How to Measure Thermal Expansion in Liquid Nitrogen Applications

OCT 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Thermal Expansion Measurement Background and Objectives

Thermal expansion measurement in cryogenic environments, particularly in liquid nitrogen applications, has evolved significantly over the past several decades. Initially, researchers relied on rudimentary mechanical methods that offered limited precision under extreme temperature conditions. The field gained momentum in the 1960s with the space race, as aerospace applications demanded materials that could maintain dimensional stability at cryogenic temperatures. This historical progression has established a foundation for today's sophisticated measurement techniques.

The fundamental challenge in measuring thermal expansion at cryogenic temperatures stems from the physical principle that most materials contract when cooled, but at varying rates depending on their molecular structure and bonding characteristics. This differential contraction becomes critical in applications where multiple materials interface, such as in superconducting magnets, LNG storage facilities, and aerospace components operating in extreme environments.

Current technological objectives in this field focus on developing measurement systems capable of sub-micron precision while maintaining stability in the harsh 77K environment of liquid nitrogen. These systems must account for the significant temperature gradient between ambient and cryogenic conditions, which introduces measurement complexities not present in standard thermal expansion testing. Additionally, modern applications require real-time monitoring capabilities rather than static measurements.

The scientific community has established several standardized methodologies for cryogenic thermal expansion measurement, including dilatometry, interferometry, and capacitance-based techniques. Each approach offers distinct advantages depending on the specific application requirements, material properties, and desired measurement precision. The evolution of these methodologies reflects the growing sophistication of cryogenic engineering across multiple industries.

Recent technological advancements have enabled more precise measurements through the integration of digital imaging, laser-based systems, and advanced computational models that can account for secondary effects such as thermal gradients and mechanical stresses. These innovations have expanded the application scope beyond traditional aerospace and energy sectors to include emerging fields like quantum computing, where dimensional stability at cryogenic temperatures is paramount.

The ultimate goal of current research efforts is to develop universal, reliable, and cost-effective measurement protocols that can be standardized across industries. This standardization would facilitate material selection, component design, and system integration for the growing number of applications requiring cryogenic thermal stability. Furthermore, establishing predictive models based on empirical measurement data represents a frontier in this field, potentially reducing the need for extensive physical testing in future development cycles.

The fundamental challenge in measuring thermal expansion at cryogenic temperatures stems from the physical principle that most materials contract when cooled, but at varying rates depending on their molecular structure and bonding characteristics. This differential contraction becomes critical in applications where multiple materials interface, such as in superconducting magnets, LNG storage facilities, and aerospace components operating in extreme environments.

Current technological objectives in this field focus on developing measurement systems capable of sub-micron precision while maintaining stability in the harsh 77K environment of liquid nitrogen. These systems must account for the significant temperature gradient between ambient and cryogenic conditions, which introduces measurement complexities not present in standard thermal expansion testing. Additionally, modern applications require real-time monitoring capabilities rather than static measurements.

The scientific community has established several standardized methodologies for cryogenic thermal expansion measurement, including dilatometry, interferometry, and capacitance-based techniques. Each approach offers distinct advantages depending on the specific application requirements, material properties, and desired measurement precision. The evolution of these methodologies reflects the growing sophistication of cryogenic engineering across multiple industries.

Recent technological advancements have enabled more precise measurements through the integration of digital imaging, laser-based systems, and advanced computational models that can account for secondary effects such as thermal gradients and mechanical stresses. These innovations have expanded the application scope beyond traditional aerospace and energy sectors to include emerging fields like quantum computing, where dimensional stability at cryogenic temperatures is paramount.

The ultimate goal of current research efforts is to develop universal, reliable, and cost-effective measurement protocols that can be standardized across industries. This standardization would facilitate material selection, component design, and system integration for the growing number of applications requiring cryogenic thermal stability. Furthermore, establishing predictive models based on empirical measurement data represents a frontier in this field, potentially reducing the need for extensive physical testing in future development cycles.

Market Analysis for Liquid Nitrogen Measurement Technologies

The global market for liquid nitrogen measurement technologies is experiencing robust growth, driven primarily by expanding applications in cryogenic research, healthcare, food preservation, and industrial manufacturing. Current market valuations indicate the cryogenic equipment sector exceeds $20 billion globally, with measurement technologies representing approximately 15% of this market. The compound annual growth rate (CAGR) for specialized thermal expansion measurement tools in cryogenic environments is projected at 7.8% through 2028, outpacing the broader instrumentation market.

