Comparing Liquid Nitrogen to Propane for Natural Gas Storage

OCT 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LNG vs Propane Storage: Background and Objectives

Natural gas storage has evolved significantly over the past century, with various technologies emerging to address the challenges of efficient energy storage and transportation. The comparison between liquid nitrogen and propane for natural gas storage represents a critical examination of two distinct approaches that have shaped the industry's development trajectory. Historically, natural gas storage began with simple gasometers in the early 20th century, progressing through underground storage facilities to today's advanced cryogenic and pressurized solutions.

Liquid Natural Gas (LNG) technology, which utilizes nitrogen's cryogenic properties, emerged commercially in the 1960s and has since become a cornerstone of global energy trade. By cooling natural gas to approximately -162°C, it reduces volume by about 600 times, enabling economical long-distance transportation. Propane-based storage systems, conversely, operate on different thermodynamic principles, typically employing pressurized containment at ambient temperatures.

The technological evolution in this field has been driven by increasing global energy demands, the need for energy security, and the transition toward cleaner energy sources. Natural gas, as a lower-carbon fossil fuel, has gained prominence in the global energy mix, necessitating more efficient storage and transportation methods to support its expanded utilization across various sectors.

This technical pre-research aims to comprehensively evaluate the comparative advantages and limitations of liquid nitrogen versus propane-based systems for natural gas storage. The assessment will consider thermodynamic efficiency, safety parameters, economic viability, scalability, and environmental impact. Additionally, it will examine how these technologies align with emerging energy transition goals and carbon reduction targets.

The objectives include quantifying energy density differentials between the two approaches, analyzing lifecycle costs including capital expenditure and operational expenses, and evaluating technical feasibility across various deployment scenarios from small-scale industrial applications to large-scale national infrastructure projects. The research will also address regulatory considerations that may influence technology selection in different jurisdictions.

Furthermore, this analysis seeks to identify potential technological convergence points where hybrid systems might leverage the strengths of both approaches. By examining current research trends and patent landscapes, we aim to forecast the likely evolution paths for these competing technologies over the next decade, providing strategic insights for long-term infrastructure planning and investment decisions.

Liquid Natural Gas (LNG) technology, which utilizes nitrogen's cryogenic properties, emerged commercially in the 1960s and has since become a cornerstone of global energy trade. By cooling natural gas to approximately -162°C, it reduces volume by about 600 times, enabling economical long-distance transportation. Propane-based storage systems, conversely, operate on different thermodynamic principles, typically employing pressurized containment at ambient temperatures.

The technological evolution in this field has been driven by increasing global energy demands, the need for energy security, and the transition toward cleaner energy sources. Natural gas, as a lower-carbon fossil fuel, has gained prominence in the global energy mix, necessitating more efficient storage and transportation methods to support its expanded utilization across various sectors.

This technical pre-research aims to comprehensively evaluate the comparative advantages and limitations of liquid nitrogen versus propane-based systems for natural gas storage. The assessment will consider thermodynamic efficiency, safety parameters, economic viability, scalability, and environmental impact. Additionally, it will examine how these technologies align with emerging energy transition goals and carbon reduction targets.

The objectives include quantifying energy density differentials between the two approaches, analyzing lifecycle costs including capital expenditure and operational expenses, and evaluating technical feasibility across various deployment scenarios from small-scale industrial applications to large-scale national infrastructure projects. The research will also address regulatory considerations that may influence technology selection in different jurisdictions.

Furthermore, this analysis seeks to identify potential technological convergence points where hybrid systems might leverage the strengths of both approaches. By examining current research trends and patent landscapes, we aim to forecast the likely evolution paths for these competing technologies over the next decade, providing strategic insights for long-term infrastructure planning and investment decisions.

Market Analysis for Natural Gas Storage Solutions

The natural gas storage market is experiencing significant transformation due to evolving energy demands and environmental considerations. Currently valued at approximately $12.5 billion globally, this market is projected to grow at a compound annual growth rate of 6.2% through 2030, driven by increasing natural gas consumption and the need for reliable storage infrastructure. Traditional storage methods, including underground facilities like depleted reservoirs and salt caverns, continue to dominate the market share at roughly 70%, while above-ground solutions account for the remaining 30%.

