Comparing Liquid Nitrogen vs Helium for Cryogenic Applications

OCT 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Cooling Evolution and Objectives

Cryogenic cooling technologies have evolved significantly since the early 20th century, transforming from laboratory curiosities to essential components in numerous scientific and industrial applications. The journey began with the liquefaction of gases, a breakthrough achievement that opened doors to exploring matter at extremely low temperatures. In 1908, Heike Kamerlingh Onnes first liquefied helium at 4.2K, following earlier successes with nitrogen liquefaction at 77K. These milestones established the foundation for modern cryogenic applications.

The evolution of cryogenic cooling technologies accelerated during the mid-20th century, driven by aerospace developments and the growing semiconductor industry. The 1950s and 1960s witnessed significant advancements in insulation techniques, storage vessels, and transfer systems, making cryogenic fluids more practical for industrial use. Liquid nitrogen emerged as a cost-effective solution for many applications, while liquid helium remained essential for achieving temperatures below 4.2K.

Recent decades have seen remarkable progress in cryogenic engineering, with innovations in materials science enabling more efficient and compact cooling systems. Superconducting technologies, quantum computing, and advanced medical imaging have created new demands for reliable cryogenic cooling solutions. The development of pulse tube refrigerators, adiabatic demagnetization refrigerators, and dilution refrigerators has expanded the toolkit available to scientists and engineers working at ultra-low temperatures.

The primary objective of modern cryogenic cooling research is to develop more energy-efficient, reliable, and accessible systems. For applications requiring moderate cryogenic temperatures (above 63K), liquid nitrogen has become the preferred coolant due to its abundance, lower cost, and relative ease of handling. For ultra-low temperature applications (below 4.2K), liquid helium remains indispensable despite its scarcity and higher cost.

A critical goal in the field is addressing the growing helium shortage by developing alternative cooling technologies or improving helium recovery and recycling systems. Researchers are exploring nitrogen-based systems with mechanical refrigeration to extend their temperature range downward, potentially replacing helium in some applications. Additionally, there is significant interest in developing closed-cycle refrigeration systems that minimize cryogen consumption.

The comparison between liquid nitrogen and liquid helium represents a fundamental consideration in cryogenic engineering, with each fluid offering distinct advantages and limitations. Understanding their respective properties, handling requirements, and cooling capabilities is essential for designing optimal systems across diverse applications ranging from medical MRI machines to particle accelerators and quantum computers.

The evolution of cryogenic cooling technologies accelerated during the mid-20th century, driven by aerospace developments and the growing semiconductor industry. The 1950s and 1960s witnessed significant advancements in insulation techniques, storage vessels, and transfer systems, making cryogenic fluids more practical for industrial use. Liquid nitrogen emerged as a cost-effective solution for many applications, while liquid helium remained essential for achieving temperatures below 4.2K.

Recent decades have seen remarkable progress in cryogenic engineering, with innovations in materials science enabling more efficient and compact cooling systems. Superconducting technologies, quantum computing, and advanced medical imaging have created new demands for reliable cryogenic cooling solutions. The development of pulse tube refrigerators, adiabatic demagnetization refrigerators, and dilution refrigerators has expanded the toolkit available to scientists and engineers working at ultra-low temperatures.

The primary objective of modern cryogenic cooling research is to develop more energy-efficient, reliable, and accessible systems. For applications requiring moderate cryogenic temperatures (above 63K), liquid nitrogen has become the preferred coolant due to its abundance, lower cost, and relative ease of handling. For ultra-low temperature applications (below 4.2K), liquid helium remains indispensable despite its scarcity and higher cost.

A critical goal in the field is addressing the growing helium shortage by developing alternative cooling technologies or improving helium recovery and recycling systems. Researchers are exploring nitrogen-based systems with mechanical refrigeration to extend their temperature range downward, potentially replacing helium in some applications. Additionally, there is significant interest in developing closed-cycle refrigeration systems that minimize cryogen consumption.

The comparison between liquid nitrogen and liquid helium represents a fundamental consideration in cryogenic engineering, with each fluid offering distinct advantages and limitations. Understanding their respective properties, handling requirements, and cooling capabilities is essential for designing optimal systems across diverse applications ranging from medical MRI machines to particle accelerators and quantum computers.

Market Analysis of Cryogenic Fluid Demand

The global cryogenic fluid market has been experiencing robust growth, driven primarily by expanding applications in healthcare, metallurgy, electronics, and energy sectors. The market was valued at approximately 16.5 billion USD in 2020 and is projected to reach 26.8 billion USD by 2027, growing at a CAGR of 7.2% during the forecast period. This growth trajectory reflects the increasing industrial demand for efficient cooling solutions across various high-tech applications.

Liquid nitrogen dominates the market share, accounting for roughly 65% of the total cryogenic fluid consumption globally. Its widespread adoption stems from its relative affordability, with prices ranging from $0.10 to $0.50 per liter depending on volume and region, compared to liquid helium which can cost between $15 to $30 per liter. The healthcare sector remains the largest consumer of liquid nitrogen, utilizing it for cryopreservation of biological samples, cryosurgery, and dermatological treatments.

