How to Enhance Safety in Liquid Nitrogen Usage in Labs

OCT 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Nitrogen Safety Background and Objectives

Liquid nitrogen (LN2) has been extensively utilized in laboratory settings since the mid-20th century, serving critical functions in cryopreservation, cooling systems, and various scientific procedures. With a boiling point of -196°C (-321°F), this colorless, odorless cryogenic liquid presents significant safety challenges that have evolved alongside its expanding applications across biological research, medical facilities, and industrial laboratories.

The historical development of liquid nitrogen safety protocols reveals a trajectory of reactive measures following serious incidents. Notable accidents in academic and industrial settings during the 1980s and 1990s prompted the establishment of more rigorous safety standards. The American Chemical Society and Compressed Gas Association subsequently developed comprehensive guidelines that have become foundational to modern laboratory safety practices.

Current safety challenges primarily stem from liquid nitrogen's physical properties - particularly its 1:696 liquid-to-gas expansion ratio which can create oxygen-depleted environments and dangerous pressure buildups in confined spaces. Additionally, direct contact risks include severe cryogenic burns and tissue damage, while material embrittlement can compromise containment systems.

Recent technological advancements have introduced automated monitoring systems, improved personal protective equipment, and enhanced storage vessel designs. However, implementation remains inconsistent across different laboratory environments, with smaller facilities often lacking resources for state-of-the-art safety infrastructure.

The primary objective of this technical research is to comprehensively evaluate existing safety protocols and identify innovative approaches to enhance liquid nitrogen handling safety across diverse laboratory settings. Specifically, we aim to develop scalable solutions applicable to facilities with varying resource capabilities, from well-funded research institutions to smaller academic laboratories.

Secondary objectives include: quantifying the effectiveness of current safety technologies through empirical assessment; identifying critical gaps in existing safety frameworks; developing cost-effective monitoring solutions utilizing IoT and sensor technologies; and establishing standardized training protocols that address both technical competencies and emergency response procedures.

This research acknowledges the tension between maintaining operational efficiency and implementing robust safety measures. Therefore, proposed solutions will prioritize systems that enhance safety without significantly impeding workflow or requiring prohibitive financial investment. The ultimate goal is to establish a new safety paradigm that can be widely adopted across the scientific community, reducing incident rates while supporting the continued beneficial use of liquid nitrogen in laboratory environments.

The historical development of liquid nitrogen safety protocols reveals a trajectory of reactive measures following serious incidents. Notable accidents in academic and industrial settings during the 1980s and 1990s prompted the establishment of more rigorous safety standards. The American Chemical Society and Compressed Gas Association subsequently developed comprehensive guidelines that have become foundational to modern laboratory safety practices.

Current safety challenges primarily stem from liquid nitrogen's physical properties - particularly its 1:696 liquid-to-gas expansion ratio which can create oxygen-depleted environments and dangerous pressure buildups in confined spaces. Additionally, direct contact risks include severe cryogenic burns and tissue damage, while material embrittlement can compromise containment systems.

Recent technological advancements have introduced automated monitoring systems, improved personal protective equipment, and enhanced storage vessel designs. However, implementation remains inconsistent across different laboratory environments, with smaller facilities often lacking resources for state-of-the-art safety infrastructure.

The primary objective of this technical research is to comprehensively evaluate existing safety protocols and identify innovative approaches to enhance liquid nitrogen handling safety across diverse laboratory settings. Specifically, we aim to develop scalable solutions applicable to facilities with varying resource capabilities, from well-funded research institutions to smaller academic laboratories.

Secondary objectives include: quantifying the effectiveness of current safety technologies through empirical assessment; identifying critical gaps in existing safety frameworks; developing cost-effective monitoring solutions utilizing IoT and sensor technologies; and establishing standardized training protocols that address both technical competencies and emergency response procedures.

This research acknowledges the tension between maintaining operational efficiency and implementing robust safety measures. Therefore, proposed solutions will prioritize systems that enhance safety without significantly impeding workflow or requiring prohibitive financial investment. The ultimate goal is to establish a new safety paradigm that can be widely adopted across the scientific community, reducing incident rates while supporting the continued beneficial use of liquid nitrogen in laboratory environments.

