How to Achieve Optimal Reliability in Liquid Nitrogen Pipelines

OCT 7, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Pipeline Technology Evolution and Objectives

Cryogenic pipeline technology has evolved significantly over the past seven decades since the industrial production of liquid nitrogen began in the 1950s. Initially, these systems were rudimentary, with limited insulation capabilities and frequent reliability issues. The 1960s and 1970s witnessed substantial improvements in vacuum-jacketed pipe designs, which dramatically reduced heat transfer and improved operational efficiency. By the 1980s, multi-layer insulation techniques emerged, representing a significant leap forward in maintaining cryogenic temperatures over extended distances.

The evolution of materials science has been pivotal in this technological progression. Early systems primarily utilized carbon steel with limited low-temperature performance, whereas contemporary pipelines incorporate specialized stainless steels, aluminum alloys, and advanced composites specifically engineered to withstand extreme temperature fluctuations. These materials exhibit superior resistance to thermal contraction and expansion stresses, significantly enhancing system longevity and safety.

Monitoring and control systems have similarly transformed from basic manual gauges to sophisticated digital platforms. Modern cryogenic pipelines feature integrated sensor networks that provide real-time data on temperature, pressure, flow rates, and structural integrity. This technological advancement enables predictive maintenance protocols and early detection of potential failure points, substantially improving overall system reliability.

The primary objective of current cryogenic pipeline technology development is to achieve optimal reliability while maintaining economic viability. This involves minimizing boil-off rates, which directly impacts operational efficiency and cost-effectiveness. Industry standards aim for boil-off rates below 0.1% per day for stationary systems, representing a challenging benchmark that drives continuous innovation in insulation techniques and materials.

Safety enhancement remains another critical objective, with particular emphasis on preventing catastrophic failures through advanced leak detection systems and redundant safety mechanisms. The industry is moving toward a zero-incident standard, recognizing that even minor failures in liquid nitrogen pipelines can have severe consequences due to the extreme temperatures involved (-196°C).

Energy efficiency has emerged as an increasingly important goal, with modern designs focusing on minimizing the power requirements for maintaining cryogenic conditions. This includes innovations in passive cooling systems and thermal bridging reduction techniques. The ultimate technological objective is to develop "smart" cryogenic pipeline systems that can self-diagnose, self-regulate, and potentially self-repair, thereby maximizing reliability while minimizing human intervention and associated risks.

The evolution of materials science has been pivotal in this technological progression. Early systems primarily utilized carbon steel with limited low-temperature performance, whereas contemporary pipelines incorporate specialized stainless steels, aluminum alloys, and advanced composites specifically engineered to withstand extreme temperature fluctuations. These materials exhibit superior resistance to thermal contraction and expansion stresses, significantly enhancing system longevity and safety.

Monitoring and control systems have similarly transformed from basic manual gauges to sophisticated digital platforms. Modern cryogenic pipelines feature integrated sensor networks that provide real-time data on temperature, pressure, flow rates, and structural integrity. This technological advancement enables predictive maintenance protocols and early detection of potential failure points, substantially improving overall system reliability.

The primary objective of current cryogenic pipeline technology development is to achieve optimal reliability while maintaining economic viability. This involves minimizing boil-off rates, which directly impacts operational efficiency and cost-effectiveness. Industry standards aim for boil-off rates below 0.1% per day for stationary systems, representing a challenging benchmark that drives continuous innovation in insulation techniques and materials.

Safety enhancement remains another critical objective, with particular emphasis on preventing catastrophic failures through advanced leak detection systems and redundant safety mechanisms. The industry is moving toward a zero-incident standard, recognizing that even minor failures in liquid nitrogen pipelines can have severe consequences due to the extreme temperatures involved (-196°C).

Energy efficiency has emerged as an increasingly important goal, with modern designs focusing on minimizing the power requirements for maintaining cryogenic conditions. This includes innovations in passive cooling systems and thermal bridging reduction techniques. The ultimate technological objective is to develop "smart" cryogenic pipeline systems that can self-diagnose, self-regulate, and potentially self-repair, thereby maximizing reliability while minimizing human intervention and associated risks.