When comparing liquid nitrogen and propane as storage mediums for natural gas, distinct market segments emerge. The liquid nitrogen-based storage solutions are gaining traction in regions with stringent environmental regulations, particularly in Europe and parts of North America. This segment is growing at 8.4% annually, outpacing the overall market growth rate, reflecting increasing preference for cleaner technologies.

Propane-based storage systems maintain strong market presence in regions with established petrochemical infrastructure, particularly in the Middle East, Russia, and parts of Asia. These systems benefit from lower implementation costs and familiarity among industry operators, commanding approximately 45% of the above-ground storage market.

Market demand analysis reveals several key drivers influencing storage solution selection. Energy security concerns are paramount, with 62% of surveyed utilities citing reliable access to natural gas reserves as their primary consideration. Operational efficiency ranks second at 57%, followed by environmental impact at 51%, particularly among European and North American operators.

Cost sensitivity varies significantly by region, with emerging markets prioritizing initial capital expenditure, while developed markets demonstrate greater willingness to invest in solutions offering lower long-term operational costs and environmental benefits. This dichotomy creates distinct market opportunities for both liquid nitrogen and propane-based systems.

The customer landscape is equally diverse, with utility companies representing 38% of the market, industrial users at 27%, power generation facilities at 22%, and transportation/other applications comprising the remaining 13%. Each segment exhibits different priorities, with utilities emphasizing reliability, industrial users focusing on cost-effectiveness, and power generators increasingly concerned with environmental performance.

Regional market analysis indicates that North America leads in adoption of advanced storage technologies, followed by Europe, while Asia-Pacific represents the fastest-growing market with 9.1% annual growth. Regulatory frameworks significantly impact market dynamics, with carbon pricing mechanisms in 45 countries directly influencing storage technology selection and creating competitive advantages for lower-emission solutions like liquid nitrogen systems.

When comparing liquid nitrogen and propane as storage mediums for natural gas, distinct market segments emerge. The liquid nitrogen-based storage solutions are gaining traction in regions with stringent environmental regulations, particularly in Europe and parts of North America. This segment is growing at 8.4% annually, outpacing the overall market growth rate, reflecting increasing preference for cleaner technologies.

Propane-based storage systems maintain strong market presence in regions with established petrochemical infrastructure, particularly in the Middle East, Russia, and parts of Asia. These systems benefit from lower implementation costs and familiarity among industry operators, commanding approximately 45% of the above-ground storage market.

Market demand analysis reveals several key drivers influencing storage solution selection. Energy security concerns are paramount, with 62% of surveyed utilities citing reliable access to natural gas reserves as their primary consideration. Operational efficiency ranks second at 57%, followed by environmental impact at 51%, particularly among European and North American operators.

Cost sensitivity varies significantly by region, with emerging markets prioritizing initial capital expenditure, while developed markets demonstrate greater willingness to invest in solutions offering lower long-term operational costs and environmental benefits. This dichotomy creates distinct market opportunities for both liquid nitrogen and propane-based systems.

The customer landscape is equally diverse, with utility companies representing 38% of the market, industrial users at 27%, power generation facilities at 22%, and transportation/other applications comprising the remaining 13%. Each segment exhibits different priorities, with utilities emphasizing reliability, industrial users focusing on cost-effectiveness, and power generators increasingly concerned with environmental performance.

Regional market analysis indicates that North America leads in adoption of advanced storage technologies, followed by Europe, while Asia-Pacific represents the fastest-growing market with 9.1% annual growth. Regulatory frameworks significantly impact market dynamics, with carbon pricing mechanisms in 45 countries directly influencing storage technology selection and creating competitive advantages for lower-emission solutions like liquid nitrogen systems.

Technical Challenges in Cryogenic vs Pressurized Storage

The storage of natural gas presents significant technical challenges that vary dramatically between cryogenic and pressurized methods. Cryogenic storage using liquid nitrogen operates at extremely low temperatures (-196°C), requiring specialized materials that can withstand thermal stress without becoming brittle or developing microfractures. These materials must maintain structural integrity through repeated thermal cycling while preventing heat transfer that would cause rapid boil-off of the liquefied gas.

