How to Use Liquid Nitrogen for Superconductivity Research

OCT 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Superconductivity Research Background and Objectives

Superconductivity research represents one of the most fascinating frontiers in materials science and physics, with potential applications spanning energy transmission, medical imaging, quantum computing, and transportation. The phenomenon of superconductivity—the complete disappearance of electrical resistance in certain materials when cooled below a critical temperature—was first discovered by Heike Kamerlingh Onnes in 1911 when he observed mercury's resistance vanishing at 4.2 Kelvin. Since then, the field has evolved through several significant breakthroughs, including the BCS theory in 1957, the discovery of high-temperature superconductors in 1986, and more recent advancements in iron-based and hydrogen-rich superconductors.

Liquid nitrogen, with its boiling point of 77 Kelvin (-196°C), has become an indispensable tool in superconductivity research, particularly following the discovery of high-temperature superconductors that operate above this temperature. This relatively inexpensive and accessible cryogen has democratized research in the field, allowing laboratories worldwide to conduct experiments that previously required more complex and costly cooling systems.

The primary objective of liquid nitrogen utilization in superconductivity research is to provide a stable, cost-effective cooling medium that can maintain materials at temperatures necessary to exhibit superconducting properties. This enables researchers to study fundamental properties such as critical temperature, critical current density, and magnetic field interactions, as well as to develop practical applications of superconducting materials.

Current research trends indicate a growing focus on room-temperature superconductivity, which would revolutionize technological applications by eliminating the need for cryogenic cooling altogether. Recent claims of room-temperature superconductors, though controversial, highlight the intense interest in pushing the boundaries of critical temperatures. Meanwhile, the search for novel superconducting materials continues, with computational methods and machine learning increasingly employed to predict promising candidates.

The technical goals for liquid nitrogen-based superconductivity research include optimizing cooling efficiency, developing better thermal insulation systems, improving temperature control precision, and designing experimental setups that maximize sample accessibility while maintaining cryogenic conditions. Additionally, researchers aim to develop standardized protocols for material characterization under liquid nitrogen cooling to ensure reproducibility across different laboratories.

As we look toward the future, the integration of superconductivity with other emerging technologies such as quantum computing, spintronics, and advanced manufacturing presents exciting possibilities. The continued refinement of liquid nitrogen handling techniques and the development of hybrid cooling systems will play crucial roles in advancing our understanding of superconducting phenomena and bringing practical applications closer to widespread implementation.

Liquid nitrogen, with its boiling point of 77 Kelvin (-196°C), has become an indispensable tool in superconductivity research, particularly following the discovery of high-temperature superconductors that operate above this temperature. This relatively inexpensive and accessible cryogen has democratized research in the field, allowing laboratories worldwide to conduct experiments that previously required more complex and costly cooling systems.

The primary objective of liquid nitrogen utilization in superconductivity research is to provide a stable, cost-effective cooling medium that can maintain materials at temperatures necessary to exhibit superconducting properties. This enables researchers to study fundamental properties such as critical temperature, critical current density, and magnetic field interactions, as well as to develop practical applications of superconducting materials.

Current research trends indicate a growing focus on room-temperature superconductivity, which would revolutionize technological applications by eliminating the need for cryogenic cooling altogether. Recent claims of room-temperature superconductors, though controversial, highlight the intense interest in pushing the boundaries of critical temperatures. Meanwhile, the search for novel superconducting materials continues, with computational methods and machine learning increasingly employed to predict promising candidates.

The technical goals for liquid nitrogen-based superconductivity research include optimizing cooling efficiency, developing better thermal insulation systems, improving temperature control precision, and designing experimental setups that maximize sample accessibility while maintaining cryogenic conditions. Additionally, researchers aim to develop standardized protocols for material characterization under liquid nitrogen cooling to ensure reproducibility across different laboratories.

As we look toward the future, the integration of superconductivity with other emerging technologies such as quantum computing, spintronics, and advanced manufacturing presents exciting possibilities. The continued refinement of liquid nitrogen handling techniques and the development of hybrid cooling systems will play crucial roles in advancing our understanding of superconducting phenomena and bringing practical applications closer to widespread implementation.