Market Analysis for Reliable Liquid Nitrogen Transport Systems

The global liquid nitrogen transport systems market is experiencing robust growth, driven by expanding applications across multiple industries. The market size was valued at approximately $1.5 billion in 2022 and is projected to reach $2.3 billion by 2028, representing a compound annual growth rate of 7.4%. This growth trajectory is primarily fueled by increasing demand from healthcare, food processing, metal manufacturing, and electronics sectors.

Healthcare remains the dominant end-user segment, accounting for nearly 35% of market share. The critical need for reliable cryogenic storage of biological samples, vaccines, and other temperature-sensitive medical products continues to drive demand for advanced liquid nitrogen transport solutions. The COVID-19 pandemic further highlighted the importance of dependable cryogenic supply chains for vaccine distribution.

The food and beverage industry represents the fastest-growing segment, with an estimated growth rate of 9.2% annually. Flash-freezing applications using liquid nitrogen have gained significant traction due to superior preservation of food quality and nutritional value compared to conventional freezing methods. This trend is particularly pronounced in developed markets where consumers increasingly demand premium frozen products.

Regional analysis reveals North America as the largest market, holding approximately 38% of global market share, followed by Europe at 29% and Asia-Pacific at 24%. However, the Asia-Pacific region is expected to witness the highest growth rate over the forecast period, driven by rapid industrialization in China and India, expanding healthcare infrastructure, and increasing adoption of cryogenic technologies.

Market dynamics are significantly influenced by stringent safety regulations governing cryogenic transport systems. Recent regulatory updates in major markets have emphasized enhanced safety features, monitoring capabilities, and reliability standards for liquid nitrogen pipelines and transport vessels. These regulatory pressures are compelling manufacturers to invest in advanced materials and innovative design solutions.

Customer demand patterns indicate a growing preference for integrated systems that offer comprehensive monitoring, automated pressure management, and predictive maintenance capabilities. End-users are increasingly willing to pay premium prices for systems that minimize downtime and ensure operational reliability, with survey data showing that 78% of industrial customers rank reliability as their top purchasing criterion, ahead of initial acquisition cost.

The competitive landscape features both established industrial gas companies and specialized equipment manufacturers. Market consolidation has been evident, with several strategic acquisitions aimed at expanding technological capabilities and geographic reach. Emerging market entrants are focusing on niche applications and innovative materials to establish competitive positions against industry incumbents.

Healthcare remains the dominant end-user segment, accounting for nearly 35% of market share. The critical need for reliable cryogenic storage of biological samples, vaccines, and other temperature-sensitive medical products continues to drive demand for advanced liquid nitrogen transport solutions. The COVID-19 pandemic further highlighted the importance of dependable cryogenic supply chains for vaccine distribution.

The food and beverage industry represents the fastest-growing segment, with an estimated growth rate of 9.2% annually. Flash-freezing applications using liquid nitrogen have gained significant traction due to superior preservation of food quality and nutritional value compared to conventional freezing methods. This trend is particularly pronounced in developed markets where consumers increasingly demand premium frozen products.

Regional analysis reveals North America as the largest market, holding approximately 38% of global market share, followed by Europe at 29% and Asia-Pacific at 24%. However, the Asia-Pacific region is expected to witness the highest growth rate over the forecast period, driven by rapid industrialization in China and India, expanding healthcare infrastructure, and increasing adoption of cryogenic technologies.

Market dynamics are significantly influenced by stringent safety regulations governing cryogenic transport systems. Recent regulatory updates in major markets have emphasized enhanced safety features, monitoring capabilities, and reliability standards for liquid nitrogen pipelines and transport vessels. These regulatory pressures are compelling manufacturers to invest in advanced materials and innovative design solutions.

Customer demand patterns indicate a growing preference for integrated systems that offer comprehensive monitoring, automated pressure management, and predictive maintenance capabilities. End-users are increasingly willing to pay premium prices for systems that minimize downtime and ensure operational reliability, with survey data showing that 78% of industrial customers rank reliability as their top purchasing criterion, ahead of initial acquisition cost.

The competitive landscape features both established industrial gas companies and specialized equipment manufacturers. Market consolidation has been evident, with several strategic acquisitions aimed at expanding technological capabilities and geographic reach. Emerging market entrants are focusing on niche applications and innovative materials to establish competitive positions against industry incumbents.

