How to Improve Thermal Management in Lasers with Liquid Nitrogen

OCT 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laser Thermal Management Background and Objectives

Laser technology has evolved significantly since its inception in the 1960s, with applications spanning from telecommunications to manufacturing, medicine, and scientific research. Throughout this evolution, thermal management has remained a critical challenge limiting laser performance, efficiency, and reliability. Heat generation during laser operation is inevitable due to quantum defects, non-radiative transitions, and absorption losses. Without effective thermal management, lasers experience beam quality degradation, wavelength drift, reduced output power, and shortened operational lifetimes.

The progression of laser thermal management techniques has moved from passive cooling methods to more sophisticated active cooling systems. Early approaches relied primarily on conductive heat sinks and forced air cooling, which proved inadequate for high-power applications. Water cooling subsequently became the industry standard for many systems, offering improved heat transfer capabilities while maintaining operational simplicity.

Recent technological advancements have pushed laser systems toward higher power densities and more compact designs, creating unprecedented thermal challenges that conventional cooling methods struggle to address. This has driven interest in cryogenic cooling solutions, particularly liquid nitrogen-based systems, which offer significant advantages due to nitrogen's excellent thermal properties at its boiling point of 77K.

The primary objective of this technical research is to comprehensively evaluate the potential of liquid nitrogen cooling systems to overcome current thermal management limitations in high-performance laser systems. Specifically, we aim to investigate how liquid nitrogen cooling can enhance beam quality stability, increase maximum operational power, extend device lifetime, and improve overall system efficiency compared to conventional cooling methods.

Secondary objectives include identifying the optimal design configurations for liquid nitrogen cooling systems in various laser architectures, assessing the practical implementation challenges including safety considerations, and evaluating the economic viability of such systems in commercial applications. The research will also explore hybrid cooling approaches that combine liquid nitrogen with other thermal management techniques to optimize performance across different operational regimes.

The technological trajectory suggests that as laser applications continue to demand higher powers and better beam qualities, advanced thermal management solutions will become increasingly critical. Liquid nitrogen cooling represents a promising frontier in this domain, potentially enabling next-generation laser capabilities that are currently unattainable with conventional cooling methods. This research aims to establish a clear understanding of both the theoretical limits and practical implementation pathways for liquid nitrogen-based thermal management in laser systems.

The progression of laser thermal management techniques has moved from passive cooling methods to more sophisticated active cooling systems. Early approaches relied primarily on conductive heat sinks and forced air cooling, which proved inadequate for high-power applications. Water cooling subsequently became the industry standard for many systems, offering improved heat transfer capabilities while maintaining operational simplicity.

Recent technological advancements have pushed laser systems toward higher power densities and more compact designs, creating unprecedented thermal challenges that conventional cooling methods struggle to address. This has driven interest in cryogenic cooling solutions, particularly liquid nitrogen-based systems, which offer significant advantages due to nitrogen's excellent thermal properties at its boiling point of 77K.

The primary objective of this technical research is to comprehensively evaluate the potential of liquid nitrogen cooling systems to overcome current thermal management limitations in high-performance laser systems. Specifically, we aim to investigate how liquid nitrogen cooling can enhance beam quality stability, increase maximum operational power, extend device lifetime, and improve overall system efficiency compared to conventional cooling methods.

Secondary objectives include identifying the optimal design configurations for liquid nitrogen cooling systems in various laser architectures, assessing the practical implementation challenges including safety considerations, and evaluating the economic viability of such systems in commercial applications. The research will also explore hybrid cooling approaches that combine liquid nitrogen with other thermal management techniques to optimize performance across different operational regimes.

The technological trajectory suggests that as laser applications continue to demand higher powers and better beam qualities, advanced thermal management solutions will become increasingly critical. Liquid nitrogen cooling represents a promising frontier in this domain, potentially enabling next-generation laser capabilities that are currently unattainable with conventional cooling methods. This research aims to establish a clear understanding of both the theoretical limits and practical implementation pathways for liquid nitrogen-based thermal management in laser systems.

Market Demand for Advanced Laser Cooling Solutions

The global market for advanced laser cooling solutions is experiencing robust growth, driven primarily by increasing applications of high-power lasers across multiple industries. The demand for liquid nitrogen cooling systems specifically has seen a compound annual growth rate exceeding 7% since 2019, with the market value projected to reach $3.2 billion by 2027. This growth trajectory reflects the critical need for more efficient thermal management solutions in laser systems.