Liquid helium, despite its significantly higher cost, maintains a critical position in specialized markets due to its unparalleled cooling capabilities, reaching temperatures as low as 4.2 Kelvin. The demand for liquid helium is particularly strong in advanced research facilities, MRI manufacturing, and quantum computing development. However, the market faces supply constraints due to limited natural sources and extraction challenges, with the United States, Qatar, and Algeria being the primary producers.

Regional analysis reveals that North America currently leads the cryogenic fluid market with approximately 35% market share, followed by Europe (28%) and Asia-Pacific (25%). The Asia-Pacific region, particularly China and India, is expected to witness the fastest growth rate of 9.1% annually through 2027, driven by rapid industrialization and healthcare infrastructure development.

The semiconductor industry represents an emerging demand driver for both cryogenic fluids, with annual consumption increasing by 12% as manufacturers adopt advanced cooling technologies for next-generation chips. Similarly, the quantum computing sector is projected to increase its helium consumption by 18% annually over the next five years, potentially straining the already limited global helium supply.

Supply chain dynamics reveal significant vulnerabilities, particularly for helium, where geopolitical factors and production limitations have caused price volatility of up to 30% in recent years. This has prompted research into helium recycling systems, which can recover up to 95% of used helium in closed-loop applications, potentially alleviating supply pressures in specialized industries.

Liquid nitrogen dominates the market share, accounting for roughly 65% of the total cryogenic fluid consumption globally. Its widespread adoption stems from its relative affordability, with prices ranging from $0.10 to $0.50 per liter depending on volume and region, compared to liquid helium which can cost between $15 to $30 per liter. The healthcare sector remains the largest consumer of liquid nitrogen, utilizing it for cryopreservation of biological samples, cryosurgery, and dermatological treatments.

Liquid helium, despite its significantly higher cost, maintains a critical position in specialized markets due to its unparalleled cooling capabilities, reaching temperatures as low as 4.2 Kelvin. The demand for liquid helium is particularly strong in advanced research facilities, MRI manufacturing, and quantum computing development. However, the market faces supply constraints due to limited natural sources and extraction challenges, with the United States, Qatar, and Algeria being the primary producers.

Regional analysis reveals that North America currently leads the cryogenic fluid market with approximately 35% market share, followed by Europe (28%) and Asia-Pacific (25%). The Asia-Pacific region, particularly China and India, is expected to witness the fastest growth rate of 9.1% annually through 2027, driven by rapid industrialization and healthcare infrastructure development.

The semiconductor industry represents an emerging demand driver for both cryogenic fluids, with annual consumption increasing by 12% as manufacturers adopt advanced cooling technologies for next-generation chips. Similarly, the quantum computing sector is projected to increase its helium consumption by 18% annually over the next five years, potentially straining the already limited global helium supply.

Supply chain dynamics reveal significant vulnerabilities, particularly for helium, where geopolitical factors and production limitations have caused price volatility of up to 30% in recent years. This has prompted research into helium recycling systems, which can recover up to 95% of used helium in closed-loop applications, potentially alleviating supply pressures in specialized industries.

Current Challenges in Cryogenic Technology

Despite significant advancements in cryogenic technology, the field continues to face substantial challenges that limit broader application and efficiency. The most pressing issue remains the high cost associated with cryogenic fluids, particularly liquid helium, which has seen price volatility due to supply constraints and increasing demand from quantum computing and medical imaging sectors. Liquid nitrogen, while more affordable, cannot reach the ultra-low temperatures required for certain applications, creating a technological gap in the mid-range temperature requirements.

Energy efficiency presents another significant hurdle, as maintaining cryogenic temperatures requires substantial energy input. Current systems experience considerable thermal losses during operation, with estimates suggesting that conventional cryocoolers operate at only 10-15% of Carnot efficiency. This inefficiency translates directly into higher operational costs and environmental impact, limiting the sustainability of cryogenic applications.

Material limitations further complicate cryogenic technology advancement. Standard materials become brittle at extremely low temperatures, while specialized cryogenic materials significantly increase system costs. The search for cost-effective materials that maintain structural integrity and thermal properties at cryogenic temperatures remains an active research area with limited breakthrough solutions.

Storage and transport infrastructure poses additional challenges, particularly for liquid helium which requires specialized dewars with sophisticated multi-layer insulation systems. Boil-off rates during transport can reach 1-2% per day for helium compared to 0.5-1% for nitrogen, representing significant product loss and economic inefficiency. The lack of standardized distribution networks for helium further exacerbates accessibility issues for many potential users.

Safety concerns persist across cryogenic applications, with asphyxiation risks in confined spaces and potential pressure build-up in closed systems requiring sophisticated venting mechanisms. While liquid nitrogen systems have benefited from decades of industrial safety protocols, the handling of liquid helium demands more specialized training and equipment, creating barriers to adoption in less specialized settings.