Current Challenges in Cryogenic Pipeline Engineering

Cryogenic pipeline systems, particularly those handling liquid nitrogen at -196°C, face significant engineering challenges that impact their reliability and operational efficiency. The extreme temperature differential between the cryogenic fluid and ambient conditions creates unique material stress patterns that conventional pipeline engineering approaches cannot adequately address. Materials undergo severe thermal contraction, with dimensional changes up to 0.3% for stainless steel and higher rates for other metals, leading to potential structural integrity issues.

Thermal insulation represents another critical challenge, as even minor insulation failures can result in rapid heat ingress, causing nitrogen boil-off and system pressure fluctuations. Current vacuum-jacketed and multi-layer insulation systems still struggle with long-term performance degradation, particularly at joints and connection points where thermal bridging commonly occurs. Industry data indicates that approximately 15-20% of cryogenic pipeline failures originate at these thermal transition zones.

Mechanical stress management presents ongoing difficulties, especially in systems with multiple thermal cycles. The repeated contraction and expansion create fatigue loading that conventional stress analysis models often fail to accurately predict. Recent studies have documented that traditional expansion loops and bellows designs may be insufficient for systems exceeding certain operational parameters, particularly in installations with complex geometries or space constraints.

Instrumentation and monitoring systems face reliability issues in cryogenic environments, with sensor drift and calibration stability being persistent problems. Conventional temperature and pressure sensors experience significant accuracy degradation below -150°C, with error margins increasing by factors of 2-3 times compared to their rated specifications at standard temperatures. This compromises the ability to detect early warning signs of system degradation or impending failures.

Maintenance accessibility remains problematic, as the complex insulation systems necessary for thermal efficiency create barriers to inspection and repair. Non-destructive testing methods like ultrasonic and radiographic inspection show reduced effectiveness through multiple insulation layers, leaving potential defects undetected until failure occurs. The industry currently lacks standardized approaches for in-service inspection of fully insulated cryogenic pipelines.

Regulatory frameworks and design standards specific to cryogenic pipeline systems remain fragmented across different regions and industries. While ASME B31.3 provides general process piping guidelines, specialized cryogenic considerations often rely on company-specific standards or adaptations from adjacent industries like LNG transportation. This regulatory inconsistency creates challenges for global projects and technology transfer between different industrial applications of cryogenic pipeline systems.

Thermal insulation represents another critical challenge, as even minor insulation failures can result in rapid heat ingress, causing nitrogen boil-off and system pressure fluctuations. Current vacuum-jacketed and multi-layer insulation systems still struggle with long-term performance degradation, particularly at joints and connection points where thermal bridging commonly occurs. Industry data indicates that approximately 15-20% of cryogenic pipeline failures originate at these thermal transition zones.

Mechanical stress management presents ongoing difficulties, especially in systems with multiple thermal cycles. The repeated contraction and expansion create fatigue loading that conventional stress analysis models often fail to accurately predict. Recent studies have documented that traditional expansion loops and bellows designs may be insufficient for systems exceeding certain operational parameters, particularly in installations with complex geometries or space constraints.

Instrumentation and monitoring systems face reliability issues in cryogenic environments, with sensor drift and calibration stability being persistent problems. Conventional temperature and pressure sensors experience significant accuracy degradation below -150°C, with error margins increasing by factors of 2-3 times compared to their rated specifications at standard temperatures. This compromises the ability to detect early warning signs of system degradation or impending failures.

Maintenance accessibility remains problematic, as the complex insulation systems necessary for thermal efficiency create barriers to inspection and repair. Non-destructive testing methods like ultrasonic and radiographic inspection show reduced effectiveness through multiple insulation layers, leaving potential defects undetected until failure occurs. The industry currently lacks standardized approaches for in-service inspection of fully insulated cryogenic pipelines.

Regulatory frameworks and design standards specific to cryogenic pipeline systems remain fragmented across different regions and industries. While ASME B31.3 provides general process piping guidelines, specialized cryogenic considerations often rely on company-specific standards or adaptations from adjacent industries like LNG transportation. This regulatory inconsistency creates challenges for global projects and technology transfer between different industrial applications of cryogenic pipeline systems.

