Comparing Microinjection Molding Techniques for Thermal Management

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microinjection Molding Thermal Management Background & Objectives

Microinjection molding has emerged as a critical manufacturing technology in the miniaturization trend across various industries, particularly for components requiring precise thermal management. The evolution of this technology dates back to the late 1980s when conventional injection molding techniques were adapted to produce increasingly smaller components. Over the past three decades, significant advancements have been made in machine design, material science, and process control, enabling the production of micro-components with unprecedented precision and functionality.

The trajectory of microinjection molding development has been largely driven by demands from the medical, electronics, and automotive sectors, where miniaturization continues to be a dominant trend. Recent technological innovations have focused on enhancing the thermal management capabilities of micro-molded components, addressing challenges related to heat dissipation, thermal conductivity, and temperature regulation in confined spaces.

The primary objective of this technical research is to comprehensively compare various microinjection molding techniques specifically optimized for thermal management applications. This includes evaluating variothermal processes, conformal cooling systems, high-conductivity material formulations, and hybrid molding approaches that integrate multiple materials with complementary thermal properties.

Current research indicates a growing interest in developing microinjection molding processes that can produce components with embedded thermal management features, such as micro-channels, heat sinks, and thermally conductive pathways. These advancements aim to address the increasing thermal challenges in miniaturized electronic devices, medical implants, and automotive sensors operating in high-temperature environments.

The technical evolution trend points toward greater integration of simulation tools with physical manufacturing processes, allowing for more accurate prediction and control of thermal behaviors during both the molding process and in the final application. Machine learning algorithms are increasingly being employed to optimize process parameters for specific thermal management requirements.

This research seeks to establish a framework for evaluating the effectiveness of different microinjection molding techniques in achieving specific thermal management objectives, including heat dissipation efficiency, thermal stability, and temperature uniformity. Additionally, it aims to identify emerging technologies and methodologies that could potentially revolutionize thermal management in micro-molded components over the next decade.

By examining the historical development, current capabilities, and future directions of microinjection molding for thermal management, this research will provide valuable insights for manufacturers seeking to enhance the thermal performance of their miniaturized components while maintaining production efficiency and cost-effectiveness.

The trajectory of microinjection molding development has been largely driven by demands from the medical, electronics, and automotive sectors, where miniaturization continues to be a dominant trend. Recent technological innovations have focused on enhancing the thermal management capabilities of micro-molded components, addressing challenges related to heat dissipation, thermal conductivity, and temperature regulation in confined spaces.

The primary objective of this technical research is to comprehensively compare various microinjection molding techniques specifically optimized for thermal management applications. This includes evaluating variothermal processes, conformal cooling systems, high-conductivity material formulations, and hybrid molding approaches that integrate multiple materials with complementary thermal properties.

Current research indicates a growing interest in developing microinjection molding processes that can produce components with embedded thermal management features, such as micro-channels, heat sinks, and thermally conductive pathways. These advancements aim to address the increasing thermal challenges in miniaturized electronic devices, medical implants, and automotive sensors operating in high-temperature environments.

The technical evolution trend points toward greater integration of simulation tools with physical manufacturing processes, allowing for more accurate prediction and control of thermal behaviors during both the molding process and in the final application. Machine learning algorithms are increasingly being employed to optimize process parameters for specific thermal management requirements.

This research seeks to establish a framework for evaluating the effectiveness of different microinjection molding techniques in achieving specific thermal management objectives, including heat dissipation efficiency, thermal stability, and temperature uniformity. Additionally, it aims to identify emerging technologies and methodologies that could potentially revolutionize thermal management in micro-molded components over the next decade.

By examining the historical development, current capabilities, and future directions of microinjection molding for thermal management, this research will provide valuable insights for manufacturers seeking to enhance the thermal performance of their miniaturized components while maintaining production efficiency and cost-effectiveness.

Market Demand Analysis for Thermal Management Solutions

The thermal management solutions market is experiencing robust growth driven by increasing miniaturization of electronic devices and the rising demand for efficient heat dissipation systems. The global thermal management market was valued at approximately 11.4 billion USD in 2020 and is projected to reach 18.8 billion USD by 2026, growing at a CAGR of 8.2% during the forecast period. This growth is particularly evident in industries such as automotive electronics, consumer electronics, healthcare devices, and aerospace applications.

