How to Improve Semiconductor Manufacturing with Liquid Nitrogen

OCT 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Semiconductor Cooling Technology Background and Objectives

Semiconductor manufacturing has evolved significantly since its inception in the 1960s, with cooling technology playing an increasingly critical role in the production process. The semiconductor industry has consistently pursued Moore's Law, doubling transistor density approximately every two years, which has led to increasingly complex thermal management challenges. As feature sizes have shrunk below 5nm, heat dissipation has become a fundamental limiting factor in both manufacturing precision and device performance.

Liquid nitrogen cooling technology emerged in the 1970s as a specialized solution for certain semiconductor applications, but has gained renewed attention as manufacturers push the boundaries of miniaturization and performance. With a boiling point of -196°C (77K), liquid nitrogen offers exceptional cooling capabilities that conventional refrigeration systems cannot match. The historical trajectory shows a clear trend toward more sophisticated temperature control systems as manufacturing tolerances have tightened.

The primary objective of implementing liquid nitrogen in semiconductor manufacturing is to achieve precise temperature control during critical fabrication processes. This includes photolithography, where thermal expansion can cause misalignment at nanometer scales, and etching processes where reaction rates are highly temperature-dependent. Additionally, liquid nitrogen cooling aims to reduce defect rates caused by thermal stress and improve overall yield rates in high-precision manufacturing environments.

Current cooling technologies in semiconductor fabrication primarily rely on chilled water systems, conventional refrigeration, and in some cases, helium-based cryogenic systems. However, these approaches face limitations in achieving ultra-low temperatures while maintaining temperature stability across large silicon wafers. The industry seeks solutions that can provide more uniform cooling, faster temperature transitions, and greater energy efficiency.

The technological evolution in this field is closely tied to advances in materials science, fluid dynamics, and thermal engineering. Recent innovations have focused on developing more efficient heat exchangers, advanced insulation materials, and precise flow control systems that can maintain temperature uniformity across 300mm and larger wafers during processing.

Looking forward, the semiconductor industry aims to develop cooling technologies that can support the next generation of manufacturing processes, including extreme ultraviolet lithography (EUV) and 3D chip stacking, which present even greater thermal management challenges. The goal is to establish cooling solutions that not only enable more advanced manufacturing processes but also contribute to sustainability objectives by reducing overall energy consumption in semiconductor fabrication facilities.

Liquid nitrogen cooling technology emerged in the 1970s as a specialized solution for certain semiconductor applications, but has gained renewed attention as manufacturers push the boundaries of miniaturization and performance. With a boiling point of -196°C (77K), liquid nitrogen offers exceptional cooling capabilities that conventional refrigeration systems cannot match. The historical trajectory shows a clear trend toward more sophisticated temperature control systems as manufacturing tolerances have tightened.

The primary objective of implementing liquid nitrogen in semiconductor manufacturing is to achieve precise temperature control during critical fabrication processes. This includes photolithography, where thermal expansion can cause misalignment at nanometer scales, and etching processes where reaction rates are highly temperature-dependent. Additionally, liquid nitrogen cooling aims to reduce defect rates caused by thermal stress and improve overall yield rates in high-precision manufacturing environments.

Current cooling technologies in semiconductor fabrication primarily rely on chilled water systems, conventional refrigeration, and in some cases, helium-based cryogenic systems. However, these approaches face limitations in achieving ultra-low temperatures while maintaining temperature stability across large silicon wafers. The industry seeks solutions that can provide more uniform cooling, faster temperature transitions, and greater energy efficiency.

The technological evolution in this field is closely tied to advances in materials science, fluid dynamics, and thermal engineering. Recent innovations have focused on developing more efficient heat exchangers, advanced insulation materials, and precise flow control systems that can maintain temperature uniformity across 300mm and larger wafers during processing.