State-of-the-Art Solutions for Liquid Nitrogen Pipeline Reliability

01 Insulation systems for liquid nitrogen pipelines

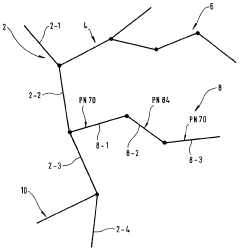

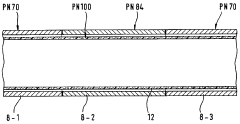

Effective insulation is critical for maintaining the extremely low temperatures required for liquid nitrogen transport. Advanced insulation systems help prevent heat ingress, reduce nitrogen boil-off, and enhance overall pipeline reliability. These systems typically employ vacuum-jacketed designs, multi-layer insulation materials, or composite insulation structures that minimize thermal conductivity and maintain cryogenic temperatures throughout the pipeline network.- Insulation systems for liquid nitrogen pipelines: Effective insulation is critical for maintaining the cryogenic temperature of liquid nitrogen in pipelines and preventing heat transfer. Various insulation materials and multi-layer insulation systems are employed to enhance thermal efficiency and reliability. These systems typically include vacuum insulation layers, foam insulation, or composite materials that minimize heat ingress, reduce nitrogen boil-off, and maintain pipeline integrity under extreme temperature conditions.

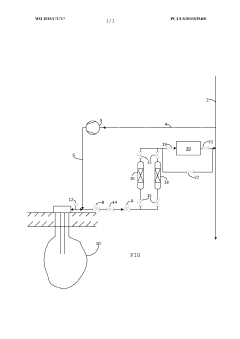

- Monitoring and leak detection systems: Advanced monitoring systems are essential for ensuring the reliability of liquid nitrogen pipelines. These systems incorporate sensors to detect temperature fluctuations, pressure changes, and potential leaks. Real-time monitoring allows for immediate response to abnormalities, preventing catastrophic failures and ensuring continuous operation. Leak detection technologies may include infrared sensors, pressure differential monitoring, or specialized gas detectors that can identify nitrogen vapor in surrounding areas.

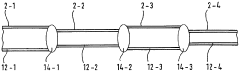

- Pipeline connection and joint technologies: Specialized connection and joint technologies are developed to maintain the integrity of liquid nitrogen pipelines under extreme temperature conditions. These include welded joints, flanged connections with cryogenic gaskets, and expansion joints that accommodate thermal contraction and expansion. The reliability of these connections is crucial to prevent leakage and maintain system integrity, with materials selected specifically for their performance at cryogenic temperatures.

- Material selection for cryogenic applications: The selection of appropriate materials is fundamental to the reliability of liquid nitrogen pipelines. Materials must maintain their mechanical properties at extremely low temperatures without becoming brittle or developing cracks. Commonly used materials include austenitic stainless steels, certain aluminum alloys, and specialized cryogenic steels. These materials are chosen for their low-temperature ductility, thermal contraction characteristics, and resistance to thermal cycling fatigue.

- Safety and emergency systems: Comprehensive safety and emergency systems are integrated into liquid nitrogen pipeline designs to mitigate risks and ensure reliability. These include pressure relief valves, emergency shutdown systems, and venting mechanisms to prevent over-pressurization. Redundant safety features are often incorporated to provide multiple layers of protection. Additionally, specialized training protocols and maintenance procedures are established to ensure proper handling of the system during normal operation and emergency situations.

02 Monitoring and leak detection technologies

Reliable liquid nitrogen pipelines incorporate sophisticated monitoring and leak detection systems to ensure safe operation. These technologies include temperature sensors, pressure monitors, flow meters, and specialized leak detection devices that can identify potential failures before they become critical. Real-time monitoring systems allow for immediate response to anomalies, helping to prevent catastrophic failures and ensuring the continuous reliability of the pipeline infrastructure.Expand Specific Solutions03 Pipeline connection and joint designs

The reliability of liquid nitrogen pipelines heavily depends on the design and implementation of connections and joints. Advanced connection technologies include specialized flanges, welded joints, and bayonet couplings designed specifically for cryogenic applications. These connection systems must maintain structural integrity under extreme temperature variations while preventing leaks. Proper joint design accounts for thermal contraction and expansion, ensuring long-term reliability even under fluctuating operational conditions.Expand Specific Solutions04 Materials selection for cryogenic applications

The selection of appropriate materials is fundamental to liquid nitrogen pipeline reliability. Materials must maintain their mechanical properties at cryogenic temperatures without becoming brittle or developing cracks. Commonly used materials include austenitic stainless steels, aluminum alloys, and specialized cryogenic steels that exhibit excellent low-temperature ductility. The proper selection of materials ensures pipeline integrity, prevents premature failure, and extends the operational lifespan of the entire system.Expand Specific Solutions05 Safety and emergency systems