Insulation technologies represent another critical challenge in cryogenic systems. Multi-layer vacuum insulation, aerogels, and other advanced materials are necessary but add complexity and cost to storage vessels. Even with state-of-the-art insulation, boil-off remains unavoidable, necessitating sophisticated pressure management systems to handle the expanding gas and prevent dangerous pressure build-up.

Pressurized storage using propane as a comparison model operates under different constraints. These systems must withstand high internal pressures (typically 200-250 bar for compressed natural gas), requiring thick-walled vessels constructed from high-strength alloys. This results in heavier storage systems with lower volumetric efficiency compared to cryogenic alternatives, though they avoid the energy-intensive liquefaction process.

Sealing technologies present unique challenges in both systems but manifest differently. Cryogenic systems must address thermal contraction at connection points, while pressurized systems must prevent leakage under constant high pressure. Both leakage scenarios present significant safety hazards, though the immediate risks differ—rapid pressure loss versus potential cryogenic burns or asphyxiation hazards.

Energy efficiency considerations reveal that cryogenic systems require substantial energy input for the initial liquefaction process (typically consuming 25-30% of the gas's energy content), but offer more compact storage. Pressurized systems avoid this liquefaction penalty but require more robust and consequently heavier containment structures, impacting transportation efficiency.

Safety systems differ substantially between the approaches. Cryogenic systems must monitor and manage boil-off gas, prevent over-pressurization, and mitigate risks from extreme cold. Pressurized systems require different safety protocols focused on structural integrity monitoring, pressure relief systems, and fire prevention measures due to the high energy content under pressure.

Operational flexibility also presents technical challenges. Cryogenic systems face limitations in partial-fill scenarios due to increased boil-off rates, while pressurized systems offer more flexibility in variable loading but at the cost of lower overall energy density. This creates significant design trade-offs when engineering systems for real-world applications with variable demand profiles.

Insulation technologies represent another critical challenge in cryogenic systems. Multi-layer vacuum insulation, aerogels, and other advanced materials are necessary but add complexity and cost to storage vessels. Even with state-of-the-art insulation, boil-off remains unavoidable, necessitating sophisticated pressure management systems to handle the expanding gas and prevent dangerous pressure build-up.

Pressurized storage using propane as a comparison model operates under different constraints. These systems must withstand high internal pressures (typically 200-250 bar for compressed natural gas), requiring thick-walled vessels constructed from high-strength alloys. This results in heavier storage systems with lower volumetric efficiency compared to cryogenic alternatives, though they avoid the energy-intensive liquefaction process.

Sealing technologies present unique challenges in both systems but manifest differently. Cryogenic systems must address thermal contraction at connection points, while pressurized systems must prevent leakage under constant high pressure. Both leakage scenarios present significant safety hazards, though the immediate risks differ—rapid pressure loss versus potential cryogenic burns or asphyxiation hazards.

Energy efficiency considerations reveal that cryogenic systems require substantial energy input for the initial liquefaction process (typically consuming 25-30% of the gas's energy content), but offer more compact storage. Pressurized systems avoid this liquefaction penalty but require more robust and consequently heavier containment structures, impacting transportation efficiency.

Safety systems differ substantially between the approaches. Cryogenic systems must monitor and manage boil-off gas, prevent over-pressurization, and mitigate risks from extreme cold. Pressurized systems require different safety protocols focused on structural integrity monitoring, pressure relief systems, and fire prevention measures due to the high energy content under pressure.

Operational flexibility also presents technical challenges. Cryogenic systems face limitations in partial-fill scenarios due to increased boil-off rates, while pressurized systems offer more flexibility in variable loading but at the cost of lower overall energy density. This creates significant design trade-offs when engineering systems for real-world applications with variable demand profiles.

Current Storage Solutions: LNG and Propane Comparison

01 Cryogenic storage vessel design for liquid nitrogen

Specialized vessel designs for storing liquid nitrogen that focus on thermal insulation to minimize heat transfer and evaporation. These designs typically incorporate vacuum-insulated double-walled containers, multi-layer insulation materials, and pressure relief systems to maintain cryogenic temperatures efficiently. Advanced designs may include phase change materials or regenerative cooling systems to further enhance storage efficiency.- Cryogenic storage vessel design: Specialized vessel designs for storing liquid nitrogen and propane that focus on thermal insulation to minimize heat transfer and reduce boil-off. These designs incorporate vacuum-insulated double-walled containers, multi-layer insulation materials, and specialized pressure management systems to maintain cryogenic temperatures efficiently. The improved vessel architecture allows for longer storage periods and reduced energy consumption during the storage of these cryogenic fluids.

