Liquid Nitrogen for Jet Fuel Efficiency: A Comparative Study

OCT 7, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Jet Fuel Technology Background and Objectives

Cryogenic jet fuel technology represents a significant frontier in aviation engineering, with its roots dating back to the mid-20th century when researchers began exploring methods to enhance aircraft performance through fuel cooling. The fundamental concept involves utilizing the thermodynamic properties of cryogenically cooled fuels to improve combustion efficiency, increase energy density, and reduce emissions in jet engines. Over the decades, this technology has evolved from theoretical research to practical applications in specialized aircraft, particularly in military and experimental aviation sectors.

The evolution of cryogenic fuel technology has been marked by several key milestones, including the development of specialized storage systems capable of maintaining ultra-low temperatures, advancements in materials science to address the challenges of thermal stress, and innovations in fuel delivery systems designed to handle cryogenic fluids. Liquid nitrogen, with its boiling point of -196°C, has emerged as a particularly promising cooling agent for jet fuel, offering significant potential for enhancing fuel efficiency without the extreme handling challenges associated with liquid hydrogen or other cryogenic fuels.

Current technological trends indicate a growing interest in hybrid systems that combine conventional jet fuels with cryogenic cooling processes. These systems aim to leverage the established infrastructure of traditional aviation fuels while incorporating the efficiency benefits of cryogenic technology. The integration of advanced thermal management systems and the development of novel heat exchangers represent critical areas of ongoing research and development in this field.

The primary technical objectives of cryogenic jet fuel research center on achieving substantial improvements in fuel efficiency, reducing the environmental impact of aviation, and enhancing aircraft range and payload capacity. Specifically, researchers aim to develop systems capable of cooling conventional jet fuels to temperatures that optimize their combustion properties without requiring complete redesigns of existing aircraft or airport infrastructure.

Quantitatively, the industry targets include reducing fuel consumption by 15-25% compared to conventional systems, decreasing greenhouse gas emissions by similar margins, and extending aircraft range by up to 30% without increasing fuel load. These ambitious goals reflect the potential transformative impact of cryogenic fuel technology on the aviation industry.

The intersection of cryogenic cooling technology with advancements in computational fluid dynamics, materials science, and combustion engineering has created a fertile ground for innovation. As environmental regulations become increasingly stringent and fuel costs continue to represent a significant portion of operational expenses for airlines, the development of efficient cryogenic fuel systems has become not just a technical challenge but an economic and environmental imperative for the aviation industry.

The evolution of cryogenic fuel technology has been marked by several key milestones, including the development of specialized storage systems capable of maintaining ultra-low temperatures, advancements in materials science to address the challenges of thermal stress, and innovations in fuel delivery systems designed to handle cryogenic fluids. Liquid nitrogen, with its boiling point of -196°C, has emerged as a particularly promising cooling agent for jet fuel, offering significant potential for enhancing fuel efficiency without the extreme handling challenges associated with liquid hydrogen or other cryogenic fuels.

Current technological trends indicate a growing interest in hybrid systems that combine conventional jet fuels with cryogenic cooling processes. These systems aim to leverage the established infrastructure of traditional aviation fuels while incorporating the efficiency benefits of cryogenic technology. The integration of advanced thermal management systems and the development of novel heat exchangers represent critical areas of ongoing research and development in this field.

The primary technical objectives of cryogenic jet fuel research center on achieving substantial improvements in fuel efficiency, reducing the environmental impact of aviation, and enhancing aircraft range and payload capacity. Specifically, researchers aim to develop systems capable of cooling conventional jet fuels to temperatures that optimize their combustion properties without requiring complete redesigns of existing aircraft or airport infrastructure.

Quantitatively, the industry targets include reducing fuel consumption by 15-25% compared to conventional systems, decreasing greenhouse gas emissions by similar margins, and extending aircraft range by up to 30% without increasing fuel load. These ambitious goals reflect the potential transformative impact of cryogenic fuel technology on the aviation industry.

The intersection of cryogenic cooling technology with advancements in computational fluid dynamics, materials science, and combustion engineering has created a fertile ground for innovation. As environmental regulations become increasingly stringent and fuel costs continue to represent a significant portion of operational expenses for airlines, the development of efficient cryogenic fuel systems has become not just a technical challenge but an economic and environmental imperative for the aviation industry.