Measurement and control systems at cryogenic temperatures present unique challenges, as conventional sensors often fail or provide inaccurate readings at extreme cold. The development of reliable, precise instrumentation capable of functioning at temperatures approaching absolute zero remains an active research area with significant room for improvement, particularly for applications requiring temperature stability within millikelvin ranges.

Addressing these interconnected challenges requires interdisciplinary approaches combining materials science, thermodynamics, and engineering innovations to develop next-generation cryogenic systems that balance performance requirements with practical considerations of cost, efficiency, and accessibility.

Energy efficiency presents another significant hurdle, as maintaining cryogenic temperatures requires substantial energy input. Current systems experience considerable thermal losses during operation, with estimates suggesting that conventional cryocoolers operate at only 10-15% of Carnot efficiency. This inefficiency translates directly into higher operational costs and environmental impact, limiting the sustainability of cryogenic applications.

Material limitations further complicate cryogenic technology advancement. Standard materials become brittle at extremely low temperatures, while specialized cryogenic materials significantly increase system costs. The search for cost-effective materials that maintain structural integrity and thermal properties at cryogenic temperatures remains an active research area with limited breakthrough solutions.

Storage and transport infrastructure poses additional challenges, particularly for liquid helium which requires specialized dewars with sophisticated multi-layer insulation systems. Boil-off rates during transport can reach 1-2% per day for helium compared to 0.5-1% for nitrogen, representing significant product loss and economic inefficiency. The lack of standardized distribution networks for helium further exacerbates accessibility issues for many potential users.

Safety concerns persist across cryogenic applications, with asphyxiation risks in confined spaces and potential pressure build-up in closed systems requiring sophisticated venting mechanisms. While liquid nitrogen systems have benefited from decades of industrial safety protocols, the handling of liquid helium demands more specialized training and equipment, creating barriers to adoption in less specialized settings.

Measurement and control systems at cryogenic temperatures present unique challenges, as conventional sensors often fail or provide inaccurate readings at extreme cold. The development of reliable, precise instrumentation capable of functioning at temperatures approaching absolute zero remains an active research area with significant room for improvement, particularly for applications requiring temperature stability within millikelvin ranges.

Addressing these interconnected challenges requires interdisciplinary approaches combining materials science, thermodynamics, and engineering innovations to develop next-generation cryogenic systems that balance performance requirements with practical considerations of cost, efficiency, and accessibility.