Looking forward, the semiconductor industry aims to develop cooling technologies that can support the next generation of manufacturing processes, including extreme ultraviolet lithography (EUV) and 3D chip stacking, which present even greater thermal management challenges. The goal is to establish cooling solutions that not only enable more advanced manufacturing processes but also contribute to sustainability objectives by reducing overall energy consumption in semiconductor fabrication facilities.

Market Demand for Advanced Semiconductor Manufacturing Solutions

The semiconductor industry is experiencing unprecedented demand for advanced manufacturing solutions, driven by the relentless pursuit of Moore's Law and the expanding applications of semiconductor technology across industries. Market research indicates that the global semiconductor manufacturing equipment market is projected to reach $103.5 billion by 2025, growing at a CAGR of 8.2% from 2020. This growth is fueled by increasing investments in fabrication facilities and the continuous push toward smaller node sizes, which require more sophisticated manufacturing processes.

Liquid nitrogen-based cooling solutions represent a significant segment within this market, as thermal management becomes increasingly critical at advanced nodes. The demand for cryogenic cooling systems in semiconductor manufacturing is growing at approximately 9.7% annually, outpacing the overall equipment market growth rate.

Consumer electronics continue to be the primary driver of semiconductor demand, accounting for approximately 32% of the total market. However, emerging applications in automotive (particularly for electric vehicles and autonomous driving systems), artificial intelligence, and high-performance computing are rapidly expanding their market share, collectively representing about 28% of semiconductor demand and growing at double-digit rates annually.

The transition to 5nm, 3nm, and eventually 2nm process nodes is creating substantial demand for advanced cooling solutions that can maintain stable temperatures during increasingly complex manufacturing processes. Industry surveys indicate that 87% of semiconductor manufacturers consider thermal management as one of their top three technical challenges in scaling to next-generation nodes.

Geographically, East Asia dominates the market for semiconductor manufacturing equipment, with Taiwan, South Korea, and China accounting for over 65% of global demand. However, recent initiatives in the United States and European Union to strengthen domestic semiconductor manufacturing capabilities are expected to diversify this demand landscape over the next decade.

The industry's push toward more environmentally sustainable manufacturing processes is also influencing market demand. Liquid nitrogen cooling systems are increasingly valued not only for their technical performance but also for their potential to reduce overall energy consumption in semiconductor fabrication facilities by up to 15% compared to conventional cooling methods.

Customer requirements are evolving beyond pure performance metrics to include considerations of total cost of ownership, integration with existing systems, and adaptability to future process nodes. This shift is creating opportunities for solutions that can demonstrate long-term value through improved yield rates, reduced downtime, and extended equipment lifespan.

Liquid nitrogen-based cooling solutions represent a significant segment within this market, as thermal management becomes increasingly critical at advanced nodes. The demand for cryogenic cooling systems in semiconductor manufacturing is growing at approximately 9.7% annually, outpacing the overall equipment market growth rate.

Consumer electronics continue to be the primary driver of semiconductor demand, accounting for approximately 32% of the total market. However, emerging applications in automotive (particularly for electric vehicles and autonomous driving systems), artificial intelligence, and high-performance computing are rapidly expanding their market share, collectively representing about 28% of semiconductor demand and growing at double-digit rates annually.

The transition to 5nm, 3nm, and eventually 2nm process nodes is creating substantial demand for advanced cooling solutions that can maintain stable temperatures during increasingly complex manufacturing processes. Industry surveys indicate that 87% of semiconductor manufacturers consider thermal management as one of their top three technical challenges in scaling to next-generation nodes.

Geographically, East Asia dominates the market for semiconductor manufacturing equipment, with Taiwan, South Korea, and China accounting for over 65% of global demand. However, recent initiatives in the United States and European Union to strengthen domestic semiconductor manufacturing capabilities are expected to diversify this demand landscape over the next decade.

The industry's push toward more environmentally sustainable manufacturing processes is also influencing market demand. Liquid nitrogen cooling systems are increasingly valued not only for their technical performance but also for their potential to reduce overall energy consumption in semiconductor fabrication facilities by up to 15% compared to conventional cooling methods.

