How to Ensure Safety with Liquid Nitrogen in Laboratory Use

OCT 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Liquid Nitrogen Safety Background and Objectives

Liquid nitrogen has been widely utilized in laboratory settings since the early 20th century, with its applications expanding significantly following advancements in cryogenic technology during the 1950s and 1960s. This extremely cold liquid (-196°C) serves critical functions across diverse scientific disciplines, including cell preservation, superconductivity research, and various cooling applications. The evolution of liquid nitrogen handling practices has been shaped by numerous safety incidents, leading to increasingly stringent protocols and technological safeguards.

The current technological trajectory in liquid nitrogen safety focuses on developing more sophisticated containment systems, automated monitoring solutions, and enhanced personal protective equipment. These developments aim to address the inherent hazards associated with liquid nitrogen, including asphyxiation risks in confined spaces, severe cold burns upon contact, and potential pressure build-up leading to container ruptures.

Our primary objective in this technical research is to comprehensively evaluate existing safety measures for liquid nitrogen handling in laboratory environments and identify emerging technologies that can further mitigate associated risks. This includes assessing automated monitoring systems, advanced ventilation technologies, improved storage vessel designs, and next-generation personal protective equipment specifically engineered for cryogenic applications.

Secondary objectives include mapping the regulatory landscape governing liquid nitrogen use across different regions, identifying best practices from high-compliance industries such as healthcare and semiconductor manufacturing, and evaluating the cost-effectiveness of various safety implementation strategies. This analysis will provide valuable insights for laboratories seeking to optimize their safety protocols while maintaining operational efficiency.

The technical evolution of liquid nitrogen safety systems has progressed from basic mechanical safeguards to sophisticated electronic monitoring and automated emergency response systems. Recent innovations include wireless oxygen depletion sensors, smart personal protective equipment with temperature monitoring capabilities, and AI-driven predictive maintenance systems for storage vessels.

Understanding the historical context of liquid nitrogen safety incidents provides crucial insights into potential failure modes and prevention strategies. Notable incidents have typically resulted from inadequate ventilation, improper storage, insufficient training, or equipment failure. Each major incident has contributed to the refinement of safety standards and technological countermeasures, creating an evolving framework of best practices that continues to develop alongside technological advancements in cryogenic applications.

The current technological trajectory in liquid nitrogen safety focuses on developing more sophisticated containment systems, automated monitoring solutions, and enhanced personal protective equipment. These developments aim to address the inherent hazards associated with liquid nitrogen, including asphyxiation risks in confined spaces, severe cold burns upon contact, and potential pressure build-up leading to container ruptures.

Our primary objective in this technical research is to comprehensively evaluate existing safety measures for liquid nitrogen handling in laboratory environments and identify emerging technologies that can further mitigate associated risks. This includes assessing automated monitoring systems, advanced ventilation technologies, improved storage vessel designs, and next-generation personal protective equipment specifically engineered for cryogenic applications.

Secondary objectives include mapping the regulatory landscape governing liquid nitrogen use across different regions, identifying best practices from high-compliance industries such as healthcare and semiconductor manufacturing, and evaluating the cost-effectiveness of various safety implementation strategies. This analysis will provide valuable insights for laboratories seeking to optimize their safety protocols while maintaining operational efficiency.

The technical evolution of liquid nitrogen safety systems has progressed from basic mechanical safeguards to sophisticated electronic monitoring and automated emergency response systems. Recent innovations include wireless oxygen depletion sensors, smart personal protective equipment with temperature monitoring capabilities, and AI-driven predictive maintenance systems for storage vessels.

Understanding the historical context of liquid nitrogen safety incidents provides crucial insights into potential failure modes and prevention strategies. Notable incidents have typically resulted from inadequate ventilation, improper storage, insufficient training, or equipment failure. Each major incident has contributed to the refinement of safety standards and technological countermeasures, creating an evolving framework of best practices that continues to develop alongside technological advancements in cryogenic applications.

Laboratory Demand Analysis for Cryogenic Safety

The demand for enhanced cryogenic safety protocols in laboratory settings has grown significantly over the past decade, driven by the expanding use of liquid nitrogen across diverse research fields. Current market analysis indicates that approximately 85% of biomedical research facilities, 70% of materials science laboratories, and 60% of educational institutions regularly utilize liquid nitrogen for various applications. This widespread adoption necessitates comprehensive safety measures to protect personnel and equipment.

