How to Assess Structural Integrity Post Liquid Nitrogen Exposure

OCT 7, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Structural Integrity Background and Objectives

Cryogenic environments present unique challenges for structural materials, with liquid nitrogen exposure being particularly significant due to its widespread use in various industries. The historical development of cryogenic structural integrity assessment began in the mid-20th century with the advent of space exploration and advanced medical technologies. Early research focused primarily on understanding basic material behavior at extremely low temperatures, while modern approaches have evolved to incorporate sophisticated computational models and non-destructive testing methodologies.

The evolution of cryogenic structural integrity assessment has been driven by critical incidents in aerospace, medical, and industrial applications where structural failures at cryogenic temperatures resulted in catastrophic consequences. These incidents highlighted the need for specialized testing protocols and assessment criteria specifically designed for materials subjected to extreme cold environments.

Current technological trends in this field include the development of advanced composite materials with enhanced cryogenic performance, implementation of real-time monitoring systems for continuous structural health assessment, and the integration of machine learning algorithms for predictive failure analysis. The convergence of materials science, structural engineering, and digital technologies is reshaping how we approach cryogenic structural integrity challenges.

The primary objective of cryogenic structural integrity assessment post liquid nitrogen exposure is to accurately determine the remaining service life and safety margins of affected structures. This involves quantifying the changes in mechanical properties, identifying potential microstructural alterations, and evaluating the presence of thermal stress-induced damage that may compromise structural performance under operational conditions.

Secondary objectives include developing standardized testing protocols that can be implemented across various industries, establishing clear acceptance criteria for components exposed to cryogenic temperatures, and creating comprehensive databases of material behavior under cryogenic conditions to inform future design and maintenance decisions.

Long-term goals in this field encompass the development of self-healing materials capable of mitigating cryogenic damage, implementation of digital twin technologies for real-time structural health monitoring, and establishment of unified international standards for cryogenic structural integrity assessment. These advancements would significantly enhance safety and reliability while reducing maintenance costs across industries reliant on cryogenic technologies.

The technical challenges being addressed include the complex phase transformations that occur in materials at cryogenic temperatures, the difficulty in accurately simulating thermal cycling effects, and the limitations of current non-destructive testing methods in detecting cryogenic damage. Overcoming these challenges requires interdisciplinary collaboration and innovative approaches to testing and analysis.

The evolution of cryogenic structural integrity assessment has been driven by critical incidents in aerospace, medical, and industrial applications where structural failures at cryogenic temperatures resulted in catastrophic consequences. These incidents highlighted the need for specialized testing protocols and assessment criteria specifically designed for materials subjected to extreme cold environments.

Current technological trends in this field include the development of advanced composite materials with enhanced cryogenic performance, implementation of real-time monitoring systems for continuous structural health assessment, and the integration of machine learning algorithms for predictive failure analysis. The convergence of materials science, structural engineering, and digital technologies is reshaping how we approach cryogenic structural integrity challenges.

The primary objective of cryogenic structural integrity assessment post liquid nitrogen exposure is to accurately determine the remaining service life and safety margins of affected structures. This involves quantifying the changes in mechanical properties, identifying potential microstructural alterations, and evaluating the presence of thermal stress-induced damage that may compromise structural performance under operational conditions.

Secondary objectives include developing standardized testing protocols that can be implemented across various industries, establishing clear acceptance criteria for components exposed to cryogenic temperatures, and creating comprehensive databases of material behavior under cryogenic conditions to inform future design and maintenance decisions.

Long-term goals in this field encompass the development of self-healing materials capable of mitigating cryogenic damage, implementation of digital twin technologies for real-time structural health monitoring, and establishment of unified international standards for cryogenic structural integrity assessment. These advancements would significantly enhance safety and reliability while reducing maintenance costs across industries reliant on cryogenic technologies.

The technical challenges being addressed include the complex phase transformations that occur in materials at cryogenic temperatures, the difficulty in accurately simulating thermal cycling effects, and the limitations of current non-destructive testing methods in detecting cryogenic damage. Overcoming these challenges requires interdisciplinary collaboration and innovative approaches to testing and analysis.

Market Analysis for Cryogenic Testing Solutions

The global market for cryogenic testing solutions has experienced significant growth in recent years, driven primarily by increasing demand across aerospace, healthcare, energy, and advanced materials sectors. Current market valuation stands at approximately 3.2 billion USD with a compound annual growth rate of 5.7% projected through 2028, according to industry analyses from Frost & Sullivan and Markets and Markets research groups.

