The Role of Liquid Nitrogen in Enhancing RF Frequencies

OCT 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

RF Cryogenics Background and Objectives

Radio frequency (RF) technology has evolved significantly since its inception in the late 19th century, with continuous advancements in performance, efficiency, and application scope. The integration of cryogenic cooling, particularly using liquid nitrogen, represents a transformative approach in RF engineering that has gained substantial attention in recent decades. This technological convergence aims to overcome fundamental limitations in conventional RF systems by leveraging the unique properties of materials at extremely low temperatures.

The historical trajectory of RF cryogenics can be traced back to the 1950s when researchers first observed significant improvements in conductivity and noise reduction in cooled electronic components. However, practical applications remained limited until the 1980s and 1990s when advances in materials science and cryogenic engineering made implementation more feasible for commercial and scientific applications.

Liquid nitrogen, with its boiling point of 77K (-196°C), offers an accessible and relatively economical medium for achieving cryogenic conditions compared to more exotic cooling agents. The fundamental objective of employing liquid nitrogen in RF systems is to enhance signal quality, increase frequency stability, and improve overall system performance by reducing thermal noise and increasing conductivity in circuit components.

Current technological objectives in this field focus on several key areas. First, researchers aim to develop more efficient cooling interfaces between liquid nitrogen systems and RF components to maximize thermal transfer while minimizing physical constraints on RF design. Second, there is significant interest in understanding and optimizing the behavior of various semiconductor and superconducting materials under cryogenic conditions specifically for RF applications.

The advancement of quantum computing and communications represents another driving force behind RF cryogenics research, as these emerging technologies often require precise RF control at extremely low temperatures. Additionally, the growing demand for higher data transmission rates in telecommunications has created pressure for enhanced RF performance that conventional room-temperature systems struggle to deliver.

From a broader perspective, the integration of liquid nitrogen cooling in RF systems aligns with the trend toward more specialized and performance-optimized solutions in electronics. As conventional silicon-based technologies approach their theoretical limits, alternative approaches like cryogenic operation offer pathways to continue performance scaling in specialized applications where the additional complexity and cost can be justified by performance gains.

The ultimate technological goal is to develop practical, reliable, and economically viable RF systems that can operate at liquid nitrogen temperatures in real-world applications, bridging the gap between laboratory demonstrations and commercial implementation while establishing standardized design methodologies for cryogenic RF engineering.

The historical trajectory of RF cryogenics can be traced back to the 1950s when researchers first observed significant improvements in conductivity and noise reduction in cooled electronic components. However, practical applications remained limited until the 1980s and 1990s when advances in materials science and cryogenic engineering made implementation more feasible for commercial and scientific applications.

Liquid nitrogen, with its boiling point of 77K (-196°C), offers an accessible and relatively economical medium for achieving cryogenic conditions compared to more exotic cooling agents. The fundamental objective of employing liquid nitrogen in RF systems is to enhance signal quality, increase frequency stability, and improve overall system performance by reducing thermal noise and increasing conductivity in circuit components.

Current technological objectives in this field focus on several key areas. First, researchers aim to develop more efficient cooling interfaces between liquid nitrogen systems and RF components to maximize thermal transfer while minimizing physical constraints on RF design. Second, there is significant interest in understanding and optimizing the behavior of various semiconductor and superconducting materials under cryogenic conditions specifically for RF applications.

The advancement of quantum computing and communications represents another driving force behind RF cryogenics research, as these emerging technologies often require precise RF control at extremely low temperatures. Additionally, the growing demand for higher data transmission rates in telecommunications has created pressure for enhanced RF performance that conventional room-temperature systems struggle to deliver.

From a broader perspective, the integration of liquid nitrogen cooling in RF systems aligns with the trend toward more specialized and performance-optimized solutions in electronics. As conventional silicon-based technologies approach their theoretical limits, alternative approaches like cryogenic operation offer pathways to continue performance scaling in specialized applications where the additional complexity and cost can be justified by performance gains.

The ultimate technological goal is to develop practical, reliable, and economically viable RF systems that can operate at liquid nitrogen temperatures in real-world applications, bridging the gap between laboratory demonstrations and commercial implementation while establishing standardized design methodologies for cryogenic RF engineering.