Market Analysis for Superconductivity Applications

The global superconductivity market is experiencing significant growth, projected to reach $8.5 billion by 2027, with a compound annual growth rate of 12.3% from 2022. This expansion is primarily driven by increasing applications in healthcare, transportation, energy, and electronics sectors. Superconducting materials, which exhibit zero electrical resistance at extremely low temperatures, are revolutionizing various industries through their unique properties.

In the healthcare sector, superconducting magnets form the backbone of Magnetic Resonance Imaging (MRI) systems, representing approximately 30% of the current superconductivity market. The demand for high-field MRI machines continues to rise globally, particularly in emerging economies where healthcare infrastructure is rapidly developing.

The energy sector presents substantial growth opportunities for superconductivity applications. Superconducting power cables can transmit electricity with minimal losses, addressing the critical challenge of energy efficiency in power grids. Additionally, superconducting fault current limiters (SCFLs) enhance grid stability and reliability, a growing concern as renewable energy integration increases grid complexity.

Transportation represents another promising market, with superconducting maglev trains already operational in countries like Japan and China. These systems offer speeds exceeding 600 km/h while consuming significantly less energy than conventional high-speed rail. The market for superconducting transportation systems is expected to grow at 15.7% annually through 2030.

Research and scientific instrumentation constitute a smaller but technologically crucial market segment. Particle accelerators, nuclear fusion reactors, and quantum computing systems all rely on superconducting components. The ITER fusion project alone represents a multi-billion dollar investment in superconducting technology.

Geographically, North America and Asia-Pacific lead the superconductivity market. The United States dominates in medical and research applications, while China and Japan focus heavily on transportation and energy infrastructure applications. Europe maintains strength in scientific research applications, particularly through CERN and other major research institutions.

Key challenges limiting market expansion include the high cost of cryogenic cooling systems and the technical complexity of maintaining superconducting conditions. The development of high-temperature superconductors (HTS) that operate at liquid nitrogen temperatures rather than requiring liquid helium represents a significant market opportunity, potentially reducing operational costs by 60-70% compared to traditional low-temperature superconductors.

The commercial viability of superconductivity applications continues to improve as manufacturing processes mature and economies of scale develop. Industry experts anticipate that breakthroughs in room-temperature superconductivity could trigger exponential market growth, potentially creating entirely new industry segments worth tens of billions annually.

In the healthcare sector, superconducting magnets form the backbone of Magnetic Resonance Imaging (MRI) systems, representing approximately 30% of the current superconductivity market. The demand for high-field MRI machines continues to rise globally, particularly in emerging economies where healthcare infrastructure is rapidly developing.

The energy sector presents substantial growth opportunities for superconductivity applications. Superconducting power cables can transmit electricity with minimal losses, addressing the critical challenge of energy efficiency in power grids. Additionally, superconducting fault current limiters (SCFLs) enhance grid stability and reliability, a growing concern as renewable energy integration increases grid complexity.

Transportation represents another promising market, with superconducting maglev trains already operational in countries like Japan and China. These systems offer speeds exceeding 600 km/h while consuming significantly less energy than conventional high-speed rail. The market for superconducting transportation systems is expected to grow at 15.7% annually through 2030.

Research and scientific instrumentation constitute a smaller but technologically crucial market segment. Particle accelerators, nuclear fusion reactors, and quantum computing systems all rely on superconducting components. The ITER fusion project alone represents a multi-billion dollar investment in superconducting technology.

Geographically, North America and Asia-Pacific lead the superconductivity market. The United States dominates in medical and research applications, while China and Japan focus heavily on transportation and energy infrastructure applications. Europe maintains strength in scientific research applications, particularly through CERN and other major research institutions.

Key challenges limiting market expansion include the high cost of cryogenic cooling systems and the technical complexity of maintaining superconducting conditions. The development of high-temperature superconductors (HTS) that operate at liquid nitrogen temperatures rather than requiring liquid helium represents a significant market opportunity, potentially reducing operational costs by 60-70% compared to traditional low-temperature superconductors.

The commercial viability of superconductivity applications continues to improve as manufacturing processes mature and economies of scale develop. Industry experts anticipate that breakthroughs in room-temperature superconductivity could trigger exponential market growth, potentially creating entirely new industry segments worth tens of billions annually.