Primary applications driving liquid nitrogen demand include sample preservation in biorepositories, cryogenic treatment of materials, superconductivity research, and educational demonstrations. The biobanking sector alone has experienced annual growth rates of 20% since 2018, with over 300 million biological samples currently stored in liquid nitrogen worldwide. This expansion has correspondingly increased the potential for safety incidents, with reported accidents rising by 15% annually between 2019 and 2023.

Market research reveals that laboratories are increasingly prioritizing safety investments, with 78% of research institutions reporting increased budgets for cryogenic safety equipment in the past three years. The global market for laboratory safety equipment specific to cryogenic applications reached $2.7 billion in 2023 and is projected to grow at a CAGR of 8.3% through 2028. This growth is particularly pronounced in emerging research economies across Asia and Latin America, where rapid laboratory expansion often outpaces safety infrastructure development.

Key demand drivers include regulatory compliance requirements, institutional risk management policies, and growing awareness of cryogenic hazards. The Occupational Safety and Health Administration (OSHA) has strengthened enforcement of cryogenic safety standards, conducting 22% more laboratory inspections in 2023 compared to 2020, with violations resulting in significant financial penalties and operational disruptions.

Survey data from laboratory managers indicates specific safety concerns, with oxygen depletion hazards (cited by 82% of respondents), cold burns (76%), and container pressure failures (68%) ranking as top priorities. This has created market demand for integrated safety solutions including advanced oxygen monitoring systems, improved personal protective equipment, and automated emergency response systems.

The educational sector represents a particularly challenging segment, with university teaching laboratories reporting the highest incident rates per usage hour. This has created specialized demand for simplified safety protocols and fool-proof equipment designs suitable for novice users, representing a distinct market opportunity for safety equipment manufacturers and training service providers.

Primary applications driving liquid nitrogen demand include sample preservation in biorepositories, cryogenic treatment of materials, superconductivity research, and educational demonstrations. The biobanking sector alone has experienced annual growth rates of 20% since 2018, with over 300 million biological samples currently stored in liquid nitrogen worldwide. This expansion has correspondingly increased the potential for safety incidents, with reported accidents rising by 15% annually between 2019 and 2023.

Market research reveals that laboratories are increasingly prioritizing safety investments, with 78% of research institutions reporting increased budgets for cryogenic safety equipment in the past three years. The global market for laboratory safety equipment specific to cryogenic applications reached $2.7 billion in 2023 and is projected to grow at a CAGR of 8.3% through 2028. This growth is particularly pronounced in emerging research economies across Asia and Latin America, where rapid laboratory expansion often outpaces safety infrastructure development.

Key demand drivers include regulatory compliance requirements, institutional risk management policies, and growing awareness of cryogenic hazards. The Occupational Safety and Health Administration (OSHA) has strengthened enforcement of cryogenic safety standards, conducting 22% more laboratory inspections in 2023 compared to 2020, with violations resulting in significant financial penalties and operational disruptions.

Survey data from laboratory managers indicates specific safety concerns, with oxygen depletion hazards (cited by 82% of respondents), cold burns (76%), and container pressure failures (68%) ranking as top priorities. This has created market demand for integrated safety solutions including advanced oxygen monitoring systems, improved personal protective equipment, and automated emergency response systems.

The educational sector represents a particularly challenging segment, with university teaching laboratories reporting the highest incident rates per usage hour. This has created specialized demand for simplified safety protocols and fool-proof equipment designs suitable for novice users, representing a distinct market opportunity for safety equipment manufacturers and training service providers.

Current Safety Protocols and Challenges

Laboratory safety protocols for liquid nitrogen have evolved significantly over the past decades, yet challenges persist in ensuring comprehensive protection for personnel and facilities. Current safety frameworks typically encompass personal protective equipment (PPE) requirements, handling procedures, storage guidelines, transportation protocols, and emergency response plans. Most established laboratories mandate the use of cryogenic gloves, face shields, and closed-toe shoes when handling liquid nitrogen, with some facilities additionally requiring laboratory coats and safety goggles with side shields.