Market Analysis of Laboratory Safety Equipment

The laboratory safety equipment market has experienced significant growth in recent years, driven by increasing awareness of workplace safety regulations and the rising number of laboratory accidents. The global laboratory safety equipment market was valued at approximately $2.3 billion in 2022 and is projected to reach $3.5 billion by 2028, growing at a CAGR of 7.2% during the forecast period. This growth is particularly evident in regions with stringent safety regulations such as North America and Europe.

Liquid nitrogen safety equipment represents a substantial segment within this market, accounting for about 15% of the total laboratory safety equipment sales. This segment includes specialized storage dewars, cryogenic gloves, face shields, aprons, and automated handling systems designed specifically for liquid nitrogen applications. The demand for these products has been steadily increasing due to the expanding use of liquid nitrogen in various scientific fields including cell preservation, cryotherapy, and material testing.

Regional analysis reveals that North America dominates the laboratory safety equipment market with approximately 35% market share, followed by Europe (30%) and Asia-Pacific (25%). The Asia-Pacific region, particularly China and India, is expected to witness the fastest growth rate due to rapid industrialization, increasing R&D investments, and growing awareness about laboratory safety standards.

Key market drivers include stringent government regulations regarding laboratory safety, increasing incidents of laboratory accidents involving cryogenic materials, growing adoption of liquid nitrogen in healthcare and life sciences research, and rising investments in R&D activities across pharmaceutical and biotechnology sectors. The COVID-19 pandemic has further accelerated market growth as laboratories worldwide have heightened their safety protocols.

Market segmentation by end-user shows that academic and research institutions account for the largest share (40%), followed by pharmaceutical and biotechnology companies (30%), healthcare facilities (15%), and industrial laboratories (15%). The academic segment's dominance is attributed to the extensive use of liquid nitrogen in various research applications and the implementation of strict safety protocols in educational institutions.

Pricing trends indicate that premium safety equipment with advanced features such as automated monitoring systems and smart alerts command higher prices but are gaining popularity due to their enhanced safety benefits. The average cost of a comprehensive liquid nitrogen safety kit has increased by 12% over the past three years, reflecting both inflation and the integration of advanced technologies.

Customer behavior analysis shows increasing preference for integrated safety solutions rather than individual products, with 65% of laboratory managers preferring to purchase complete safety packages from a single vendor to ensure compatibility and consistent quality.

Liquid nitrogen safety equipment represents a substantial segment within this market, accounting for about 15% of the total laboratory safety equipment sales. This segment includes specialized storage dewars, cryogenic gloves, face shields, aprons, and automated handling systems designed specifically for liquid nitrogen applications. The demand for these products has been steadily increasing due to the expanding use of liquid nitrogen in various scientific fields including cell preservation, cryotherapy, and material testing.

Regional analysis reveals that North America dominates the laboratory safety equipment market with approximately 35% market share, followed by Europe (30%) and Asia-Pacific (25%). The Asia-Pacific region, particularly China and India, is expected to witness the fastest growth rate due to rapid industrialization, increasing R&D investments, and growing awareness about laboratory safety standards.

Key market drivers include stringent government regulations regarding laboratory safety, increasing incidents of laboratory accidents involving cryogenic materials, growing adoption of liquid nitrogen in healthcare and life sciences research, and rising investments in R&D activities across pharmaceutical and biotechnology sectors. The COVID-19 pandemic has further accelerated market growth as laboratories worldwide have heightened their safety protocols.

Market segmentation by end-user shows that academic and research institutions account for the largest share (40%), followed by pharmaceutical and biotechnology companies (30%), healthcare facilities (15%), and industrial laboratories (15%). The academic segment's dominance is attributed to the extensive use of liquid nitrogen in various research applications and the implementation of strict safety protocols in educational institutions.

Pricing trends indicate that premium safety equipment with advanced features such as automated monitoring systems and smart alerts command higher prices but are gaining popularity due to their enhanced safety benefits. The average cost of a comprehensive liquid nitrogen safety kit has increased by 12% over the past three years, reflecting both inflation and the integration of advanced technologies.

Customer behavior analysis shows increasing preference for integrated safety solutions rather than individual products, with 65% of laboratory managers preferring to purchase complete safety packages from a single vendor to ensure compatibility and consistent quality.