Healthcare and biomedical sectors constitute the largest market segment, accounting for nearly 40% of demand for precise thermal expansion measurement technologies. This is largely attributed to the critical requirements in biospecimen storage, where even minor temperature fluctuations can compromise sample integrity. The semiconductor industry follows closely, representing 25% of market demand, where ultra-precise measurements are essential for manufacturing processes involving cryogenic cooling systems.

Regional analysis reveals North America dominates the market with 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the fastest growth trajectory at 9.3% annually, driven by expanding semiconductor manufacturing and healthcare infrastructure investments in China, South Korea, and Singapore.

Customer segmentation shows distinct requirements across different sectors. Research institutions prioritize measurement accuracy and data integration capabilities, while industrial applications emphasize durability and operational reliability under extreme conditions. Healthcare facilities focus on compliance with regulatory standards and measurement consistency for quality assurance purposes.

Price sensitivity varies significantly by application. High-end research applications demonstrate low price elasticity, with customers willing to invest in premium solutions offering superior accuracy. Conversely, industrial applications show moderate price sensitivity, balancing performance requirements against cost considerations.

The competitive landscape features both specialized instrumentation companies and diversified scientific equipment manufacturers. Key market players include Linde Cryogenics, Air Products, Lake Shore Cryotronics, and TE Connectivity, collectively holding approximately 65% market share. Recent market consolidation through strategic acquisitions indicates a trend toward integrated measurement solution offerings.

Emerging market opportunities exist in developing regions where cryogenic applications are expanding in medical and food preservation sectors. Additionally, the growing space industry presents a specialized niche market for thermal expansion measurement technologies capable of functioning in extreme environments beyond terrestrial applications.

Healthcare and biomedical sectors constitute the largest market segment, accounting for nearly 40% of demand for precise thermal expansion measurement technologies. This is largely attributed to the critical requirements in biospecimen storage, where even minor temperature fluctuations can compromise sample integrity. The semiconductor industry follows closely, representing 25% of market demand, where ultra-precise measurements are essential for manufacturing processes involving cryogenic cooling systems.

Regional analysis reveals North America dominates the market with 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the fastest growth trajectory at 9.3% annually, driven by expanding semiconductor manufacturing and healthcare infrastructure investments in China, South Korea, and Singapore.

Customer segmentation shows distinct requirements across different sectors. Research institutions prioritize measurement accuracy and data integration capabilities, while industrial applications emphasize durability and operational reliability under extreme conditions. Healthcare facilities focus on compliance with regulatory standards and measurement consistency for quality assurance purposes.

Price sensitivity varies significantly by application. High-end research applications demonstrate low price elasticity, with customers willing to invest in premium solutions offering superior accuracy. Conversely, industrial applications show moderate price sensitivity, balancing performance requirements against cost considerations.

The competitive landscape features both specialized instrumentation companies and diversified scientific equipment manufacturers. Key market players include Linde Cryogenics, Air Products, Lake Shore Cryotronics, and TE Connectivity, collectively holding approximately 65% market share. Recent market consolidation through strategic acquisitions indicates a trend toward integrated measurement solution offerings.

Emerging market opportunities exist in developing regions where cryogenic applications are expanding in medical and food preservation sectors. Additionally, the growing space industry presents a specialized niche market for thermal expansion measurement technologies capable of functioning in extreme environments beyond terrestrial applications.

Current Challenges in Cryogenic Thermal Expansion Measurement

Measuring thermal expansion in cryogenic environments, particularly in liquid nitrogen applications, presents significant technical challenges that continue to impede precise material characterization. The extreme low temperature of liquid nitrogen (-196°C) creates a hostile environment for conventional measurement instruments, causing sensor drift, calibration issues, and material property alterations that compromise measurement accuracy.

Conventional contact measurement techniques such as strain gauges and extensometers face severe limitations at cryogenic temperatures. Adhesives used to bond strain gauges to test specimens often fail at these extreme temperatures, while the electrical properties of the gauges themselves change unpredictably, introducing systematic errors. Extensometers designed for room temperature applications typically become brittle and inaccurate when exposed to liquid nitrogen.

Non-contact optical measurement systems, while promising alternatives, encounter their own set of challenges. Optical windows required for viewing specimens in cryogenic chambers often fog or frost, distorting measurements. Laser interferometry systems, though theoretically capable of high precision, suffer from beam path distortions caused by temperature gradients between the cryogenic environment and ambient conditions.