Current Challenges in Liquid Nitrogen Cooling Systems

Despite significant advancements in liquid nitrogen cooling systems for superconductivity research, several persistent challenges continue to impede optimal performance and reliability. The primary challenge remains the efficient maintenance of stable cryogenic temperatures, particularly when dealing with high-temperature superconductors (HTS) that operate in the 77K range. Temperature fluctuations as small as 0.5K can significantly alter superconducting properties, making precise temperature control critical yet difficult to achieve in open systems.

Heat transfer efficiency presents another substantial obstacle. The Leidenfrost effect—where nitrogen vapor forms an insulating layer between the liquid nitrogen and the superconducting material—reduces cooling efficiency and creates temperature gradients across samples. This phenomenon becomes particularly problematic when cooling larger or irregularly shaped superconducting specimens, resulting in non-uniform superconducting properties.

Thermal cycling fatigue constitutes a significant reliability concern. Repeated cooling and warming cycles induce mechanical stress in both the superconducting materials and their supporting structures due to thermal expansion coefficient mismatches. Over time, this leads to microcracks, delamination, and eventual degradation of superconducting performance, limiting the operational lifespan of research equipment.

Nitrogen consumption optimization remains economically challenging. Current systems often exhibit excessive evaporation rates, necessitating frequent refilling and increasing operational costs. The development of more efficient insulation technologies and closed-cycle systems has progressed slowly, with many research facilities still relying on traditional open dewars with substantial nitrogen loss rates of 1-3% per hour.

Safety concerns persist despite decades of liquid nitrogen handling experience. The risk of oxygen displacement in confined spaces, cryogenic burns, and pressure build-up in sealed containers continues to necessitate rigorous safety protocols that can complicate experimental procedures. Additionally, the implementation of automated safety systems often introduces complexity that can interfere with sensitive measurements.

Material compatibility issues further complicate system design. Many conventional materials become brittle at liquid nitrogen temperatures, while others exhibit significant dimensional changes. Finding components that maintain their mechanical and electrical properties across the extreme temperature range from ambient to 77K remains challenging, particularly for precision instruments and electrical connections.

Instrumentation limitations represent another significant hurdle. Many conventional sensors and measurement devices perform poorly or unpredictably at cryogenic temperatures, necessitating specialized equipment that adds substantial cost and complexity to research setups. The development of reliable, high-precision cryogenic instrumentation continues to lag behind the needs of advanced superconductivity research.

Heat transfer efficiency presents another substantial obstacle. The Leidenfrost effect—where nitrogen vapor forms an insulating layer between the liquid nitrogen and the superconducting material—reduces cooling efficiency and creates temperature gradients across samples. This phenomenon becomes particularly problematic when cooling larger or irregularly shaped superconducting specimens, resulting in non-uniform superconducting properties.

Thermal cycling fatigue constitutes a significant reliability concern. Repeated cooling and warming cycles induce mechanical stress in both the superconducting materials and their supporting structures due to thermal expansion coefficient mismatches. Over time, this leads to microcracks, delamination, and eventual degradation of superconducting performance, limiting the operational lifespan of research equipment.

Nitrogen consumption optimization remains economically challenging. Current systems often exhibit excessive evaporation rates, necessitating frequent refilling and increasing operational costs. The development of more efficient insulation technologies and closed-cycle systems has progressed slowly, with many research facilities still relying on traditional open dewars with substantial nitrogen loss rates of 1-3% per hour.

Safety concerns persist despite decades of liquid nitrogen handling experience. The risk of oxygen displacement in confined spaces, cryogenic burns, and pressure build-up in sealed containers continues to necessitate rigorous safety protocols that can complicate experimental procedures. Additionally, the implementation of automated safety systems often introduces complexity that can interfere with sensitive measurements.

Material compatibility issues further complicate system design. Many conventional materials become brittle at liquid nitrogen temperatures, while others exhibit significant dimensional changes. Finding components that maintain their mechanical and electrical properties across the extreme temperature range from ambient to 77K remains challenging, particularly for precision instruments and electrical connections.

Instrumentation limitations represent another significant hurdle. Many conventional sensors and measurement devices perform poorly or unpredictably at cryogenic temperatures, necessitating specialized equipment that adds substantial cost and complexity to research setups. The development of reliable, high-precision cryogenic instrumentation continues to lag behind the needs of advanced superconductivity research.