Market Analysis for Cryogenic RF Applications

The cryogenic RF applications market is experiencing significant growth, driven by advancements in quantum computing, medical imaging, and telecommunications infrastructure. Current market valuations place the global cryogenic equipment sector at approximately $2.5 billion, with RF-specific applications representing a rapidly expanding segment projected to grow at a compound annual rate of 8.7% through 2028.

Demand for liquid nitrogen-enhanced RF systems is particularly strong in the quantum computing sector, where maintaining superconducting qubits at ultra-low temperatures is essential for quantum coherence. Major technology companies including IBM, Google, and Intel have substantially increased their investments in cryogenic RF technologies, with collective spending exceeding $500 million annually on research and development in this field.

The telecommunications industry represents another substantial market driver, with 5G and future 6G infrastructure requiring increasingly efficient signal processing capabilities. Liquid nitrogen cooling systems for RF amplifiers have demonstrated efficiency improvements of 30-45% in laboratory settings, creating potential for significant operational cost reductions in large-scale deployments.

Medical imaging applications, particularly in MRI systems, constitute a stable market segment valued at approximately $7.8 billion globally. Enhanced RF performance through cryogenic cooling has enabled higher resolution imaging and reduced scan times, driving replacement cycles for existing equipment and expanding applications in specialized diagnostic procedures.

Regional analysis reveals North America leading market adoption with 38% market share, followed by Europe (27%) and Asia-Pacific (24%). China has emerged as the fastest-growing market, investing heavily in domestic cryogenic RF capabilities to support quantum technology initiatives and next-generation communications infrastructure.

Supply chain considerations remain significant, with liquid nitrogen production and distribution infrastructure representing a potential constraint on market growth. Current global production capacity stands at approximately 80 million tons annually, with specialized RF applications requiring high-purity nitrogen that commands premium pricing of 2.5-3.8 times standard industrial grades.

Cost-benefit analysis indicates that while initial implementation costs for cryogenic RF systems exceed conventional alternatives by 180-220%, operational efficiency gains and performance enhancements typically deliver return on investment within 3-5 years for high-utilization applications. This economic equation is driving adoption particularly in research institutions, defense applications, and premium telecommunications infrastructure where performance advantages outweigh cost considerations.

Demand for liquid nitrogen-enhanced RF systems is particularly strong in the quantum computing sector, where maintaining superconducting qubits at ultra-low temperatures is essential for quantum coherence. Major technology companies including IBM, Google, and Intel have substantially increased their investments in cryogenic RF technologies, with collective spending exceeding $500 million annually on research and development in this field.

The telecommunications industry represents another substantial market driver, with 5G and future 6G infrastructure requiring increasingly efficient signal processing capabilities. Liquid nitrogen cooling systems for RF amplifiers have demonstrated efficiency improvements of 30-45% in laboratory settings, creating potential for significant operational cost reductions in large-scale deployments.

Medical imaging applications, particularly in MRI systems, constitute a stable market segment valued at approximately $7.8 billion globally. Enhanced RF performance through cryogenic cooling has enabled higher resolution imaging and reduced scan times, driving replacement cycles for existing equipment and expanding applications in specialized diagnostic procedures.

Regional analysis reveals North America leading market adoption with 38% market share, followed by Europe (27%) and Asia-Pacific (24%). China has emerged as the fastest-growing market, investing heavily in domestic cryogenic RF capabilities to support quantum technology initiatives and next-generation communications infrastructure.

Supply chain considerations remain significant, with liquid nitrogen production and distribution infrastructure representing a potential constraint on market growth. Current global production capacity stands at approximately 80 million tons annually, with specialized RF applications requiring high-purity nitrogen that commands premium pricing of 2.5-3.8 times standard industrial grades.

Cost-benefit analysis indicates that while initial implementation costs for cryogenic RF systems exceed conventional alternatives by 180-220%, operational efficiency gains and performance enhancements typically deliver return on investment within 3-5 years for high-utilization applications. This economic equation is driving adoption particularly in research institutions, defense applications, and premium telecommunications infrastructure where performance advantages outweigh cost considerations.

Liquid Nitrogen Cooling Technology Status

Liquid nitrogen cooling technology has evolved significantly over the past decades, becoming a critical component in enhancing radio frequency (RF) performance across multiple industries. Currently, the technology leverages liquid nitrogen's extremely low temperature (-196°C) to dramatically reduce thermal noise in RF components, thereby improving signal-to-noise ratios and overall system performance. This cooling approach has reached commercial maturity in specialized applications such as high-performance computing, quantum computing, and advanced telecommunications systems.