The aerospace and defense sectors represent the largest market segment, accounting for roughly 32% of the total market share. This dominance stems from the critical need for materials that can withstand extreme temperature variations in spacecraft, satellites, and aviation components. The healthcare sector follows closely at 27%, with applications in biospecimen preservation, MRI equipment, and emerging cryotherapy treatments driving consistent demand growth.

Regional analysis reveals North America currently leads the market with approximately 38% share, attributed to its robust aerospace industry and substantial R&D investments. Asia-Pacific represents the fastest-growing region with a projected growth rate of 7.3% annually, primarily driven by China, Japan, and South Korea's expanding industrial base and increasing adoption of advanced manufacturing technologies requiring cryogenic testing.

Customer segmentation shows large enterprises constitute approximately 65% of the market, while small and medium enterprises represent a growing segment as testing equipment becomes more accessible and modular solutions enter the market. Government and research institutions account for roughly 22% of end-users, highlighting the significant role of public funding in this sector.

Key market drivers include increasingly stringent safety standards across industries, growing adoption of cryogenic technologies in new applications, and the rising importance of material qualification for extreme environments. The push toward space exploration by both governmental agencies and private companies has created substantial demand for specialized testing protocols for structural integrity assessment following liquid nitrogen exposure.

Market challenges primarily revolve around high equipment costs, specialized operator training requirements, and safety concerns associated with handling cryogenic materials. Additionally, the lack of standardized testing protocols specifically addressing post-liquid nitrogen exposure assessment represents a significant market gap that innovative solution providers could potentially address.

Customer pain points consistently identified in market surveys include difficulties in real-time monitoring during cryogenic testing, challenges in data interpretation, and concerns about test result reliability and reproducibility. These pain points present clear opportunities for technology providers who can deliver integrated solutions combining advanced sensing technologies with sophisticated data analytics capabilities.

The aerospace and defense sectors represent the largest market segment, accounting for roughly 32% of the total market share. This dominance stems from the critical need for materials that can withstand extreme temperature variations in spacecraft, satellites, and aviation components. The healthcare sector follows closely at 27%, with applications in biospecimen preservation, MRI equipment, and emerging cryotherapy treatments driving consistent demand growth.

Regional analysis reveals North America currently leads the market with approximately 38% share, attributed to its robust aerospace industry and substantial R&D investments. Asia-Pacific represents the fastest-growing region with a projected growth rate of 7.3% annually, primarily driven by China, Japan, and South Korea's expanding industrial base and increasing adoption of advanced manufacturing technologies requiring cryogenic testing.

Customer segmentation shows large enterprises constitute approximately 65% of the market, while small and medium enterprises represent a growing segment as testing equipment becomes more accessible and modular solutions enter the market. Government and research institutions account for roughly 22% of end-users, highlighting the significant role of public funding in this sector.

Key market drivers include increasingly stringent safety standards across industries, growing adoption of cryogenic technologies in new applications, and the rising importance of material qualification for extreme environments. The push toward space exploration by both governmental agencies and private companies has created substantial demand for specialized testing protocols for structural integrity assessment following liquid nitrogen exposure.

Market challenges primarily revolve around high equipment costs, specialized operator training requirements, and safety concerns associated with handling cryogenic materials. Additionally, the lack of standardized testing protocols specifically addressing post-liquid nitrogen exposure assessment represents a significant market gap that innovative solution providers could potentially address.

Customer pain points consistently identified in market surveys include difficulties in real-time monitoring during cryogenic testing, challenges in data interpretation, and concerns about test result reliability and reproducibility. These pain points present clear opportunities for technology providers who can deliver integrated solutions combining advanced sensing technologies with sophisticated data analytics capabilities.

Current Challenges in Post-Liquid Nitrogen Exposure Assessment

The assessment of structural integrity following liquid nitrogen exposure presents significant technical challenges that require comprehensive understanding and innovative approaches. Current methodologies face limitations in accurately evaluating the extent of material degradation and predicting long-term performance after cryogenic exposure.

One primary challenge lies in the non-uniform thermal gradients created during liquid nitrogen exposure. Materials experience different cooling rates across their structure, leading to complex stress distributions that are difficult to map and quantify. Conventional non-destructive testing (NDT) methods often fail to detect micro-cracks and internal defects that form during rapid temperature transitions, particularly in composite materials and advanced alloys.