Customer requirements are evolving beyond pure performance metrics to include considerations of total cost of ownership, integration with existing systems, and adaptability to future process nodes. This shift is creating opportunities for solutions that can demonstrate long-term value through improved yield rates, reduced downtime, and extended equipment lifespan.

Liquid Nitrogen Application Status and Technical Challenges

Liquid nitrogen has become an integral component in modern semiconductor manufacturing processes, offering unique thermal properties that address critical challenges in the industry. Currently, liquid nitrogen is widely utilized for temperature control during various manufacturing stages, particularly in photolithography where precise thermal management is essential for achieving nanometer-scale feature sizes. The extreme cold temperature (-196°C) provides exceptional cooling capabilities that conventional refrigeration systems cannot match.

Despite its widespread adoption, several technical challenges persist in liquid nitrogen applications for semiconductor manufacturing. Storage and handling present significant difficulties due to its cryogenic nature, requiring specialized vacuum-insulated containers to minimize evaporation losses. Even with advanced storage systems, boil-off rates typically range from 0.3% to 1.5% per day, representing both economic and operational inefficiencies.

Distribution systems within fabrication facilities face challenges related to thermal insulation, pressure management, and precise flow control. Maintaining consistent temperature profiles across semiconductor wafers during processing remains problematic, with temperature gradients as small as 0.1°C potentially causing critical defects in advanced nodes below 5nm.

Safety concerns constitute another major challenge, as liquid nitrogen can cause severe cold burns, asphyxiation in confined spaces due to oxygen displacement, and pressure buildup in improperly vented systems. These risks necessitate comprehensive safety protocols and specialized training for personnel.

Energy efficiency represents a growing concern as semiconductor manufacturers face increasing pressure to reduce carbon footprints. The production and liquefaction of nitrogen is energy-intensive, typically consuming 0.4-0.7 kWh per kilogram of liquid nitrogen produced, contributing significantly to operational costs and environmental impact.

Automation and integration challenges exist in incorporating liquid nitrogen systems with Industry 4.0 manufacturing paradigms. Real-time monitoring of liquid nitrogen parameters and automated response systems remain underdeveloped compared to other aspects of semiconductor manufacturing automation.

Geographical disparities in liquid nitrogen availability and quality present additional complications for global semiconductor supply chains. Regions with less developed industrial gas infrastructure may experience reliability issues in liquid nitrogen supply, affecting manufacturing consistency and quality control.

Recent technological advancements have begun addressing these challenges through improved insulation materials, more efficient liquefaction processes, and enhanced distribution systems, yet significant opportunities for innovation remain in optimizing liquid nitrogen utilization in semiconductor manufacturing.

Despite its widespread adoption, several technical challenges persist in liquid nitrogen applications for semiconductor manufacturing. Storage and handling present significant difficulties due to its cryogenic nature, requiring specialized vacuum-insulated containers to minimize evaporation losses. Even with advanced storage systems, boil-off rates typically range from 0.3% to 1.5% per day, representing both economic and operational inefficiencies.

Distribution systems within fabrication facilities face challenges related to thermal insulation, pressure management, and precise flow control. Maintaining consistent temperature profiles across semiconductor wafers during processing remains problematic, with temperature gradients as small as 0.1°C potentially causing critical defects in advanced nodes below 5nm.

Safety concerns constitute another major challenge, as liquid nitrogen can cause severe cold burns, asphyxiation in confined spaces due to oxygen displacement, and pressure buildup in improperly vented systems. These risks necessitate comprehensive safety protocols and specialized training for personnel.

Energy efficiency represents a growing concern as semiconductor manufacturers face increasing pressure to reduce carbon footprints. The production and liquefaction of nitrogen is energy-intensive, typically consuming 0.4-0.7 kWh per kilogram of liquid nitrogen produced, contributing significantly to operational costs and environmental impact.

Automation and integration challenges exist in incorporating liquid nitrogen systems with Industry 4.0 manufacturing paradigms. Real-time monitoring of liquid nitrogen parameters and automated response systems remain underdeveloped compared to other aspects of semiconductor manufacturing automation.