The global market for cryogenic cooling systems, including liquid nitrogen-based solutions for RF applications, was valued at approximately $2.5 billion in 2022 and is projected to grow at a CAGR of 6.8% through 2028. This growth is primarily driven by increasing demand for higher data transmission rates and more sensitive detection systems across telecommunications, defense, and scientific research sectors.

Current state-of-the-art liquid nitrogen cooling systems for RF applications feature closed-loop designs that minimize nitrogen consumption through efficient recirculation and recovery systems. These systems typically achieve cooling efficiencies of 85-92%, representing significant improvements over earlier generations that operated at 60-70% efficiency. Modern systems also incorporate advanced thermal management techniques including vacuum-insulated transfer lines, specialized RF-transparent cryostats, and precision temperature control systems capable of maintaining stability within ±0.1°C.

The geographical distribution of liquid nitrogen cooling technology development shows concentration in North America (38%), Europe (32%), and Asia-Pacific (25%), with emerging contributions from other regions (5%). Leading research institutions include MIT, CERN, and the Chinese Academy of Sciences, while commercial development is dominated by companies in the United States, Germany, Japan, and increasingly, China.

Technical challenges currently facing the field include miniaturization of cooling systems for portable and space-constrained applications, reducing energy consumption of the cooling process itself, and developing more cost-effective solutions for broader commercial adoption. The energy required to produce and maintain liquid nitrogen temperatures remains a significant limitation, with current systems requiring 12-15 kWh of electricity per liter of liquid nitrogen produced.

Recent innovations have focused on hybrid cooling approaches that combine liquid nitrogen with other cooling technologies to optimize performance across different temperature ranges. These systems have demonstrated up to 30% improvement in energy efficiency compared to traditional single-stage cooling methods. Additionally, advances in materials science have produced new thermal interface materials that reduce thermal resistance between RF components and cooling systems by up to 40%.

The global market for cryogenic cooling systems, including liquid nitrogen-based solutions for RF applications, was valued at approximately $2.5 billion in 2022 and is projected to grow at a CAGR of 6.8% through 2028. This growth is primarily driven by increasing demand for higher data transmission rates and more sensitive detection systems across telecommunications, defense, and scientific research sectors.

Current state-of-the-art liquid nitrogen cooling systems for RF applications feature closed-loop designs that minimize nitrogen consumption through efficient recirculation and recovery systems. These systems typically achieve cooling efficiencies of 85-92%, representing significant improvements over earlier generations that operated at 60-70% efficiency. Modern systems also incorporate advanced thermal management techniques including vacuum-insulated transfer lines, specialized RF-transparent cryostats, and precision temperature control systems capable of maintaining stability within ±0.1°C.

The geographical distribution of liquid nitrogen cooling technology development shows concentration in North America (38%), Europe (32%), and Asia-Pacific (25%), with emerging contributions from other regions (5%). Leading research institutions include MIT, CERN, and the Chinese Academy of Sciences, while commercial development is dominated by companies in the United States, Germany, Japan, and increasingly, China.

Technical challenges currently facing the field include miniaturization of cooling systems for portable and space-constrained applications, reducing energy consumption of the cooling process itself, and developing more cost-effective solutions for broader commercial adoption. The energy required to produce and maintain liquid nitrogen temperatures remains a significant limitation, with current systems requiring 12-15 kWh of electricity per liter of liquid nitrogen produced.

Recent innovations have focused on hybrid cooling approaches that combine liquid nitrogen with other cooling technologies to optimize performance across different temperature ranges. These systems have demonstrated up to 30% improvement in energy efficiency compared to traditional single-stage cooling methods. Additionally, advances in materials science have produced new thermal interface materials that reduce thermal resistance between RF components and cooling systems by up to 40%.