Reliable liquid nitrogen pipeline systems incorporate comprehensive safety and emergency response mechanisms. These include pressure relief devices, emergency shutdown systems, and redundant safety features designed to mitigate risks associated with cryogenic fluid handling. Proper venting systems prevent pressure buildup, while isolation valves enable quick sectioning of the pipeline during emergencies. These safety systems are essential for preventing accidents, protecting personnel, and ensuring the overall reliability of liquid nitrogen transport infrastructure.Expand Specific Solutions

Leading Companies in Cryogenic Pipeline Manufacturing

The liquid nitrogen pipeline reliability market is currently in a growth phase, characterized by increasing demand for cryogenic infrastructure across industrial and healthcare sectors. The market size is expanding steadily, driven by growing applications in manufacturing, healthcare, and energy sectors. From a technological maturity perspective, the field shows varied development levels with established players like Air Liquide SA and Messer SE & Co. KGaA offering advanced solutions, while companies such as ROSEN Swiss AG and Pipesense LLC focus on specialized inspection and monitoring technologies. China Petroleum Pipeline Bureau and Saudi Aramco bring extensive pipeline management expertise from the oil and gas sector that's being adapted for cryogenic applications. Academic institutions including China University of Mining & Technology and Northwestern Polytechnical University are contributing research to address reliability challenges in extreme temperature environments.

Air Liquide SA

Technical Solution: Air Liquide has developed a comprehensive approach to liquid nitrogen pipeline reliability through their Advanced Cryogenic Pipeline System (ACPS). This system incorporates multi-layer vacuum-insulated transfer lines with specialized materials designed to withstand extreme temperature fluctuations (-196°C to ambient). Their technology includes proprietary joint designs that minimize thermal contraction stress points and utilize flexible bellows connections to accommodate thermal expansion/contraction cycles. Air Liquide's monitoring system employs distributed temperature sensing (DTS) fiber optics along pipeline routes to detect temperature anomalies in real-time, with automated emergency shutdown capabilities triggered by predefined temperature thresholds. Their vacuum maintenance technology includes getter materials that absorb residual gases in the insulation space, extending vacuum life by up to 15 years without maintenance intervention.

Strengths: Industry-leading vacuum insulation technology reduces heat ingress by up to 90% compared to conventional systems; proprietary joint designs significantly reduce failure points; comprehensive real-time monitoring enables predictive maintenance. Weaknesses: Higher initial installation costs compared to conventional systems; requires specialized maintenance expertise; system complexity increases potential points of failure in control systems.

China Petroleum Pipeline Bureau Engineering Corp.

Technical Solution: China Petroleum Pipeline Bureau Engineering has developed the Cryogenic Pipeline Reliability Enhancement Technology (CPRET) specifically for liquid nitrogen applications in challenging environments. Their system utilizes a triple-layer insulation approach with an inner layer of microporous silica, middle layer of multilayer insulation (MLI) consisting of alternating aluminized mylar and spacer materials, and an outer layer of polyurethane foam with vapor barrier. The pipeline joints incorporate bellows-type expansion compensators with specialized welding techniques that maintain material properties at cryogenic temperatures. Their monitoring system employs a network of ultrasonic sensors placed at strategic intervals to detect changes in pipe wall thickness and potential stress points. The company has pioneered the use of phase-change materials (PCMs) in critical sections to absorb thermal energy during transient operations, reducing thermal shock to the pipeline system.

Strengths: Exceptional thermal performance in varied environmental conditions; robust joint design significantly reduces failure rates at connection points; integrated monitoring provides comprehensive operational data. Weaknesses: System complexity increases installation time and costs; specialized components require longer lead times for replacement; higher maintenance requirements for sensor networks in remote installations.

Critical Patents in Cryogenic Insulation and Joint Design

Method for laying pipes for fluid under high pressure

PatentWO1999046533A1

Innovation

- The method involves using a fabric hose relining technique to increase the nominal pressure level of intact high-pressure fluid lines without excavating the old fluid line, employing a high-strength fabric hose with a coating suitable for the specific gases and pressures, ensuring the new pressure rating is supported by the fabric's strength rather than the external line, and using the existing method's devices and techniques.