Current Safety Challenges in Liquid Nitrogen Handling

Liquid nitrogen handling in laboratory settings presents significant safety challenges due to its extreme cryogenic properties, with temperatures of -196°C (-321°F). The primary hazards include severe cold burns, asphyxiation in confined spaces, and potential pressure-related accidents. Despite established safety protocols, incidents continue to occur globally, highlighting persistent gaps in safety management.

Contact-related injuries remain the most common challenge, with laboratory personnel experiencing tissue damage ranging from mild frostbite to severe necrosis requiring medical intervention. These injuries often result from improper handling techniques, inadequate personal protective equipment (PPE), or momentary lapses in attention during transfer operations.

Asphyxiation risk presents a more insidious danger, as liquid nitrogen expands approximately 700 times when converting to gas, potentially displacing oxygen in poorly ventilated areas. Modern laboratories frequently lack adequate oxygen monitoring systems or have improperly calibrated alarms, creating dangerous blind spots in safety infrastructure. This risk is compounded in basement laboratories or facilities with suboptimal ventilation design.

Pressure-related accidents constitute another significant challenge, occurring when liquid nitrogen is stored in non-vented containers or when transfer lines become blocked. The resulting pressure buildup can lead to container ruptures or explosive decompression events. Incident reports indicate that improper storage vessel selection and inadequate maintenance of pressure relief systems contribute significantly to these occurrences.

Training deficiencies represent a persistent underlying challenge across laboratory environments. Analysis of incident reports reveals that many accidents involve personnel with insufficient training or those who have become complacent about safety procedures through routine use. The transient nature of academic laboratory populations, with regular turnover of students and researchers, exacerbates this challenge.

Emergency response preparedness shows concerning gaps in many institutional settings. Audits reveal inadequate first aid supplies specific to cryogenic injuries, unclear evacuation procedures for nitrogen release scenarios, and insufficient staff knowledge regarding appropriate immediate response actions. These deficiencies can transform minor incidents into major emergencies.

Regulatory compliance varies significantly across different regions and institutional types, creating inconsistent safety standards. While some facilities adhere to comprehensive guidelines from organizations like the Compressed Gas Association or OSHA, others operate with minimal oversight, particularly in developing regions or small-scale research operations.

Equipment aging and maintenance issues compound these challenges, with many laboratories utilizing outdated storage dewars, transfer hoses, or dispensing systems that lack modern safety features. Budget constraints often delay replacement of aging equipment, creating elevated risk environments where preventable failures become more likely.

Contact-related injuries remain the most common challenge, with laboratory personnel experiencing tissue damage ranging from mild frostbite to severe necrosis requiring medical intervention. These injuries often result from improper handling techniques, inadequate personal protective equipment (PPE), or momentary lapses in attention during transfer operations.

Asphyxiation risk presents a more insidious danger, as liquid nitrogen expands approximately 700 times when converting to gas, potentially displacing oxygen in poorly ventilated areas. Modern laboratories frequently lack adequate oxygen monitoring systems or have improperly calibrated alarms, creating dangerous blind spots in safety infrastructure. This risk is compounded in basement laboratories or facilities with suboptimal ventilation design.

Pressure-related accidents constitute another significant challenge, occurring when liquid nitrogen is stored in non-vented containers or when transfer lines become blocked. The resulting pressure buildup can lead to container ruptures or explosive decompression events. Incident reports indicate that improper storage vessel selection and inadequate maintenance of pressure relief systems contribute significantly to these occurrences.

Training deficiencies represent a persistent underlying challenge across laboratory environments. Analysis of incident reports reveals that many accidents involve personnel with insufficient training or those who have become complacent about safety procedures through routine use. The transient nature of academic laboratory populations, with regular turnover of students and researchers, exacerbates this challenge.

Emergency response preparedness shows concerning gaps in many institutional settings. Audits reveal inadequate first aid supplies specific to cryogenic injuries, unclear evacuation procedures for nitrogen release scenarios, and insufficient staff knowledge regarding appropriate immediate response actions. These deficiencies can transform minor incidents into major emergencies.

Regulatory compliance varies significantly across different regions and institutional types, creating inconsistent safety standards. While some facilities adhere to comprehensive guidelines from organizations like the Compressed Gas Association or OSHA, others operate with minimal oversight, particularly in developing regions or small-scale research operations.

Equipment aging and maintenance issues compound these challenges, with many laboratories utilizing outdated storage dewars, transfer hoses, or dispensing systems that lack modern safety features. Budget constraints often delay replacement of aging equipment, creating elevated risk environments where preventable failures become more likely.