Geographical disparities in liquid nitrogen availability and quality present additional complications for global semiconductor supply chains. Regions with less developed industrial gas infrastructure may experience reliability issues in liquid nitrogen supply, affecting manufacturing consistency and quality control.

Recent technological advancements have begun addressing these challenges through improved insulation materials, more efficient liquefaction processes, and enhanced distribution systems, yet significant opportunities for innovation remain in optimizing liquid nitrogen utilization in semiconductor manufacturing.

Current Liquid Nitrogen Implementation Methods

01 Cryogenic storage and transportation systems

Liquid nitrogen storage and transportation systems are designed to maintain extremely low temperatures while minimizing evaporation losses. These systems typically include vacuum-insulated vessels, specialized valves, and pressure management components. Advanced designs incorporate multi-layer insulation, automated monitoring systems, and safety features to prevent pressure build-up. These innovations enable efficient long-distance transport and extended storage periods for liquid nitrogen in various industrial and scientific applications.- Cryogenic storage and transportation systems: Specialized systems for storing and transporting liquid nitrogen at extremely low temperatures. These systems include insulated containers, vessels, and tanks designed to minimize heat transfer and maintain the cryogenic state of liquid nitrogen. Advanced insulation techniques and pressure management systems are employed to prevent rapid evaporation and ensure safe handling during transportation and storage.

- Cooling applications in industrial processes: Liquid nitrogen is widely used as a cooling agent in various industrial processes due to its extremely low temperature. Applications include rapid freezing of food products, cooling of electronic components during manufacturing, temperature control in chemical reactions, and material processing where precise temperature management is critical. These systems often incorporate specialized heat exchangers and controlled release mechanisms.

- Medical and biological preservation techniques: Liquid nitrogen is utilized in medical and biological fields for cryopreservation of biological samples, tissues, and cells. The ultra-low temperatures achieved with liquid nitrogen allow for long-term storage of biological materials with minimal degradation. Systems for controlled freezing rates and specialized storage containers are designed to maintain sample integrity and viability during the preservation process.

- Cryotherapy and dermatological applications: Liquid nitrogen is employed in medical treatments, particularly in dermatology for cryotherapy procedures. These applications involve controlled application of liquid nitrogen to treat skin conditions, remove lesions, and perform other therapeutic interventions. Specialized delivery devices are designed to provide precise application while ensuring patient safety and treatment effectiveness.

- Safety systems and handling equipment: Specialized equipment and safety systems designed for the safe handling and use of liquid nitrogen. These include protective gear, automated dispensing systems, monitoring devices for oxygen levels, pressure relief mechanisms, and emergency response equipment. Such systems are critical due to the hazards associated with liquid nitrogen, including extreme cold burns, asphyxiation risks, and pressure buildup concerns.

02 Medical and biological applications

Liquid nitrogen is widely used in medical and biological fields due to its extreme cold temperature properties. Applications include cryopreservation of biological samples, cryosurgery for removing abnormal tissues, and cryotherapy treatments. Systems have been developed for controlled application of liquid nitrogen in dermatological procedures, fertility preservation, and long-term storage of biological materials. These technologies incorporate precise temperature control mechanisms and specialized delivery devices to ensure safe and effective treatment or preservation.Expand Specific Solutions03 Industrial cooling and manufacturing processes

Liquid nitrogen serves as an efficient cooling medium in various industrial processes due to its extremely low temperature. It is utilized in food freezing, metal processing, electronics manufacturing, and chemical production. Systems have been developed to precisely control the application of liquid nitrogen for rapid cooling, shrink fitting, and creating inert atmospheres. These technologies include specialized spray nozzles, immersion systems, and automated temperature control mechanisms that optimize nitrogen usage while ensuring product quality and process efficiency.Expand Specific Solutions04 Energy systems and superconductivity applications