Microinjection molding techniques for thermal management are gaining significant traction due to their ability to produce complex, miniaturized components with high precision. The market demand is primarily fueled by the semiconductor industry, where thermal management is critical for maintaining optimal performance and extending device lifespan. With the increasing power density of electronic components, traditional cooling methods are becoming insufficient, creating a substantial market opportunity for advanced microinjection molding solutions.

The automotive sector represents one of the fastest-growing segments for thermal management solutions, with electric vehicles (EVs) driving demand for sophisticated thermal control systems. The EV thermal management market alone is expected to grow at a CAGR of 24.6% through 2025, creating substantial opportunities for microinjection molded components in battery cooling systems, power electronics, and motor cooling applications.

Healthcare and medical devices constitute another significant market segment, with the increasing adoption of miniaturized diagnostic equipment and implantable devices requiring advanced thermal management solutions. The medical device thermal management market is projected to grow at a CAGR of 7.8% through 2026, with microinjection molded components playing a crucial role in ensuring device reliability and patient safety.

Regional analysis indicates that Asia-Pacific dominates the market, accounting for approximately 42% of the global thermal management solutions market, followed by North America and Europe. China, Japan, and South Korea are the key contributors in the Asia-Pacific region, driven by their strong electronics manufacturing base and increasing investments in advanced manufacturing technologies.

Customer requirements are evolving toward more integrated thermal management solutions that offer higher efficiency, smaller footprints, and enhanced reliability. There is a growing demand for materials with superior thermal conductivity that can be processed through microinjection molding techniques. Additionally, sustainability concerns are influencing market preferences, with increasing demand for eco-friendly materials and energy-efficient thermal management solutions.

Microinjection molding techniques for thermal management are gaining significant traction due to their ability to produce complex, miniaturized components with high precision. The market demand is primarily fueled by the semiconductor industry, where thermal management is critical for maintaining optimal performance and extending device lifespan. With the increasing power density of electronic components, traditional cooling methods are becoming insufficient, creating a substantial market opportunity for advanced microinjection molding solutions.

The automotive sector represents one of the fastest-growing segments for thermal management solutions, with electric vehicles (EVs) driving demand for sophisticated thermal control systems. The EV thermal management market alone is expected to grow at a CAGR of 24.6% through 2025, creating substantial opportunities for microinjection molded components in battery cooling systems, power electronics, and motor cooling applications.

Healthcare and medical devices constitute another significant market segment, with the increasing adoption of miniaturized diagnostic equipment and implantable devices requiring advanced thermal management solutions. The medical device thermal management market is projected to grow at a CAGR of 7.8% through 2026, with microinjection molded components playing a crucial role in ensuring device reliability and patient safety.

Regional analysis indicates that Asia-Pacific dominates the market, accounting for approximately 42% of the global thermal management solutions market, followed by North America and Europe. China, Japan, and South Korea are the key contributors in the Asia-Pacific region, driven by their strong electronics manufacturing base and increasing investments in advanced manufacturing technologies.

Customer requirements are evolving toward more integrated thermal management solutions that offer higher efficiency, smaller footprints, and enhanced reliability. There is a growing demand for materials with superior thermal conductivity that can be processed through microinjection molding techniques. Additionally, sustainability concerns are influencing market preferences, with increasing demand for eco-friendly materials and energy-efficient thermal management solutions.

Current Techniques and Challenges in Microinjection Molding

Microinjection molding (μIM) represents a critical manufacturing process for producing miniaturized plastic components with high precision and complex geometries. The current landscape of microinjection molding techniques specifically applied to thermal management applications reveals several distinct methodologies, each with unique capabilities and limitations.

Conventional microinjection molding remains the foundation of the industry, utilizing scaled-down versions of traditional injection molding equipment. This approach typically employs mold temperatures below the glass transition temperature of the polymer, resulting in rapid cycle times but often compromising the replication quality of micro-features. When applied to thermal management components, this technique struggles with achieving the high aspect ratios necessary for efficient heat transfer structures.