Existing Liquid Nitrogen Safety Technologies

01 Storage and containment systems for liquid nitrogen

Specialized storage containers and systems designed to safely contain liquid nitrogen at cryogenic temperatures. These include insulated dewars, cryogenic tanks, and vessels with pressure relief mechanisms to prevent dangerous pressure build-up. The designs incorporate vacuum insulation technology and safety valves to maintain temperature stability and prevent accidents during storage and transportation.- Storage and containment systems for liquid nitrogen: Specialized storage containers and systems designed to safely contain liquid nitrogen at cryogenic temperatures. These include insulated dewars, cryogenic tanks, and vessels with pressure relief mechanisms to prevent dangerous pressure build-up. The designs incorporate vacuum insulation technology and safety valves to minimize evaporation and manage the risks associated with the extreme cold temperatures of liquid nitrogen.

- Personal protective equipment for handling liquid nitrogen: Safety equipment designed to protect individuals handling liquid nitrogen from cryogenic burns and asphyxiation hazards. This includes specialized gloves, face shields, aprons, and full-body protection suits that provide insulation against extreme cold. The protective gear is made from materials that remain flexible at ultra-low temperatures while providing thermal insulation to prevent tissue damage from contact with liquid nitrogen or its vapors.

- Ventilation and oxygen monitoring systems: Systems designed to prevent oxygen depletion hazards in areas where liquid nitrogen is used or stored. These include automated ventilation systems that activate when oxygen levels drop below safe thresholds, gas detection alarms that monitor nitrogen concentration in the air, and emergency response systems that trigger when unsafe conditions are detected. These systems help prevent asphyxiation risks associated with nitrogen gas displacing oxygen in confined spaces.

- Safe transfer and handling equipment: Specialized equipment for the safe transfer and handling of liquid nitrogen to minimize spill risks and exposure. This includes cryogenic pumps, phase separators, transfer hoses with thermal insulation, and automated dispensing systems that reduce direct contact with the cryogenic liquid. These devices incorporate safety features such as quick-disconnect couplings, overflow prevention mechanisms, and ergonomic designs to facilitate safe handling procedures.

- Emergency response and safety training systems: Systems and protocols designed for emergency response to liquid nitrogen accidents, including spills, leaks, or exposure incidents. These include emergency shutdown mechanisms, first aid stations specifically equipped for cryogenic injuries, evacuation route indicators, and training simulators that prepare personnel for handling liquid nitrogen safely. The systems also incorporate documentation and training materials on proper handling procedures and emergency protocols.

02 Personal protective equipment for handling liquid nitrogen

Safety equipment designed to protect individuals handling liquid nitrogen from cryogenic burns and asphyxiation hazards. This includes specialized gloves, face shields, aprons, and full-body protection suits that provide insulation against extreme cold. The protective gear is made from materials resistant to cryogenic temperatures and designed to prevent direct contact between liquid nitrogen and skin.Expand Specific Solutions03 Ventilation and monitoring systems

Systems designed to monitor oxygen levels and provide adequate ventilation in areas where liquid nitrogen is used or stored. These include oxygen depletion sensors, automatic ventilation systems, and alarms that activate when oxygen levels fall below safe thresholds. The monitoring equipment helps prevent asphyxiation hazards by ensuring sufficient oxygen concentration in confined spaces where liquid nitrogen is present.Expand Specific Solutions04 Safe handling and transfer mechanisms

Specialized equipment and procedures for the safe transfer of liquid nitrogen between containers. These include automated dispensing systems, pressure-controlled transfer lines, and spill prevention mechanisms. The transfer systems are designed to minimize direct contact with the cryogenic liquid and reduce the risk of splashing or spillage during pouring and dispensing operations.Expand Specific Solutions05 Emergency response and safety training protocols

Comprehensive safety protocols and emergency response procedures for handling liquid nitrogen accidents. These include first aid measures for cryogenic burns, evacuation procedures for nitrogen leaks, and training programs for personnel working with liquid nitrogen. The protocols outline proper emergency response steps and safety measures to minimize injuries and damage in case of accidents.Expand Specific Solutions

Leading Manufacturers in Cryogenic Safety Solutions

The liquid nitrogen safety enhancement market is in a growth phase, with increasing laboratory adoption driving demand for advanced safety solutions. The market size is expanding due to stricter safety regulations and growing awareness of cryogenic hazards. Technologically, the field shows varying maturity levels, with established players like Air Liquide SA and Messer SE & Co. KGaA offering comprehensive safety systems, while innovative solutions emerge from specialized companies such as Boreas Cryo Safety with their patented weight-based monitoring systems. Chinese manufacturers including Zhongke Meiling Cryogenics and Wuhan Huchuang are rapidly advancing with integrated safety features, while research institutions like Jilin University and the National Institute for Materials Science contribute to safety standards development through fundamental research.