Industrial manufacturing represents the largest market segment, accounting for approximately 42% of the total demand. In this sector, high-power laser cutting, welding, and additive manufacturing processes require precise temperature control to maintain beam quality and extend operational lifetimes. The automotive and aerospace industries have emerged as particularly aggressive adopters, implementing liquid nitrogen cooling systems to enhance precision manufacturing capabilities.

Medical applications constitute the fastest-growing segment, with demand increasing at nearly 9% annually. Surgical lasers, dermatological treatments, and ophthalmological procedures all benefit from the superior cooling capacity of liquid nitrogen systems. Healthcare providers increasingly recognize that advanced cooling solutions directly correlate with improved patient outcomes and reduced procedural complications.

Research institutions and scientific laboratories form another significant market segment, representing approximately 18% of current demand. These organizations require ultra-stable laser environments for quantum computing research, spectroscopy, and materials science applications. The demand from this sector is characterized by requirements for extremely precise temperature control, often at cryogenic levels.

Geographically, North America leads the market with a 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region demonstrates the highest growth rate, driven by rapid industrialization in China, South Korea, and India. These countries are investing heavily in advanced manufacturing capabilities that rely on high-power laser systems.

End-users consistently express demand for five key performance attributes: improved energy efficiency, reduced system footprint, lower operational costs, enhanced reliability, and simplified maintenance requirements. Market research indicates that customers are willing to pay premium prices for cooling solutions that deliver measurable improvements in laser performance metrics, including beam stability, power output consistency, and operational duty cycles.

The market also shows increasing interest in integrated solutions that combine liquid nitrogen cooling with comprehensive thermal management systems, including real-time monitoring, predictive maintenance capabilities, and automated temperature regulation. This trend reflects the broader industry movement toward smart manufacturing and Industry 4.0 principles, where thermal management becomes part of a connected production ecosystem.

Industrial manufacturing represents the largest market segment, accounting for approximately 42% of the total demand. In this sector, high-power laser cutting, welding, and additive manufacturing processes require precise temperature control to maintain beam quality and extend operational lifetimes. The automotive and aerospace industries have emerged as particularly aggressive adopters, implementing liquid nitrogen cooling systems to enhance precision manufacturing capabilities.

Medical applications constitute the fastest-growing segment, with demand increasing at nearly 9% annually. Surgical lasers, dermatological treatments, and ophthalmological procedures all benefit from the superior cooling capacity of liquid nitrogen systems. Healthcare providers increasingly recognize that advanced cooling solutions directly correlate with improved patient outcomes and reduced procedural complications.

Research institutions and scientific laboratories form another significant market segment, representing approximately 18% of current demand. These organizations require ultra-stable laser environments for quantum computing research, spectroscopy, and materials science applications. The demand from this sector is characterized by requirements for extremely precise temperature control, often at cryogenic levels.

Geographically, North America leads the market with a 38% share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region demonstrates the highest growth rate, driven by rapid industrialization in China, South Korea, and India. These countries are investing heavily in advanced manufacturing capabilities that rely on high-power laser systems.

End-users consistently express demand for five key performance attributes: improved energy efficiency, reduced system footprint, lower operational costs, enhanced reliability, and simplified maintenance requirements. Market research indicates that customers are willing to pay premium prices for cooling solutions that deliver measurable improvements in laser performance metrics, including beam stability, power output consistency, and operational duty cycles.

The market also shows increasing interest in integrated solutions that combine liquid nitrogen cooling with comprehensive thermal management systems, including real-time monitoring, predictive maintenance capabilities, and automated temperature regulation. This trend reflects the broader industry movement toward smart manufacturing and Industry 4.0 principles, where thermal management becomes part of a connected production ecosystem.

Current Challenges in Laser Thermal Management

Laser systems face significant thermal management challenges that limit their performance, efficiency, and reliability. Heat generation during laser operation occurs through multiple mechanisms, including quantum defect heating, non-radiative decay, and absorption losses. These thermal loads can cause beam quality degradation, wavelength drift, reduced output power, and in severe cases, catastrophic optical damage to laser components.

Conventional cooling methods such as forced air convection and water cooling systems have proven inadequate for high-power laser applications. Air cooling suffers from low heat transfer coefficients and limited capacity to remove concentrated heat loads. Water cooling offers improved thermal conductivity but introduces concerns regarding electrical safety, corrosion, and maintenance complexity. Additionally, microchannel coolers, while effective, often face clogging issues and flow distribution challenges.