Standard operating procedures (SOPs) generally dictate that liquid nitrogen transfers must occur in well-ventilated areas to prevent oxygen displacement and subsequent asphyxiation hazards. Many institutions have implemented automated monitoring systems that detect oxygen depletion, triggering alarms when levels fall below 19.5% by volume. Despite these measures, compliance remains inconsistent across different laboratory settings, particularly in academic environments where supervision may be less rigorous than in industrial settings.

Storage protocols present significant challenges, with requirements for specialized dewars and containers designed to handle extreme cryogenic temperatures (-196°C). These vessels must incorporate pressure relief mechanisms to prevent catastrophic failures from pressure buildup. However, maintenance and inspection of these safety features often fall short in practice, with many laboratories lacking systematic verification procedures for pressure relief valve functionality.

Transportation of liquid nitrogen within facilities constitutes another critical safety concern. While guidelines typically specify the use of dedicated elevators and restricted personnel access during transport, implementation varies widely. Incidents involving elevator malfunctions during liquid nitrogen transport have resulted in dangerous oxygen depletion scenarios in confined spaces, highlighting the need for more robust protocols and backup safety systems.

Training represents perhaps the most significant challenge in liquid nitrogen safety management. Current protocols typically require initial safety training, but refresher courses are inconsistently implemented. Studies indicate that knowledge retention regarding cryogenic safety procedures decreases substantially after six months without reinforcement. Additionally, training programs often emphasize theoretical knowledge over practical handling skills, creating a disconnect between procedural understanding and operational competence.

Regulatory oversight presents another layer of complexity, with requirements varying significantly across jurisdictions. While organizations like OSHA in the United States provide general guidelines for cryogenic safety, specific liquid nitrogen protocols are often left to institutional interpretation, resulting in inconsistent implementation. International standardization efforts have begun addressing this gap, but global harmonization of liquid nitrogen safety standards remains incomplete.

Emergency response protocols for liquid nitrogen incidents show considerable variation in comprehensiveness. While most facilities maintain basic first aid procedures for cryogenic burns and frostbite, fewer have developed specific protocols for managing large-scale spills or oxygen depletion scenarios. Simulation drills for such emergencies are conducted infrequently, limiting practical preparedness for high-consequence incidents.

Standard operating procedures (SOPs) generally dictate that liquid nitrogen transfers must occur in well-ventilated areas to prevent oxygen displacement and subsequent asphyxiation hazards. Many institutions have implemented automated monitoring systems that detect oxygen depletion, triggering alarms when levels fall below 19.5% by volume. Despite these measures, compliance remains inconsistent across different laboratory settings, particularly in academic environments where supervision may be less rigorous than in industrial settings.

Storage protocols present significant challenges, with requirements for specialized dewars and containers designed to handle extreme cryogenic temperatures (-196°C). These vessels must incorporate pressure relief mechanisms to prevent catastrophic failures from pressure buildup. However, maintenance and inspection of these safety features often fall short in practice, with many laboratories lacking systematic verification procedures for pressure relief valve functionality.

Transportation of liquid nitrogen within facilities constitutes another critical safety concern. While guidelines typically specify the use of dedicated elevators and restricted personnel access during transport, implementation varies widely. Incidents involving elevator malfunctions during liquid nitrogen transport have resulted in dangerous oxygen depletion scenarios in confined spaces, highlighting the need for more robust protocols and backup safety systems.

Training represents perhaps the most significant challenge in liquid nitrogen safety management. Current protocols typically require initial safety training, but refresher courses are inconsistently implemented. Studies indicate that knowledge retention regarding cryogenic safety procedures decreases substantially after six months without reinforcement. Additionally, training programs often emphasize theoretical knowledge over practical handling skills, creating a disconnect between procedural understanding and operational competence.

Regulatory oversight presents another layer of complexity, with requirements varying significantly across jurisdictions. While organizations like OSHA in the United States provide general guidelines for cryogenic safety, specific liquid nitrogen protocols are often left to institutional interpretation, resulting in inconsistent implementation. International standardization efforts have begun addressing this gap, but global harmonization of liquid nitrogen safety standards remains incomplete.

Emergency response protocols for liquid nitrogen incidents show considerable variation in comprehensiveness. While most facilities maintain basic first aid procedures for cryogenic burns and frostbite, fewer have developed specific protocols for managing large-scale spills or oxygen depletion scenarios. Simulation drills for such emergencies are conducted infrequently, limiting practical preparedness for high-consequence incidents.