Thermal gradients represent another significant obstacle in cryogenic thermal expansion measurement. The rapid cooling rates and poor thermal conductivity of certain materials create non-uniform temperature distributions across test specimens, resulting in differential expansion rates that complicate data interpretation. These gradients can lead to internal stresses and temporary or permanent deformation that mask true thermal expansion behavior.

Calibration and reference standards pose additional challenges. Standard reference materials certified for thermal expansion properties at cryogenic temperatures are limited, making system calibration difficult. Furthermore, the reference materials themselves may exhibit different behavior when repeatedly cycled between ambient and cryogenic temperatures, introducing calibration drift over time.

Data acquisition systems must also contend with the harsh cryogenic environment. Electronic components often experience significant drift when exposed to extreme temperature gradients, requiring complex compensation algorithms or physical isolation strategies. Signal noise increases substantially at cryogenic temperatures, necessitating sophisticated filtering techniques that may inadvertently remove subtle but important measurement features.

Material phase transitions represent a particularly complex challenge. Many materials undergo structural phase changes at cryogenic temperatures, resulting in non-linear expansion behavior that conventional measurement models fail to accurately capture. These transitions can occur gradually across temperature ranges rather than at discrete points, further complicating measurement and interpretation.

Conventional contact measurement techniques such as strain gauges and extensometers face severe limitations at cryogenic temperatures. Adhesives used to bond strain gauges to test specimens often fail at these extreme temperatures, while the electrical properties of the gauges themselves change unpredictably, introducing systematic errors. Extensometers designed for room temperature applications typically become brittle and inaccurate when exposed to liquid nitrogen.

Non-contact optical measurement systems, while promising alternatives, encounter their own set of challenges. Optical windows required for viewing specimens in cryogenic chambers often fog or frost, distorting measurements. Laser interferometry systems, though theoretically capable of high precision, suffer from beam path distortions caused by temperature gradients between the cryogenic environment and ambient conditions.

Thermal gradients represent another significant obstacle in cryogenic thermal expansion measurement. The rapid cooling rates and poor thermal conductivity of certain materials create non-uniform temperature distributions across test specimens, resulting in differential expansion rates that complicate data interpretation. These gradients can lead to internal stresses and temporary or permanent deformation that mask true thermal expansion behavior.

Calibration and reference standards pose additional challenges. Standard reference materials certified for thermal expansion properties at cryogenic temperatures are limited, making system calibration difficult. Furthermore, the reference materials themselves may exhibit different behavior when repeatedly cycled between ambient and cryogenic temperatures, introducing calibration drift over time.

Data acquisition systems must also contend with the harsh cryogenic environment. Electronic components often experience significant drift when exposed to extreme temperature gradients, requiring complex compensation algorithms or physical isolation strategies. Signal noise increases substantially at cryogenic temperatures, necessitating sophisticated filtering techniques that may inadvertently remove subtle but important measurement features.

Material phase transitions represent a particularly complex challenge. Many materials undergo structural phase changes at cryogenic temperatures, resulting in non-linear expansion behavior that conventional measurement models fail to accurately capture. These transitions can occur gradually across temperature ranges rather than at discrete points, further complicating measurement and interpretation.

Existing Thermal Expansion Measurement Methods for LN2 Environments

01 Dilatometer-based thermal expansion measurement

Dilatometers are widely used instruments for measuring thermal expansion of materials. These devices measure dimensional changes in a sample as temperature varies. Modern dilatometers can provide high precision measurements across a wide temperature range, allowing for accurate determination of thermal expansion coefficients. Various types of dilatometers exist, including push-rod, optical, and capacitance dilatometers, each with specific advantages for different material types and temperature ranges.- Dilatometer-based thermal expansion measurement: Dilatometers are specialized instruments used to measure thermal expansion of materials with high precision. These devices typically measure dimensional changes in a sample as temperature varies, allowing for accurate determination of thermal expansion coefficients. Modern dilatometers may incorporate digital sensors, automated temperature control systems, and computer interfaces for data acquisition and analysis, enabling researchers to characterize materials across wide temperature ranges.

- Optical methods for thermal expansion measurement: Optical techniques provide non-contact methods for measuring thermal expansion with high accuracy. These approaches include laser interferometry, digital image correlation, and optical displacement sensors that can detect nanometer-scale dimensional changes. By using light to measure displacement, these methods avoid mechanical contact issues and can be applied to a wide range of materials, including those with complex geometries or at extreme temperatures.

