges and increased costs. The refrigerant leakage risk also remains a persistent environmental concern, with average annual leakage rates in industrial systems estimated at 8-15% of total charge.

Water consumption represents another critical sustainability metric, with liquid nitrogen systems offering substantial advantages by eliminating the need for cooling water. Traditional air-cooled systems with supplemental water cooling can consume 2-4 gallons of water per ton-hour of cooling, while liquid nitrogen systems require virtually no water during operation, an increasingly valuable attribute in water-stressed regions.

Lifecycle assessment studies indicate that the sustainability equation between these technologies is highly context-dependent, influenced by factors including operational scale, duty cycle, local energy mix, and system lifespan. Recent industry trends show increasing adoption of hybrid solutions that leverage the advantages of both technologies while mitigating their respective environmental drawbacks.

Total Cost of Ownership Analysis

When evaluating liquid nitrogen versus air-cooled systems for industrial cooling applications, a comprehensive Total Cost of Ownership (TCO) analysis is essential for making informed investment decisions. The initial capital expenditure for liquid nitrogen systems typically includes storage tanks, piping infrastructure, safety equipment, and specialized handling systems, which generally represents a higher upfront investment compared to air-cooled alternatives. However, the installation costs for air-cooled systems may escalate due to requirements for substantial electrical infrastructure and space allocation for heat exchangers and compressors.

Operational expenses constitute a significant portion of the TCO equation. Liquid nitrogen systems incur recurring costs for nitrogen supply, which fluctuates based on market conditions, consumption volume, and delivery logistics. These systems generally require less electrical power for operation, potentially resulting in lower utility bills. Conversely, air-cooled systems demand substantial electricity for compressors and fans, making them vulnerable to rising energy costs and peak demand charges.

Maintenance requirements differ significantly between these cooling technologies. Liquid nitrogen systems feature fewer moving parts, potentially reducing mechanical failure rates and associated maintenance costs. However, they necessitate specialized training for safe handling and regular inspection of cryogenic components. Air-cooled systems typically require more frequent maintenance interventions, including filter replacements, compressor servicing, and heat exchanger cleaning, but these procedures are generally more standardized and widely understood by maintenance personnel.

The expected service life and depreciation schedules also impact TCO calculations. Liquid nitrogen equipment often demonstrates longer operational lifespans due to simpler mechanical designs and reduced wear patterns. Air-cooled systems may require more frequent component replacements or complete system upgrades, particularly in harsh industrial environments where dust and contaminants accelerate deterioration of heat exchange surfaces.

Environmental compliance costs represent an increasingly important TCO factor. Liquid nitrogen systems produce minimal direct emissions but have an embedded carbon footprint from nitrogen production and transportation. Air-cooled systems using traditional refrigerants face potential regulatory challenges and phase-out schedules for certain compounds, potentially necessitating costly system retrofits or replacements to maintain compliance with evolving environmental regulations.

Productivity impacts must also be monetized within the TCO framework. Liquid nitrogen systems can achieve more rapid cooling and maintain more precise temperature control in certain applications, potentially enhancing production throughput and product quality. The associated revenue improvements or rejection rate reductions should be quantified and incorporated into the long-term financial assessment when comparing these competing cooling technologies.

Operational expenses constitute a significant portion of the TCO equation. Liquid nitrogen systems incur recurring costs for nitrogen supply, which fluctuates based on market conditions, consumption volume, and delivery logistics. These systems generally require less electrical power for operation, potentially resulting in lower utility bills. Conversely, air-cooled systems demand substantial electricity for compressors and fans, making them vulnerable to rising energy costs and peak demand charges.

Maintenance requirements differ significantly between these cooling technologies. Liquid nitrogen systems feature fewer moving parts, potentially reducing mechanical failure rates and associated maintenance costs. However, they necessitate specialized training for safe handling and regular inspection of cryogenic components. Air-cooled systems typically require more frequent maintenance interventions, including filter replacements, compressor servicing, and heat exchanger cleaning, but these procedures are generally more standardized and widely understood by maintenance personnel.

The expected service life and depreciation schedules also impact TCO calculations. Liquid nitrogen equipment often demonstrates longer operational lifespans due to simpler mechanical designs and reduced wear patterns. Air-cooled systems may require more frequent component replacements or complete system upgrades, particularly in harsh industrial environments where dust and contaminants accelerate deterioration of heat exchange surfaces.

Environmental compliance costs represent an increasingly important TCO factor. Liquid nitrogen systems produce minimal direct emissions but have an embedded carbon footprint from nitrogen production and transportation. Air-cooled systems using traditional refrigerants face potential regulatory challenges and phase-out schedules for certain compounds, potentially necessitating costly system retrofits or replacements to maintain compliance with evolving environmental regulations.

Productivity impacts must also be monetized within the TCO framework. Liquid nitrogen systems can achieve more rapid cooling and maintain more precise temperature control in certain applications, potentially enhancing production throughput and product quality. The associated revenue improvements or rejection rate reductions should be quantified and incorporated into the long-term financial assessment when comparing these competing cooling technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!