Air Liquide SA

Technical Solution: Air Liquide has developed comprehensive safety systems for laboratory liquid nitrogen handling, including their SmartSafe™ technology that incorporates real-time monitoring of oxygen levels, temperature control, and automated emergency response protocols. Their solution integrates IoT sensors throughout laboratory spaces to detect nitrogen leaks before they reach dangerous levels. The company's safety framework includes specialized cryogenic storage vessels with advanced vacuum insulation and pressure relief systems that minimize the risk of rapid pressure buildup and potential explosions. Air Liquide also provides automated filling systems that eliminate direct human contact with liquid nitrogen during transfers, significantly reducing the risk of cryogenic burns and splash incidents. Their safety protocols include comprehensive training programs and certification for laboratory personnel.

Strengths: Global infrastructure allows for consistent safety standards implementation across multiple facilities; extensive experience in industrial gas handling translates to robust safety protocols. Weaknesses: Higher implementation costs compared to simpler solutions; requires significant technical infrastructure that may be challenging for smaller laboratories to maintain.

Shanghai Origincell Biological Cryo Equipment Co. Ltd.

Technical Solution: Shanghai Origincell has developed an integrated biological laboratory safety system specifically for liquid nitrogen applications in biobanking and cell preservation. Their BioSafe™ cryogenic storage systems incorporate multiple redundant safety features, including automated level monitoring, pressure relief systems, and oxygen depletion detection. The company's approach focuses on minimizing human interaction with liquid nitrogen through automated filling systems that operate during non-working hours to reduce exposure risks. Their cryogenic storage vessels feature specialized neck designs that minimize nitrogen evaporation while also reducing the risk of ice formation that can compromise pressure relief systems. Origincell has pioneered the development of "smart" cryogenic laboratories with centralized monitoring of all safety parameters, including oxygen levels, nitrogen consumption patterns, and equipment status, with automated alerts sent to laboratory managers when parameters deviate from safe ranges.

Strengths: Specialized expertise in biological applications of liquid nitrogen provides highly relevant solutions for biomedical laboratories; integrated approach to safety across storage, handling, and facility design. Weaknesses: Solutions primarily focused on biobanking applications may not address all laboratory use cases; regional focus may limit global support capabilities.

Key Innovations in Cryogenic Risk Mitigation

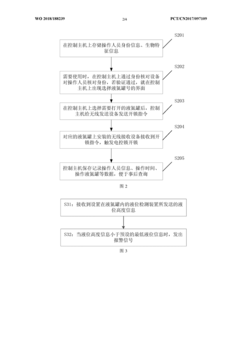

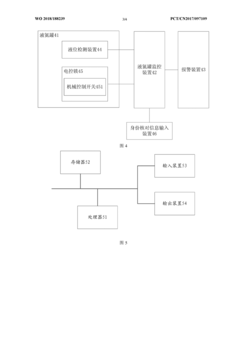

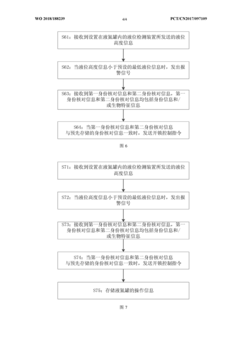

Liquid nitrogen tank control system, method, storage medium, and electronic device

PatentWO2018188239A1

Innovation

- A liquid nitrogen tank management system including a control host, identity verification equipment, wireless sending equipment, wireless receiving equipment and an electronically controlled lock is adopted. The electronically controlled lock is controlled to open the liquid nitrogen tank through identity verification and wireless signals, combined with a liquid level detection device and alarm. The device implements automatic monitoring and double verification.