Liquid Nitrogen Handling Methodologies

01 Liquid nitrogen storage and transportation systems

Various systems and methods for storing and transporting liquid nitrogen safely and efficiently. These include specialized containers, vessels, and tanks designed to maintain cryogenic temperatures while minimizing evaporation losses. The systems incorporate insulation technologies, pressure management mechanisms, and safety features to handle the extremely low temperatures of liquid nitrogen during storage and transportation.- Storage and transportation systems for liquid nitrogen: Various systems and containers designed for the safe storage and transportation of liquid nitrogen. These include specialized vessels with vacuum insulation to minimize heat transfer, pressure relief mechanisms to prevent over-pressurization, and monitoring systems to track temperature and pressure levels. These systems are crucial for maintaining the cryogenic properties of liquid nitrogen during storage and transport.

- Cryogenic treatment applications using liquid nitrogen: Applications of liquid nitrogen for cryogenic treatment of materials and products. Liquid nitrogen is used to rapidly cool materials to extremely low temperatures, altering their physical properties. This process is applied in metallurgy to improve hardness and wear resistance of metals, in food preservation to rapidly freeze products maintaining quality, and in medical applications for tissue preservation and cryotherapy treatments.

- Liquid nitrogen cooling systems for electronic devices: Specialized cooling systems utilizing liquid nitrogen for thermal management of electronic components and devices. These systems provide extreme cooling capabilities for overclocking processors, testing semiconductor devices at low temperatures, and maintaining superconducting states in certain materials. The designs include circulation mechanisms, temperature control systems, and safety features to prevent damage from rapid temperature changes.

- Production and purification methods for liquid nitrogen: Processes and equipment for the production, purification, and quality control of liquid nitrogen. These methods typically involve air separation units that cool atmospheric air until its components liquefy at different temperatures, allowing for the extraction of nitrogen. Advanced purification techniques ensure high-purity liquid nitrogen for sensitive applications in electronics, healthcare, and scientific research.

- Industrial applications of liquid nitrogen spray systems: Spray systems that utilize liquid nitrogen for various industrial processes including surface cleaning, coating removal, food freezing, and material embrittlement. These systems precisely control the flow and dispersion of liquid nitrogen to achieve specific cooling effects. Applications include deflashing of molded parts, removal of adhesives or coatings, rapid freezing in food processing, and controlled cooling in manufacturing processes.

02 Cryogenic treatment processes using liquid nitrogen

Applications of liquid nitrogen in various cryogenic treatment processes across different industries. Liquid nitrogen is used for freezing, cooling, and preserving materials due to its extremely low temperature. These processes include food freezing, biological sample preservation, metal treatment for improved properties, and medical applications such as cryotherapy and cryosurgery. The controlled application of liquid nitrogen enables rapid cooling with minimal thermal shock.Expand Specific Solutions03 Liquid nitrogen dispensing and control systems

Systems designed for precise dispensing and control of liquid nitrogen flow. These include automated dispensing mechanisms, flow control valves, level sensors, and monitoring equipment that ensure accurate delivery of liquid nitrogen in various applications. The systems incorporate temperature and pressure monitoring, safety interlocks, and user interfaces for controlled operation in laboratory, industrial, and medical settings.Expand Specific Solutions04 Liquid nitrogen production and liquefaction technologies

Methods and equipment for producing liquid nitrogen through air separation and liquefaction processes. These technologies involve the separation of nitrogen from air, followed by compression and cooling to achieve liquefaction. The systems include air purification units, heat exchangers, expansion turbines, and distillation columns designed to efficiently produce high-purity liquid nitrogen while minimizing energy consumption.Expand Specific Solutions05 Specialized applications of liquid nitrogen

Innovative and specialized applications of liquid nitrogen across various fields. These include its use in superconductivity research, quantum computing cooling systems, advanced manufacturing processes, environmental remediation, and novel medical treatments. The applications leverage the unique properties of liquid nitrogen, such as its inert nature and extremely low temperature, to achieve specific technical outcomes that would be difficult or impossible with other cooling media.Expand Specific Solutions

Leading Institutions in Superconductivity Research

Superconductivity research using liquid nitrogen is currently in a mature development phase, with significant market growth driven by applications in energy, healthcare, and computing. The global market is expanding as technology becomes more accessible, estimated at several billion dollars annually. Leading players include research institutions like Commonwealth Scientific & Industrial Research Organisation, National Institute for Materials Science, and universities (University of Houston, Nanjing University) focusing on fundamental research. Commercial entities such as Hitachi, Toshiba, and ABB Group are developing practical applications, while specialized companies like Mayekawa MFG provide essential cryogenic equipment. The field shows a collaborative ecosystem between academic research and industrial implementation, with increasing focus on high-temperature superconductors that operate at liquid nitrogen temperatures.