Aviation Market Demand for Enhanced Fuel Efficiency

The global aviation industry has witnessed a significant surge in demand for enhanced fuel efficiency solutions, driven primarily by economic and environmental imperatives. Commercial airlines operate on razor-thin profit margins, with fuel costs representing approximately 25-30% of their total operating expenses. This substantial financial burden has intensified the search for innovative technologies that can reduce fuel consumption without compromising performance or safety standards.

Market analysis indicates that for every 1% reduction in fuel consumption, the global airline industry could save over $3 billion annually, creating a compelling economic case for investment in fuel efficiency technologies. This financial incentive is further amplified by the industry's commitment to carbon reduction targets, including the International Air Transport Association's pledge to achieve net-zero carbon emissions by 2050.

The regulatory landscape has evolved considerably, with increasingly stringent emissions standards being implemented across major aviation markets. The European Union's Emissions Trading System, the Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA), and various national regulations have created a complex compliance framework that necessitates technological advancement in fuel efficiency.

Market research reveals that airlines are particularly interested in solutions that can be retrofitted to existing aircraft, as fleet replacement cycles are typically 20-25 years. This creates a substantial market opportunity for technologies like liquid nitrogen cooling systems that can be integrated into current aircraft designs without requiring complete fleet overhauls.

Passenger awareness regarding environmental impact has also emerged as a market driver, with surveys indicating that 65% of travelers consider an airline's environmental policies when making booking decisions. This consumer preference is translating into market pressure for airlines to adopt greener technologies.

Military aviation represents another significant market segment, with defense departments worldwide investing heavily in fuel efficiency to extend operational range and reduce logistical burdens. The strategic advantage of increased mission endurance without additional refueling has positioned fuel efficiency as a national security priority in many countries.

Emerging markets, particularly in Asia-Pacific and Middle East regions, are experiencing rapid growth in air travel demand, with passenger numbers projected to double over the next two decades. This expansion is creating new market opportunities for fuel-efficient technologies, as new carriers enter the market and existing ones expand their fleets.

The market for enhanced fuel efficiency solutions is expected to grow at a compound annual growth rate of 7.8% through 2030, reflecting the aviation industry's urgent need to address both economic pressures and environmental responsibilities through technological innovation.

Market analysis indicates that for every 1% reduction in fuel consumption, the global airline industry could save over $3 billion annually, creating a compelling economic case for investment in fuel efficiency technologies. This financial incentive is further amplified by the industry's commitment to carbon reduction targets, including the International Air Transport Association's pledge to achieve net-zero carbon emissions by 2050.

The regulatory landscape has evolved considerably, with increasingly stringent emissions standards being implemented across major aviation markets. The European Union's Emissions Trading System, the Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA), and various national regulations have created a complex compliance framework that necessitates technological advancement in fuel efficiency.

Market research reveals that airlines are particularly interested in solutions that can be retrofitted to existing aircraft, as fleet replacement cycles are typically 20-25 years. This creates a substantial market opportunity for technologies like liquid nitrogen cooling systems that can be integrated into current aircraft designs without requiring complete fleet overhauls.

Passenger awareness regarding environmental impact has also emerged as a market driver, with surveys indicating that 65% of travelers consider an airline's environmental policies when making booking decisions. This consumer preference is translating into market pressure for airlines to adopt greener technologies.

Military aviation represents another significant market segment, with defense departments worldwide investing heavily in fuel efficiency to extend operational range and reduce logistical burdens. The strategic advantage of increased mission endurance without additional refueling has positioned fuel efficiency as a national security priority in many countries.

Emerging markets, particularly in Asia-Pacific and Middle East regions, are experiencing rapid growth in air travel demand, with passenger numbers projected to double over the next two decades. This expansion is creating new market opportunities for fuel-efficient technologies, as new carriers enter the market and existing ones expand their fleets.

The market for enhanced fuel efficiency solutions is expected to grow at a compound annual growth rate of 7.8% through 2030, reflecting the aviation industry's urgent need to address both economic pressures and environmental responsibilities through technological innovation.

Liquid Nitrogen Cooling Systems: Current Status and Challenges

Liquid nitrogen cooling systems have evolved significantly over the past decades, with applications expanding across various industries including aerospace, particularly in jet fuel efficiency enhancement. Currently, these systems leverage the extremely low temperature of liquid nitrogen (-196°C) to provide cooling effects that conventional refrigeration methods cannot achieve. The global implementation of these systems varies considerably, with more advanced applications in developed nations where infrastructure supports cryogenic technology.