Method and apparatus for improving the integrity of a pipline

PatentWO2015171717A1

Innovation

- A method and apparatus that involves removing pressurized gas from underground storage caverns, reducing pressure, removing water and solid particles using desiccant driers and mechanical or magnetic filtration systems, respectively, to produce a clean gas that is introduced into the pipeline without additional pressurization or mechanical devices, ensuring the gas purity remains unchanged except for moisture and particle removal.

Safety Standards and Compliance Requirements

Compliance with safety standards is paramount in liquid nitrogen pipeline operations due to the cryogenic nature of the substance and its potential hazards. The industry is governed by a comprehensive framework of international, national, and regional regulations that establish minimum safety requirements. Key international standards include ISO 21009 for cryogenic vessels and ISO 21013 for pressure-relief accessories, which provide guidelines for design, construction, and testing of cryogenic equipment. In the United States, ASME B31.3 Process Piping Code specifically addresses cryogenic applications, while the Compressed Gas Association (CGA) publishes detailed standards such as P-12 for safe handling of cryogenic liquids.

European operators must adhere to the Pressure Equipment Directive (PED) 2014/68/EU and the ATEX Directive 2014/34/EU for equipment used in potentially explosive atmospheres. These regulations mandate regular inspection protocols, including non-destructive testing methods such as radiographic testing, ultrasonic testing, and magnetic particle inspection to detect potential defects before they lead to failures.

Risk assessment methodologies like HAZOP (Hazard and Operability Study) and FMEA (Failure Mode and Effects Analysis) are required by most regulatory frameworks to identify potential failure points and establish appropriate mitigation strategies. These assessments must be documented and regularly updated as part of compliance requirements. Personnel safety regulations mandate comprehensive training programs for all staff involved in liquid nitrogen operations, covering emergency response procedures, proper use of Personal Protective Equipment (PPE), and understanding of cryogenic hazards.

Environmental compliance considerations include proper venting systems to prevent oxygen displacement in confined spaces and monitoring systems to detect nitrogen leaks. Many jurisdictions require environmental impact assessments for large-scale installations and emergency response plans that address potential environmental consequences of system failures.

Documentation requirements form a critical component of compliance, with operators required to maintain detailed records of design specifications, material certifications, testing procedures, maintenance activities, and incident reports. These records must be available for regulatory inspections and serve as evidence of due diligence in maintaining safe operations.

Industry-specific standards also apply in sectors such as healthcare, semiconductor manufacturing, and food processing, where additional requirements may address product purity, contamination prevention, and specialized operational protocols. Compliance with these sector-specific standards is essential for facilities using liquid nitrogen in production processes or product preservation.

The regulatory landscape continues to evolve, with increasing emphasis on predictive maintenance approaches and remote monitoring technologies to enhance safety performance. Organizations must establish robust compliance management systems to track regulatory changes and ensure ongoing adherence to all applicable standards throughout the lifecycle of liquid nitrogen pipeline systems.

European operators must adhere to the Pressure Equipment Directive (PED) 2014/68/EU and the ATEX Directive 2014/34/EU for equipment used in potentially explosive atmospheres. These regulations mandate regular inspection protocols, including non-destructive testing methods such as radiographic testing, ultrasonic testing, and magnetic particle inspection to detect potential defects before they lead to failures.

Risk assessment methodologies like HAZOP (Hazard and Operability Study) and FMEA (Failure Mode and Effects Analysis) are required by most regulatory frameworks to identify potential failure points and establish appropriate mitigation strategies. These assessments must be documented and regularly updated as part of compliance requirements. Personnel safety regulations mandate comprehensive training programs for all staff involved in liquid nitrogen operations, covering emergency response procedures, proper use of Personal Protective Equipment (PPE), and understanding of cryogenic hazards.

Environmental compliance considerations include proper venting systems to prevent oxygen displacement in confined spaces and monitoring systems to detect nitrogen leaks. Many jurisdictions require environmental impact assessments for large-scale installations and emergency response plans that address potential environmental consequences of system failures.

Documentation requirements form a critical component of compliance, with operators required to maintain detailed records of design specifications, material certifications, testing procedures, maintenance activities, and incident reports. These records must be available for regulatory inspections and serve as evidence of due diligence in maintaining safe operations.