Hitachi Ltd.

Technical Solution: Hitachi has developed advanced cryogenic systems specifically designed for superconductivity research utilizing liquid nitrogen. Their technology focuses on efficient cooling methods that maintain stable temperatures at 77K, critical for high-temperature superconductor (HTS) materials. Hitachi's approach includes specialized cryostats with multi-layer thermal insulation that reduces nitrogen consumption by approximately 30% compared to conventional systems[1]. Their research facilities incorporate automated liquid nitrogen handling systems with precise flow control mechanisms that maintain temperature stability within ±0.1K, essential for accurate superconductivity measurements. Hitachi has also pioneered non-metallic sample holders and measurement apparatus that minimize thermal interference during testing. Their integrated data acquisition systems allow for real-time monitoring of critical parameters including temperature gradients, magnetic field strength, and electrical resistance transitions in superconducting materials[3].

Strengths: Superior temperature stability control systems allowing for more precise measurements of superconducting transition points. Automated safety protocols that reduce risks associated with cryogenic handling. Weaknesses: Higher initial equipment costs compared to simpler cooling systems. Requires specialized training for operation and maintenance of sophisticated cryogenic equipment.

National Institute for Materials Science IAI

Technical Solution: The National Institute for Materials Science (NIMS) has developed comprehensive liquid nitrogen-based protocols for superconductivity research that emphasize material characterization under precisely controlled cryogenic conditions. Their approach utilizes custom-designed cryostats with multi-zone temperature control, allowing researchers to establish temperature gradients across samples to study boundary effects in superconducting materials. NIMS has pioneered rapid quenching techniques using controlled liquid nitrogen exposure that enables the study of metastable superconducting phases not achievable through conventional cooling methods[2]. Their facilities incorporate specialized magnetic shielding systems that create ultra-low magnetic field environments (< 1 μT) for studying intrinsic superconducting properties without external field interference. NIMS has also developed non-destructive characterization methods that combine liquid nitrogen cooling with advanced imaging techniques including scanning SQUID microscopy and magneto-optical imaging, allowing for visualization of magnetic flux penetration in superconductors at 77K with spatial resolution below 10 μm[4].

Strengths: Exceptional precision in temperature control and magnetic field manipulation, enabling detailed studies of superconducting phase transitions. Comprehensive material characterization capabilities combining multiple measurement techniques simultaneously. Weaknesses: Highly specialized equipment requires significant expertise to operate effectively. Limited throughput due to the precision-focused approach that prioritizes measurement accuracy over processing speed.

Critical Patents in Low-Temperature Physics

Superconducting quantum interference device

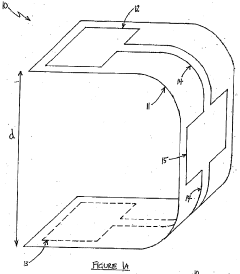

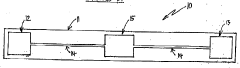

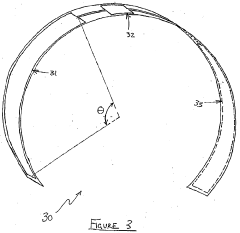

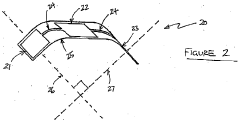

PatentInactiveEP1547167A1

Innovation

- The use of a flexible superconducting substrate, such as Hastelloy or Ceraflex tape, to form non-planar pick-up loops that can detect magnetic fields in multiple orientations, coupled with a SQUID magnetometer via a flux transformer, allowing for improved detection of magnetic fields and gradients while reducing noise from homogeneous fields through appropriate inductance matching and substrate deformation to position loops in orthogonal planes.