- Thermal expansion measurement for electronic components: Specialized techniques have been developed to measure thermal expansion in electronic components and semiconductor materials. These methods address the challenges of measuring expansion in miniaturized circuits, multi-layer structures, and heterogeneous material systems. The measurements are critical for predicting thermal stress, preventing failures in electronic packages, and designing reliable integrated circuits that can withstand thermal cycling during operation.

- High-temperature thermal expansion measurement systems: Measuring thermal expansion at elevated temperatures requires specialized equipment that can maintain stable conditions while accurately detecting dimensional changes. These systems often incorporate furnaces with precise temperature control, heat-resistant measurement probes, and environmental chambers that can operate under vacuum or controlled atmospheres. Such equipment is essential for characterizing materials used in high-temperature applications like aerospace components, refractory materials, and thermal barrier coatings.

- Computational methods and data analysis for thermal expansion: Advanced computational techniques enhance the accuracy and interpretation of thermal expansion measurements. These include statistical analysis methods, machine learning algorithms for pattern recognition, and simulation models that can predict thermal behavior. Software systems can process raw measurement data, compensate for instrumental errors, and calculate thermal expansion coefficients across different temperature ranges, enabling researchers to better understand material behavior and develop improved materials with controlled thermal expansion properties.

02 Laser-based thermal expansion measurement techniques

Laser interferometry and other laser-based techniques offer non-contact methods for measuring thermal expansion with high precision. These systems use laser beams to detect minute dimensional changes in materials as they are heated or cooled. The advantages include extremely high resolution measurements, ability to measure at high temperatures, and elimination of mechanical contact that might influence results. Advanced laser systems can incorporate multiple measurement points to account for non-uniform expansion and provide real-time data acquisition.Expand Specific Solutions03 Thermal expansion measurement for electronic components and circuits

Specialized methods have been developed to measure thermal expansion in electronic components, circuit boards, and semiconductor materials. These techniques are critical for ensuring reliability in electronic devices where thermal expansion mismatch can lead to failures. Measurement systems may incorporate microscale sensing elements, optical techniques, or electrical resistance measurements to detect dimensional changes. The data is essential for designing reliable electronic packages that can withstand thermal cycling without mechanical failure.Expand Specific Solutions04 High-temperature thermal expansion measurement systems

Specialized equipment and methodologies have been developed for measuring thermal expansion at extremely high temperatures. These systems often incorporate refractory materials, specialized heating elements, and non-contact measurement techniques to operate in harsh environments. Applications include characterizing materials for aerospace, nuclear, and industrial furnace applications. The measurement systems may use radiation shielding, controlled atmospheres, or vacuum environments to ensure accurate results at elevated temperatures.Expand Specific Solutions05 Automated and computer-controlled thermal expansion measurement

Modern thermal expansion measurement systems incorporate automation, computer control, and advanced data processing capabilities. These systems allow for programmed temperature profiles, continuous data collection, and sophisticated analysis of expansion behavior. Software algorithms can compensate for measurement artifacts, calculate precise expansion coefficients, and identify phase transitions or other material changes. Automated systems improve measurement reproducibility and enable high-throughput characterization of multiple samples under identical conditions.Expand Specific Solutions

Leading Companies and Research Institutions in Cryogenic Metrology

The thermal expansion measurement in liquid nitrogen applications is in a mature development stage, with a growing market driven by semiconductor, aerospace, and cryogenic research sectors. The technology demonstrates high maturity levels, with established players like MIT and CEA leading academic research, while industrial innovation comes from companies such as Schlumberger, SCHOTT AG, and Toray Industries. These organizations have developed specialized instrumentation and methodologies for precise thermal expansion measurement at extremely low temperatures. The competitive landscape features collaboration between research institutions and commercial entities, with recent advancements focusing on nanoscale measurement techniques and materials characterization under cryogenic conditions.

Massachusetts Institute of Technology

Technical Solution: MIT has developed advanced cryogenic dilatometry systems specifically designed for liquid nitrogen applications. Their approach combines laser interferometry with specialized sample holders that minimize thermal gradients. The system utilizes a Michelson interferometer setup with one beam path containing the sample, allowing for nanometer-scale resolution of dimensional changes. MIT researchers have implemented digital image correlation techniques to map non-uniform expansion across complex geometries. Their latest innovation incorporates fiber Bragg grating sensors embedded within materials to provide real-time internal strain measurements during thermal cycling between room temperature and 77K. This multi-method approach enables comprehensive characterization of both isotropic and anisotropic materials under cryogenic conditions, with demonstrated measurement accuracy of ±0.05×10^-6 K^-1 for thermal expansion coefficients.