Variothermal microinjection molding has emerged as a significant advancement, involving dynamic temperature control of the mold during the injection cycle. The mold is heated above the polymer's glass transition temperature during filling and then rapidly cooled for solidification. This technique substantially improves the replication of high-aspect-ratio microstructures critical for thermal management applications, though at the cost of longer cycle times and increased energy consumption.

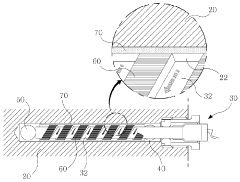

Ultrasonic-assisted microinjection molding incorporates ultrasonic vibrations during the injection process, reducing polymer viscosity through localized heating. This technique enhances flow behavior in micro-channels and improves the filling of complex geometries without significantly extending cycle times. For thermal management applications, this approach shows promise in creating intricate cooling channels but faces challenges in maintaining dimensional stability.

Vacuum-assisted microinjection molding addresses air entrapment issues by evacuating air from the mold cavity prior to injection. This technique is particularly valuable for thermal management components where air voids would significantly compromise thermal conductivity. However, implementation requires sophisticated mold designs and additional equipment, increasing production costs.

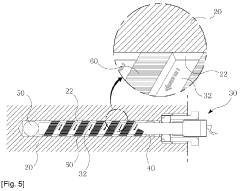

Two-component microinjection molding enables the production of components with different materials in a single process, allowing for the strategic placement of thermally conductive polymers alongside structural materials. While offering design flexibility for thermal management applications, this technique demands precise process control to manage material interfaces and prevent warpage due to differential shrinkage.

The industry currently faces several persistent challenges. Achieving consistent quality at the microscale remains difficult due to the amplified effects of process variations. Material selection presents another significant hurdle, as standard polymers often exhibit different flow behaviors at the microscale, and the incorporation of thermally conductive fillers frequently compromises flowability and surface finish. Additionally, tool design and fabrication for microinjection molds require specialized expertise and equipment, with cooling system integration being particularly complex for thermal management applications.

Conventional microinjection molding remains the foundation of the industry, utilizing scaled-down versions of traditional injection molding equipment. This approach typically employs mold temperatures below the glass transition temperature of the polymer, resulting in rapid cycle times but often compromising the replication quality of micro-features. When applied to thermal management components, this technique struggles with achieving the high aspect ratios necessary for efficient heat transfer structures.

Variothermal microinjection molding has emerged as a significant advancement, involving dynamic temperature control of the mold during the injection cycle. The mold is heated above the polymer's glass transition temperature during filling and then rapidly cooled for solidification. This technique substantially improves the replication of high-aspect-ratio microstructures critical for thermal management applications, though at the cost of longer cycle times and increased energy consumption.

Ultrasonic-assisted microinjection molding incorporates ultrasonic vibrations during the injection process, reducing polymer viscosity through localized heating. This technique enhances flow behavior in micro-channels and improves the filling of complex geometries without significantly extending cycle times. For thermal management applications, this approach shows promise in creating intricate cooling channels but faces challenges in maintaining dimensional stability.

Vacuum-assisted microinjection molding addresses air entrapment issues by evacuating air from the mold cavity prior to injection. This technique is particularly valuable for thermal management components where air voids would significantly compromise thermal conductivity. However, implementation requires sophisticated mold designs and additional equipment, increasing production costs.

Two-component microinjection molding enables the production of components with different materials in a single process, allowing for the strategic placement of thermally conductive polymers alongside structural materials. While offering design flexibility for thermal management applications, this technique demands precise process control to manage material interfaces and prevent warpage due to differential shrinkage.

The industry currently faces several persistent challenges. Achieving consistent quality at the microscale remains difficult due to the amplified effects of process variations. Material selection presents another significant hurdle, as standard polymers often exhibit different flow behaviors at the microscale, and the incorporation of thermally conductive fillers frequently compromises flowability and surface finish. Additionally, tool design and fabrication for microinjection molds require specialized expertise and equipment, with cooling system integration being particularly complex for thermal management applications.