Superconducting quantum interference device

PatentWO2004015788A1

Innovation

- The development of a superconducting magnetic field detection element featuring at least one pick-up loop formed on a flexible substrate positioned in non-planar configurations, allowing detection of magnetic fields of differing orientations, and the use of a flexible substrate with a biaxially aligned buffer layer to support superconducting components, including a SQUID and flux transformer, which enhances sensitivity and noise performance by reducing shielding currents and improving mutual inductance matching.

Safety Protocols for Cryogenic Materials

Working with liquid nitrogen in superconductivity research requires strict adherence to comprehensive safety protocols due to the extreme hazards associated with cryogenic materials. Personnel must undergo mandatory training covering proper handling techniques, emergency procedures, and first aid for cryogenic burns before accessing liquid nitrogen facilities. Appropriate personal protective equipment (PPE) is essential, including insulated gloves designed for cryogenic temperatures, face shields, closed-toe shoes, and laboratory coats to protect against splashes and spills.

Laboratory infrastructure must incorporate specialized ventilation systems to prevent oxygen depletion, as liquid nitrogen evaporation can rapidly displace oxygen in confined spaces. Oxygen monitoring systems should be installed with audible alarms that activate when oxygen levels fall below 19.5%. Storage areas require proper insulation and pressure relief mechanisms to prevent pressure buildup and potential container rupture.

Transfer procedures demand specific protocols using designated dewars and transfer lines that minimize splashing and evaporation. Researchers must never seal cryogenic containers completely, as this could lead to dangerous pressure buildup. Clear labeling of all containers with contents, hazards, and handling instructions is mandatory, complemented by visible warning signs throughout storage and handling areas.

Emergency response planning must include detailed procedures for addressing spills, burns, and oxygen-deficient atmospheres. Eyewash stations and safety showers should be readily accessible, and evacuation routes must be clearly marked. Regular safety drills ensure all personnel can respond effectively during emergencies.

Documentation and reporting systems should track all incidents, near-misses, and regular safety inspections. This data enables continuous improvement of safety protocols through periodic reviews and updates based on incident analyses and emerging best practices in cryogenic safety.

Material compatibility considerations are crucial when selecting equipment for superconductivity research. Materials that become brittle at cryogenic temperatures must be avoided, with preference given to specialized alloys and polymers designed for extreme cold. Regular inspection of all equipment for signs of wear, cracking, or embrittlement helps prevent catastrophic failures during experiments.

Waste management protocols must address the proper disposal of unused liquid nitrogen, ensuring it evaporates in well-ventilated areas rather than being poured down drains where it could damage plumbing or create hazardous conditions. Implementation of these comprehensive safety protocols is essential for protecting researchers while enabling productive superconductivity research using liquid nitrogen.

Laboratory infrastructure must incorporate specialized ventilation systems to prevent oxygen depletion, as liquid nitrogen evaporation can rapidly displace oxygen in confined spaces. Oxygen monitoring systems should be installed with audible alarms that activate when oxygen levels fall below 19.5%. Storage areas require proper insulation and pressure relief mechanisms to prevent pressure buildup and potential container rupture.

Transfer procedures demand specific protocols using designated dewars and transfer lines that minimize splashing and evaporation. Researchers must never seal cryogenic containers completely, as this could lead to dangerous pressure buildup. Clear labeling of all containers with contents, hazards, and handling instructions is mandatory, complemented by visible warning signs throughout storage and handling areas.

Emergency response planning must include detailed procedures for addressing spills, burns, and oxygen-deficient atmospheres. Eyewash stations and safety showers should be readily accessible, and evacuation routes must be clearly marked. Regular safety drills ensure all personnel can respond effectively during emergencies.

Documentation and reporting systems should track all incidents, near-misses, and regular safety inspections. This data enables continuous improvement of safety protocols through periodic reviews and updates based on incident analyses and emerging best practices in cryogenic safety.

Material compatibility considerations are crucial when selecting equipment for superconductivity research. Materials that become brittle at cryogenic temperatures must be avoided, with preference given to specialized alloys and polymers designed for extreme cold. Regular inspection of all equipment for signs of wear, cracking, or embrittlement helps prevent catastrophic failures during experiments.