Strengths: Exceptional measurement precision at nanometer scale; capability to characterize both homogeneous and composite materials; real-time monitoring during thermal cycling. Weaknesses: Complex setup requiring specialized expertise; higher implementation cost compared to conventional methods; limited to laboratory environments rather than industrial settings.

Schlumberger Holdings Ltd.

Technical Solution: Schlumberger has engineered a specialized thermal expansion measurement system for downhole tools and materials operating in cryogenic environments. Their approach combines fiber optic sensing with proprietary data analysis algorithms specifically calibrated for liquid nitrogen temperatures. The system utilizes Fiber Bragg Grating (FBG) sensors embedded within materials to provide distributed strain measurements across complex geometries. Schlumberger's innovation includes temperature compensation techniques that isolate mechanical strain from thermally-induced optical effects in the fiber sensors. For metal components, they've developed a resonant ultrasound spectroscopy method that correlates changes in natural frequencies with dimensional changes during cooling. Their measurement protocol incorporates multiple cooling/warming cycles to characterize hysteresis effects critical for equipment reliability. The system features remote monitoring capabilities for continuous assessment during simulated operational conditions. Field validation has demonstrated measurement accuracy of ±1×10^-6 K^-1 for thermal expansion coefficients in oil and gas equipment materials at temperatures down to 77K.

Strengths: Designed specifically for oil and gas industry applications; capable of in-situ measurements during simulated operations; excellent performance with metallic materials. Weaknesses: Less effective with non-homogeneous materials; requires specialized installation of sensors; higher measurement uncertainty compared to laboratory techniques.

Key Technologies for Ultra-Low Temperature Dimensional Metrology

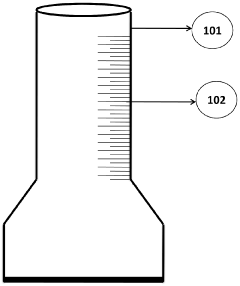

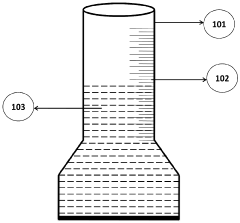

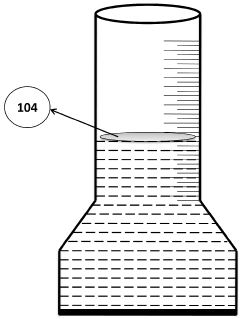

Apparatus for measuring thermal expansion of liquid with controlled evaporation

PatentInactiveIN202241060832A

Innovation

- A compact apparatus using a round bottom flask with an aluminium foil boat shape and evaporation controller, where the liquid sample is heated by a one-dimensional planar heater, and evaporation is controlled by counting bubbles deposited on the foil, allowing for precise measurement of liquid expansion from ambient temperature to 80°C.

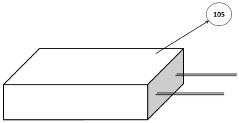

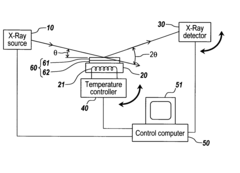

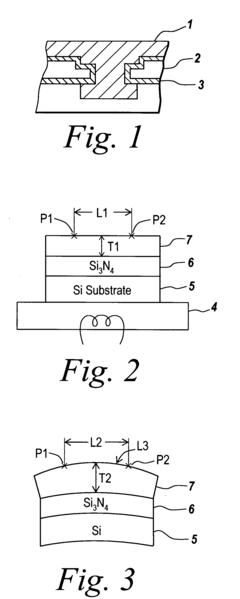

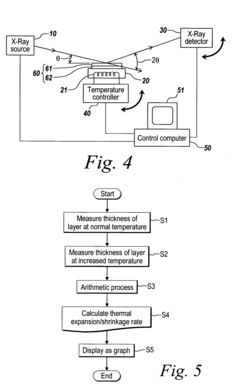

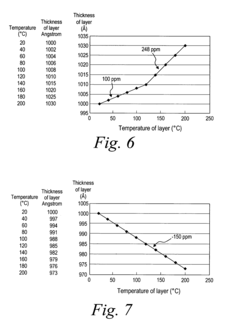

Apparatus and method for measuring or applying thermal expansion/shrinkage rate

PatentInactiveUS20050143950A1

Innovation

- An automatic thermal expansion/shrinkage rate measuring system using X-ray reflection to calculate the thickness of thin films at varying temperatures, allowing for accurate determination and maintenance of favorable expansion/shrinkage rates, incorporating a programmable temperature controller and multi-chamber processing apparatus for mass production integration.