The transient nature of cryogenic damage poses another significant obstacle. Some materials exhibit immediate structural changes upon exposure, while others develop defects progressively over time after returning to ambient temperatures. This time-dependent behavior complicates assessment protocols and necessitates multiple evaluation stages, increasing both cost and complexity of integrity verification.

Current sensor technologies demonstrate limited effectiveness in extreme cold environments. Many conventional sensors lose accuracy or fail completely at cryogenic temperatures, creating blind spots in real-time monitoring during exposure events. The development of cryogenic-compatible sensing systems remains an active but challenging research area.

Material characterization after exposure presents additional difficulties. Standard mechanical testing procedures may not adequately capture the altered failure mechanisms that emerge following cryogenic cycling. Brittle fracture modes, delamination in composites, and hydrogen embrittlement can manifest differently after liquid nitrogen exposure, requiring specialized testing protocols that are not yet standardized across industries.

Computational modeling faces significant limitations in predicting post-exposure integrity. Current simulation tools struggle to accurately incorporate the complex phase transformations, microstructural changes, and residual stress distributions that occur during cryogenic cycling. The multi-physics nature of these phenomena requires sophisticated models that integrate thermal, mechanical, and material science principles.

Regulatory frameworks and industry standards for post-cryogenic exposure assessment remain fragmented and incomplete. Different sectors (aerospace, medical, energy) have developed isolated approaches, leading to inconsistent evaluation criteria and safety margins. This lack of standardization complicates cross-industry knowledge transfer and technology adoption.

The economic constraints of comprehensive assessment further complicate the landscape. Thorough evaluation often requires expensive equipment and specialized expertise, creating barriers for smaller organizations and limiting widespread implementation of robust assessment protocols.

One primary challenge lies in the non-uniform thermal gradients created during liquid nitrogen exposure. Materials experience different cooling rates across their structure, leading to complex stress distributions that are difficult to map and quantify. Conventional non-destructive testing (NDT) methods often fail to detect micro-cracks and internal defects that form during rapid temperature transitions, particularly in composite materials and advanced alloys.

The transient nature of cryogenic damage poses another significant obstacle. Some materials exhibit immediate structural changes upon exposure, while others develop defects progressively over time after returning to ambient temperatures. This time-dependent behavior complicates assessment protocols and necessitates multiple evaluation stages, increasing both cost and complexity of integrity verification.

Current sensor technologies demonstrate limited effectiveness in extreme cold environments. Many conventional sensors lose accuracy or fail completely at cryogenic temperatures, creating blind spots in real-time monitoring during exposure events. The development of cryogenic-compatible sensing systems remains an active but challenging research area.

Material characterization after exposure presents additional difficulties. Standard mechanical testing procedures may not adequately capture the altered failure mechanisms that emerge following cryogenic cycling. Brittle fracture modes, delamination in composites, and hydrogen embrittlement can manifest differently after liquid nitrogen exposure, requiring specialized testing protocols that are not yet standardized across industries.

Computational modeling faces significant limitations in predicting post-exposure integrity. Current simulation tools struggle to accurately incorporate the complex phase transformations, microstructural changes, and residual stress distributions that occur during cryogenic cycling. The multi-physics nature of these phenomena requires sophisticated models that integrate thermal, mechanical, and material science principles.

Regulatory frameworks and industry standards for post-cryogenic exposure assessment remain fragmented and incomplete. Different sectors (aerospace, medical, energy) have developed isolated approaches, leading to inconsistent evaluation criteria and safety margins. This lack of standardization complicates cross-industry knowledge transfer and technology adoption.

The economic constraints of comprehensive assessment further complicate the landscape. Thorough evaluation often requires expensive equipment and specialized expertise, creating barriers for smaller organizations and limiting widespread implementation of robust assessment protocols.

Existing NDT Techniques for Cryogenic Damage Evaluation

01 Non-destructive testing methods for structural integrity assessment

Various non-destructive testing methods can be employed to assess the structural integrity of components without causing damage. These methods include ultrasonic testing, radiographic inspection, magnetic particle testing, and acoustic emission monitoring. These techniques allow for the detection of internal defects, cracks, corrosion, and other structural anomalies that could compromise integrity, enabling preventive maintenance and ensuring safety of structures.- Non-destructive testing methods for structural integrity assessment: Various non-destructive testing methods can be employed to assess the structural integrity of components without causing damage. These methods include ultrasonic testing, acoustic emission monitoring, radiographic inspection, and magnetic particle testing. These techniques allow for the detection of internal defects, cracks, and other structural anomalies that could compromise the integrity of structures in various industries including aerospace, oil and gas, and construction.