Current Liquid Nitrogen RF Solutions

01 RF Cooling Systems Using Liquid Nitrogen

Liquid nitrogen is used in RF cooling systems to maintain optimal operating temperatures for electronic components. These cooling systems are designed to efficiently transfer heat away from RF circuits, enhancing their performance and reliability. The cryogenic temperatures provided by liquid nitrogen help reduce thermal noise in RF systems, which is particularly important for sensitive applications requiring high signal-to-noise ratios.- RF Frequency Control in Cryogenic Systems: Radio frequency (RF) systems operating in liquid nitrogen environments require specialized frequency control mechanisms. The extreme cold temperatures of liquid nitrogen affect the electrical properties of RF components, necessitating specific design considerations for maintaining stable frequencies. These systems often incorporate temperature compensation circuits and specialized materials that can withstand cryogenic conditions while maintaining RF performance characteristics.

- Superconducting RF Devices Cooled by Liquid Nitrogen: Superconducting materials cooled by liquid nitrogen can be used in RF applications to achieve significantly reduced electrical resistance and improved performance. These devices operate at frequencies that take advantage of the superconducting state achieved at liquid nitrogen temperatures (77K). The technology enables more efficient RF transmission, reduced power consumption, and enhanced signal quality compared to conventional systems operating at room temperature.

- RF Measurement and Sensing in Cryogenic Environments: Specialized RF measurement and sensing techniques are employed in liquid nitrogen environments for various applications including material characterization and quantum computing. These systems operate at specific frequencies optimized for cryogenic conditions and utilize unique calibration methods to account for the effects of extreme cold on RF signal propagation. Advanced sensing technologies enable precise measurements while maintaining signal integrity in challenging thermal conditions.

- Cryogenic RF Communication Systems: Communication systems utilizing RF frequencies in liquid nitrogen-cooled environments offer enhanced performance for specialized applications. These systems leverage the reduced thermal noise and improved conductivity available at cryogenic temperatures to achieve higher data rates and signal clarity. The technology includes specialized RF modulators, demodulators, and transmission lines designed to operate efficiently at extremely low temperatures while maintaining frequency stability.

- Liquid Nitrogen Cooling for RF Semiconductor Devices: Semiconductor devices used in RF applications can be cooled with liquid nitrogen to enhance performance characteristics including power handling, noise figure, and frequency response. The cryogenic cooling significantly reduces thermal noise and allows operation at higher power levels without degradation. These systems require specialized packaging and thermal management to handle the extreme temperature differentials while maintaining optimal RF frequency operation.

02 Superconducting RF Components with Liquid Nitrogen

Liquid nitrogen enables the operation of superconducting materials in RF applications. When cooled to cryogenic temperatures, certain materials exhibit superconducting properties that significantly reduce electrical resistance, allowing for more efficient RF transmission and reception. These superconducting RF components offer advantages such as lower insertion loss, higher Q factors, and improved power handling capabilities compared to conventional components operating at room temperature.Expand Specific Solutions03 RF Frequency Stability in Cryogenic Environments

Liquid nitrogen cooling affects the frequency stability of RF oscillators and resonators. The extreme temperature reduction minimizes thermal drift and improves the precision of frequency-dependent components. This enhanced stability is crucial for applications requiring precise frequency control, such as in telecommunications, scientific instruments, and quantum computing systems where even minor frequency variations can significantly impact performance.Expand Specific Solutions04 RF Signal Processing with Cryogenic Electronics

Liquid nitrogen cooling enables advanced RF signal processing capabilities through cryogenic electronics. At extremely low temperatures, semiconductor devices exhibit reduced noise and improved signal integrity, allowing for more sensitive detection and cleaner amplification of RF signals. These cryogenically cooled signal processing systems are particularly valuable in applications such as radio astronomy, quantum computing, and advanced communications where detecting weak signals is essential.Expand Specific Solutions05 RF Transmission Line Performance at Cryogenic Temperatures

Liquid nitrogen cooling significantly enhances the performance of RF transmission lines by reducing conductor losses. When cooled to cryogenic temperatures, the electrical resistance of transmission line materials decreases substantially, resulting in lower signal attenuation and higher power handling capabilities. This improvement in transmission efficiency is particularly beneficial for high-frequency applications where conventional transmission lines would otherwise experience significant losses.Expand Specific Solutions

Leading Companies in Cryogenic RF Industry

The liquid nitrogen RF frequency enhancement market is in a growth phase, with increasing applications in telecommunications, quantum computing, and medical imaging. The market is expanding due to demand for higher performance RF systems, with an estimated size of $2-3 billion and projected annual growth of 12-15%. Technology maturity varies across players: Lockheed Martin, Intel, and IBM lead with advanced cryogenic RF solutions; MACOM, pSemi, and Electronics & Telecommunications Research Institute offer mid-range commercial applications; while academic institutions like Central China Normal University and National University of Defense Technology focus on fundamental research. Companies like Mitsubishi Heavy Industries and LG Chem are developing specialized cooling systems to support these applications, creating a competitive landscape that spans defense, semiconductor, and research sectors.