Safety Standards and Protocols for Liquid Nitrogen Testing

Working with liquid nitrogen requires strict adherence to comprehensive safety standards and protocols due to its extreme low temperature (-196°C) and associated hazards. The American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) have established specific guidelines for handling cryogenic materials, including ASTM D7193 and ISO 21009, which outline safety requirements for vessels and equipment used in liquid nitrogen applications.

Personal protective equipment (PPE) is mandatory when conducting thermal expansion measurements in liquid nitrogen environments. This includes insulated gloves designed for cryogenic work, face shields or safety goggles, closed-toe shoes, and laboratory coats without pockets where liquid nitrogen could potentially collect. All measurement equipment must be certified for use at cryogenic temperatures to prevent catastrophic failures during testing procedures.

Laboratory ventilation systems must maintain adequate air exchange rates to prevent oxygen depletion in case of nitrogen gas accumulation. Oxygen monitoring systems should be installed in enclosed testing areas, with alarms set to activate at oxygen levels below 19.5% by volume, as recommended by the Occupational Safety and Health Administration (OSHA).

Emergency response protocols must be clearly documented and prominently displayed in testing areas. These should include first aid procedures for cryogenic burns, evacuation routes, and emergency contact information. Regular drills should be conducted to ensure all personnel are familiar with emergency procedures. Additionally, specialized first aid kits for cryogenic injuries should be readily accessible in all testing facilities.

Material compatibility verification is essential before conducting thermal expansion measurements. Materials that become brittle at cryogenic temperatures, such as certain plastics and rubbers, must be identified and avoided. Testing equipment should be gradually cooled to prevent thermal shock, which could compromise measurement accuracy and create safety hazards.

Data recording procedures must include safety parameters such as temperature gradients, pressure readings, and oxygen levels throughout the testing process. Any anomalies in these readings should trigger immediate safety protocols. All measurement activities must be documented in standardized logs that include safety checks performed before, during, and after testing.

Training certification requirements ensure that only qualified personnel conduct thermal expansion measurements with liquid nitrogen. This training should cover cryogenic hazards, proper handling techniques, emergency response, and specific measurement methodologies. Certification should be renewed periodically, with refresher courses addressing any updates to safety standards or measurement techniques.

Personal protective equipment (PPE) is mandatory when conducting thermal expansion measurements in liquid nitrogen environments. This includes insulated gloves designed for cryogenic work, face shields or safety goggles, closed-toe shoes, and laboratory coats without pockets where liquid nitrogen could potentially collect. All measurement equipment must be certified for use at cryogenic temperatures to prevent catastrophic failures during testing procedures.

Laboratory ventilation systems must maintain adequate air exchange rates to prevent oxygen depletion in case of nitrogen gas accumulation. Oxygen monitoring systems should be installed in enclosed testing areas, with alarms set to activate at oxygen levels below 19.5% by volume, as recommended by the Occupational Safety and Health Administration (OSHA).

Emergency response protocols must be clearly documented and prominently displayed in testing areas. These should include first aid procedures for cryogenic burns, evacuation routes, and emergency contact information. Regular drills should be conducted to ensure all personnel are familiar with emergency procedures. Additionally, specialized first aid kits for cryogenic injuries should be readily accessible in all testing facilities.

Material compatibility verification is essential before conducting thermal expansion measurements. Materials that become brittle at cryogenic temperatures, such as certain plastics and rubbers, must be identified and avoided. Testing equipment should be gradually cooled to prevent thermal shock, which could compromise measurement accuracy and create safety hazards.

Data recording procedures must include safety parameters such as temperature gradients, pressure readings, and oxygen levels throughout the testing process. Any anomalies in these readings should trigger immediate safety protocols. All measurement activities must be documented in standardized logs that include safety checks performed before, during, and after testing.