- Computational modeling and simulation for structural integrity prediction: Advanced computational modeling and simulation techniques are used to predict and assess structural integrity under various loading conditions. These methods include finite element analysis, computational fluid dynamics, and digital twin technology. By creating virtual models of physical structures, engineers can simulate stress distributions, fatigue behavior, and failure modes to identify potential weaknesses before they manifest in actual structures.

- Monitoring systems for continuous structural integrity assessment: Continuous monitoring systems employ sensors and data analytics to assess structural integrity in real-time. These systems utilize strain gauges, accelerometers, fiber optic sensors, and wireless sensor networks to collect data on structural performance. The collected data is analyzed using machine learning algorithms to detect anomalies, predict potential failures, and optimize maintenance schedules for critical infrastructure such as bridges, buildings, and industrial facilities.

- Risk-based inspection methodologies for structural integrity management: Risk-based inspection methodologies prioritize inspection resources based on the likelihood and consequences of structural failures. These approaches involve systematic risk assessment, probability-based analysis, and decision-making frameworks to optimize inspection intervals and techniques. By focusing on high-risk components, these methodologies improve the efficiency and effectiveness of structural integrity management programs in industries such as power generation, petrochemical, and manufacturing.

- Materials characterization techniques for structural integrity evaluation: Advanced materials characterization techniques are essential for evaluating the structural integrity of components by analyzing material properties at various scales. These techniques include microscopy, spectroscopy, hardness testing, and crystallographic analysis to assess material degradation mechanisms such as corrosion, creep, and embrittlement. Understanding the microstructural changes in materials helps in predicting their long-term performance and remaining useful life in critical applications.

02 Computational modeling and simulation for structural integrity analysis

Advanced computational modeling and simulation techniques are used to predict structural behavior under various loading conditions. Finite element analysis (FEA), computational fluid dynamics (CFD), and other numerical methods help engineers assess stress distributions, fatigue life, and failure modes. These computational approaches enable virtual testing of structures before physical implementation, optimizing designs and identifying potential weak points in complex structural systems.Expand Specific Solutions03 Structural health monitoring systems for continuous integrity assessment

Continuous monitoring systems employ sensors and data analytics to provide real-time assessment of structural integrity. These systems utilize strain gauges, accelerometers, fiber optic sensors, and wireless sensor networks to detect changes in structural behavior. By continuously monitoring parameters such as vibration, displacement, and strain, these systems can identify early signs of structural degradation, allowing for timely intervention before catastrophic failure occurs.Expand Specific Solutions04 Risk-based inspection and integrity management frameworks

Risk-based approaches prioritize inspection and maintenance activities based on the probability and consequences of failure. These frameworks incorporate factors such as material properties, operating conditions, environmental factors, and historical performance data to assess structural risks. By focusing resources on high-risk components, these methodologies optimize maintenance strategies and enhance overall structural reliability while managing costs effectively.Expand Specific Solutions05 Advanced materials and repair techniques for structural integrity enhancement

Innovative materials and repair methods are developed to enhance structural integrity and extend service life. These include composite materials, self-healing materials, corrosion-resistant coatings, and advanced welding techniques. Additionally, novel repair strategies such as composite patching, structural reinforcement, and in-situ rehabilitation methods provide solutions for maintaining and restoring structural integrity without complete replacement of components.Expand Specific Solutions

Leading Organizations in Cryogenic Structural Analysis

The structural integrity assessment post liquid nitrogen exposure market is in a growth phase, with increasing applications across energy, aerospace, and industrial sectors. The market is expanding due to rising safety concerns and regulatory requirements, estimated at approximately $3-5 billion globally. Technologically, the field shows varying maturity levels with established players like Halliburton, Schlumberger, and Boeing offering advanced solutions for cryogenic integrity testing. Newer entrants such as Inversa Systems and NDE Solutions are introducing innovative non-destructive evaluation techniques. The Electric Power Research Institute and academic institutions like Beijing University of Chemical Technology are advancing research in this domain, while oil majors including Saudi Aramco and Petrobras are implementing specialized assessment protocols for their cryogenic infrastructure.

Halliburton Energy Services, Inc.