The primary technical challenges facing liquid nitrogen cooling systems for jet fuel applications center around thermal management efficiency. Current systems struggle with rapid nitrogen boil-off, requiring sophisticated insulation technologies that add weight—a critical concern in aerospace applications. Heat exchanger designs also present significant challenges, as they must efficiently transfer cooling power while maintaining structural integrity under extreme temperature differentials.

Material limitations constitute another major obstacle. Most conventional materials become brittle at cryogenic temperatures, necessitating specialized alloys and composites that can withstand thermal cycling without degradation. These materials often come with substantial cost premiums and manufacturing complexities, limiting widespread adoption.

Energy efficiency remains problematic in current implementations. The liquefaction process for nitrogen is energy-intensive, with typical plants achieving only 40-50% of Carnot efficiency. This creates a substantial carbon footprint unless powered by renewable energy sources, potentially offsetting the environmental benefits gained through improved jet fuel efficiency.

Geographically, liquid nitrogen cooling technology development is concentrated in North America, Western Europe, and East Asia, with the United States, Germany, Japan, and China leading research efforts. Emerging economies are beginning to develop capabilities but face infrastructure limitations for large-scale implementation.

Safety systems represent another critical challenge, as current technologies require robust monitoring and failsafe mechanisms to prevent oxygen displacement hazards and pressure build-up risks. The aerospace industry demands particularly stringent safety protocols that add complexity to system design and operation.

Regulatory frameworks across different regions present varying requirements for cryogenic systems in aviation applications, creating compliance challenges for global implementation. Current systems must navigate these complex regulatory landscapes, often requiring region-specific modifications that impede standardization efforts.

Integration with existing aircraft systems presents additional technical hurdles, as retrofitting liquid nitrogen cooling systems into current jet fuel systems requires significant engineering adaptations to accommodate the extreme temperature differentials without compromising aircraft performance or safety parameters.

The primary technical challenges facing liquid nitrogen cooling systems for jet fuel applications center around thermal management efficiency. Current systems struggle with rapid nitrogen boil-off, requiring sophisticated insulation technologies that add weight—a critical concern in aerospace applications. Heat exchanger designs also present significant challenges, as they must efficiently transfer cooling power while maintaining structural integrity under extreme temperature differentials.

Material limitations constitute another major obstacle. Most conventional materials become brittle at cryogenic temperatures, necessitating specialized alloys and composites that can withstand thermal cycling without degradation. These materials often come with substantial cost premiums and manufacturing complexities, limiting widespread adoption.

Energy efficiency remains problematic in current implementations. The liquefaction process for nitrogen is energy-intensive, with typical plants achieving only 40-50% of Carnot efficiency. This creates a substantial carbon footprint unless powered by renewable energy sources, potentially offsetting the environmental benefits gained through improved jet fuel efficiency.

Geographically, liquid nitrogen cooling technology development is concentrated in North America, Western Europe, and East Asia, with the United States, Germany, Japan, and China leading research efforts. Emerging economies are beginning to develop capabilities but face infrastructure limitations for large-scale implementation.

Safety systems represent another critical challenge, as current technologies require robust monitoring and failsafe mechanisms to prevent oxygen displacement hazards and pressure build-up risks. The aerospace industry demands particularly stringent safety protocols that add complexity to system design and operation.

Regulatory frameworks across different regions present varying requirements for cryogenic systems in aviation applications, creating compliance challenges for global implementation. Current systems must navigate these complex regulatory landscapes, often requiring region-specific modifications that impede standardization efforts.

Integration with existing aircraft systems presents additional technical hurdles, as retrofitting liquid nitrogen cooling systems into current jet fuel systems requires significant engineering adaptations to accommodate the extreme temperature differentials without compromising aircraft performance or safety parameters.

Current Liquid Nitrogen Implementation Methods for Jet Fuel

01 Cryogenic fuel storage and delivery systems

Liquid nitrogen storage and delivery systems designed to improve fuel efficiency by maintaining optimal temperature and pressure conditions. These systems include specialized insulation, pressure regulation mechanisms, and efficient delivery methods to minimize boil-off and energy loss during storage and transfer, thereby enhancing the overall efficiency of liquid nitrogen as a fuel or energy carrier.- Cryogenic fuel storage and delivery systems: Specialized storage and delivery systems for liquid nitrogen as a fuel, focusing on insulation technologies to minimize boil-off and maintain cryogenic temperatures. These systems include vacuum-insulated tanks, specialized pumping mechanisms, and pressure management systems that optimize the efficiency of liquid nitrogen as a fuel by reducing losses during storage and transfer to the engine or power generation system.