Technical Comparison of N2 vs He Cooling Solutions

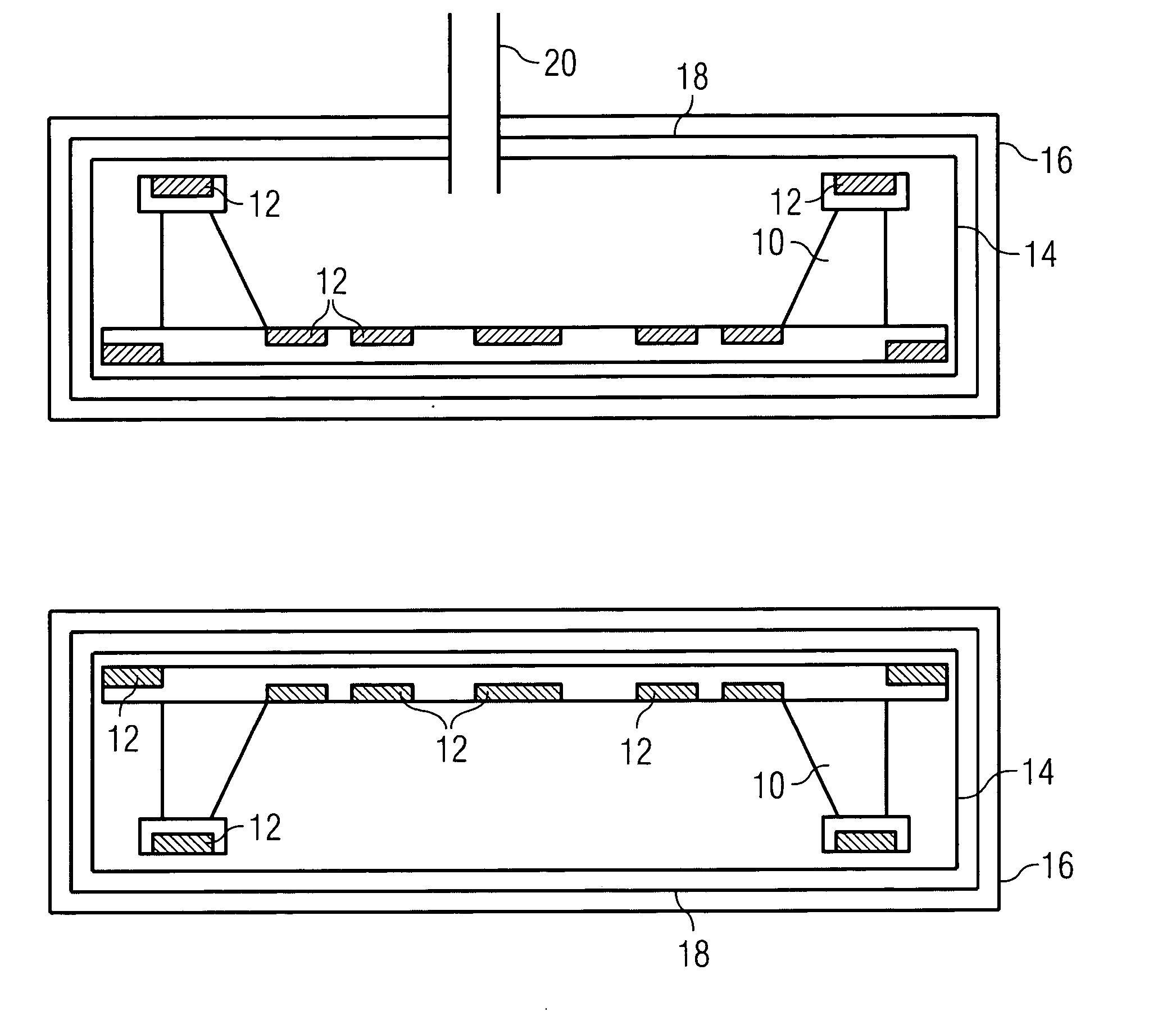

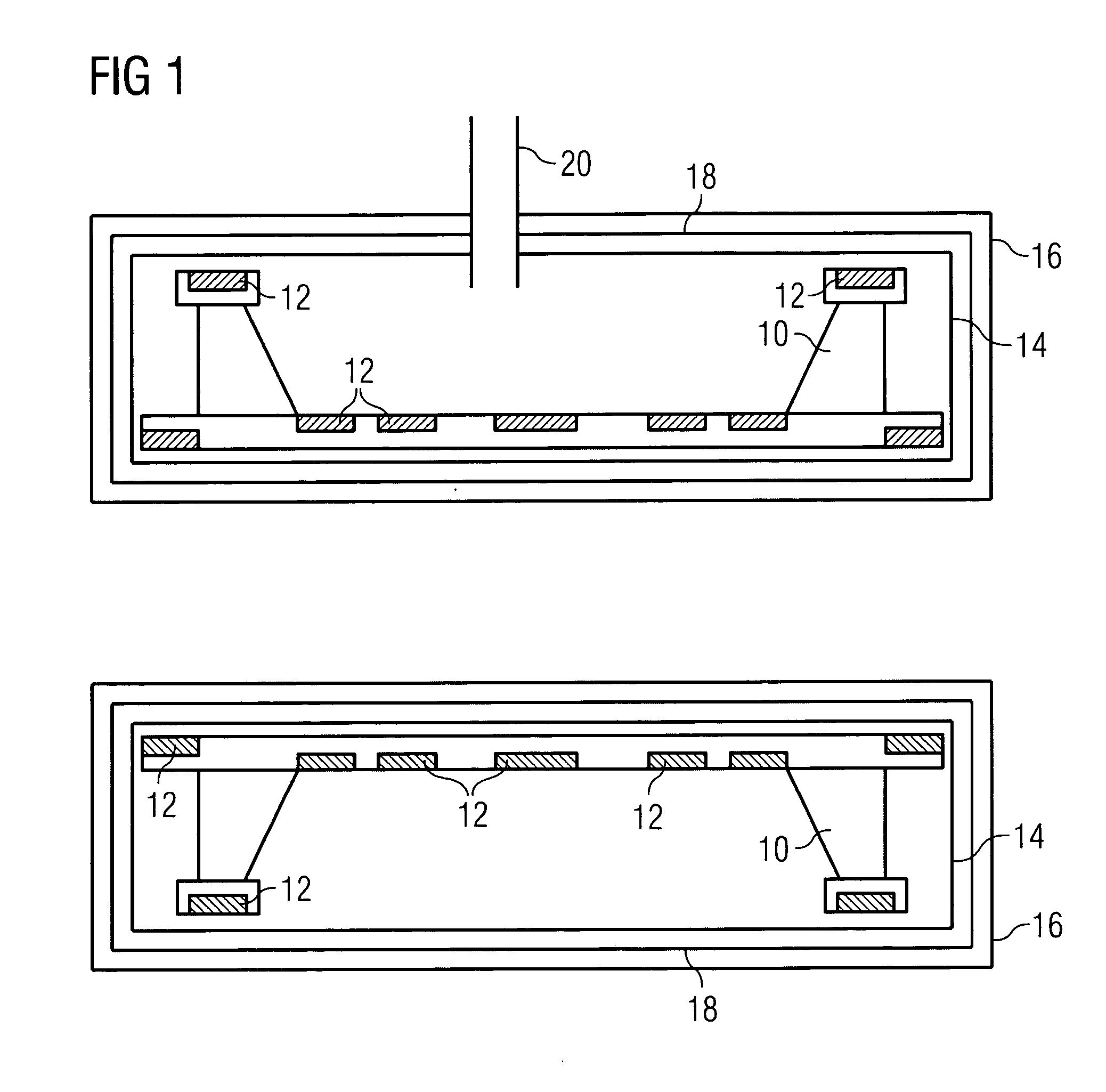

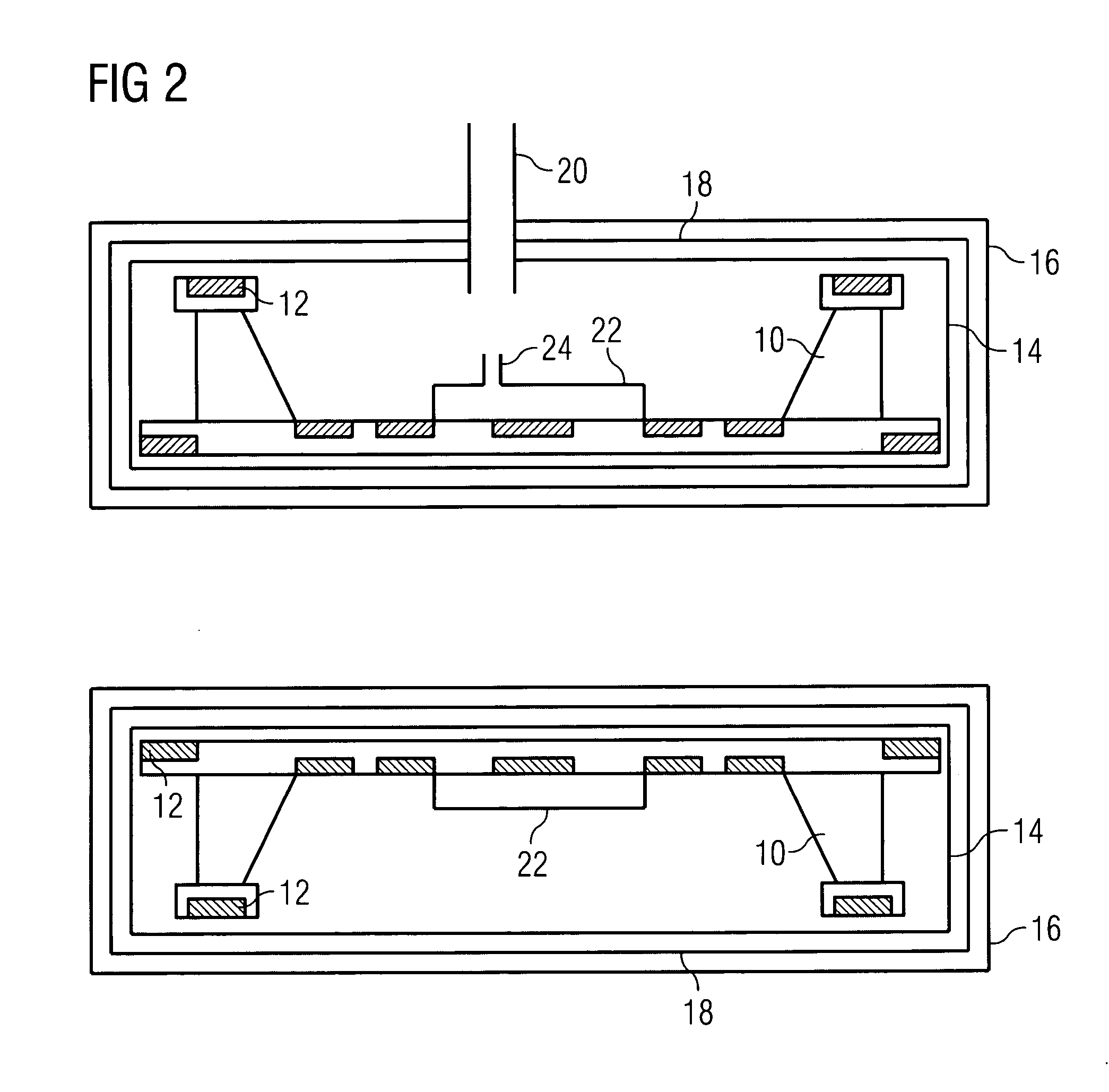

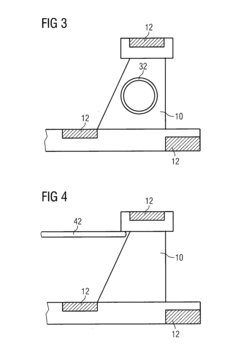

01 Cryogenic storage and transport systems

Specialized systems for storing and transporting liquid nitrogen and liquid helium at extremely low temperatures. These systems typically include vacuum-insulated vessels, specialized valves, and thermal management components to minimize heat transfer and maintain the cryogenic state. The designs focus on preventing evaporation losses and ensuring safety during handling of these ultra-cold liquids.- Cryogenic storage and transport systems: Systems designed for the efficient storage and transport of liquid nitrogen and liquid helium. These systems typically include specialized containers with vacuum insulation to minimize heat transfer and evaporation of the cryogenic liquids. The designs incorporate features to maintain extremely low temperatures required for these liquids, with liquid nitrogen at -196°C and liquid helium at -269°C, and often include pressure relief mechanisms to prevent dangerous pressure buildup.