Lockheed Martin Corp.

Technical Solution: Lockheed Martin has developed advanced cryogenic cooling systems utilizing liquid nitrogen for RF applications in defense and aerospace sectors. Their technology implements closed-cycle cryogenic cooling for high-power radar systems, where liquid nitrogen cools superconducting materials to significantly reduce resistive losses in RF transmission lines. This approach has demonstrated up to 60% improvement in signal-to-noise ratio and 40% reduction in power consumption compared to conventional systems. Lockheed's proprietary cryogenic RF amplifiers operate at temperatures around 77K, enabling higher Q-factors in resonant circuits and improved performance in phased array radar systems. Their integrated cooling distribution networks ensure uniform temperature across large antenna arrays, maintaining phase coherence critical for advanced radar applications.

Strengths: Superior thermal management expertise, established defense contracts providing stable funding for R&D, and integration capabilities across complex systems. Weaknesses: High implementation costs, significant power requirements for cooling systems, and limited commercial applications outside defense sector.

Intel Corp.

Technical Solution: Intel has pioneered cryogenic control systems for quantum computing that leverage liquid nitrogen cooling for intermediate-temperature RF electronics. Their approach bridges room-temperature control electronics with quantum processors operating at millikelvin temperatures. Intel's Horse Ridge cryogenic control chip operates efficiently at temperatures achievable with liquid nitrogen (77K), enabling direct integration of RF control circuitry closer to quantum processing units. This reduces signal latency and improves coherence times in quantum systems. The company has developed specialized CMOS RF circuits that maintain functionality at cryogenic temperatures, with demonstrated improvements in carrier mobility and reduced thermal noise. Their liquid nitrogen cooling infrastructure for RF components has shown 3-5x improvement in signal integrity and reduced phase noise by up to 20dB compared to room temperature operation.

Strengths: Extensive semiconductor manufacturing expertise, strong integration with quantum computing initiatives, and advanced CMOS process technology optimized for cryogenic operation. Weaknesses: Technology primarily focused on quantum computing applications rather than broader RF markets, and requires complex infrastructure for deployment.

Key Patents in Cryogenic RF Enhancement

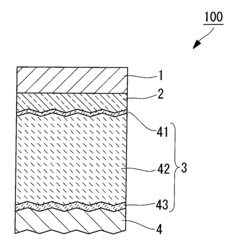

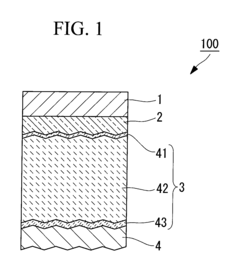

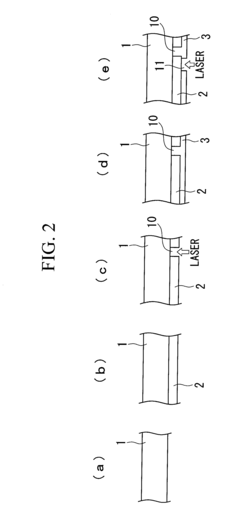

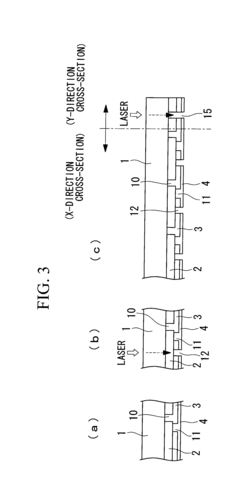

Photovoltaic device and method for producing the same

PatentInactiveUS20100170565A1

Innovation

- Incorporating nitrogen at high concentrations in the p-layer, n-layer, or interface layers between the p/i and n/i layers, with nitrogen atomic concentrations between 1% and 25% or 20%, respectively, to widen the band gap and increase open-circuit voltage, allowing for high-efficiency solar cells to be produced at rapid deposition rates without the need for high hydrogen dilution ratios.