Training certification requirements ensure that only qualified personnel conduct thermal expansion measurements with liquid nitrogen. This training should cover cryogenic hazards, proper handling techniques, emergency response, and specific measurement methodologies. Certification should be renewed periodically, with refresher courses addressing any updates to safety standards or measurement techniques.

Material Selection Criteria for Cryogenic Applications

Material selection for cryogenic applications, particularly those involving liquid nitrogen (LN2) at -196°C, requires careful consideration of thermal expansion properties. The extreme temperature gradient between ambient and cryogenic conditions creates significant thermal contraction challenges that must be addressed through proper material selection.

Metals commonly used in cryogenic applications include austenitic stainless steels (304, 316), aluminum alloys, copper alloys, and nickel alloys. These materials demonstrate favorable combinations of mechanical strength, toughness, and thermal conductivity at cryogenic temperatures. Austenitic stainless steels maintain excellent ductility and do not undergo ductile-to-brittle transition at LN2 temperatures, making them particularly valuable for structural components.

Non-metallic materials also play crucial roles in cryogenic systems. Polytetrafluoroethylene (PTFE), polyimides, and certain glass-reinforced composites maintain flexibility and structural integrity at extremely low temperatures. These materials often serve as thermal insulators, gaskets, and seals where metal-to-metal contact must be avoided to prevent thermal bridging.

The coefficient of thermal expansion (CTE) represents a critical selection parameter. Materials with low CTE values experience less dimensional change during cooling and warming cycles, reducing mechanical stress and potential failure points. Invar (Fe-36Ni) alloy, with its exceptionally low CTE, finds specialized applications where dimensional stability is paramount.

Thermal conductivity considerations must balance competing requirements. High thermal conductivity materials like copper and aluminum facilitate efficient heat transfer in heat exchangers and cooling systems. Conversely, low thermal conductivity materials serve as thermal barriers to minimize heat ingress and cryogen boil-off in storage vessels.

Material compatibility with liquid nitrogen must be verified to prevent embrittlement, stress corrosion cracking, or other degradation mechanisms. Some polymers and elastomers become brittle and crack at cryogenic temperatures, while others maintain sufficient flexibility. Oxygen compatibility must also be considered, as liquid oxygen can form in systems where air condensation occurs.

Manufacturing processes significantly impact material performance at cryogenic temperatures. Welding, for instance, can create heat-affected zones with altered microstructures and reduced low-temperature toughness. Post-weld heat treatments and proper quality control procedures help mitigate these risks and ensure system integrity throughout the operational temperature range.

Metals commonly used in cryogenic applications include austenitic stainless steels (304, 316), aluminum alloys, copper alloys, and nickel alloys. These materials demonstrate favorable combinations of mechanical strength, toughness, and thermal conductivity at cryogenic temperatures. Austenitic stainless steels maintain excellent ductility and do not undergo ductile-to-brittle transition at LN2 temperatures, making them particularly valuable for structural components.

Non-metallic materials also play crucial roles in cryogenic systems. Polytetrafluoroethylene (PTFE), polyimides, and certain glass-reinforced composites maintain flexibility and structural integrity at extremely low temperatures. These materials often serve as thermal insulators, gaskets, and seals where metal-to-metal contact must be avoided to prevent thermal bridging.

The coefficient of thermal expansion (CTE) represents a critical selection parameter. Materials with low CTE values experience less dimensional change during cooling and warming cycles, reducing mechanical stress and potential failure points. Invar (Fe-36Ni) alloy, with its exceptionally low CTE, finds specialized applications where dimensional stability is paramount.

Thermal conductivity considerations must balance competing requirements. High thermal conductivity materials like copper and aluminum facilitate efficient heat transfer in heat exchangers and cooling systems. Conversely, low thermal conductivity materials serve as thermal barriers to minimize heat ingress and cryogen boil-off in storage vessels.

Material compatibility with liquid nitrogen must be verified to prevent embrittlement, stress corrosion cracking, or other degradation mechanisms. Some polymers and elastomers become brittle and crack at cryogenic temperatures, while others maintain sufficient flexibility. Oxygen compatibility must also be considered, as liquid oxygen can form in systems where air condensation occurs.

Manufacturing processes significantly impact material performance at cryogenic temperatures. Welding, for instance, can create heat-affected zones with altered microstructures and reduced low-temperature toughness. Post-weld heat treatments and proper quality control procedures help mitigate these risks and ensure system integrity throughout the operational temperature range.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!