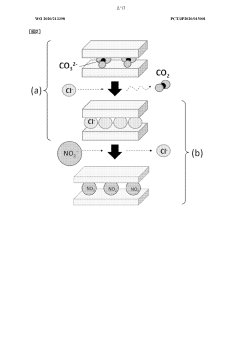

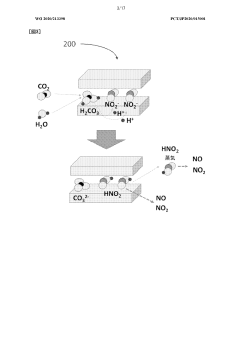

Nitrogen-based gas sustained release agent, nitrogen-based gas sustained release body comprising same, nitrogen-based gas sustained release method using sustained release body, breathing instrument, wrapping body, and sustained release device

PatentWO2020213398A1

Innovation

- A nitrogen-based gas sustained release agent using layered double hydroxide (LDH) with nitrite or nitrate ions, which slowly releases nitrogen oxides by reacting with carbon dioxide and water vapor, allowing for controlled concentration and time of release, and can be combined with reducing or oxidizing agents to produce various nitrogen gases.

Regulatory Compliance for Cryogenic Materials

Regulatory compliance for cryogenic materials, particularly liquid nitrogen, is a critical framework that laboratories must adhere to for ensuring safety and legal operation. In the United States, the Occupational Safety and Health Administration (OSHA) establishes comprehensive guidelines under 29 CFR 1910.101 specifically addressing compressed gases and related materials. These regulations mandate proper storage container specifications, handling protocols, and ventilation requirements for cryogenic substances.

The American Society of Mechanical Engineers (ASME) further contributes to the regulatory landscape through its Boiler and Pressure Vessel Code, which sets forth design and construction standards for cryogenic storage vessels. Compliance with these codes is essential for preventing catastrophic failures that could result in rapid nitrogen release and subsequent asphyxiation hazards.

European laboratories operate under the European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR) and the Pressure Equipment Directive (PED), which govern the transportation and containment of cryogenic materials. These frameworks establish harmonized safety standards across EU member states, facilitating consistent implementation of safety protocols.

The International Organization for Standardization (ISO) provides global standards through ISO 21009 for vacuum-insulated vessels and ISO 24490 for cryogenic containers, offering technical specifications that manufacturers and laboratories worldwide can reference for compliance. These standards address critical aspects such as materials compatibility, pressure relief mechanisms, and insulation requirements.

Laboratory-specific regulations often require documented risk assessments for cryogenic operations, including detailed emergency response procedures for nitrogen spills or oxygen-deficient atmospheres. Many jurisdictions mandate oxygen monitoring systems in areas where liquid nitrogen is used or stored, with automatic alarms triggered when oxygen levels fall below 19.5% by volume.

Training requirements constitute another significant regulatory component, with most frameworks requiring documented evidence of staff competency in cryogenic handling. This typically includes certification of training on personal protective equipment usage, emergency procedures, and first aid for cryogenic burns.

Regular inspection and maintenance schedules for cryogenic equipment are legally mandated in most regulatory frameworks, with requirements for documented verification of pressure relief valve functionality, vacuum integrity testing, and container recertification at specified intervals. Non-compliance with these maintenance protocols can result in significant penalties and liability exposure.

The American Society of Mechanical Engineers (ASME) further contributes to the regulatory landscape through its Boiler and Pressure Vessel Code, which sets forth design and construction standards for cryogenic storage vessels. Compliance with these codes is essential for preventing catastrophic failures that could result in rapid nitrogen release and subsequent asphyxiation hazards.

European laboratories operate under the European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR) and the Pressure Equipment Directive (PED), which govern the transportation and containment of cryogenic materials. These frameworks establish harmonized safety standards across EU member states, facilitating consistent implementation of safety protocols.

The International Organization for Standardization (ISO) provides global standards through ISO 21009 for vacuum-insulated vessels and ISO 24490 for cryogenic containers, offering technical specifications that manufacturers and laboratories worldwide can reference for compliance. These standards address critical aspects such as materials compatibility, pressure relief mechanisms, and insulation requirements.

Laboratory-specific regulations often require documented risk assessments for cryogenic operations, including detailed emergency response procedures for nitrogen spills or oxygen-deficient atmospheres. Many jurisdictions mandate oxygen monitoring systems in areas where liquid nitrogen is used or stored, with automatic alarms triggered when oxygen levels fall below 19.5% by volume.