Temperature gradients within laser gain media represent another critical challenge. These gradients induce thermal lensing effects, stress-induced birefringence, and mechanical distortions that significantly impact beam quality and pointing stability. For semiconductor lasers, temperature sensitivity manifests as threshold current increases and slope efficiency decreases, typically following exponential relationships with temperature.

Material limitations further complicate thermal management efforts. Many optical materials exhibit poor thermal conductivity, limiting heat dissipation capabilities. Thermal expansion mismatches between different components create mechanical stress during temperature cycling, potentially leading to alignment issues or component failure. Interface thermal resistance at material boundaries also creates bottlenecks for efficient heat transfer.

High-power laser systems face additional challenges related to cooling system integration. The physical size constraints of cooling apparatus often conflict with optical design requirements. Vibrations from cooling systems can introduce mechanical instabilities affecting beam quality and alignment precision. Furthermore, the power consumption of active cooling systems represents a significant operational overhead, reducing overall system efficiency.

Cryogenic cooling approaches, particularly using liquid nitrogen, present their own implementation challenges. These include managing the complexity of cryogenic delivery systems, addressing thermal cycling stresses during cooldown and warmup cycles, and ensuring proper thermal isolation to prevent condensation on optical surfaces. The cost and availability of cryogens also present logistical challenges for continuous operation in various deployment scenarios.

Emerging applications in mobile platforms, aerospace, and defense sectors impose additional constraints on thermal management solutions, demanding systems that are compact, lightweight, and capable of operating in variable environmental conditions while maintaining precise temperature control.

Conventional cooling methods such as forced air convection and water cooling systems have proven inadequate for high-power laser applications. Air cooling suffers from low heat transfer coefficients and limited capacity to remove concentrated heat loads. Water cooling offers improved thermal conductivity but introduces concerns regarding electrical safety, corrosion, and maintenance complexity. Additionally, microchannel coolers, while effective, often face clogging issues and flow distribution challenges.

Temperature gradients within laser gain media represent another critical challenge. These gradients induce thermal lensing effects, stress-induced birefringence, and mechanical distortions that significantly impact beam quality and pointing stability. For semiconductor lasers, temperature sensitivity manifests as threshold current increases and slope efficiency decreases, typically following exponential relationships with temperature.

Material limitations further complicate thermal management efforts. Many optical materials exhibit poor thermal conductivity, limiting heat dissipation capabilities. Thermal expansion mismatches between different components create mechanical stress during temperature cycling, potentially leading to alignment issues or component failure. Interface thermal resistance at material boundaries also creates bottlenecks for efficient heat transfer.

High-power laser systems face additional challenges related to cooling system integration. The physical size constraints of cooling apparatus often conflict with optical design requirements. Vibrations from cooling systems can introduce mechanical instabilities affecting beam quality and alignment precision. Furthermore, the power consumption of active cooling systems represents a significant operational overhead, reducing overall system efficiency.

Cryogenic cooling approaches, particularly using liquid nitrogen, present their own implementation challenges. These include managing the complexity of cryogenic delivery systems, addressing thermal cycling stresses during cooldown and warmup cycles, and ensuring proper thermal isolation to prevent condensation on optical surfaces. The cost and availability of cryogens also present logistical challenges for continuous operation in various deployment scenarios.

Emerging applications in mobile platforms, aerospace, and defense sectors impose additional constraints on thermal management solutions, demanding systems that are compact, lightweight, and capable of operating in variable environmental conditions while maintaining precise temperature control.

Liquid Nitrogen Cooling Systems and Implementation

01 Direct liquid nitrogen cooling systems for lasers

Direct liquid nitrogen cooling systems involve the circulation of liquid nitrogen through channels or chambers in direct contact with laser components. This method provides efficient heat removal by utilizing the low temperature of liquid nitrogen to absorb heat generated during laser operation. The direct cooling approach enables rapid temperature reduction and maintains stable operating conditions for high-power laser systems, preventing thermal damage and ensuring consistent beam quality.- Direct liquid nitrogen cooling systems for lasers: Direct cooling systems utilize liquid nitrogen in direct contact with laser components to efficiently dissipate heat. These systems typically involve circulation of liquid nitrogen through channels or chambers surrounding the laser medium or other heat-generating components. This approach provides rapid and efficient cooling, maintaining optimal operating temperatures for high-power laser systems and preventing thermal damage to sensitive components.