Technical Solution: Halliburton has developed a comprehensive Cryogenic Structural Integrity Assessment (CSIA) protocol specifically designed for oil and gas infrastructure exposed to liquid nitrogen during fracturing operations. Their approach combines advanced non-destructive testing (NDT) methods with proprietary algorithms to evaluate material embrittlement. The protocol includes phased array ultrasonic testing (PAUT) that can detect micro-fractures as small as 0.1mm in steel components after cryogenic exposure. Halliburton's system incorporates real-time monitoring during liquid nitrogen application, with temperature sensors strategically placed to map thermal gradients and identify potential stress concentration points. Their assessment methodology includes a three-stage evaluation: immediate post-exposure inspection, 24-hour delayed inspection to identify delayed cracking, and long-term integrity monitoring using permanently installed sensors that communicate with their WellLife™ asset management system.

Strengths: Industry-specific expertise in oil and gas infrastructure allows for highly contextualized assessments. Their integrated monitoring approach provides continuous data rather than point-in-time evaluations. Weaknesses: System is primarily optimized for wellbore components and may require significant adaptation for other industrial applications. The comprehensive approach requires specialized training and equipment that may be cost-prohibitive for smaller operations.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has pioneered an integrated approach to post-cryogenic structural assessment through their CryoScan™ technology suite. This system combines multiple inspection technologies including acoustic emission testing, infrared thermography, and advanced ultrasonic techniques specifically calibrated for materials exposed to extreme temperature differentials. Their proprietary software analyzes microstructural changes in metals after liquid nitrogen exposure, particularly focusing on weld integrity and stress concentration zones. The system employs machine learning algorithms trained on thousands of cryogenic exposure scenarios to predict potential failure points before they become critical. Schlumberger's methodology includes a comprehensive material characterization process that accounts for different steel grades and alloys commonly used in industrial applications, with specific correction factors for various exposure durations and cooling rates. Their assessment protocol includes both immediate post-exposure evaluation and scheduled follow-up inspections to monitor any progressive deterioration that might occur as a result of delayed hydrogen embrittlement or other time-dependent failure mechanisms.

Strengths: Multi-modal inspection approach provides redundant verification of structural integrity. Their machine learning algorithms offer predictive capabilities beyond traditional inspection methods. Weaknesses: System requires significant computational resources and specialized expertise to implement effectively. The technology is primarily developed for oil and gas applications and may need adaptation for other industries.

Critical Technologies for Low-Temperature Material Assessment

Method and apparatus for measuring hydrogen concentration in zirconium alloy components in the fuel pool of a nuclear power plant

PatentInactiveUS20070279050A1

Innovation

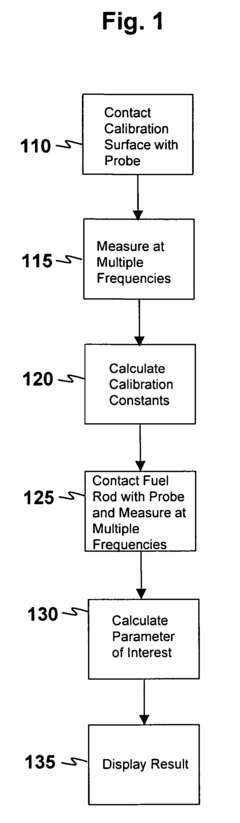

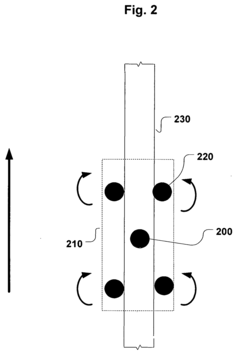

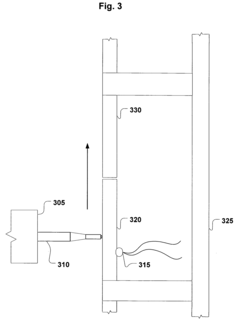

- A direct in-situ method using an eddy current probe calibrated with standards that account for background variables like zirconium oxide thickness, crud thickness, and temperature, allowing for precise hydrogen concentration measurement along the fuel rod cladding without destructive sampling.