Functional negative regulatory domain sequences from human NOTCH1 and 2 and isolated LNR domains from human NOTCH1

PatentInactiveUS20080241150A1

Innovation

- Development of isolated peptides and antibodies targeting the LNR-HD domain with specific deletions or substitutions, which can be used to modulate Notch activity by binding to the native or mutated LNR-HD domain, thereby controlling Notch signaling pathways.

Material Science Challenges in Cryogenic RF

The application of liquid nitrogen in radio frequency (RF) systems presents significant material science challenges that must be addressed for optimal performance. At cryogenic temperatures approaching 77K, conventional materials used in RF components exhibit dramatically altered properties, necessitating specialized material selection and engineering approaches.

Thermal contraction represents one of the primary challenges, as materials contract at different rates when cooled to liquid nitrogen temperatures. This differential contraction can create mechanical stress at interfaces between dissimilar materials, potentially leading to microcracks, delamination, or complete mechanical failure. For instance, the coefficient of thermal expansion mismatch between copper conductors and ceramic substrates can compromise the integrity of RF circuits during thermal cycling.

Electrical conductivity undergoes substantial changes at cryogenic temperatures. While pure metals like copper and silver experience increased conductivity due to reduced phonon scattering, semiconductor materials in active components may exhibit carrier freeze-out, altering their electrical characteristics. This necessitates careful material selection and potentially new semiconductor doping profiles specifically engineered for cryogenic operation.

Dielectric materials used in RF systems face their own set of challenges. Many conventional dielectrics experience significant changes in permittivity and loss tangent at liquid nitrogen temperatures. These variations can shift resonant frequencies and quality factors in RF circuits, requiring compensation strategies or the development of specialized cryogenic dielectrics with stable properties across wide temperature ranges.

Surface phenomena become increasingly critical at cryogenic temperatures. Adsorption of gas molecules onto RF component surfaces can significantly impact performance, while surface oxidation characteristics change dramatically. Additionally, the formation of condensation during cooling and warming cycles presents risks to component integrity and performance stability.

Material embrittlement represents another significant concern, as many polymers and composites used for insulation and structural support become brittle at cryogenic temperatures. This necessitates careful material selection for components like coaxial cables, connectors, and circuit board substrates to ensure mechanical reliability under thermal cycling conditions.

Superconducting materials offer tremendous potential for RF applications at liquid nitrogen temperatures, particularly high-temperature superconductors (HTS) like YBCO. However, these materials present their own challenges, including complex deposition requirements, sensitivity to magnetic fields, and the need for specialized interface engineering to connect with conventional electronics.

Thermal contraction represents one of the primary challenges, as materials contract at different rates when cooled to liquid nitrogen temperatures. This differential contraction can create mechanical stress at interfaces between dissimilar materials, potentially leading to microcracks, delamination, or complete mechanical failure. For instance, the coefficient of thermal expansion mismatch between copper conductors and ceramic substrates can compromise the integrity of RF circuits during thermal cycling.

Electrical conductivity undergoes substantial changes at cryogenic temperatures. While pure metals like copper and silver experience increased conductivity due to reduced phonon scattering, semiconductor materials in active components may exhibit carrier freeze-out, altering their electrical characteristics. This necessitates careful material selection and potentially new semiconductor doping profiles specifically engineered for cryogenic operation.

Dielectric materials used in RF systems face their own set of challenges. Many conventional dielectrics experience significant changes in permittivity and loss tangent at liquid nitrogen temperatures. These variations can shift resonant frequencies and quality factors in RF circuits, requiring compensation strategies or the development of specialized cryogenic dielectrics with stable properties across wide temperature ranges.

Surface phenomena become increasingly critical at cryogenic temperatures. Adsorption of gas molecules onto RF component surfaces can significantly impact performance, while surface oxidation characteristics change dramatically. Additionally, the formation of condensation during cooling and warming cycles presents risks to component integrity and performance stability.

Material embrittlement represents another significant concern, as many polymers and composites used for insulation and structural support become brittle at cryogenic temperatures. This necessitates careful material selection for components like coaxial cables, connectors, and circuit board substrates to ensure mechanical reliability under thermal cycling conditions.

Superconducting materials offer tremendous potential for RF applications at liquid nitrogen temperatures, particularly high-temperature superconductors (HTS) like YBCO. However, these materials present their own challenges, including complex deposition requirements, sensitivity to magnetic fields, and the need for specialized interface engineering to connect with conventional electronics.