- Cryogenic cooling for semiconductor and diode lasers: Specialized liquid nitrogen cooling systems designed specifically for semiconductor and diode lasers. These systems address the unique thermal management requirements of semiconductor laser devices, which are particularly sensitive to temperature fluctuations. Cryogenic cooling with liquid nitrogen significantly improves the performance, efficiency, and wavelength stability of these lasers while extending their operational lifetime by reducing thermal stress.

- Closed-loop liquid nitrogen circulation systems: Advanced closed-loop systems that continuously circulate and recycle liquid nitrogen for sustainable laser cooling. These systems incorporate sophisticated temperature control mechanisms, pressure regulation, and insulation to maintain consistent cooling performance while minimizing nitrogen consumption. The closed-loop design allows for extended operation periods without the need for frequent nitrogen replenishment, making them suitable for industrial and research applications requiring continuous operation.

- Hybrid cooling systems combining liquid nitrogen with other methods: Innovative hybrid cooling approaches that integrate liquid nitrogen cooling with other thermal management techniques such as thermoelectric cooling, heat pipes, or microchannel cooling. These hybrid systems leverage the advantages of multiple cooling methods to achieve optimal thermal performance across different operating conditions. The combination allows for more precise temperature control and can address varying cooling requirements of different laser components within the same system.

- Compact and portable liquid nitrogen cooling for mobile laser applications: Miniaturized and portable liquid nitrogen cooling systems designed for field deployable and mobile laser applications. These systems feature lightweight components, efficient insulation, and optimized nitrogen consumption to maintain cooling performance while minimizing size and weight. Special attention is given to safety features, ease of operation, and quick-connect interfaces to facilitate deployment in various environments outside of controlled laboratory settings.

02 Cryogenic cooling chambers and enclosures for laser systems

Specialized cryogenic chambers and enclosures are designed to contain laser components within a controlled low-temperature environment. These chambers may be vacuum-insulated to minimize heat transfer and maintain cryogenic temperatures efficiently. The enclosures can accommodate various laser configurations while providing thermal isolation from ambient conditions. This approach allows for comprehensive cooling of the entire laser assembly rather than just specific components, resulting in more uniform temperature distribution and enhanced overall system performance.Expand Specific Solutions03 Heat exchangers and thermal management interfaces for laser cooling

Advanced heat exchanger designs facilitate efficient thermal transfer between laser components and liquid nitrogen cooling systems. These interfaces may incorporate specialized materials with high thermal conductivity to maximize heat dissipation. Some designs feature multi-stage cooling arrangements that gradually reduce temperature to prevent thermal shock to sensitive components. The heat exchangers are engineered to maintain uniform cooling across laser elements, preventing hotspots and thermal gradients that could affect beam quality and system reliability.Expand Specific Solutions04 Automated temperature control and monitoring systems

Sophisticated control systems regulate liquid nitrogen flow and temperature to maintain optimal laser operating conditions. These systems incorporate temperature sensors, flow meters, and feedback loops to dynamically adjust cooling parameters based on real-time thermal load. Advanced monitoring capabilities provide early detection of potential cooling system failures or thermal anomalies. Some implementations include predictive algorithms that anticipate cooling needs based on laser duty cycles, optimizing nitrogen consumption while ensuring consistent thermal management.Expand Specific Solutions05 Integration of liquid nitrogen cooling with other thermal management techniques

Hybrid cooling approaches combine liquid nitrogen with other thermal management methods such as thermoelectric cooling, heat pipes, or secondary cooling loops. These integrated systems provide multi-stage temperature control, allowing for precise thermal management across different components with varying cooling requirements. The combination of techniques can optimize nitrogen consumption while maintaining critical components at cryogenic temperatures. Such hybrid approaches often offer redundancy in cooling capabilities, enhancing system reliability and providing fail-safe mechanisms for high-value laser applications.Expand Specific Solutions

Leading Companies in Laser Cooling Industry

The thermal management in lasers using liquid nitrogen is currently in a growth phase, with the market expanding due to increasing demand for high-power laser applications. The global market size is estimated to reach several billion dollars by 2025, driven by applications in manufacturing, healthcare, and defense sectors. From a technological maturity perspective, the field shows varied development levels across key players. Companies like Air Liquide, Linde Sverige, and Cryofocus Medtech have established significant expertise in cryogenic cooling systems, while research institutions such as Jiangsu University and Lawrence Livermore National Security are advancing fundamental innovations. Boeing, Northrop Grumman, and Snake Creek Lasers represent the industrial application segment, integrating liquid nitrogen cooling into high-performance laser systems for specialized applications.