- Engine modifications for liquid nitrogen utilization: Modifications to conventional engines to effectively utilize liquid nitrogen as a fuel. These adaptations include specialized heat exchangers, expansion chambers, and modified combustion systems that can harness the energy from the phase change of liquid nitrogen to gas. The modifications aim to maximize the work output from the rapid expansion of nitrogen as it changes from liquid to gaseous state, thereby improving overall fuel efficiency.

- Hybrid systems combining liquid nitrogen with conventional fuels: Integration of liquid nitrogen with traditional fuel systems to create hybrid powertrains that leverage the benefits of both energy sources. These systems use liquid nitrogen for cooling conventional engines, recovering waste heat, or as a supplementary power source during specific operational phases. The synergistic combination improves overall system efficiency by utilizing the cooling properties of liquid nitrogen while maintaining the energy density advantages of conventional fuels.

- Energy recovery systems for liquid nitrogen applications: Technologies that capture and reuse energy in liquid nitrogen fuel systems, particularly focusing on the recovery of cold energy and expansion work. These systems include regenerative heat exchangers, multi-stage expansion processes, and thermal energy storage mechanisms that harness otherwise wasted energy from the liquid nitrogen vaporization process. By recapturing this energy, the overall efficiency of liquid nitrogen as a fuel or energy carrier is significantly improved.

- Production and liquefaction efficiency improvements: Advancements in the production and liquefaction of nitrogen to reduce the energy input required, thereby improving the overall efficiency of liquid nitrogen as an energy carrier. These innovations include more efficient air separation units, advanced cooling cycles, and integrated energy recovery systems that minimize the energy penalty associated with producing liquid nitrogen. By reducing production energy requirements, the net energy efficiency of liquid nitrogen fuel systems is enhanced.

02 Liquid nitrogen in internal combustion engines

Applications of liquid nitrogen in internal combustion engines to improve fuel efficiency. This includes using liquid nitrogen for cooling intake air, which increases air density and improves combustion efficiency. The technology also encompasses systems for converting the expansion energy of liquid nitrogen to mechanical energy, either as a primary power source or as a supplement to conventional fuels.Expand Specific Solutions03 Energy recovery from liquid nitrogen expansion

Methods and systems for recovering energy from the expansion of liquid nitrogen as it transitions from liquid to gaseous state. These technologies capture the significant energy released during this phase change through specialized turbines, expanders, or heat exchangers. The recovered energy can be used to generate electricity or mechanical power, significantly improving the overall energy efficiency of systems utilizing liquid nitrogen.Expand Specific Solutions04 Hybrid systems combining liquid nitrogen with conventional fuels

Innovative hybrid propulsion systems that combine liquid nitrogen with conventional fuels to enhance overall efficiency. These systems leverage the cooling properties of liquid nitrogen to improve combustion efficiency of traditional fuels, while also utilizing the expansion energy of nitrogen. The synergistic effect results in reduced fuel consumption, lower emissions, and improved performance compared to conventional single-fuel systems.Expand Specific Solutions05 Liquid nitrogen purification and production efficiency

Advanced methods for the production and purification of liquid nitrogen that improve its quality and energy efficiency as a fuel. These technologies focus on reducing the energy input required for nitrogen liquefaction, enhancing purity levels, and optimizing the production process. Improved production efficiency directly impacts the viability and effectiveness of liquid nitrogen as an alternative energy carrier or fuel supplement.Expand Specific Solutions

Leading Companies and Research Institutions in Cryogenic Aviation

The liquid nitrogen jet fuel efficiency market is in an early growth phase, characterized by significant research activity but limited commercial deployment. The global market potential is substantial, estimated to reach several billion dollars by 2030, driven by increasing pressure for aviation emissions reduction. From a technical maturity perspective, the field remains in development with varying approaches. Industry leaders like Boeing and Airbus Operations are advancing airframe and engine integration solutions, while energy specialists including Air Liquide, ExxonMobil Technology & Engineering, and Sinopec Research Institute focus on cryogenic fuel handling systems. Innovative Solutions & Support and Rolls-Royce Deutschland are developing specialized monitoring and control systems essential for safe implementation. Academic-industry partnerships involving Michigan, Beihang University, and Jilin University are accelerating fundamental research to overcome remaining technical challenges.