- Cooling and refrigeration applications: Applications utilizing liquid nitrogen and liquid helium as cooling agents in various scientific and industrial processes. These cryogenic fluids are employed in superconducting systems, medical equipment, and laboratory research where ultra-low temperatures are required. The cooling systems often involve heat exchangers, circulation mechanisms, and temperature control systems to maintain precise thermal conditions for sensitive equipment or materials.

- Production and liquefaction methods: Methods and apparatus for producing and liquefying nitrogen and helium gases. These processes typically involve compression, purification, and cooling stages to transform gases into their liquid states. Advanced techniques may include multi-stage cooling cycles, specialized heat exchangers, and energy recovery systems to improve efficiency. The liquefaction processes are designed to handle the significant temperature differences between ambient conditions and the cryogenic states of these elements.

- Safety and handling equipment: Specialized equipment and systems designed for the safe handling and use of liquid nitrogen and liquid helium. These include protective gear, automated dispensing systems, monitoring devices for oxygen levels, and emergency response equipment. Safety features often address the risks of asphyxiation, cold burns, and pressure buildup associated with cryogenic liquids. The equipment is designed to minimize direct contact with these extremely cold substances and prevent accidents during transfer operations.

- Specialized applications in scientific research: Advanced applications of liquid nitrogen and liquid helium in scientific research, particularly in fields requiring extremely low temperatures. These include quantum computing, particle physics experiments, superconductivity research, and materials science. The cryogenic environments created by these liquids enable the study of quantum phenomena, the operation of sensitive detection equipment, and the testing of materials under extreme conditions. Specialized apparatus is designed to maintain stable cryogenic conditions while allowing for experimental access and measurement.

02 Cooling applications in scientific instruments

Liquid nitrogen and liquid helium are used as cooling agents in scientific instruments such as superconducting magnets, particle accelerators, and quantum computing systems. These cryogenic fluids enable the operation of sensitive equipment at temperatures approaching absolute zero, which is essential for certain physical phenomena like superconductivity to occur.Expand Specific Solutions03 Recondensation and recycling systems

Technologies for recapturing and recycling evaporated helium and nitrogen gases back into their liquid states. These systems are designed to improve efficiency and reduce operational costs, particularly important for liquid helium which is a limited and expensive resource. The recondensation process typically involves compression, cooling, and liquefaction stages to return the gases to their cryogenic liquid form.Expand Specific Solutions04 Cryogenic cooling for medical and biological applications

Applications of liquid nitrogen and liquid helium in medical and biological fields, including cryosurgery, cryopreservation of biological samples, and cooling of medical imaging equipment such as MRI machines. These applications leverage the extreme cold temperatures to preserve tissues, destroy abnormal cells, or enable superconducting magnets to function in diagnostic equipment.Expand Specific Solutions05 Safety and monitoring systems for cryogenic liquids

Specialized safety systems designed to monitor and manage the risks associated with handling liquid nitrogen and liquid helium. These include oxygen level monitors, pressure relief systems, temperature sensors, and automated emergency response mechanisms. The systems are critical for preventing accidents related to asphyxiation, pressure buildup, or rapid expansion that can occur when these cryogenic liquids evaporate.Expand Specific Solutions

Leading Companies in Cryogenic Industry

The cryogenic applications market is in a growth phase, with liquid nitrogen and helium technologies competing across various industrial sectors. The global market is expanding rapidly, driven by increasing demand in healthcare, electronics, and energy sectors. Technologically, liquid nitrogen solutions have reached maturity with widespread adoption, while helium-based systems represent a more specialized, premium segment due to helium's scarcity. Leading players include industrial gas giants like Linde GmbH and Air Liquide SA, who dominate commercial applications, alongside specialized equipment manufacturers such as Chart Inc. and Cosmodyne LLC. Research institutions like Technical Institute of Physics & Chemistry CAS and Commonwealth Scientific & Industrial Research Organisation are advancing next-generation cryogenic technologies, while companies like CSIC Pride Cryogenic Technology focus on specialized ultra-low temperature applications where helium maintains critical advantages despite supply challenges.

LINDA AG

Technical Solution: Linde has developed comprehensive cryogenic solutions comparing liquid nitrogen (LN2) and liquid helium (LHe) for various applications. Their technology focuses on optimized cryogenic systems that leverage the distinct properties of both cryogens. For LN2 applications (77K), Linde has engineered efficient closed-loop nitrogen liquefaction systems with recovery rates exceeding 95%, significantly reducing operational costs. For helium applications (4.2K), they've pioneered helium recapture and purification technology that achieves 99% recovery rates, addressing helium's scarcity and high cost. Their comparative analysis shows LN2 systems require approximately 20 times less energy than equivalent helium systems, though helium provides access to significantly lower temperatures necessary for certain superconducting and quantum applications.