Air Liquide SA

Technical Solution: Air Liquide has developed comprehensive liquid nitrogen thermal management solutions specifically designed for high-power laser systems. Their approach integrates industrial gas expertise with specialized cryogenic engineering for laser applications. The company offers custom-designed cryostats and flow systems that provide precise temperature control between 77K and 120K, optimized for different laser gain media requirements. Their technology includes advanced phase-separation systems that ensure consistent liquid-phase nitrogen delivery to critical components while minimizing pressure fluctuations that could affect cooling performance. Air Liquide has engineered specialized thermal interface materials that maintain excellent thermal conductivity at cryogenic temperatures while accommodating differential thermal expansion between components. Their systems incorporate sophisticated monitoring and control technologies that optimize nitrogen consumption while maintaining thermal stability. The company has also developed specialized insulation systems and heat exchangers that minimize thermal losses throughout the cooling circuit, improving overall system efficiency and reducing operating costs.

Strengths: Comprehensive end-to-end solutions including nitrogen supply infrastructure, extensive experience with industrial-scale cryogenic systems, and global service network for maintenance support. Weaknesses: Solutions often require significant facility modifications, systems can be oversized for smaller research applications, and may have higher initial capital costs than specialized smaller-scale solutions.

Wavelight Laser Technologies

Technical Solution: Wavelight Laser Technologies has developed a proprietary cryogenic cooling system for medical and industrial laser applications using liquid nitrogen. Their approach focuses on compact, efficient cooling for precision laser systems used in ophthalmology and dermatology. The technology employs a miniaturized closed-cycle liquid nitrogen circulation system with specialized micro-channel heat exchangers directly integrated with laser diode arrays. Their design incorporates vacuum-insulated transfer lines with minimal thermal mass to enable rapid temperature changes when needed. The system features advanced thermal interface materials specifically engineered for cryogenic applications that maintain excellent thermal conductivity while accommodating differential thermal expansion between components. Wavelight's solution includes a proprietary control system that monitors and adjusts cooling parameters in real-time, optimizing both cooling efficiency and laser performance parameters. The company has demonstrated significant improvements in beam quality, wavelength stability, and operational lifetime of their laser systems when operated under cryogenic conditions.

Strengths: Compact design suitable for medical environments, precise temperature control optimized for specific laser wavelengths, and improved beam quality for sensitive applications. Weaknesses: Higher operational costs compared to conventional cooling, requires periodic liquid nitrogen replenishment, and has limited scalability for very high-power applications.

Critical Patents in Cryogenic Laser Cooling

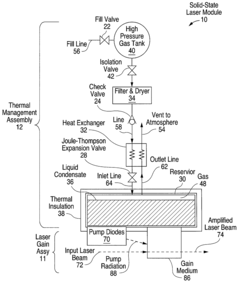

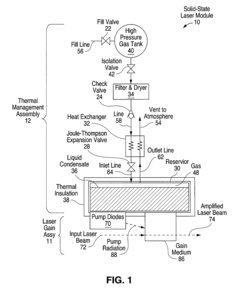

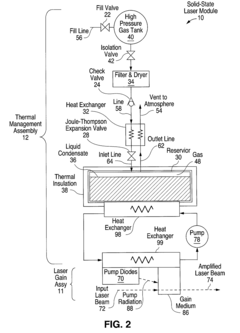

Laser thermal management systems and methods

PatentActiveUS7532652B2

Innovation

- A thermal management system utilizing a high-pressure gas tank connected to an open-cycle Joule-Thompson refrigerator, with a reservoir for condensing gas and venting evaporated gas, and incorporating photolithographically produced heat exchangers and gas mixtures like nitrogen, ethane, and propane to enhance refrigeration efficiency.