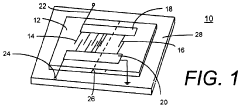

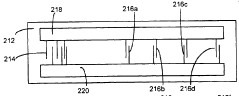

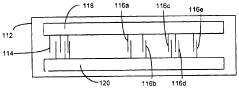

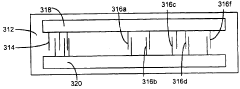

Remote sensing of structural integrity using a surface acoustic wave sensor

PatentInactiveUS5821425A

Innovation

- A small, passive, low-cost RF SAW sensing device with a piezoelectric crystal substrate and interdigital transducers, which becomes inoperative when critical strain is exceeded, allowing remote interrogation via a companion transceiver, and an alternative embodiment with output taps that measure strain-induced changes in phase velocity and delay time.

Safety Standards and Compliance Requirements

Compliance with established safety standards is paramount when assessing structural integrity after liquid nitrogen exposure. Organizations must adhere to ASME Boiler and Pressure Vessel Code Section VIII, which provides comprehensive guidelines for pressure vessels that may be subjected to cryogenic temperatures. This standard outlines material selection criteria, design considerations, and inspection protocols specifically relevant to structures exposed to extreme cold.

The American Society for Testing and Materials (ASTM) has developed several standards directly applicable to cryogenic applications, including ASTM E1003 for standard test method for hydrostatic leak testing and ASTM F1921 for oxygen compatibility of materials for oxygen service. These standards provide testing methodologies that can be incorporated into post-exposure assessment protocols to ensure structural components maintain their integrity.

International Organization for Standardization (ISO) requirements, particularly ISO 21013 for cryogenic vessels and ISO 24490 for cryogenic containers, establish global benchmarks for safety and performance. Organizations operating across international boundaries must navigate these varying requirements while maintaining consistent assessment practices.

Regulatory frameworks differ significantly by region and industry. In the United States, the Occupational Safety and Health Administration (OSHA) mandates specific requirements under 29 CFR 1910.103 for handling and storage of cryogenic materials, while the European Union follows the Pressure Equipment Directive (PED) 2014/68/EU. These regulations establish minimum safety requirements that must be incorporated into any structural integrity assessment program.

Industry-specific standards provide additional guidance tailored to particular applications. For example, aerospace applications follow SAE ARP5316 for liquid nitrogen systems in aircraft, while medical and laboratory environments adhere to NFPA 99 Health Care Facilities Code for safe handling of cryogenic fluids in healthcare settings.

Documentation requirements constitute a critical component of compliance. Organizations must maintain detailed records of all assessments, including inspection methodologies, findings, corrective actions, and verification of remediation effectiveness. These records serve both as evidence of compliance and as valuable historical data for predicting future structural behavior under similar conditions.

Training and certification requirements ensure that personnel conducting structural assessments possess the necessary expertise. The American Society for Nondestructive Testing (ASNT) provides certification programs specifically for inspectors working with cryogenic systems, establishing minimum competency standards that organizations should require for personnel performing post-exposure assessments.

The American Society for Testing and Materials (ASTM) has developed several standards directly applicable to cryogenic applications, including ASTM E1003 for standard test method for hydrostatic leak testing and ASTM F1921 for oxygen compatibility of materials for oxygen service. These standards provide testing methodologies that can be incorporated into post-exposure assessment protocols to ensure structural components maintain their integrity.

International Organization for Standardization (ISO) requirements, particularly ISO 21013 for cryogenic vessels and ISO 24490 for cryogenic containers, establish global benchmarks for safety and performance. Organizations operating across international boundaries must navigate these varying requirements while maintaining consistent assessment practices.

Regulatory frameworks differ significantly by region and industry. In the United States, the Occupational Safety and Health Administration (OSHA) mandates specific requirements under 29 CFR 1910.103 for handling and storage of cryogenic materials, while the European Union follows the Pressure Equipment Directive (PED) 2014/68/EU. These regulations establish minimum safety requirements that must be incorporated into any structural integrity assessment program.

Industry-specific standards provide additional guidance tailored to particular applications. For example, aerospace applications follow SAE ARP5316 for liquid nitrogen systems in aircraft, while medical and laboratory environments adhere to NFPA 99 Health Care Facilities Code for safe handling of cryogenic fluids in healthcare settings.

Documentation requirements constitute a critical component of compliance. Organizations must maintain detailed records of all assessments, including inspection methodologies, findings, corrective actions, and verification of remediation effectiveness. These records serve both as evidence of compliance and as valuable historical data for predicting future structural behavior under similar conditions.