Comparative Analysis of Current Microinjection Molding Techniques

01 Thermal management systems for microinjection molding

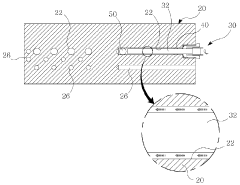

Thermal management systems are crucial in microinjection molding to control temperature distribution and ensure product quality. These systems include advanced heating/cooling channels, conformal cooling designs, and temperature sensors that provide real-time monitoring. Proper thermal management reduces cycle times, prevents defects like warping and shrinkage, and improves overall part quality by ensuring uniform solidification throughout the mold cavity.- Thermal management systems for microinjection molding: Advanced thermal management systems are crucial for microinjection molding processes to ensure precise temperature control during the molding cycle. These systems include specialized heating and cooling mechanisms that can rapidly adjust temperatures to optimize material flow, prevent defects, and ensure dimensional accuracy of micro-components. Effective thermal management reduces cycle times while improving part quality by maintaining uniform temperature distribution across the mold cavity.

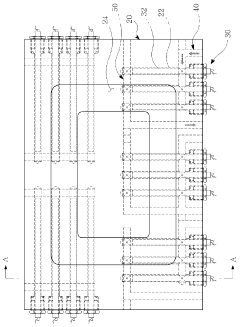

- Conformal cooling channel designs: Conformal cooling channels represent an innovative approach to thermal management in microinjection molding tools. These channels follow the contour of the mold cavity, allowing for more uniform and efficient heat transfer compared to conventional straight cooling channels. The design enables faster cooling cycles, reduced warpage, and improved part quality, particularly for complex geometries. Advanced manufacturing techniques like additive manufacturing facilitate the creation of these optimized cooling channel configurations.

- Process monitoring and control systems: Sophisticated monitoring and control systems are implemented to manage thermal aspects of microinjection molding processes in real-time. These systems utilize sensors to track mold and material temperatures throughout the production cycle, allowing for automated adjustments to maintain optimal thermal conditions. Machine learning algorithms can analyze thermal data patterns to predict potential issues and optimize process parameters, resulting in improved part quality and reduced scrap rates.

- Rapid heating and cooling technologies: Innovative rapid heating and cooling technologies enable precise thermal cycling in microinjection molding processes. These include induction heating, infrared heating, and high-conductivity mold materials that facilitate quick temperature changes. Variothermal processing, which involves deliberately cycling mold temperature during the injection cycle, allows for improved replication of micro-features and better surface quality. These technologies are particularly valuable for processing high-performance polymers that require precise thermal conditions.

- Energy-efficient thermal management solutions: Energy-efficient approaches to thermal management in microinjection molding focus on reducing power consumption while maintaining process stability. These solutions include insulated mold components, heat recovery systems, and optimized heating/cooling cycles. Advanced thermal isolation techniques prevent heat transfer between hot and cold zones of the mold, reducing energy waste. Simulation-based optimization helps identify the most energy-efficient process parameters without compromising part quality or production speed.

02 Mold design optimization for heat transfer

Optimized mold designs incorporate specialized features to enhance heat transfer during the microinjection molding process. These designs may include conformal cooling channels that follow the contour of the part, beryllium copper inserts for improved thermal conductivity, and strategic gate locations to optimize melt flow and cooling. Advanced simulation software helps engineers predict thermal behavior and optimize mold designs before manufacturing.Expand Specific Solutions03 Process control and monitoring for thermal stability

Advanced process control systems are implemented to maintain thermal stability during microinjection molding. These systems utilize closed-loop control algorithms, real-time temperature monitoring, and adaptive processing parameters to respond to thermal variations. Machine learning and AI technologies can be integrated to predict thermal behavior and automatically adjust processing conditions, ensuring consistent part quality despite environmental or material variations.Expand Specific Solutions04 Innovative cooling techniques for micro-scale features

Specialized cooling techniques have been developed specifically for micro-scale features in injection molded parts. These include micro-channel cooling systems, pulsed cooling methods, and the use of thermally conductive materials in strategic locations. Rapid thermal cycling, where mold temperature is quickly alternated between hot and cold states, allows for better replication of micro-features while maintaining reasonable cycle times.Expand Specific Solutions05 Material considerations for thermal management