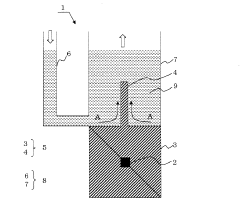

Solid-state laser apparatus

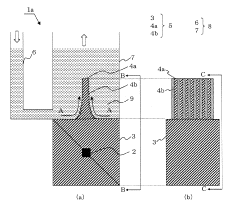

PatentInactiveJP2008218658A

Innovation

- The laser device employs a highly thermally conductive metal body with a large surface area in contact with liquid nitrogen, using a structure like a flat plate or wedge shape to prevent vortex formation, and incorporates a heat-dissipating metal protrusion into the cooling medium to enhance cooling efficiency.

Safety Protocols for Liquid Nitrogen Handling

Liquid nitrogen handling in laser thermal management systems requires rigorous safety protocols due to its extremely low temperature (-196°C) and associated hazards. All personnel involved must undergo comprehensive training covering cryogenic safety fundamentals, emergency procedures, and proper handling techniques before accessing liquid nitrogen facilities. Personal protective equipment is mandatory, including insulated gloves, face shields, closed-toe shoes, and laboratory coats to prevent cold burns and tissue damage from accidental exposure.

Storage considerations are critical for safe implementation. Liquid nitrogen must be stored in specialized Dewar flasks or cryogenic containers designed to withstand extreme temperatures and prevent rapid evaporation. These containers should never be completely sealed as nitrogen gas expansion can create dangerous pressure buildup. Storage areas require adequate ventilation systems capable of maintaining oxygen levels above 19.5% to prevent asphyxiation hazards, with oxygen monitoring systems installed to provide alerts when levels drop below safe thresholds.

Transportation protocols must be established for moving liquid nitrogen between storage and laser cooling systems. Dedicated carts with securing mechanisms prevent container tipping, while designated routes minimize exposure to personnel. Transfer operations represent particularly high-risk activities requiring specialized equipment such as phase separators and cryogenic transfer lines to minimize splashing and nitrogen boil-off.

Emergency response procedures must address potential incidents including cryogenic burns, oxygen depletion, and spills. First aid stations equipped with materials for treating cold burns should be readily accessible, while emergency ventilation systems must be capable of rapid air exchange. Clear evacuation routes and assembly points should be established and regularly practiced through emergency drills.

Regular system maintenance and inspection schedules are essential for preventing safety incidents. This includes routine checks of insulation integrity, valve functionality, and monitoring system calibration. Documentation of all safety procedures, training records, and incident reports supports continuous improvement of safety protocols and regulatory compliance.

Integration of these safety protocols with laser operation procedures ensures that thermal management benefits are achieved without compromising personnel safety. Automated monitoring systems can be implemented to track nitrogen levels, system temperatures, and oxygen concentration, with automated shutdowns triggered when parameters exceed safe operating ranges. These comprehensive safety measures enable the effective utilization of liquid nitrogen's superior cooling properties while maintaining a secure working environment.

Storage considerations are critical for safe implementation. Liquid nitrogen must be stored in specialized Dewar flasks or cryogenic containers designed to withstand extreme temperatures and prevent rapid evaporation. These containers should never be completely sealed as nitrogen gas expansion can create dangerous pressure buildup. Storage areas require adequate ventilation systems capable of maintaining oxygen levels above 19.5% to prevent asphyxiation hazards, with oxygen monitoring systems installed to provide alerts when levels drop below safe thresholds.

Transportation protocols must be established for moving liquid nitrogen between storage and laser cooling systems. Dedicated carts with securing mechanisms prevent container tipping, while designated routes minimize exposure to personnel. Transfer operations represent particularly high-risk activities requiring specialized equipment such as phase separators and cryogenic transfer lines to minimize splashing and nitrogen boil-off.

Emergency response procedures must address potential incidents including cryogenic burns, oxygen depletion, and spills. First aid stations equipped with materials for treating cold burns should be readily accessible, while emergency ventilation systems must be capable of rapid air exchange. Clear evacuation routes and assembly points should be established and regularly practiced through emergency drills.

Regular system maintenance and inspection schedules are essential for preventing safety incidents. This includes routine checks of insulation integrity, valve functionality, and monitoring system calibration. Documentation of all safety procedures, training records, and incident reports supports continuous improvement of safety protocols and regulatory compliance.

Integration of these safety protocols with laser operation procedures ensures that thermal management benefits are achieved without compromising personnel safety. Automated monitoring systems can be implemented to track nitrogen levels, system temperatures, and oxygen concentration, with automated shutdowns triggered when parameters exceed safe operating ranges. These comprehensive safety measures enable the effective utilization of liquid nitrogen's superior cooling properties while maintaining a secure working environment.