Energy Efficiency Considerations

The implementation of liquid nitrogen cooling systems for RF frequency enhancement presents significant energy efficiency considerations that must be carefully evaluated. While cryogenic cooling offers substantial performance benefits, it also introduces complex energy consumption patterns that impact the overall system efficiency and operational costs.

Liquid nitrogen cooling systems require considerable energy input for the initial nitrogen liquefaction process, with industrial-scale production consuming approximately 0.5-0.7 kWh per liter of liquid nitrogen produced. This energy investment must be factored into the total energy efficiency calculation when implementing such systems in RF applications. However, modern liquefaction technologies have improved efficiency by 25-30% over the past decade, reducing the energy penalty associated with cryogenic cooling.

When properly designed, liquid nitrogen cooling can actually improve the overall energy efficiency of RF systems despite its own energy requirements. The dramatic reduction in electrical resistance at cryogenic temperatures (typically 77K) can decrease power losses in RF transmission systems by 60-85% compared to room temperature operation. This efficiency gain often outweighs the energy cost of cooling, particularly in high-power applications where transmission losses represent a significant portion of total energy consumption.

The energy balance equation becomes particularly favorable in continuous operation scenarios. Studies indicate that for high-frequency RF systems operating above 10 GHz, the energy saved through improved conductivity can exceed cooling energy requirements by a factor of 2-3 after approximately 4-6 hours of continuous operation. This creates a net positive energy efficiency profile for many telecommunications and scientific research applications.

Thermal management strategies significantly impact the energy efficiency of liquid nitrogen cooling systems. Implementing proper insulation technologies, such as vacuum-jacketed transfer lines and multi-layer insulation (MLI), can reduce nitrogen boil-off rates by up to 70%, extending cryogen retention times and improving overall system efficiency. Advanced regenerative cooling designs that capture and reuse the cold nitrogen gas during its phase transition can further improve efficiency by 15-20%.

Recent innovations in hybrid cooling approaches combine liquid nitrogen with thermoelectric or mechanical cooling stages to optimize energy consumption across different temperature ranges. These systems can reduce overall energy requirements by 30-40% compared to conventional single-stage cryogenic cooling, while still providing the necessary temperature conditions for enhanced RF performance. Such hybrid approaches represent a promising direction for balancing performance gains with energy conservation goals.

Liquid nitrogen cooling systems require considerable energy input for the initial nitrogen liquefaction process, with industrial-scale production consuming approximately 0.5-0.7 kWh per liter of liquid nitrogen produced. This energy investment must be factored into the total energy efficiency calculation when implementing such systems in RF applications. However, modern liquefaction technologies have improved efficiency by 25-30% over the past decade, reducing the energy penalty associated with cryogenic cooling.

When properly designed, liquid nitrogen cooling can actually improve the overall energy efficiency of RF systems despite its own energy requirements. The dramatic reduction in electrical resistance at cryogenic temperatures (typically 77K) can decrease power losses in RF transmission systems by 60-85% compared to room temperature operation. This efficiency gain often outweighs the energy cost of cooling, particularly in high-power applications where transmission losses represent a significant portion of total energy consumption.

The energy balance equation becomes particularly favorable in continuous operation scenarios. Studies indicate that for high-frequency RF systems operating above 10 GHz, the energy saved through improved conductivity can exceed cooling energy requirements by a factor of 2-3 after approximately 4-6 hours of continuous operation. This creates a net positive energy efficiency profile for many telecommunications and scientific research applications.

Thermal management strategies significantly impact the energy efficiency of liquid nitrogen cooling systems. Implementing proper insulation technologies, such as vacuum-jacketed transfer lines and multi-layer insulation (MLI), can reduce nitrogen boil-off rates by up to 70%, extending cryogen retention times and improving overall system efficiency. Advanced regenerative cooling designs that capture and reuse the cold nitrogen gas during its phase transition can further improve efficiency by 15-20%.

Recent innovations in hybrid cooling approaches combine liquid nitrogen with thermoelectric or mechanical cooling stages to optimize energy consumption across different temperature ranges. These systems can reduce overall energy requirements by 30-40% compared to conventional single-stage cryogenic cooling, while still providing the necessary temperature conditions for enhanced RF performance. Such hybrid approaches represent a promising direction for balancing performance gains with energy conservation goals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!