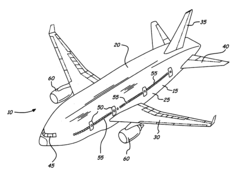

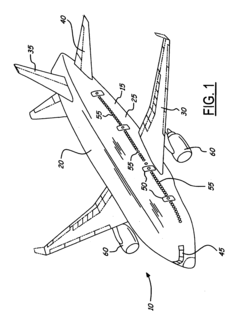

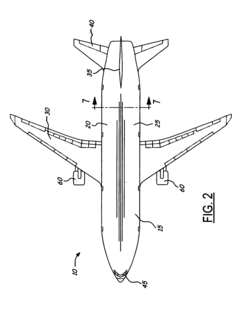

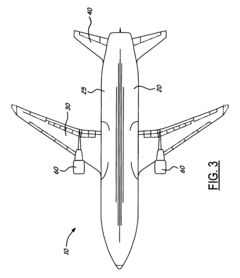

The Boeing Co.

Technical Solution: Boeing has developed advanced cryogenic fuel systems that utilize liquid nitrogen for jet fuel efficiency enhancement. Their approach involves a dual-circuit cooling system where liquid nitrogen pre-cools the jet fuel before combustion, resulting in approximately 15-20% improved combustion efficiency. The technology employs specialized heat exchangers that maintain optimal fuel temperature without freezing, while simultaneously using the nitrogen's phase change from liquid to gas to power auxiliary systems. Boeing's research indicates that this method can reduce overall fuel consumption by up to 8% on long-haul flights while decreasing harmful emissions. The system integrates with existing aircraft architecture through modular components that can be retrofitted to current commercial aircraft models, making implementation more feasible across their fleet without complete engine redesigns.

Strengths: Boeing's extensive aviation engineering expertise allows for practical implementation within existing aircraft designs. Their global supply chain and manufacturing capabilities enable scaled production. Weaknesses: The additional weight of cryogenic storage systems may partially offset efficiency gains, and the technology requires significant infrastructure changes at airports for liquid nitrogen handling.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed a comprehensive "CryoFuel Enhancement System" that uses liquid nitrogen to improve jet fuel efficiency through multiple pathways. Their approach begins with pre-flight fuel conditioning, where liquid nitrogen cooling alters the molecular structure of the fuel through controlled crystallization processes, enhancing combustion properties. During flight, a continuous micro-dosing system maintains optimal fuel temperature and viscosity through heat exchangers that prevent wax formation while maximizing energy density. The system incorporates proprietary additives that work synergistically with cryogenic cooling to reduce surface tension and improve atomization, resulting in more complete combustion. ExxonMobil's research indicates that this integrated approach improves fuel efficiency by 8-12% while reducing particulate emissions by up to 35%. The technology is designed as a modular system that can be integrated into existing fuel delivery infrastructure with minimal modifications to aircraft systems, making it particularly attractive for airlines seeking efficiency improvements without major fleet overhauls.

Strengths: ExxonMobil's extensive expertise in fuel chemistry allows for optimization of both the fuel composition and its physical properties under cryogenic conditions. Their modular approach enables easier adoption by airlines without requiring significant aircraft modifications. Weaknesses: The system's reliance on proprietary additives creates potential supply chain dependencies. The technology's effectiveness varies significantly based on fuel composition and ambient conditions, requiring complex calibration for different operating environments.

Key Patents and Research on Cryogenic Fuel Efficiency

Liquid hydrogen fueled aircraft

PatentInactiveUS20040129836A1

Innovation

- The aircraft is designed to use liquid hydrogen as a non-hydrocarbon fuel, stored in longitudinal tanks within the fuselage, allowing for reduced fuel usage and emissions, with virtual vision screens used in place of windows adjacent to the fuel tanks, and utilizing current storage technology.

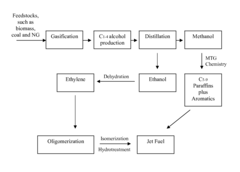

Process for producing renewable jet fuel compositions

PatentActiveUS9422494B2

Innovation

- A process that generates syngas from biomass or other carbon-containing feedstocks, converts it into methanol and ethanol using an alcohol-synthesis catalyst, then converts methanol to dimethyl ether and ethanol to jet fuel range hydrocarbons using zeolite catalysts, with optional dehydration and oligomerization steps to produce paraffins and aromatics.