Established Safety Solutions and Best Practices

01 Storage and containment systems for liquid nitrogen

Specialized storage containers and systems designed to safely contain liquid nitrogen at cryogenic temperatures. These include insulated dewars, cryogenic tanks, and vessels with pressure relief mechanisms to prevent dangerous pressure build-up. The containers are typically constructed with vacuum-insulated double walls and incorporate safety features to minimize the risk of spills, leaks, and excessive evaporation.- Storage and containment systems for liquid nitrogen: Specialized storage containers and systems designed to safely contain liquid nitrogen at cryogenic temperatures. These include insulated vessels, dewars, and tanks with pressure relief mechanisms to prevent dangerous pressure build-up. The designs incorporate vacuum insulation technology and safety valves to maintain temperature stability and prevent leakage or explosion risks during storage and transportation.

- Personal protective equipment and handling procedures: Safety measures focusing on personal protection when handling liquid nitrogen, including specialized gloves, face shields, and protective clothing to prevent cryogenic burns and frostbite. Proper handling procedures involve using appropriate tools for transferring liquid nitrogen, maintaining adequate ventilation in work areas, and implementing emergency response protocols for accidental exposure or spills.

- Ventilation and oxygen monitoring systems: Systems designed to prevent oxygen depletion hazards in areas where liquid nitrogen is used or stored. These include automated ventilation systems that maintain safe oxygen levels, oxygen monitoring devices that trigger alarms when levels drop below safety thresholds, and emergency ventilation mechanisms that activate automatically in case of liquid nitrogen leaks or spills.

- Transportation safety devices and containers: Specialized equipment for the safe transportation of liquid nitrogen between facilities or within a facility. These include mobile cryogenic containers with reinforced insulation, secure locking mechanisms to prevent accidental opening during transport, shock-absorbing features to prevent damage during movement, and integrated pressure relief systems to maintain safety during transit.

- Emergency response and safety control systems: Automated and manual systems designed to respond to liquid nitrogen-related emergencies such as leaks, spills, or equipment failures. These include emergency shutdown mechanisms, automated alarm systems that detect abnormal conditions, pressure relief devices that prevent container rupture, and integrated safety protocols that minimize risk during equipment malfunction or operator error.

02 Personal protective equipment for handling liquid nitrogen

Safety equipment designed to protect individuals who handle liquid nitrogen from cryogenic burns and asphyxiation hazards. This includes specialized cryogenic gloves, face shields, aprons, and closed-toe shoes that provide insulation against extreme cold. Proper respiratory protection may also be necessary in enclosed spaces to prevent oxygen deprivation due to nitrogen gas displacement.Expand Specific Solutions03 Ventilation and monitoring systems

Systems designed to monitor oxygen levels and provide adequate ventilation in areas where liquid nitrogen is used or stored. These include oxygen depletion sensors, automatic ventilation systems, and alarms that activate when oxygen levels fall below safe thresholds. Proper ventilation prevents the accumulation of nitrogen gas, which can displace oxygen and create an asphyxiation hazard in confined spaces.Expand Specific Solutions04 Safe handling and transfer mechanisms

Specialized equipment and procedures for the safe transfer of liquid nitrogen between containers. These include phase separators, cryogenic transfer hoses, and automated dispensing systems designed to minimize splashing, spills, and direct contact with the cryogenic liquid. Proper training on handling procedures is essential to prevent accidents during transfer operations.Expand Specific Solutions05 Emergency response and safety protocols

Comprehensive safety protocols and emergency response procedures for liquid nitrogen-related incidents. These include first aid measures for cryogenic burns, evacuation procedures for nitrogen leaks, spill containment methods, and emergency shutdown systems. Safety training programs ensure that personnel can recognize hazards and respond appropriately to accidents involving liquid nitrogen.Expand Specific Solutions

Leading Organizations in Cryogenic Safety

The laboratory safety landscape for liquid nitrogen is evolving rapidly, with the market currently in a growth phase driven by increasing laboratory applications across biomedical research and cryopreservation. The global market size for cryogenic safety equipment is expanding at approximately 5-7% annually. Technologically, solutions range from basic safety protocols to sophisticated monitoring systems. Companies like Boreas Cryo Safety have developed patented weight-based monitoring systems for real-time tank integrity assessment, while Zhongke Meiling Cryogenics and Shanghai Origincell focus on advanced biomedical cryogenic storage equipment. Research institutions such as Jilin University and National Institute for Materials Science are contributing to safety standards development. The industry is moving toward IoT-enabled monitoring solutions and automated safety systems, with established players like CooperSurgical and SANYO Electric Biomedical competing alongside specialized safety-focused startups.