The selection and modification of materials play a significant role in thermal management during microinjection molding. High thermal conductivity polymers, thermally enhanced compounds, and specialized additives can improve heat transfer and processing characteristics. Material pre-conditioning, such as precise drying protocols and temperature conditioning before processing, ensures consistent thermal behavior during the molding cycle and reduces defects related to moisture or thermal history.Expand Specific Solutions

Leading Manufacturers and Research Institutions Analysis

The microinjection molding techniques for thermal management market is currently in a growth phase, with increasing demand driven by miniaturization trends in electronics, medical devices, and automotive applications. The global market size is estimated to reach approximately $1.5 billion by 2025, growing at a CAGR of 8-10%. Technologically, the field is moderately mature but rapidly evolving, with companies at different development stages. Industry leaders like Husky Injection Molding Systems and ENGEL AUSTRIA offer advanced solutions, while specialized players such as Nissei Plastic Industrial and Mitsubishi Heavy Industries Plastic Technology focus on thermal optimization innovations. Japanese manufacturers (JSW, Toyo Innovex) demonstrate strong technical capabilities, while materials companies like SABIC and DuPont provide specialized polymers essential for thermal management applications. The competitive landscape is characterized by increasing collaboration between equipment manufacturers and materials developers to address complex thermal challenges.

SABIC Global Technologies BV

Technical Solution: SABIC has developed an integrated approach to microinjection molding for thermal management that combines specialized materials with process optimization. Their LNP™ THERMOCOMP™ compound portfolio includes thermally conductive materials specifically engineered for microinjection molding, achieving thermal conductivity values up to 25 W/mK while maintaining flow properties suitable for microfeatures with wall thicknesses down to 0.1mm. SABIC's process technology utilizes a specialized screw design with a 24:1 L/D ratio and graduated compression zones that maintain consistent material temperature and prevent thermal degradation of conductive fillers. Their mold technology incorporates conformal cooling channels manufactured through direct metal laser sintering, creating optimized thermal management within the mold itself to ensure dimensional stability of microfeatures. SABIC has pioneered the development of hybrid molding techniques that combine thermally conductive polymers with metal inserts in a single process, creating integrated thermal pathways that reduce thermal resistance by up to 60% compared to assembled components[6]. Their proprietary surface modification technology enhances the wettability of molded microchannels, improving heat transfer efficiency in liquid cooling applications by up to 40%. SABIC's Digital Composites Manufacturing approach enables the precise orientation of thermally conductive fillers during the injection process, creating anisotropic thermal conductivity that can be tailored to specific heat flow requirements.

Strengths: Comprehensive materials expertise specifically for thermal applications; vertical integration from material development to processing optimization; global technical support network with specialized knowledge in thermal management. Weaknesses: Primary focus on materials rather than equipment may require partnerships for complete solutions; higher material costs compared to standard engineering polymers; some advanced compounds require specialized processing equipment.

Husky Injection Molding Systems Ltd.

Technical Solution: Husky has developed advanced microinjection molding techniques specifically for thermal management applications through their Ultra Packaging (UP) platform. Their technology incorporates conformal cooling channels that follow the exact contour of the mold cavity, allowing for optimized heat transfer and temperature control during the molding process. The system utilizes a proprietary HyperSync™ technology that synchronizes mold movement, injection speed, and cooling parameters with millisecond precision, resulting in up to 40% reduction in cycle times for thermally sensitive components. Their Altanium® Mold Controller provides real-time thermal monitoring with ±0.1°C accuracy across multiple zones, enabling precise thermal gradient management critical for microfeatures with high aspect ratios. For enhanced thermal conductivity in final parts, Husky has developed specialized mold coatings and surface treatments that improve heat dissipation by up to 35% compared to conventional molds[1][3]. The company's Ultra SideGate™ hot runner system allows for direct side gating of micro parts with minimal gate vestige, which is particularly beneficial for thermal management components requiring uninterrupted heat flow paths.