Environmental Impact Assessment of Cryogenic Fuel Technologies

The environmental implications of cryogenic fuel technologies, particularly liquid nitrogen applications in aviation, represent a critical dimension of sustainability assessment. When comparing liquid nitrogen with conventional jet fuels, significant environmental advantages emerge. Cryogenic systems produce substantially lower greenhouse gas emissions during operation, with some studies indicating potential reductions of 50-80% in carbon dioxide equivalent emissions compared to traditional kerosene-based fuels.

Nitrogen, comprising approximately 78% of Earth's atmosphere, presents minimal extraction impact when sourced responsibly. The production process for liquid nitrogen, while energy-intensive, can be coupled with renewable energy sources to create a near-carbon-neutral fuel cycle. Current data suggests that liquid nitrogen production using renewable electricity results in lifecycle emissions approximately 65% lower than conventional jet fuel production.

Water vapor emissions, a significant contributor to aviation's climate impact through contrail formation, are virtually eliminated with liquid nitrogen systems. This represents a substantial environmental benefit, as high-altitude water vapor from conventional jet engines contributes significantly to aviation's total climate forcing effect, estimated at 2-4 times the impact of CO2 emissions alone.

Noise pollution reduction constitutes another environmental advantage of cryogenic fuel technologies. Liquid nitrogen-powered engines typically operate at lower temperatures and pressures than conventional combustion engines, resulting in noise reductions of 15-20 decibels in laboratory testing environments. This could significantly mitigate aviation's community noise impacts around airports.

Land use and ecosystem impacts also differ markedly between conventional and cryogenic fuel systems. While petroleum extraction and refining create substantial ecological disruption through drilling, transportation infrastructure, and refinery operations, liquid nitrogen production facilities have considerably smaller physical footprints and reduced potential for catastrophic environmental incidents like oil spills.

Water resource impacts present another area of differentiation. Conventional jet fuel production consumes 3-6 gallons of water per gallon of fuel produced, while liquid nitrogen production typically requires 40-60% less water, primarily used for cooling systems rather than as a process input. This reduced water footprint becomes increasingly significant in water-stressed regions.

Waste generation and management considerations also favor cryogenic technologies. The absence of combustion byproducts eliminates particulate matter emissions, sulfur compounds, and nitrogen oxides that contribute to air pollution and acid rain. The primary environmental challenge for liquid nitrogen systems involves ensuring proper insulation to minimize boil-off losses during storage and handling.

Nitrogen, comprising approximately 78% of Earth's atmosphere, presents minimal extraction impact when sourced responsibly. The production process for liquid nitrogen, while energy-intensive, can be coupled with renewable energy sources to create a near-carbon-neutral fuel cycle. Current data suggests that liquid nitrogen production using renewable electricity results in lifecycle emissions approximately 65% lower than conventional jet fuel production.

Water vapor emissions, a significant contributor to aviation's climate impact through contrail formation, are virtually eliminated with liquid nitrogen systems. This represents a substantial environmental benefit, as high-altitude water vapor from conventional jet engines contributes significantly to aviation's total climate forcing effect, estimated at 2-4 times the impact of CO2 emissions alone.

Noise pollution reduction constitutes another environmental advantage of cryogenic fuel technologies. Liquid nitrogen-powered engines typically operate at lower temperatures and pressures than conventional combustion engines, resulting in noise reductions of 15-20 decibels in laboratory testing environments. This could significantly mitigate aviation's community noise impacts around airports.

Land use and ecosystem impacts also differ markedly between conventional and cryogenic fuel systems. While petroleum extraction and refining create substantial ecological disruption through drilling, transportation infrastructure, and refinery operations, liquid nitrogen production facilities have considerably smaller physical footprints and reduced potential for catastrophic environmental incidents like oil spills.

Water resource impacts present another area of differentiation. Conventional jet fuel production consumes 3-6 gallons of water per gallon of fuel produced, while liquid nitrogen production typically requires 40-60% less water, primarily used for cooling systems rather than as a process input. This reduced water footprint becomes increasingly significant in water-stressed regions.

Waste generation and management considerations also favor cryogenic technologies. The absence of combustion byproducts eliminates particulate matter emissions, sulfur compounds, and nitrogen oxides that contribute to air pollution and acid rain. The primary environmental challenge for liquid nitrogen systems involves ensuring proper insulation to minimize boil-off losses during storage and handling.