Energy Efficiency in Cryogenic Cooling Systems

Energy efficiency in cryogenic cooling systems represents a critical factor in the optimization of liquid nitrogen-based thermal management for laser applications. The fundamental challenge lies in balancing the exceptional cooling capabilities of liquid nitrogen against its energy-intensive production and maintenance requirements. Current cryogenic cooling systems typically operate at 15-30% efficiency, with significant energy losses occurring during the gas liquefaction process and through heat transfer inefficiencies.

Advanced insulation technologies have emerged as key contributors to energy efficiency improvements. Multi-layer vacuum insulation (MLVI) systems can reduce heat leakage by up to 85% compared to conventional methods, while aerogel-based solutions offer thermal conductivity values as low as 0.013 W/mK, significantly outperforming traditional materials. These advancements directly translate to reduced nitrogen boil-off rates and lower operational energy requirements.

Regenerative cooling cycles represent another frontier in efficiency optimization. By capturing and reusing the cooling potential of nitrogen as it transitions from liquid to gas phase, these systems can achieve energy recovery rates of 40-60%. The implementation of pulse tube refrigerators and Stirling cycle coolers further enhances this approach, with coefficient of performance (COP) values reaching 0.3-0.5 at cryogenic temperatures—a substantial improvement over earlier technologies.

Intelligent control systems have demonstrated potential for 15-25% energy savings through predictive load management and dynamic flow control. Machine learning algorithms that anticipate cooling demands based on laser operational patterns can optimize nitrogen delivery, while variable-speed cryopumps adjust to real-time requirements rather than operating at constant capacity. These adaptive systems minimize overcooling and reduce the energy footprint of the entire thermal management process.

Hybrid cooling architectures that strategically combine liquid nitrogen with thermoelectric or mechanical cooling stages have shown promise in laboratory settings. These integrated approaches leverage the strengths of each cooling method while mitigating their individual inefficiencies. For instance, using thermoelectric pre-cooling before liquid nitrogen stages can reduce overall nitrogen consumption by 20-30% while maintaining equivalent thermal performance at the laser interface.

The economic implications of these efficiency improvements are substantial, with potential operational cost reductions of 30-45% over system lifetimes. However, implementation challenges remain, including higher initial capital investments and the need for specialized expertise in system integration and maintenance. The development of standardized efficiency metrics and testing protocols will be essential for comparing different approaches and driving further innovation in this rapidly evolving field.

Advanced insulation technologies have emerged as key contributors to energy efficiency improvements. Multi-layer vacuum insulation (MLVI) systems can reduce heat leakage by up to 85% compared to conventional methods, while aerogel-based solutions offer thermal conductivity values as low as 0.013 W/mK, significantly outperforming traditional materials. These advancements directly translate to reduced nitrogen boil-off rates and lower operational energy requirements.

Regenerative cooling cycles represent another frontier in efficiency optimization. By capturing and reusing the cooling potential of nitrogen as it transitions from liquid to gas phase, these systems can achieve energy recovery rates of 40-60%. The implementation of pulse tube refrigerators and Stirling cycle coolers further enhances this approach, with coefficient of performance (COP) values reaching 0.3-0.5 at cryogenic temperatures—a substantial improvement over earlier technologies.

Intelligent control systems have demonstrated potential for 15-25% energy savings through predictive load management and dynamic flow control. Machine learning algorithms that anticipate cooling demands based on laser operational patterns can optimize nitrogen delivery, while variable-speed cryopumps adjust to real-time requirements rather than operating at constant capacity. These adaptive systems minimize overcooling and reduce the energy footprint of the entire thermal management process.

Hybrid cooling architectures that strategically combine liquid nitrogen with thermoelectric or mechanical cooling stages have shown promise in laboratory settings. These integrated approaches leverage the strengths of each cooling method while mitigating their individual inefficiencies. For instance, using thermoelectric pre-cooling before liquid nitrogen stages can reduce overall nitrogen consumption by 20-30% while maintaining equivalent thermal performance at the laser interface.

The economic implications of these efficiency improvements are substantial, with potential operational cost reductions of 30-45% over system lifetimes. However, implementation challenges remain, including higher initial capital investments and the need for specialized expertise in system integration and maintenance. The development of standardized efficiency metrics and testing protocols will be essential for comparing different approaches and driving further innovation in this rapidly evolving field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!