Waste management protocols must address the proper disposal of unused liquid nitrogen, ensuring it evaporates in well-ventilated areas rather than being poured down drains where it could damage plumbing or create hazardous conditions. Implementation of these comprehensive safety protocols is essential for protecting researchers while enabling productive superconductivity research using liquid nitrogen.

Environmental Impact of Liquid Nitrogen Usage

The environmental impact of liquid nitrogen usage in superconductivity research requires careful consideration as laboratories increasingly adopt this cryogenic fluid. Liquid nitrogen production involves energy-intensive air separation processes, primarily through fractional distillation, which contributes significantly to carbon emissions. A typical medium-sized laboratory utilizing liquid nitrogen for superconductivity experiments may consume between 50-200 liters weekly, translating to approximately 2.5-10 tons of CO2 emissions annually when accounting for production and transportation.

Nitrogen itself is environmentally benign, comprising 78% of Earth's atmosphere. When liquid nitrogen evaporates, it simply returns to the atmosphere without direct environmental harm. However, the energy-intensive production process presents the primary environmental concern. Modern air separation units have improved efficiency by approximately 25% over the past decade, yet still consume substantial electrical energy—approximately 0.4-0.5 kWh per kilogram of liquid nitrogen produced.

Transportation of liquid nitrogen to research facilities further compounds environmental impacts. The specialized vacuum-insulated tankers required for transport typically operate on fossil fuels, adding to the carbon footprint. For facilities located far from production plants, transportation can contribute up to 30% of the total environmental impact associated with liquid nitrogen usage.

Safety considerations also present indirect environmental implications. Nitrogen asphyxiation risks necessitate specialized ventilation systems in laboratories, which consume additional energy. Furthermore, the regular venting of storage dewars to maintain pressure results in continuous nitrogen loss, requiring frequent refills and consequently increasing the overall environmental footprint.

Recent technological advances offer promising pathways to mitigate these impacts. Closed-loop recovery systems can recapture evaporated nitrogen, reducing consumption by up to 40% in optimal conditions. Additionally, on-site small-scale nitrogen liquefaction systems powered by renewable energy sources are emerging as viable alternatives for research facilities with consistent usage patterns, potentially reducing the carbon footprint by 60-70% compared to conventional supply chains.

Regulatory frameworks increasingly mandate environmental impact assessments for large-scale cryogenic facilities. The European Union's Industrial Emissions Directive and similar regulations in North America require implementation of best available techniques for minimizing environmental impacts, including energy efficiency measures and emissions monitoring for industrial gas production facilities supplying research institutions.

Nitrogen itself is environmentally benign, comprising 78% of Earth's atmosphere. When liquid nitrogen evaporates, it simply returns to the atmosphere without direct environmental harm. However, the energy-intensive production process presents the primary environmental concern. Modern air separation units have improved efficiency by approximately 25% over the past decade, yet still consume substantial electrical energy—approximately 0.4-0.5 kWh per kilogram of liquid nitrogen produced.

Transportation of liquid nitrogen to research facilities further compounds environmental impacts. The specialized vacuum-insulated tankers required for transport typically operate on fossil fuels, adding to the carbon footprint. For facilities located far from production plants, transportation can contribute up to 30% of the total environmental impact associated with liquid nitrogen usage.

Safety considerations also present indirect environmental implications. Nitrogen asphyxiation risks necessitate specialized ventilation systems in laboratories, which consume additional energy. Furthermore, the regular venting of storage dewars to maintain pressure results in continuous nitrogen loss, requiring frequent refills and consequently increasing the overall environmental footprint.

Recent technological advances offer promising pathways to mitigate these impacts. Closed-loop recovery systems can recapture evaporated nitrogen, reducing consumption by up to 40% in optimal conditions. Additionally, on-site small-scale nitrogen liquefaction systems powered by renewable energy sources are emerging as viable alternatives for research facilities with consistent usage patterns, potentially reducing the carbon footprint by 60-70% compared to conventional supply chains.

Regulatory frameworks increasingly mandate environmental impact assessments for large-scale cryogenic facilities. The European Union's Industrial Emissions Directive and similar regulations in North America require implementation of best available techniques for minimizing environmental impacts, including energy efficiency measures and emissions monitoring for industrial gas production facilities supplying research institutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!