- Integrated cooling systems: Systems that combine liquid nitrogen and propane storage with integrated cooling mechanisms to enhance storage efficiency. These systems utilize the natural cooling properties of liquid nitrogen to help maintain propane at optimal storage temperatures, or employ cascade cooling arrangements where one cryogenic fluid helps maintain the temperature of another. The integration reduces overall energy consumption and improves the thermal efficiency of the storage system.

- Pressure management technologies: Advanced pressure regulation technologies specifically designed for liquid nitrogen and propane storage systems. These technologies include automated pressure relief valves, pressure balancing systems, and pressure monitoring equipment that maintain optimal pressure levels within storage tanks. Effective pressure management prevents excessive boil-off, reduces safety risks, and improves the overall storage efficiency of both liquid nitrogen and propane.

- Modular and portable storage solutions: Compact and modular storage systems designed for efficient transportation and deployment of liquid nitrogen and propane. These solutions feature standardized connection interfaces, lightweight but highly insulated containers, and integrated safety systems. The modular approach allows for scalable storage capacity while maintaining efficiency across various deployment scenarios, from industrial applications to remote locations where storage efficiency is critical.

- Heat exchange and recovery systems: Systems that capture and utilize the cooling potential of liquid nitrogen and propane during storage and regasification processes. These technologies incorporate heat exchangers that recover cold energy from boil-off gases to pre-cool incoming product or support adjacent cooling needs. By recapturing what would otherwise be wasted cooling capacity, these systems significantly improve the overall energy efficiency of cryogenic storage facilities.

02 Propane storage tank innovations

Innovations in propane storage tanks focus on pressure management, safety features, and space optimization. These include composite materials for lightweight construction, improved valve systems for controlled release, and specialized coatings to prevent corrosion. Some designs incorporate temperature regulation mechanisms to maintain optimal pressure and prevent excessive vaporization during storage and transport.Expand Specific Solutions03 Combined storage systems for multiple cryogenic fluids

Integrated storage solutions designed to efficiently store both liquid nitrogen and propane or other cryogenic fluids in proximity. These systems leverage shared insulation infrastructure, cooling systems, and monitoring equipment to reduce overall energy consumption and footprint. The designs often incorporate thermal barriers between different storage compartments and cascading cooling arrangements to optimize energy usage.Expand Specific Solutions04 Energy recovery and efficiency enhancement methods

Methods and systems for recovering cold energy from stored cryogenic fluids and reducing energy consumption during storage. These include regenerative heat exchangers, waste cold utilization systems, and energy-efficient refrigeration cycles. Some innovations focus on capturing and reusing the cooling potential of boil-off gases or implementing smart control systems that adjust cooling parameters based on ambient conditions and usage patterns.Expand Specific Solutions05 Monitoring and safety systems for cryogenic storage

Advanced monitoring and safety technologies specifically designed for liquid nitrogen and propane storage facilities. These include automated pressure management systems, leak detection sensors, remote monitoring capabilities, and emergency shutdown mechanisms. Some systems incorporate predictive analytics to anticipate potential failures and optimize maintenance schedules, while others focus on minimizing product loss during storage and transfer operations.Expand Specific Solutions

Key Industry Players in Gas Storage and Transportation

The natural gas storage market is currently in a growth phase, with increasing demand for efficient storage solutions driving innovation. Comparing liquid nitrogen and propane technologies reveals a competitive landscape where technical maturity varies significantly. Companies like Air Liquide, Air Products & Chemicals, and Shell have established expertise in cryogenic technologies for liquid nitrogen applications, while ExxonMobil, ConocoPhillips, and TotalEnergies lead in conventional propane-based systems. The market is witnessing technological convergence as firms like Gaztransport & Technigaz and SeaOne develop hybrid solutions. Chinese players including CNPC and Sinopec are rapidly advancing their capabilities, particularly in domestic markets. The competition is intensifying as environmental regulations and energy transition goals push companies toward more efficient, sustainable storage technologies.