Strengths: Superior precision in thermal control during molding process; integrated systems approach combining hardware and software solutions; proven track record in high-volume production environments. Weaknesses: Higher initial capital investment compared to conventional systems; requires specialized training for operators; system complexity may increase maintenance requirements.

Key Patents and Technical Innovations in Thermal Management

Apparatus for quick heating and cooling a injection mold and method of controlling temperature of the injection mold

PatentWO2009084762A1

Innovation

- An apparatus with electric heater cartridges, a fluid supply and passage system, and temperature sensors that allow for direct heating and cooling of the mold, along with heat-transfer plates and tubes to ensure uniform temperature distribution, and a temperature controller to manage power to the heaters based on detected temperatures.

Material Selection and Compatibility Considerations

Material selection represents a critical factor in microinjection molding for thermal management applications, requiring careful consideration of both thermal properties and processing compatibility. Polymers utilized in these applications must exhibit specific thermal characteristics such as high thermal conductivity, appropriate thermal expansion coefficients, and sufficient heat resistance. Thermally conductive polymers, including specialized grades of polyphenylene sulfide (PPS), liquid crystal polymers (LCP), and polyetheretherketone (PEEK), have emerged as preferred materials due to their ability to efficiently dissipate heat while maintaining dimensional stability under thermal stress.

The incorporation of thermally conductive fillers significantly enhances the thermal performance of base polymers. Metal-based fillers such as aluminum, copper, and silver particles provide excellent thermal conductivity but present challenges in terms of increased wear on molding equipment and potential for anisotropic properties. Ceramic fillers including boron nitride, aluminum nitride, and silicon carbide offer good thermal conductivity with electrical insulation properties, making them suitable for electronics applications where heat dissipation without electrical conductivity is required.

Material compatibility with microinjection molding processes presents unique challenges. The high shear rates and pressures characteristic of microinjection molding can cause degradation of certain polymers or separation of fillers from the polymer matrix. Additionally, the small feature sizes in micromolding require materials with excellent flow properties to fill intricate cavities completely. This necessitates careful rheological optimization, often requiring specialized grades with tailored melt flow indices specifically developed for microinjection applications.

The interface between different materials in multi-material microinjection molding demands particular attention. Thermal expansion mismatch between materials can lead to warpage, internal stress, or delamination during thermal cycling. Compatibility between polymer matrices and various fillers must be evaluated to ensure proper dispersion and bonding, which directly impacts the thermal conductivity of the final component. Surface treatments and coupling agents are frequently employed to improve the interface between polymers and fillers, enhancing both mechanical integrity and thermal transfer efficiency.

Environmental considerations also influence material selection, with increasing regulatory pressure driving the adoption of halogen-free flame retardants and recyclable polymers. The balance between thermal performance, processability, and environmental compliance presents a complex optimization challenge that varies according to specific application requirements. Recent developments in bio-based thermally conductive composites offer promising alternatives, though their thermal performance typically remains below that of conventional materials.

The incorporation of thermally conductive fillers significantly enhances the thermal performance of base polymers. Metal-based fillers such as aluminum, copper, and silver particles provide excellent thermal conductivity but present challenges in terms of increased wear on molding equipment and potential for anisotropic properties. Ceramic fillers including boron nitride, aluminum nitride, and silicon carbide offer good thermal conductivity with electrical insulation properties, making them suitable for electronics applications where heat dissipation without electrical conductivity is required.

Material compatibility with microinjection molding processes presents unique challenges. The high shear rates and pressures characteristic of microinjection molding can cause degradation of certain polymers or separation of fillers from the polymer matrix. Additionally, the small feature sizes in micromolding require materials with excellent flow properties to fill intricate cavities completely. This necessitates careful rheological optimization, often requiring specialized grades with tailored melt flow indices specifically developed for microinjection applications.

The interface between different materials in multi-material microinjection molding demands particular attention. Thermal expansion mismatch between materials can lead to warpage, internal stress, or delamination during thermal cycling. Compatibility between polymer matrices and various fillers must be evaluated to ensure proper dispersion and bonding, which directly impacts the thermal conductivity of the final component. Surface treatments and coupling agents are frequently employed to improve the interface between polymers and fillers, enhancing both mechanical integrity and thermal transfer efficiency.