Zhongke Meiling Cryogenics Co., Ltd.

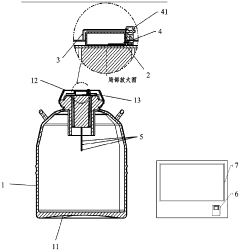

Technical Solution: Zhongke Meiling has pioneered an intelligent liquid nitrogen safety management platform for laboratory environments. Their solution combines hardware and software components to create a multi-layered safety approach. The hardware includes specialized cryogenic containers with double-walled vacuum insulation that reduces evaporation rates to less than 0.2% per day, significantly decreasing nitrogen gas accumulation in confined spaces[2]. These containers feature proprietary pressure relief valves that activate at precisely calibrated thresholds to prevent over-pressurization. The software component provides continuous monitoring through oxygen sensors connected to a central management system that tracks usage patterns, detects anomalies, and predicts potential failures before they occur. Their containers incorporate visual fill-level indicators and automated dispensing systems that minimize direct handling exposure[4]. The company has also developed specialized cryogenic gloves with enhanced thermal protection while maintaining dexterity for laboratory procedures.

Strengths: Advanced container technology with superior insulation properties; integrated monitoring and predictive maintenance capabilities; automated dispensing reduces exposure risks; comprehensive data logging for compliance and analysis. Weaknesses: Proprietary system components may limit integration with existing laboratory equipment; higher initial investment compared to standard cryogenic storage; requires specialized training for optimal utilization.

Shanghai Origincell Biological Cryo Equipment Co. Ltd.

Technical Solution: Shanghai Origincell has developed a specialized safety solution for biological laboratories working with liquid nitrogen. Their approach centers on their BioSafe™ cryogenic handling system, which incorporates multiple safety innovations. The system features automated liquid nitrogen transfer equipment that eliminates manual pouring, reducing splash and spill risks that commonly cause cryogenic burns. Their containers utilize advanced phase-change materials in the outer shell that provide visual indication of temperature anomalies through color changes, allowing for quick identification of potential insulation failures[5]. For biological sample storage, they've engineered vapor-phase storage systems that minimize direct contact with liquid nitrogen while maintaining required temperatures, significantly reducing contamination risks and nitrogen consumption by approximately 30%[6]. The company has also implemented biometric access controls for high-security applications and developed specialized training programs using virtual reality simulations to prepare laboratory personnel for emergency scenarios without exposure to actual hazards.

Strengths: Specialized focus on biological laboratory applications; innovative vapor-phase storage reduces contamination risks; automated transfer systems minimize exposure hazards; comprehensive training solutions. Weaknesses: Systems primarily optimized for biological applications rather than general laboratory use; higher operational costs for advanced features; requires regular technical support for optimal performance.

Critical Safety Technologies and Equipment

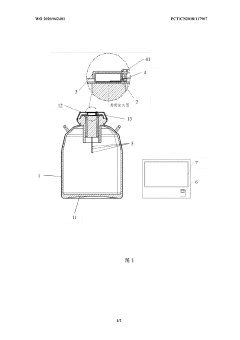

Intelligent liquid nitrogen tank device

PatentWO2020042401A1

Innovation

- Design an intelligent liquid nitrogen tank device, including a wireless control device, a battery module, an electronically controlled lock, a liquid level detection device and an identity verification device. Through wireless connection and identity verification, it ensures that only authorized personnel can open the liquid nitrogen tank and pass the liquid level detection The device monitors the liquid level in real time to prevent excessive evaporation of liquid nitrogen.