Strengths: Industry-leading helium recovery systems addressing resource scarcity; integrated supply chain control from production to delivery; proprietary heat exchanger technology reducing energy consumption by up to 30% compared to conventional systems. Weaknesses: Higher initial capital investment for helium systems; dependence on limited global helium reserves; complex infrastructure requirements for helium liquefaction.

Air Liquide SA

Technical Solution: Air Liquide has developed advanced cryogenic solutions comparing liquid nitrogen and helium applications through their Turbo-Brayton technology. This system enables efficient cooling at both nitrogen (77K) and helium (4.2K) temperatures with significantly improved energy efficiency. For nitrogen applications, their closed-cycle refrigeration systems achieve power consumption reductions of approximately 40% compared to traditional methods. Their helium conservation technology addresses the critical global helium shortage by implementing a closed-loop recovery system that recaptures over 98% of helium used in cryogenic applications. Air Liquide's comparative analysis demonstrates that while nitrogen systems offer cost advantages for applications above 63K, their helium systems provide unmatched performance for ultra-low temperature requirements, with proprietary pulse-tube cryocoolers achieving temperatures below 2K with minimal vibration for sensitive scientific instruments.

Strengths: Proprietary helium purification technology maintaining 99.999% purity levels; integrated global supply chain ensuring reliable access to both cryogens; advanced energy recovery systems reducing operational costs by up to 35%. Weaknesses: High capital expenditure requirements for helium infrastructure; complex maintenance procedures for ultra-low temperature systems; vulnerability to global helium supply constraints.

Critical Patents in Cryogenic Fluid Applications

Method and apparatus for maintaining a system at cryogenic temperatures over an extended period without active refrigeration

PatentActiveUS20060288731A1

Innovation

- A secondary cryogen, such as solid nitrogen, is used in thermal connection with the system to act as a thermal battery, absorbing latent heat during phase changes and extending the cooling period without consuming excessive working cryogens, allowing for reduced cryogen volumes and costs.

Superconducting quantum interference device

PatentInactiveEP1547167A1

Innovation

- The use of a flexible superconducting substrate, such as Hastelloy or Ceraflex tape, to form non-planar pick-up loops that can detect magnetic fields in multiple orientations, coupled with a SQUID magnetometer via a flux transformer, allowing for improved detection of magnetic fields and gradients while reducing noise from homogeneous fields through appropriate inductance matching and substrate deformation to position loops in orthogonal planes.

Supply Chain and Resource Availability

The global supply chain for cryogenic fluids presents significant differences between liquid nitrogen and helium, with implications for availability, cost, and reliability in various applications. Liquid nitrogen benefits from abundant atmospheric sourcing, comprising approximately 78% of Earth's atmosphere, allowing for widespread production facilities globally. This widespread availability translates to robust supply chains with multiple redundancies and relatively stable pricing structures, even during periods of industrial disruption.

In contrast, helium exists as a finite resource primarily extracted as a byproduct of natural gas processing from specific geological formations. The global helium supply chain is concentrated in a limited number of locations, with the United States, Qatar, Algeria, and Russia controlling approximately 80% of production capacity. This geographical concentration creates inherent vulnerabilities in the supply chain, exposing users to geopolitical risks and market volatility.

Production infrastructure requirements further differentiate these cryogens. Nitrogen liquefaction plants can be scaled efficiently and established in most industrial regions, requiring relatively modest capital investment. Helium production facilities, however, require proximity to specific natural gas fields with sufficient helium concentration (typically >0.3%) and substantial purification infrastructure, resulting in fewer global production points and higher capital barriers to entry.

Transportation logistics present another critical distinction. Liquid nitrogen's higher boiling point (-196°C) allows for more economical storage and transportation solutions with lower boil-off rates. Specialized but widely available cryogenic tankers and storage vessels suffice for nitrogen distribution networks. Helium's extremely low boiling point (-269°C) necessitates sophisticated transportation systems with advanced insulation technologies and often requires conversion to gas phase for long-distance transport, followed by re-liquefaction at destination facilities.

Resource sustainability trends indicate divergent futures for these cryogens. Nitrogen supply remains essentially unlimited with production constrained only by energy costs and infrastructure capacity. Helium, however, faces increasing supply constraints with some experts projecting potential shortages within the next two decades as known reserves deplete and consumption increases. This scarcity risk has prompted development of helium recycling systems and conservation protocols in research and industrial applications, adding operational complexity but becoming increasingly necessary for long-term viability.

In contrast, helium exists as a finite resource primarily extracted as a byproduct of natural gas processing from specific geological formations. The global helium supply chain is concentrated in a limited number of locations, with the United States, Qatar, Algeria, and Russia controlling approximately 80% of production capacity. This geographical concentration creates inherent vulnerabilities in the supply chain, exposing users to geopolitical risks and market volatility.

Production infrastructure requirements further differentiate these cryogens. Nitrogen liquefaction plants can be scaled efficiently and established in most industrial regions, requiring relatively modest capital investment. Helium production facilities, however, require proximity to specific natural gas fields with sufficient helium concentration (typically >0.3%) and substantial purification infrastructure, resulting in fewer global production points and higher capital barriers to entry.