Liquid nitrogen is utilized in energy systems and superconductivity applications where maintaining extremely low temperatures is essential. It serves as a coolant for superconducting materials in power transmission, magnetic resonance imaging systems, and particle accelerators. Innovations include efficient cooling circuits, specialized insulation systems, and methods to minimize nitrogen consumption while maintaining stable temperatures. These technologies enable practical applications of superconductivity in energy storage, power generation, and advanced scientific research equipment.Expand Specific Solutions05 Safety systems and handling equipment

Safety systems and specialized handling equipment have been developed for working with liquid nitrogen to mitigate risks associated with its extremely low temperature and expansion properties. These include automated dispensing systems, personal protective equipment, oxygen monitoring devices, and emergency ventilation systems. Innovations focus on preventing direct contact with liquid nitrogen, managing oxygen displacement risks, and controlling pressure build-up in confined spaces. These technologies ensure safe handling in laboratories, industrial settings, and during transportation while minimizing the risk of cold burns, asphyxiation, and pressure-related accidents.Expand Specific Solutions

Key Industry Players in Semiconductor Cooling Solutions

The semiconductor manufacturing industry's integration of liquid nitrogen technology is evolving through a competitive landscape characterized by established players and emerging innovators. Currently in a growth phase, this market segment is expanding as manufacturers seek more efficient cooling solutions for increasingly complex chip production processes. While the technology shows moderate maturity, industry leaders like Applied Materials, Samsung Electronics, and Taiwan Semiconductor Manufacturing Co. are driving innovation through significant R&D investments. Companies including Micron Technology, GLOBALFOUNDRIES, and Renesas Electronics are developing specialized applications for liquid nitrogen in semiconductor fabrication, focusing on enhancing production efficiency, reducing defects, and enabling advanced node manufacturing capabilities. The competitive dynamics suggest continued technological advancement as manufacturers pursue higher yields and performance improvements.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced cryogenic etching systems that utilize liquid nitrogen for precise semiconductor manufacturing. Their Centris Sym3 etch system incorporates a liquid nitrogen-based temperature control mechanism that maintains wafer temperatures between -100°C and -150°C during critical etching processes. This extreme cooling enables highly anisotropic etching with enhanced selectivity and reduced pattern distortion. The company's proprietary CryoSync technology synchronizes liquid nitrogen delivery with plasma pulsing to optimize the etching of high-aspect-ratio features down to 5nm and beyond. Their systems include specialized thermal isolation stages that prevent thermal shock to wafers while maintaining temperature uniformity within ±1°C across 300mm wafers. Applied Materials has also integrated liquid nitrogen cooling into their deposition systems, where controlled substrate temperatures significantly improve film quality and reduce defect density in advanced logic and memory applications.

Strengths: Superior temperature control enabling ultra-precise etching profiles; integrated systems approach that optimizes liquid nitrogen consumption; proven technology deployed in high-volume manufacturing. Weaknesses: Higher initial capital investment compared to conventional systems; requires specialized infrastructure for liquid nitrogen supply and handling; increased system complexity requiring advanced operator training.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed an integrated liquid nitrogen cooling architecture for their semiconductor manufacturing facilities that spans from wafer processing to final testing. Their Cryo-Etch platform utilizes liquid nitrogen to cool wafers to -180°C during critical etching steps for DRAM and NAND flash memory production, enabling aspect ratios exceeding 60:1 with minimal sidewall roughness. For advanced logic processes, Samsung employs liquid nitrogen in their deposition chambers to control film nucleation and growth, resulting in ultra-thin films with exceptional uniformity. The company's proprietary CryoClean technology uses precisely controlled liquid nitrogen jets to remove nanoscale contaminants from wafer surfaces without chemical residues. In their testing facilities, Samsung has implemented liquid nitrogen cooling for early failure detection, subjecting chips to temperatures cycling between -196°C and +150°C to identify potential reliability issues before product shipment. Their newest fabs feature automated liquid nitrogen distribution systems that optimize consumption based on real-time production demands, reducing overall usage by approximately 15% compared to conventional systems.