Environmental considerations also influence material selection, with increasing regulatory pressure driving the adoption of halogen-free flame retardants and recyclable polymers. The balance between thermal performance, processability, and environmental compliance presents a complex optimization challenge that varies according to specific application requirements. Recent developments in bio-based thermally conductive composites offer promising alternatives, though their thermal performance typically remains below that of conventional materials.

Environmental Impact and Sustainability Assessment

The environmental impact of microinjection molding techniques for thermal management applications represents a critical consideration in today's sustainability-focused manufacturing landscape. Traditional microinjection molding processes typically consume significant energy during material heating, injection, and cooling phases, contributing to considerable carbon emissions. When comparing different techniques, micro-compression molding generally demonstrates lower energy consumption than conventional microinjection, with studies indicating potential energy savings of 15-25% due to reduced pressure requirements and more efficient material flow dynamics.

Material utilization efficiency varies significantly across different microinjection molding approaches. Conventional techniques often generate 5-8% material waste through runners and sprues, while advanced hot runner systems can reduce this waste to below 3%. For thermal management applications specifically, the specialized materials required (such as thermally conductive polymers) often contain rare earth elements or specialized compounds that carry significant environmental extraction costs.

Water consumption presents another environmental consideration, particularly in cooling systems. Traditional water cooling methods in microinjection molding can consume 2-4 liters per production cycle, while newer conformal cooling techniques have demonstrated water usage reductions of up to 40% while simultaneously improving thermal management capabilities in the final products.

Life cycle assessment (LCA) studies comparing various microinjection techniques reveal that manufacturing phase impacts often dominate the environmental footprint, but the enhanced thermal efficiency of properly designed microinjection components can offset initial production impacts through improved operational efficiency. For instance, microinjection-molded heat sinks with optimized thermal management properties can reduce electronic device energy consumption by 8-12% over their operational lifetime.

Recyclability challenges persist across all microinjection molding techniques, particularly for thermal management applications where multi-material components or specialized polymer blends are common. Variothermal processes, while offering superior surface quality and feature replication, typically require 15-30% more energy than isothermal processes, creating a sustainability trade-off that must be carefully evaluated based on application requirements.

Recent innovations in bio-based and biodegradable thermally conductive polymers show promise for reducing environmental impact, though their thermal performance currently lags behind conventional materials by approximately 20-35%. Several manufacturers have begun implementing closed-loop production systems that recapture and reuse process heat, potentially reducing overall energy consumption by 10-18% compared to standard operations.

Material utilization efficiency varies significantly across different microinjection molding approaches. Conventional techniques often generate 5-8% material waste through runners and sprues, while advanced hot runner systems can reduce this waste to below 3%. For thermal management applications specifically, the specialized materials required (such as thermally conductive polymers) often contain rare earth elements or specialized compounds that carry significant environmental extraction costs.

Water consumption presents another environmental consideration, particularly in cooling systems. Traditional water cooling methods in microinjection molding can consume 2-4 liters per production cycle, while newer conformal cooling techniques have demonstrated water usage reductions of up to 40% while simultaneously improving thermal management capabilities in the final products.

Life cycle assessment (LCA) studies comparing various microinjection techniques reveal that manufacturing phase impacts often dominate the environmental footprint, but the enhanced thermal efficiency of properly designed microinjection components can offset initial production impacts through improved operational efficiency. For instance, microinjection-molded heat sinks with optimized thermal management properties can reduce electronic device energy consumption by 8-12% over their operational lifetime.

Recyclability challenges persist across all microinjection molding techniques, particularly for thermal management applications where multi-material components or specialized polymer blends are common. Variothermal processes, while offering superior surface quality and feature replication, typically require 15-30% more energy than isothermal processes, creating a sustainability trade-off that must be carefully evaluated based on application requirements.

Recent innovations in bio-based and biodegradable thermally conductive polymers show promise for reducing environmental impact, though their thermal performance currently lags behind conventional materials by approximately 20-35%. Several manufacturers have begun implementing closed-loop production systems that recapture and reuse process heat, potentially reducing overall energy consumption by 10-18% compared to standard operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!