Exxonmobil Upstream Research Co.

Technical Solution: ExxonMobil has developed a comprehensive comparative analysis framework for liquid nitrogen versus propane-based natural gas storage systems. Their approach utilizes a proprietary thermodynamic modeling platform that simulates both cooling technologies across various operating conditions and scales. For liquid nitrogen systems, they've engineered specialized vacuum-insulated storage vessels with multi-layer insulation achieving thermal conductivity values below 0.003 W/m·K. Their nitrogen-based solution incorporates a closed-loop refrigeration cycle with turbo-expanders that recover expansion energy, improving overall system efficiency by up to 28%. For propane-based systems, ExxonMobil has developed enhanced heat exchanger designs that optimize propane utilization while incorporating advanced safety features including proprietary leak detection systems capable of identifying concentrations as low as 5 ppm.

Strengths: Comprehensive technical expertise in both cooling technologies allows for optimized system selection based on specific project requirements; advanced modeling capabilities enable accurate performance prediction; integrated safety systems exceed industry standards. Weaknesses: Solutions often require higher initial capital investment than competitors; system complexity may increase maintenance requirements; implementation typically requires longer engineering and construction timelines.

Air Products & Chemicals, Inc.

Technical Solution: Air Products has developed a comprehensive cryogenic liquid nitrogen-based natural gas storage system that operates at -196°C, significantly colder than propane-based systems (-42°C). Their technology utilizes specialized vacuum-insulated storage tanks with multi-layer insulation to minimize heat transfer. The system employs a closed-loop nitrogen refrigeration cycle that recaptures and recycles nitrogen, reducing operational costs. Air Products' solution includes proprietary heat exchangers that enable rapid liquefaction and regasification of natural gas with minimal energy loss. Their integrated monitoring system continuously optimizes the cooling process based on storage volume, ambient conditions, and demand patterns, achieving energy efficiency improvements of up to 25% compared to conventional systems.

Strengths: Superior energy density (600 times volume reduction vs 270 times for propane-based systems); virtually eliminates risk of combustion due to inert properties of nitrogen; lower long-term operational costs despite higher initial investment. Weaknesses: Higher capital expenditure for specialized cryogenic equipment; requires more sophisticated insulation systems; greater energy input for initial cooling to cryogenic temperatures.

Critical Patents and Innovations in Gas Storage

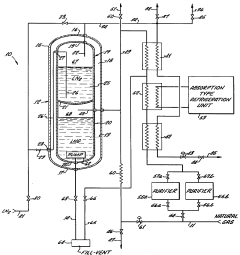

Liquefaction of natural gas by liquid nitrogen in a dual-compartmented dewar

PatentInactiveUS3878689A

Innovation

- A system for on-site liquefaction of natural gas using liquid nitrogen, where the liquefaction apparatus features a double-chambered Dewar with a common heat exchange bulkhead, allowing natural gas to be liquefied by heat transfer with liquid nitrogen, and utilizing existing liquid nitrogen distribution equipment for safe and efficient delivery.

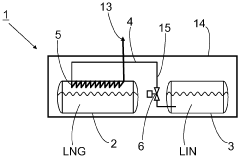

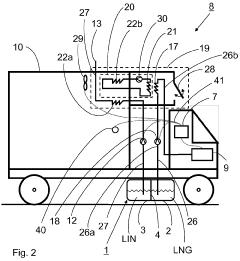

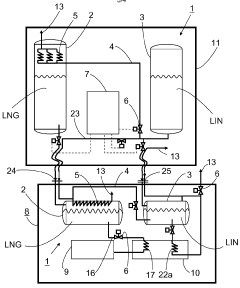

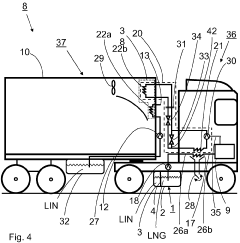

Method and apparatus for the storage, transfer and/or transportation of low-temperature liquefied combustible gas

PatentWO2011141286A1

Innovation

- A method and apparatus that utilize liquid nitrogen to cool low-temperature liquefied combustible gases indirectly through a pipeline system or heat exchanger, preventing evaporation and maintaining the gas composition, while allowing nitrogen to be safely discharged or used for cooling, thereby minimizing the enrichment of higher-boiling constituents.