Strengths: Vertically integrated approach covering the entire manufacturing process; proven technology scaled to high-volume production; significant expertise in cryogenic reliability testing. Weaknesses: High capital and operational expenditures; complex safety systems required for large-scale liquid nitrogen handling; challenges in maintaining consistent temperature profiles during rapid production changes.

Critical Patents and Innovations in Cryogenic Semiconductor Processing

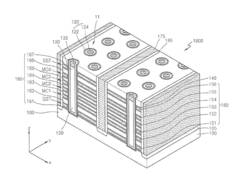

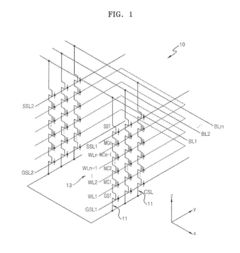

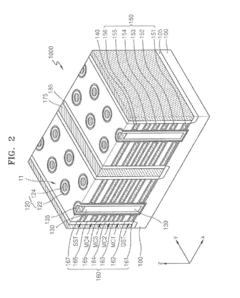

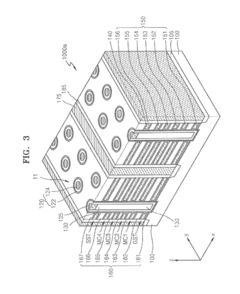

Semiconductor device and method of manufacturing the same

PatentActiveUS20150056797A1

Innovation

- A semiconductor device with a vertical structure featuring a channel region extending perpendicular to the substrate, comprising a first semiconductor layer with a nitrogen concentration of 0.2-4 at. % and a second semiconductor layer with a lower nitrogen concentration, along with a gate dielectric layer comprising tunnel, charge trapping, and blocking insulating layers, is developed. The method involves forming alternately stacked insulating and sacrificial layers, in-situ doping of nitrogen, and a rapid nitridation process to achieve a nitrogen concentration distribution that reduces trap density and improves interfacial characteristics.

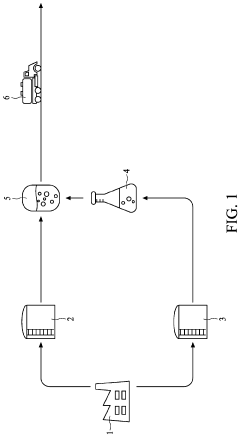

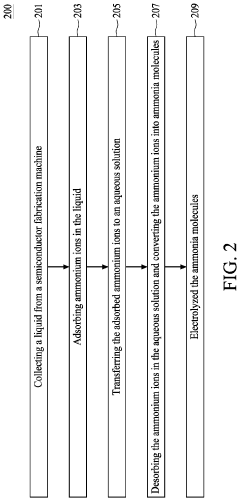

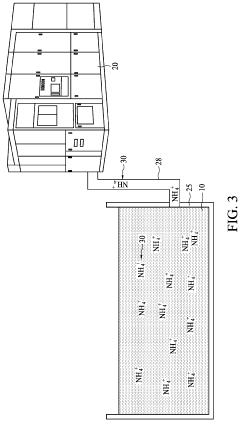

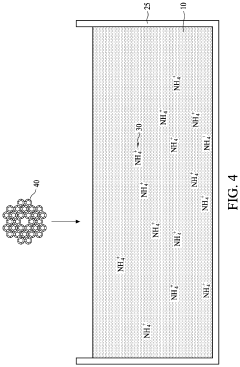

Method of processing liquid containing ammonia nitrogen from semiconductor fabrication machine

PatentPendingUS20240043295A1

Innovation

- An electrochemical method that adjusts the pH of ammonia nitrogen wastewater to convert ammonium ions into gaseous ammonia, which is then electrolyzed to produce hydrogen gas, reducing treatment and production costs by utilizing zeolites and alkaline solutions to enhance ammonia extraction and conversion.