Training requirements constitute another significant regulatory component, with most frameworks requiring documented evidence of staff competency in cryogenic handling. This typically includes certification of training on personal protective equipment usage, emergency procedures, and first aid for cryogenic burns.

Regular inspection and maintenance schedules for cryogenic equipment are legally mandated in most regulatory frameworks, with requirements for documented verification of pressure relief valve functionality, vacuum integrity testing, and container recertification at specified intervals. Non-compliance with these maintenance protocols can result in significant penalties and liability exposure.

Training Protocols for Laboratory Personnel

Comprehensive training protocols are essential for ensuring the safe handling of liquid nitrogen in laboratory environments. These protocols should begin with a mandatory orientation session for all new personnel, covering the fundamental properties of liquid nitrogen, associated hazards, and basic safety procedures. This initial training must emphasize the extreme cold temperature (-196°C) of liquid nitrogen and its potential to cause severe cryogenic burns and tissue damage upon contact with skin or eyes.

Training programs should incorporate both theoretical knowledge and practical demonstrations. The theoretical component should cover the physical properties of liquid nitrogen, including its expansion ratio (1:696 when converting from liquid to gas), which presents significant asphyxiation risks in confined spaces. Personnel must understand oxygen displacement hazards and recognize early symptoms of oxygen deficiency such as rapid breathing, diminished mental alertness, and impaired coordination.

Practical training sessions should demonstrate proper techniques for transferring liquid nitrogen between containers, using appropriate personal protective equipment (PPE), and responding to spills or splashes. These sessions must include supervised hands-on practice with actual equipment under controlled conditions. Video recordings of proper handling techniques can serve as valuable supplementary training materials for periodic review.

Emergency response procedures must form a critical component of the training protocol. Personnel should be thoroughly trained in first aid measures for cryogenic burns, including rapid but gentle warming of affected areas and immediate medical attention protocols. Additionally, training should cover evacuation procedures in case of large spills or oxygen depletion events, including the operation of oxygen monitoring systems where installed.

Certification and regular recertification requirements should be established, with documentation of all training activities maintained in personnel records. Annual refresher courses should be mandatory to reinforce safety practices and introduce any updated protocols or equipment. Specialized training modules should be developed for personnel with specific responsibilities, such as those handling large volumes or performing complex transfers.

Performance evaluation mechanisms should be implemented to assess the effectiveness of training programs. These may include practical assessments, written examinations, and observational evaluations during routine liquid nitrogen handling tasks. Training protocols should also incorporate lessons learned from incidents within the organization or reported in the broader scientific community, ensuring continuous improvement of safety practices.

Training programs should incorporate both theoretical knowledge and practical demonstrations. The theoretical component should cover the physical properties of liquid nitrogen, including its expansion ratio (1:696 when converting from liquid to gas), which presents significant asphyxiation risks in confined spaces. Personnel must understand oxygen displacement hazards and recognize early symptoms of oxygen deficiency such as rapid breathing, diminished mental alertness, and impaired coordination.

Practical training sessions should demonstrate proper techniques for transferring liquid nitrogen between containers, using appropriate personal protective equipment (PPE), and responding to spills or splashes. These sessions must include supervised hands-on practice with actual equipment under controlled conditions. Video recordings of proper handling techniques can serve as valuable supplementary training materials for periodic review.

Emergency response procedures must form a critical component of the training protocol. Personnel should be thoroughly trained in first aid measures for cryogenic burns, including rapid but gentle warming of affected areas and immediate medical attention protocols. Additionally, training should cover evacuation procedures in case of large spills or oxygen depletion events, including the operation of oxygen monitoring systems where installed.

Certification and regular recertification requirements should be established, with documentation of all training activities maintained in personnel records. Annual refresher courses should be mandatory to reinforce safety practices and introduce any updated protocols or equipment. Specialized training modules should be developed for personnel with specific responsibilities, such as those handling large volumes or performing complex transfers.

Performance evaluation mechanisms should be implemented to assess the effectiveness of training programs. These may include practical assessments, written examinations, and observational evaluations during routine liquid nitrogen handling tasks. Training protocols should also incorporate lessons learned from incidents within the organization or reported in the broader scientific community, ensuring continuous improvement of safety practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!