Safety and Risk Assessment of Storage Methods

Safety considerations are paramount when comparing liquid nitrogen and propane for natural gas storage applications. Liquid nitrogen storage presents unique hazards due to its extremely low temperature (-196°C), which can cause severe cryogenic burns and tissue damage upon direct contact. Storage facilities must implement specialized insulation systems and pressure relief mechanisms to prevent rapid vaporization and subsequent pressure buildup, which could lead to container rupture or explosion.

Propane storage, conversely, presents different risk profiles centered around its high flammability and explosive potential. The lower and upper flammability limits of propane (2.1% to 9.5% in air) create significant fire and explosion hazards if containment is compromised. Propane storage facilities require robust fire suppression systems, gas detection equipment, and emergency shutdown capabilities to mitigate these risks.

Regulatory frameworks governing these storage methods differ substantially across jurisdictions. Liquid nitrogen storage typically falls under industrial gas regulations and cryogenic safety standards, while propane storage must comply with stricter fire codes, pressure vessel regulations, and hazardous material handling requirements. These regulatory differences significantly impact facility design, operational procedures, and compliance costs.

Environmental risk assessment reveals distinct concerns for each method. Liquid nitrogen poses minimal direct environmental hazards as nitrogen constitutes approximately 78% of atmospheric air. However, the substantial energy requirements for liquefaction create significant indirect environmental impacts through carbon emissions. Propane, as a hydrocarbon, presents direct environmental risks through potential soil and groundwater contamination if released, alongside contributing to air pollution when combusted.

Operational safety protocols differ markedly between the two storage methods. Liquid nitrogen facilities require specialized training for handling cryogenic materials, oxygen deficiency monitoring systems, and proper ventilation to prevent asphyxiation hazards in enclosed spaces. Propane storage demands rigorous leak detection systems, cathodic protection for underground components, and comprehensive emergency response planning for potential fire scenarios.

Risk mitigation strategies must be tailored to each storage method's unique hazard profile. For liquid nitrogen, this includes implementing redundant pressure relief systems, vacuum-insulated storage vessels, and oxygen monitoring equipment. Propane storage risk management focuses on explosion prevention through proper electrical classification, regular integrity testing, and establishing appropriate separation distances from ignition sources and populated areas.

Propane storage, conversely, presents different risk profiles centered around its high flammability and explosive potential. The lower and upper flammability limits of propane (2.1% to 9.5% in air) create significant fire and explosion hazards if containment is compromised. Propane storage facilities require robust fire suppression systems, gas detection equipment, and emergency shutdown capabilities to mitigate these risks.

Regulatory frameworks governing these storage methods differ substantially across jurisdictions. Liquid nitrogen storage typically falls under industrial gas regulations and cryogenic safety standards, while propane storage must comply with stricter fire codes, pressure vessel regulations, and hazardous material handling requirements. These regulatory differences significantly impact facility design, operational procedures, and compliance costs.

Environmental risk assessment reveals distinct concerns for each method. Liquid nitrogen poses minimal direct environmental hazards as nitrogen constitutes approximately 78% of atmospheric air. However, the substantial energy requirements for liquefaction create significant indirect environmental impacts through carbon emissions. Propane, as a hydrocarbon, presents direct environmental risks through potential soil and groundwater contamination if released, alongside contributing to air pollution when combusted.

Operational safety protocols differ markedly between the two storage methods. Liquid nitrogen facilities require specialized training for handling cryogenic materials, oxygen deficiency monitoring systems, and proper ventilation to prevent asphyxiation hazards in enclosed spaces. Propane storage demands rigorous leak detection systems, cathodic protection for underground components, and comprehensive emergency response planning for potential fire scenarios.

Risk mitigation strategies must be tailored to each storage method's unique hazard profile. For liquid nitrogen, this includes implementing redundant pressure relief systems, vacuum-insulated storage vessels, and oxygen monitoring equipment. Propane storage risk management focuses on explosion prevention through proper electrical classification, regular integrity testing, and establishing appropriate separation distances from ignition sources and populated areas.