Energy Efficiency and Sustainability Considerations

The integration of liquid nitrogen in semiconductor manufacturing presents significant opportunities for enhancing energy efficiency and sustainability across the industry. Semiconductor fabrication facilities (fabs) are notoriously energy-intensive operations, consuming vast amounts of electricity and resources. Liquid nitrogen cooling systems can substantially reduce the energy requirements for temperature control processes, potentially decreasing overall energy consumption by 15-30% compared to conventional cooling methods.

When properly implemented, liquid nitrogen-based cooling solutions offer a closed-loop system that minimizes resource waste. The nitrogen can be recaptured, reliquefied, and reused multiple times, creating a circular resource utilization model that aligns with sustainable manufacturing principles. This represents a marked improvement over traditional cooling systems that often rely on continuous fresh water supplies or energy-intensive refrigeration.

Carbon footprint reduction constitutes another critical sustainability advantage. By replacing conventional cooling systems with liquid nitrogen alternatives, semiconductor manufacturers can potentially reduce their greenhouse gas emissions by 20-40%, depending on facility size and production volume. This reduction becomes increasingly significant as environmental regulations tighten globally and carbon pricing mechanisms expand across major manufacturing regions.

The economic sustainability of liquid nitrogen cooling systems presents a compelling case for adoption. Despite higher initial capital investments, the operational cost savings typically result in return-on-investment periods of 3-5 years. These savings derive from reduced energy consumption, decreased maintenance requirements, and potential regulatory compliance benefits related to emissions reduction targets.

Water conservation represents perhaps the most underappreciated sustainability benefit. Traditional semiconductor manufacturing consumes enormous quantities of ultra-pure water, with a single facility potentially using millions of gallons daily. Liquid nitrogen cooling systems can reduce water consumption by up to 60% in certain processes, addressing a critical sustainability concern in regions facing water scarcity challenges.

Supply chain considerations must also factor into sustainability assessments. The production and transportation of liquid nitrogen itself requires energy, though advances in air separation technology and on-site generation capabilities have significantly improved efficiency. Manufacturers implementing liquid nitrogen systems should conduct comprehensive lifecycle assessments to ensure net positive environmental impacts across the entire supply chain.

When properly implemented, liquid nitrogen-based cooling solutions offer a closed-loop system that minimizes resource waste. The nitrogen can be recaptured, reliquefied, and reused multiple times, creating a circular resource utilization model that aligns with sustainable manufacturing principles. This represents a marked improvement over traditional cooling systems that often rely on continuous fresh water supplies or energy-intensive refrigeration.

Carbon footprint reduction constitutes another critical sustainability advantage. By replacing conventional cooling systems with liquid nitrogen alternatives, semiconductor manufacturers can potentially reduce their greenhouse gas emissions by 20-40%, depending on facility size and production volume. This reduction becomes increasingly significant as environmental regulations tighten globally and carbon pricing mechanisms expand across major manufacturing regions.

The economic sustainability of liquid nitrogen cooling systems presents a compelling case for adoption. Despite higher initial capital investments, the operational cost savings typically result in return-on-investment periods of 3-5 years. These savings derive from reduced energy consumption, decreased maintenance requirements, and potential regulatory compliance benefits related to emissions reduction targets.

Water conservation represents perhaps the most underappreciated sustainability benefit. Traditional semiconductor manufacturing consumes enormous quantities of ultra-pure water, with a single facility potentially using millions of gallons daily. Liquid nitrogen cooling systems can reduce water consumption by up to 60% in certain processes, addressing a critical sustainability concern in regions facing water scarcity challenges.

Supply chain considerations must also factor into sustainability assessments. The production and transportation of liquid nitrogen itself requires energy, though advances in air separation technology and on-site generation capabilities have significantly improved efficiency. Manufacturers implementing liquid nitrogen systems should conduct comprehensive lifecycle assessments to ensure net positive environmental impacts across the entire supply chain.