Transportation logistics present another critical distinction. Liquid nitrogen's higher boiling point (-196°C) allows for more economical storage and transportation solutions with lower boil-off rates. Specialized but widely available cryogenic tankers and storage vessels suffice for nitrogen distribution networks. Helium's extremely low boiling point (-269°C) necessitates sophisticated transportation systems with advanced insulation technologies and often requires conversion to gas phase for long-distance transport, followed by re-liquefaction at destination facilities.

Resource sustainability trends indicate divergent futures for these cryogens. Nitrogen supply remains essentially unlimited with production constrained only by energy costs and infrastructure capacity. Helium, however, faces increasing supply constraints with some experts projecting potential shortages within the next two decades as known reserves deplete and consumption increases. This scarcity risk has prompted development of helium recycling systems and conservation protocols in research and industrial applications, adding operational complexity but becoming increasingly necessary for long-term viability.

Environmental Impact and Sustainability Considerations

The environmental impact of cryogenic fluids represents a critical consideration in their industrial application. Liquid nitrogen, produced through air separation, demonstrates a significantly lower environmental footprint compared to helium. The production process for liquid nitrogen primarily consumes electricity, with modern air separation units achieving increasing efficiency levels. When sourced from renewable energy, nitrogen production can approach carbon neutrality, making it an increasingly sustainable option for cryogenic applications.

Helium, conversely, presents substantial environmental challenges. As a finite resource extracted primarily from natural gas wells, helium production is intrinsically linked to fossil fuel extraction processes. The environmental impact extends beyond carbon emissions to include land disturbance, potential groundwater contamination, and methane leakage associated with extraction operations. Furthermore, helium's scarcity raises serious sustainability concerns, with global reserves projected to face critical depletion within the coming decades.

Recovery and recycling capabilities represent another significant environmental differentiator between these cryogenic fluids. Nitrogen, when released, simply returns to the atmosphere (which is 78% nitrogen naturally) with negligible environmental impact. Helium, however, once released, escapes Earth's atmosphere permanently due to its extremely low molecular weight. This irreversible loss necessitates sophisticated and often energy-intensive recovery systems in applications where helium is used.

The transportation footprint also favors nitrogen from a sustainability perspective. Liquid nitrogen can be produced locally in most industrial regions, minimizing transportation emissions. Helium, concentrated in few global locations, requires extensive transportation networks, often involving energy-intensive liquefaction, specialized containers, and long-distance shipping that contributes to its overall carbon footprint.

Regulatory frameworks increasingly reflect these environmental considerations. Many jurisdictions have implemented or are developing policies that incentivize the use of more sustainable cryogenic options. Carbon pricing mechanisms, environmental impact assessments, and sustainability reporting requirements are progressively influencing industrial choices between nitrogen and helium. Organizations seeking to reduce their environmental footprint are increasingly factoring these regulatory trends into their cryogenic technology decisions.

Looking forward, technological innovations in cryogenic efficiency may further alter the environmental calculus. Advances in insulation technology, energy recovery systems, and closed-loop cryogenic processes could potentially reduce the environmental impact of both fluids, though nitrogen is likely to maintain its fundamental sustainability advantage due to its abundance and renewable production potential.

Helium, conversely, presents substantial environmental challenges. As a finite resource extracted primarily from natural gas wells, helium production is intrinsically linked to fossil fuel extraction processes. The environmental impact extends beyond carbon emissions to include land disturbance, potential groundwater contamination, and methane leakage associated with extraction operations. Furthermore, helium's scarcity raises serious sustainability concerns, with global reserves projected to face critical depletion within the coming decades.

Recovery and recycling capabilities represent another significant environmental differentiator between these cryogenic fluids. Nitrogen, when released, simply returns to the atmosphere (which is 78% nitrogen naturally) with negligible environmental impact. Helium, however, once released, escapes Earth's atmosphere permanently due to its extremely low molecular weight. This irreversible loss necessitates sophisticated and often energy-intensive recovery systems in applications where helium is used.

The transportation footprint also favors nitrogen from a sustainability perspective. Liquid nitrogen can be produced locally in most industrial regions, minimizing transportation emissions. Helium, concentrated in few global locations, requires extensive transportation networks, often involving energy-intensive liquefaction, specialized containers, and long-distance shipping that contributes to its overall carbon footprint.

Regulatory frameworks increasingly reflect these environmental considerations. Many jurisdictions have implemented or are developing policies that incentivize the use of more sustainable cryogenic options. Carbon pricing mechanisms, environmental impact assessments, and sustainability reporting requirements are progressively influencing industrial choices between nitrogen and helium. Organizations seeking to reduce their environmental footprint are increasingly factoring these regulatory trends into their cryogenic technology decisions.

Looking forward, technological innovations in cryogenic efficiency may further alter the environmental calculus. Advances in insulation technology, energy recovery systems, and closed-loop cryogenic processes could potentially reduce the environmental impact of both fluids, though nitrogen is likely to maintain its fundamental sustainability advantage due to its abundance and renewable production potential.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!