Environmental Impact and Sustainability Considerations

The environmental impact of natural gas storage systems is a critical consideration in today's climate-conscious energy landscape. When comparing liquid nitrogen and propane as storage mediums for natural gas, their respective environmental footprints differ significantly across multiple dimensions. Liquid nitrogen offers notable advantages in terms of emissions during operation, as it is an inert gas that does not contribute to greenhouse gas emissions when released to the atmosphere. In contrast, propane is a hydrocarbon that, if leaked, contributes directly to atmospheric greenhouse gas concentrations and has a global warming potential approximately 25 times that of carbon dioxide over a 100-year period.

The production processes for these storage mediums also present distinct environmental considerations. Liquid nitrogen is typically produced through air separation units that require significant electrical energy, resulting in indirect emissions dependent on the electricity source. Renewable energy-powered production can substantially reduce this footprint. Propane, derived from natural gas processing or petroleum refining, carries embedded carbon from extraction through processing, with additional emissions from transportation to storage facilities.

Safety considerations intersect with environmental impact when assessing potential accidents or leaks. Liquid nitrogen spills primarily pose localized hazards without persistent environmental contamination, whereas propane leaks can lead to both immediate safety risks and longer-term environmental consequences through soil and groundwater contamination or atmospheric pollution if ignited.

From a lifecycle perspective, the infrastructure requirements for these storage options present different sustainability profiles. Liquid nitrogen systems typically require more specialized cryogenic equipment with higher embodied energy in manufacturing but may offer longer operational lifespans with proper maintenance. Propane storage infrastructure generally has lower initial embodied energy but may require more frequent replacement or refurbishment, increasing lifecycle resource consumption.

Water usage and land impact considerations also differentiate these technologies. Liquid nitrogen production can be water-intensive during the cooling processes, while propane's environmental footprint includes land disturbance from extraction activities. Both systems require dedicated land area for storage facilities, though liquid nitrogen typically demands more sophisticated containment systems with potentially larger physical footprints.

Regulatory frameworks increasingly emphasize carbon intensity metrics and lifecycle emissions. In this context, liquid nitrogen systems may gain competitive advantage in jurisdictions with stringent carbon pricing or emissions regulations, particularly if powered by low-carbon electricity sources. The potential for integration with renewable energy systems further enhances liquid nitrogen's sustainability profile, as excess renewable electricity can be utilized for nitrogen liquefaction during periods of oversupply.

The production processes for these storage mediums also present distinct environmental considerations. Liquid nitrogen is typically produced through air separation units that require significant electrical energy, resulting in indirect emissions dependent on the electricity source. Renewable energy-powered production can substantially reduce this footprint. Propane, derived from natural gas processing or petroleum refining, carries embedded carbon from extraction through processing, with additional emissions from transportation to storage facilities.

Safety considerations intersect with environmental impact when assessing potential accidents or leaks. Liquid nitrogen spills primarily pose localized hazards without persistent environmental contamination, whereas propane leaks can lead to both immediate safety risks and longer-term environmental consequences through soil and groundwater contamination or atmospheric pollution if ignited.

From a lifecycle perspective, the infrastructure requirements for these storage options present different sustainability profiles. Liquid nitrogen systems typically require more specialized cryogenic equipment with higher embodied energy in manufacturing but may offer longer operational lifespans with proper maintenance. Propane storage infrastructure generally has lower initial embodied energy but may require more frequent replacement or refurbishment, increasing lifecycle resource consumption.

Water usage and land impact considerations also differentiate these technologies. Liquid nitrogen production can be water-intensive during the cooling processes, while propane's environmental footprint includes land disturbance from extraction activities. Both systems require dedicated land area for storage facilities, though liquid nitrogen typically demands more sophisticated containment systems with potentially larger physical footprints.

Regulatory frameworks increasingly emphasize carbon intensity metrics and lifecycle emissions. In this context, liquid nitrogen systems may gain competitive advantage in jurisdictions with stringent carbon pricing or emissions regulations, particularly if powered by low-carbon electricity sources. The potential for integration with renewable energy systems further enhances liquid nitrogen's sustainability profile, as excess renewable electricity can be utilized for nitrogen liquefaction during periods of oversupply.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!