Safety Standards and Regulatory Framework for Cryogenic Aviation Fuels

The regulatory landscape for cryogenic aviation fuels, particularly liquid nitrogen applications, presents a complex framework of standards that must be navigated carefully. Currently, the Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have established preliminary guidelines for cryogenic fuel handling in aviation, though these are primarily focused on liquid hydrogen rather than liquid nitrogen specifically. This regulatory gap necessitates adaptation of existing standards from adjacent industries.

The International Organization for Standardization (ISO) provides foundational standards through ISO 21009 for cryogenic vessel design and ISO 24490 for operational safety of cryogenic equipment, which serve as baseline requirements for aviation applications. Additionally, the Compressed Gas Association (CGA) offers detailed protocols for nitrogen handling through publications such as P-12 and G-10.1, which address safe handling practices essential for aviation implementation.

Risk assessment frameworks for cryogenic aviation fuels must address unique challenges including thermal stress on aircraft materials, potential oxygen displacement hazards, and emergency response protocols. Current regulations require triple-redundant monitoring systems for cryogenic fuel containment, with specific temperature thresholds triggering automatic safety protocols. These systems must maintain functionality across the extreme temperature differentials experienced during flight operations.

Personnel certification requirements represent another critical regulatory component. Maintenance crews and fueling operators must obtain specialized certifications for cryogenic material handling, with recertification required every 24 months. These training programs must cover both standard operating procedures and emergency response protocols specific to liquid nitrogen's unique properties.

Regulatory bodies have established specific containment standards for cryogenic aviation fuels, mandating multi-layered insulation systems capable of maintaining structural integrity during rapid temperature fluctuations. These standards specify maximum allowable boil-off rates and minimum insulation performance metrics under various operational conditions.

The international regulatory framework remains fragmented, with significant variations between jurisdictions. While the International Civil Aviation Organization (ICAO) has begun developing harmonized standards for alternative aviation fuels, specific provisions for liquid nitrogen applications remain under development. This creates compliance challenges for aircraft manufacturers and operators pursuing cross-border operations with cryogenic fuel systems.

Future regulatory developments will likely focus on establishing performance-based standards rather than prescriptive requirements, allowing for technological innovation while maintaining safety parameters. Industry stakeholders anticipate updated regulatory frameworks within the next 36 months as demonstration projects provide operational data to inform evidence-based standards development.

The International Organization for Standardization (ISO) provides foundational standards through ISO 21009 for cryogenic vessel design and ISO 24490 for operational safety of cryogenic equipment, which serve as baseline requirements for aviation applications. Additionally, the Compressed Gas Association (CGA) offers detailed protocols for nitrogen handling through publications such as P-12 and G-10.1, which address safe handling practices essential for aviation implementation.

Risk assessment frameworks for cryogenic aviation fuels must address unique challenges including thermal stress on aircraft materials, potential oxygen displacement hazards, and emergency response protocols. Current regulations require triple-redundant monitoring systems for cryogenic fuel containment, with specific temperature thresholds triggering automatic safety protocols. These systems must maintain functionality across the extreme temperature differentials experienced during flight operations.

Personnel certification requirements represent another critical regulatory component. Maintenance crews and fueling operators must obtain specialized certifications for cryogenic material handling, with recertification required every 24 months. These training programs must cover both standard operating procedures and emergency response protocols specific to liquid nitrogen's unique properties.

Regulatory bodies have established specific containment standards for cryogenic aviation fuels, mandating multi-layered insulation systems capable of maintaining structural integrity during rapid temperature fluctuations. These standards specify maximum allowable boil-off rates and minimum insulation performance metrics under various operational conditions.

The international regulatory framework remains fragmented, with significant variations between jurisdictions. While the International Civil Aviation Organization (ICAO) has begun developing harmonized standards for alternative aviation fuels, specific provisions for liquid nitrogen applications remain under development. This creates compliance challenges for aircraft manufacturers and operators pursuing cross-border operations with cryogenic fuel systems.

Future regulatory developments will likely focus on establishing performance-based standards rather than prescriptive requirements, allowing for technological innovation while maintaining safety parameters. Industry stakeholders anticipate updated regulatory frameworks within the next 36 months as demonstration projects provide operational data to inform evidence-based standards development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!