Industry-specific standards also apply in sectors such as healthcare, semiconductor manufacturing, and food processing, where additional requirements may address product purity, contamination prevention, and specialized operational protocols. Compliance with these sector-specific standards is essential for facilities using liquid nitrogen in production processes or product preservation.

The regulatory landscape continues to evolve, with increasing emphasis on predictive maintenance approaches and remote monitoring technologies to enhance safety performance. Organizations must establish robust compliance management systems to track regulatory changes and ensure ongoing adherence to all applicable standards throughout the lifecycle of liquid nitrogen pipeline systems.

Maintenance Protocols and Lifecycle Management

Effective maintenance protocols for liquid nitrogen pipelines are essential for ensuring long-term reliability and operational safety. A comprehensive maintenance strategy should include regular inspection schedules, with visual examinations conducted weekly and more thorough assessments performed quarterly. These inspections must focus on identifying frost formation, vacuum degradation in jacketed lines, and early signs of material fatigue. Implementing predictive maintenance techniques using sensors that monitor temperature fluctuations, pressure variations, and vacuum integrity can significantly reduce unexpected failures and extend system longevity.

Documentation plays a critical role in maintenance management, requiring detailed records of all inspections, repairs, and component replacements. This historical data enables trend analysis and helps optimize maintenance intervals based on actual performance rather than generic recommendations. Proper training of maintenance personnel is equally important, ensuring they understand cryogenic safety protocols and can recognize early warning signs of potential failures.

Lifecycle management for liquid nitrogen pipelines begins with proper installation validation and extends through regular performance assessments throughout the system's operational life. Establishing clear performance benchmarks during commissioning provides valuable reference points for future evaluations. The typical lifecycle of cryogenic pipeline components varies significantly—valves may require replacement every 3-5 years, while properly maintained pipeline sections can last 15-20 years with appropriate care.

Implementing a phase-out strategy for aging components before they reach critical failure points is more cost-effective than reactive maintenance. This approach requires developing replacement schedules based on manufacturer recommendations, operational conditions, and historical performance data. For critical systems, maintaining redundant components and backup pathways ensures continuous operation during maintenance activities.

End-of-life considerations must be incorporated into the overall lifecycle management plan. This includes proper decommissioning procedures that address safety concerns related to trapped nitrogen and potential material stress from thermal cycling. Recycling and repurposing opportunities should be evaluated for components that retain structural integrity but no longer meet the stringent requirements of cryogenic service.

Cost-benefit analysis should guide maintenance decision-making, balancing immediate repair expenses against long-term reliability improvements. Organizations should establish clear metrics for evaluating maintenance effectiveness, including mean time between failures, system availability percentages, and total cost of ownership calculations that factor in both direct maintenance costs and operational impact of system downtime.

Documentation plays a critical role in maintenance management, requiring detailed records of all inspections, repairs, and component replacements. This historical data enables trend analysis and helps optimize maintenance intervals based on actual performance rather than generic recommendations. Proper training of maintenance personnel is equally important, ensuring they understand cryogenic safety protocols and can recognize early warning signs of potential failures.

Lifecycle management for liquid nitrogen pipelines begins with proper installation validation and extends through regular performance assessments throughout the system's operational life. Establishing clear performance benchmarks during commissioning provides valuable reference points for future evaluations. The typical lifecycle of cryogenic pipeline components varies significantly—valves may require replacement every 3-5 years, while properly maintained pipeline sections can last 15-20 years with appropriate care.

Implementing a phase-out strategy for aging components before they reach critical failure points is more cost-effective than reactive maintenance. This approach requires developing replacement schedules based on manufacturer recommendations, operational conditions, and historical performance data. For critical systems, maintaining redundant components and backup pathways ensures continuous operation during maintenance activities.

End-of-life considerations must be incorporated into the overall lifecycle management plan. This includes proper decommissioning procedures that address safety concerns related to trapped nitrogen and potential material stress from thermal cycling. Recycling and repurposing opportunities should be evaluated for components that retain structural integrity but no longer meet the stringent requirements of cryogenic service.

Cost-benefit analysis should guide maintenance decision-making, balancing immediate repair expenses against long-term reliability improvements. Organizations should establish clear metrics for evaluating maintenance effectiveness, including mean time between failures, system availability percentages, and total cost of ownership calculations that factor in both direct maintenance costs and operational impact of system downtime.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!