Safety Protocols and Risk Management

The integration of liquid nitrogen in semiconductor manufacturing processes necessitates comprehensive safety protocols and risk management strategies. Working with cryogenic temperatures presents unique hazards that require specialized handling procedures. Personnel must undergo rigorous training on proper liquid nitrogen handling techniques, including appropriate personal protective equipment (PPE) such as cryogenic gloves, face shields, and insulated footwear. Regular certification and refresher courses should be mandatory to ensure ongoing compliance with safety standards.

Facility design plays a crucial role in risk mitigation. Manufacturing spaces utilizing liquid nitrogen must incorporate adequate ventilation systems to prevent oxygen depletion hazards, as liquid nitrogen rapidly expands to gas form and can displace oxygen in confined spaces. Oxygen level monitoring systems should be installed with automated alarms that trigger when concentrations fall below 19.5%. Emergency shutdown protocols must be clearly defined and regularly tested to ensure rapid response during potential incidents.

Storage infrastructure requires specialized engineering considerations. Dewars and storage tanks must be equipped with pressure relief valves to prevent over-pressurization, while vacuum-insulated transfer lines should include redundant safety features. Regular inspection schedules for all containment systems are essential to identify potential failure points before incidents occur. Maintenance protocols should follow manufacturer specifications with comprehensive documentation of all service activities.

Risk assessment methodologies specific to cryogenic applications in semiconductor manufacturing should be implemented. This includes Failure Mode and Effects Analysis (FMEA) for liquid nitrogen delivery systems and Hazard and Operability Studies (HAZOP) for integration points with existing manufacturing processes. These assessments should be updated whenever process modifications occur or new equipment is installed.

Emergency response planning must address liquid nitrogen-specific scenarios including cryogenic burns, asphyxiation risks, and rapid pressure build-up situations. First aid stations should be equipped with materials for treating cryogenic injuries, and evacuation routes must be clearly marked. Regular drills should simulate various emergency scenarios to ensure personnel readiness.

Regulatory compliance represents another critical dimension of safety management. Operations must adhere to relevant standards including OSHA regulations, NFPA guidelines, and industry-specific protocols such as SEMI S2 for semiconductor manufacturing equipment safety. Documentation systems should track compliance activities and maintain records of all safety incidents, near-misses, and corrective actions to facilitate continuous improvement of safety protocols.

Facility design plays a crucial role in risk mitigation. Manufacturing spaces utilizing liquid nitrogen must incorporate adequate ventilation systems to prevent oxygen depletion hazards, as liquid nitrogen rapidly expands to gas form and can displace oxygen in confined spaces. Oxygen level monitoring systems should be installed with automated alarms that trigger when concentrations fall below 19.5%. Emergency shutdown protocols must be clearly defined and regularly tested to ensure rapid response during potential incidents.

Storage infrastructure requires specialized engineering considerations. Dewars and storage tanks must be equipped with pressure relief valves to prevent over-pressurization, while vacuum-insulated transfer lines should include redundant safety features. Regular inspection schedules for all containment systems are essential to identify potential failure points before incidents occur. Maintenance protocols should follow manufacturer specifications with comprehensive documentation of all service activities.

Risk assessment methodologies specific to cryogenic applications in semiconductor manufacturing should be implemented. This includes Failure Mode and Effects Analysis (FMEA) for liquid nitrogen delivery systems and Hazard and Operability Studies (HAZOP) for integration points with existing manufacturing processes. These assessments should be updated whenever process modifications occur or new equipment is installed.

Emergency response planning must address liquid nitrogen-specific scenarios including cryogenic burns, asphyxiation risks, and rapid pressure build-up situations. First aid stations should be equipped with materials for treating cryogenic injuries, and evacuation routes must be clearly marked. Regular drills should simulate various emergency scenarios to ensure personnel readiness.

Regulatory compliance represents another critical dimension of safety management. Operations must adhere to relevant standards including OSHA regulations, NFPA guidelines, and industry-specific protocols such as SEMI S2 for semiconductor manufacturing equipment safety. Documentation systems should track compliance activities and maintain records of all safety incidents, near-misses, and corrective actions to facilitate continuous improvement of safety protocols.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!