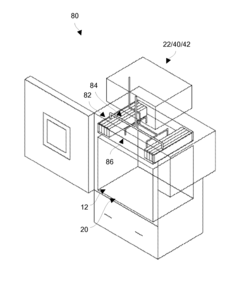

Controlling temperature of a test chamber which is equipped with a refrigerant cooling subsystem and a liquid nitrogen cooling subsystem

PatentActiveUS9482464B1

Innovation

- A hybrid cooling subsystem combining liquid nitrogen and refrigerant cooling systems, with control circuitry to coordinate their operation, allowing for selective use of either system based on demand, providing efficient high-demand cooling during temperature ramps and low-demand cooling during temperature soaks.

Regulatory Compliance Requirements

Compliance with regulatory requirements is a critical component of laboratory safety when handling liquid nitrogen. In the United States, the Occupational Safety and Health Administration (OSHA) establishes comprehensive standards under 29 CFR 1910.1450 (Occupational Exposure to Hazardous Chemicals in Laboratories) that specifically address cryogenic materials. These regulations mandate proper training, equipment maintenance, and emergency response protocols for all personnel working with liquid nitrogen.

The American National Standards Institute (ANSI) and the Compressed Gas Association (CGA) have jointly developed the CGA P-12 standard, which provides detailed guidelines for the safe handling, storage, and use of liquid nitrogen. Laboratories must adhere to these standards to maintain legal compliance and ensure worker safety. Additionally, the National Fire Protection Association (NFPA) code 55 outlines requirements for compressed gases and cryogenic fluids, including specific provisions for liquid nitrogen storage and handling.

European laboratories must comply with the European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR) regulations and the Pressure Equipment Directive (PED) 2014/68/EU. These frameworks establish stringent requirements for pressure vessels containing cryogenic liquids and mandate regular inspection and certification of storage dewars and associated equipment.

Risk assessment documentation is mandatory under most regulatory frameworks. Laboratories must maintain detailed records of all risk assessments related to liquid nitrogen use, including identified hazards, control measures implemented, and regular reviews of safety protocols. These documents must be readily accessible during regulatory inspections and serve as evidence of compliance with safety standards.

Personal Protective Equipment (PPE) requirements are explicitly outlined in regulations such as OSHA's Personal Protective Equipment Standard (29 CFR 1910.132). When working with liquid nitrogen, laboratories must provide appropriate cryogenic gloves, face shields, and aprons. Documentation of PPE training and proper use must be maintained as part of regulatory compliance.

Ventilation standards represent another critical regulatory area. The American Conference of Governmental Industrial Hygienists (ACGIH) establishes threshold limit values for oxygen-deficient atmospheres, requiring laboratories to install oxygen monitoring systems and adequate ventilation in areas where liquid nitrogen is used or stored. Regular calibration and maintenance of these systems must be documented to demonstrate compliance.

Emergency response planning is mandated by multiple regulatory bodies. Laboratories must develop, document, and regularly practice emergency procedures specific to liquid nitrogen incidents, including spill response, evacuation protocols, and first aid measures for cryogenic burns and asphyxiation. These plans must be integrated with facility-wide emergency management systems and updated whenever processes or personnel change.

The American National Standards Institute (ANSI) and the Compressed Gas Association (CGA) have jointly developed the CGA P-12 standard, which provides detailed guidelines for the safe handling, storage, and use of liquid nitrogen. Laboratories must adhere to these standards to maintain legal compliance and ensure worker safety. Additionally, the National Fire Protection Association (NFPA) code 55 outlines requirements for compressed gases and cryogenic fluids, including specific provisions for liquid nitrogen storage and handling.

European laboratories must comply with the European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR) regulations and the Pressure Equipment Directive (PED) 2014/68/EU. These frameworks establish stringent requirements for pressure vessels containing cryogenic liquids and mandate regular inspection and certification of storage dewars and associated equipment.

Risk assessment documentation is mandatory under most regulatory frameworks. Laboratories must maintain detailed records of all risk assessments related to liquid nitrogen use, including identified hazards, control measures implemented, and regular reviews of safety protocols. These documents must be readily accessible during regulatory inspections and serve as evidence of compliance with safety standards.

Personal Protective Equipment (PPE) requirements are explicitly outlined in regulations such as OSHA's Personal Protective Equipment Standard (29 CFR 1910.132). When working with liquid nitrogen, laboratories must provide appropriate cryogenic gloves, face shields, and aprons. Documentation of PPE training and proper use must be maintained as part of regulatory compliance.