Training and certification requirements ensure that personnel conducting structural assessments possess the necessary expertise. The American Society for Nondestructive Testing (ASNT) provides certification programs specifically for inspectors working with cryogenic systems, establishing minimum competency standards that organizations should require for personnel performing post-exposure assessments.

Material Selection Strategies for Cryogenic Applications

Material selection is a critical factor in determining the performance and safety of components exposed to cryogenic environments, particularly liquid nitrogen at -196°C. The extreme temperature gradient between ambient and cryogenic conditions creates unique challenges that demand specialized material considerations. Materials must maintain their structural integrity, mechanical properties, and functionality despite thermal contraction, embrittlement, and thermal shock.

Metals commonly employed in cryogenic applications include austenitic stainless steels (304L, 316L), nickel alloys, aluminum alloys (5000 and 6000 series), and copper alloys. These materials demonstrate favorable ductility retention at low temperatures, minimizing the risk of brittle fracture. Austenitic stainless steels are particularly valued for their excellent combination of strength, toughness, and corrosion resistance at cryogenic temperatures.

For non-metallic options, reinforced polymers such as glass-reinforced epoxy, polyimides, and PTFE (Teflon) offer viable alternatives where electrical insulation or weight reduction is required. These materials must be carefully selected to avoid excessive embrittlement or thermal contraction that could compromise structural integrity. Composite materials engineered specifically for cryogenic applications can provide tailored properties that balance strength, thermal conductivity, and dimensional stability.

Material selection strategies must incorporate comprehensive testing protocols that simulate actual service conditions. Charpy impact testing at cryogenic temperatures provides critical data on material toughness, while tensile testing evaluates strength and ductility retention. Thermal cycling tests between ambient and cryogenic temperatures help identify potential failure modes related to thermal fatigue or differential thermal expansion.

The coefficient of thermal expansion (CTE) represents a crucial parameter in material selection, as mismatched CTEs between joined materials can lead to stress concentration and potential failure during thermal cycling. Designers must consider not only the absolute CTE values but also the integrated thermal contraction across the entire temperature range from ambient to cryogenic conditions.

Surface treatments and coatings can enhance material performance in cryogenic environments. Techniques such as shot peening can introduce compressive surface stresses that improve fatigue resistance, while specialized coatings may provide additional protection against environmental factors or improve thermal characteristics.

Modern material selection approaches increasingly leverage computational modeling and simulation to predict material behavior under cryogenic conditions. Finite element analysis incorporating temperature-dependent material properties enables engineers to identify potential stress concentrations and failure points before physical prototyping, significantly reducing development time and costs while improving reliability.

Metals commonly employed in cryogenic applications include austenitic stainless steels (304L, 316L), nickel alloys, aluminum alloys (5000 and 6000 series), and copper alloys. These materials demonstrate favorable ductility retention at low temperatures, minimizing the risk of brittle fracture. Austenitic stainless steels are particularly valued for their excellent combination of strength, toughness, and corrosion resistance at cryogenic temperatures.

For non-metallic options, reinforced polymers such as glass-reinforced epoxy, polyimides, and PTFE (Teflon) offer viable alternatives where electrical insulation or weight reduction is required. These materials must be carefully selected to avoid excessive embrittlement or thermal contraction that could compromise structural integrity. Composite materials engineered specifically for cryogenic applications can provide tailored properties that balance strength, thermal conductivity, and dimensional stability.

Material selection strategies must incorporate comprehensive testing protocols that simulate actual service conditions. Charpy impact testing at cryogenic temperatures provides critical data on material toughness, while tensile testing evaluates strength and ductility retention. Thermal cycling tests between ambient and cryogenic temperatures help identify potential failure modes related to thermal fatigue or differential thermal expansion.

The coefficient of thermal expansion (CTE) represents a crucial parameter in material selection, as mismatched CTEs between joined materials can lead to stress concentration and potential failure during thermal cycling. Designers must consider not only the absolute CTE values but also the integrated thermal contraction across the entire temperature range from ambient to cryogenic conditions.

Surface treatments and coatings can enhance material performance in cryogenic environments. Techniques such as shot peening can introduce compressive surface stresses that improve fatigue resistance, while specialized coatings may provide additional protection against environmental factors or improve thermal characteristics.

Modern material selection approaches increasingly leverage computational modeling and simulation to predict material behavior under cryogenic conditions. Finite element analysis incorporating temperature-dependent material properties enables engineers to identify potential stress concentrations and failure points before physical prototyping, significantly reducing development time and costs while improving reliability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!