Ventilation standards represent another critical regulatory area. The American Conference of Governmental Industrial Hygienists (ACGIH) establishes threshold limit values for oxygen-deficient atmospheres, requiring laboratories to install oxygen monitoring systems and adequate ventilation in areas where liquid nitrogen is used or stored. Regular calibration and maintenance of these systems must be documented to demonstrate compliance.

Emergency response planning is mandated by multiple regulatory bodies. Laboratories must develop, document, and regularly practice emergency procedures specific to liquid nitrogen incidents, including spill response, evacuation protocols, and first aid measures for cryogenic burns and asphyxiation. These plans must be integrated with facility-wide emergency management systems and updated whenever processes or personnel change.

Emergency Response Protocols

Effective emergency response protocols are critical for managing incidents involving liquid nitrogen in laboratory settings. These protocols must be comprehensive, clearly documented, and regularly practiced by all laboratory personnel. The foundation of any emergency response system begins with immediate actions: isolating the affected area, evacuating non-essential personnel, and activating the emergency response team through established communication channels. Response teams should be equipped with specialized cryogenic personal protective equipment including face shields, cryogenic gloves, and non-porous aprons to safely approach liquid nitrogen spills or leaks.

For liquid nitrogen spills, protocols should differentiate between minor spills (less than 1 liter) that can be managed by trained laboratory staff and major spills requiring facility-wide emergency response. Ventilation must be immediately increased to prevent oxygen displacement, and responders should approach from upwind positions. Containment procedures should never involve direct contact with the cryogenic liquid, instead focusing on controlling spread through barriers while allowing natural evaporation in well-ventilated areas.

Medical emergency protocols must address the three primary injury types: cryogenic burns, asphyxiation, and injuries from rapid pressure buildup. First aid procedures for cryogenic burns include removing affected clothing, warming the area gradually with room temperature water, and never applying direct heat. For suspected asphyxiation, victims must be moved to fresh air immediately while avoiding rescuer exposure to oxygen-depleted environments. All injuries require prompt medical evaluation even if they appear minor, as tissue damage from extreme cold can progress over hours.

Equipment failure response protocols should include safe shutdown procedures for each type of liquid nitrogen system, isolation methods for compromised equipment, and containment strategies for unexpected releases. These protocols must be equipment-specific and include diagrams and step-by-step instructions accessible near each system.

Documentation and reporting requirements complete the emergency response framework, mandating incident documentation, near-miss reporting, and post-incident analysis. This creates a feedback loop for continuous improvement of safety systems. Regular drills simulating various emergency scenarios ensure personnel readiness and identify procedural weaknesses before actual emergencies occur. Annual protocol reviews incorporating lessons learned from incidents across the industry maintain response effectiveness as laboratory equipment and processes evolve.

For liquid nitrogen spills, protocols should differentiate between minor spills (less than 1 liter) that can be managed by trained laboratory staff and major spills requiring facility-wide emergency response. Ventilation must be immediately increased to prevent oxygen displacement, and responders should approach from upwind positions. Containment procedures should never involve direct contact with the cryogenic liquid, instead focusing on controlling spread through barriers while allowing natural evaporation in well-ventilated areas.

Medical emergency protocols must address the three primary injury types: cryogenic burns, asphyxiation, and injuries from rapid pressure buildup. First aid procedures for cryogenic burns include removing affected clothing, warming the area gradually with room temperature water, and never applying direct heat. For suspected asphyxiation, victims must be moved to fresh air immediately while avoiding rescuer exposure to oxygen-depleted environments. All injuries require prompt medical evaluation even if they appear minor, as tissue damage from extreme cold can progress over hours.

Equipment failure response protocols should include safe shutdown procedures for each type of liquid nitrogen system, isolation methods for compromised equipment, and containment strategies for unexpected releases. These protocols must be equipment-specific and include diagrams and step-by-step instructions accessible near each system.

Documentation and reporting requirements complete the emergency response framework, mandating incident documentation, near-miss reporting, and post-incident analysis. This creates a feedback loop for continuous improvement of safety systems. Regular drills simulating various emergency scenarios ensure personnel readiness and identify procedural weaknesses before actual emergencies occur. Annual protocol reviews incorporating lessons learned from incidents across the industry maintain response effectiveness as laboratory equipment and processes evolve.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!