Analysis of Efficiency Improvements in Microinjection Molding Techniques

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microinjection Molding Technology Evolution and Objectives

Microinjection molding technology emerged in the late 1980s as an extension of conventional injection molding, specifically designed to produce microscale components with high precision. The evolution of this technology has been driven by increasing demands in industries such as medical devices, electronics, and microfluidics, where miniaturization continues to be a critical trend. Initially limited by equipment capabilities and material constraints, microinjection molding has undergone significant advancements through iterative engineering improvements and cross-disciplinary innovations.

The 1990s marked the first commercial applications, primarily focused on simple geometries with limited precision. By the early 2000s, technological breakthroughs in machine design, particularly in injection control systems and mold fabrication techniques, enabled more complex microstructures with improved surface finishes. The development of specialized micro-molding machines by manufacturers like Wittmann Battenfeld and Arburg represented a significant milestone, moving away from adapted conventional equipment.

Material science advancements have paralleled equipment evolution, with the development of specialized polymers exhibiting enhanced flow properties at microscale. These materials have overcome traditional limitations in filling micro-cavities and replicating high-aspect-ratio features. The integration of new additives and nanocomposites has further expanded the functional capabilities of micro-molded components.

Recent technological trajectories show increasing focus on process efficiency, with particular emphasis on cycle time reduction, energy consumption optimization, and scrap minimization. Industry 4.0 principles are being incorporated through sensor integration, real-time monitoring systems, and predictive maintenance protocols, creating smarter and more responsive production environments.

The primary objective of current microinjection molding technology development is achieving higher efficiency without compromising the exceptional precision requirements. This includes reducing setup times, minimizing material waste, optimizing energy usage, and increasing throughput while maintaining dimensional accuracy at the microscale. Secondary objectives include expanding the range of processable materials and enhancing the replicability of increasingly complex microstructures.

Looking forward, the technology roadmap aims to address persistent challenges in process stability, tool longevity, and quality consistency. Emerging research focuses on developing predictive models for material behavior at the microscale, implementing advanced control algorithms for process optimization, and creating more sustainable production methods through closed-loop material recycling and energy-efficient operation.

The convergence of microinjection molding with complementary technologies such as additive manufacturing and surface functionalization represents a promising frontier, potentially enabling hybrid manufacturing approaches that combine the high throughput of injection molding with the geometric freedom of other processes.

The 1990s marked the first commercial applications, primarily focused on simple geometries with limited precision. By the early 2000s, technological breakthroughs in machine design, particularly in injection control systems and mold fabrication techniques, enabled more complex microstructures with improved surface finishes. The development of specialized micro-molding machines by manufacturers like Wittmann Battenfeld and Arburg represented a significant milestone, moving away from adapted conventional equipment.

Material science advancements have paralleled equipment evolution, with the development of specialized polymers exhibiting enhanced flow properties at microscale. These materials have overcome traditional limitations in filling micro-cavities and replicating high-aspect-ratio features. The integration of new additives and nanocomposites has further expanded the functional capabilities of micro-molded components.

Recent technological trajectories show increasing focus on process efficiency, with particular emphasis on cycle time reduction, energy consumption optimization, and scrap minimization. Industry 4.0 principles are being incorporated through sensor integration, real-time monitoring systems, and predictive maintenance protocols, creating smarter and more responsive production environments.

The primary objective of current microinjection molding technology development is achieving higher efficiency without compromising the exceptional precision requirements. This includes reducing setup times, minimizing material waste, optimizing energy usage, and increasing throughput while maintaining dimensional accuracy at the microscale. Secondary objectives include expanding the range of processable materials and enhancing the replicability of increasingly complex microstructures.

Looking forward, the technology roadmap aims to address persistent challenges in process stability, tool longevity, and quality consistency. Emerging research focuses on developing predictive models for material behavior at the microscale, implementing advanced control algorithms for process optimization, and creating more sustainable production methods through closed-loop material recycling and energy-efficient operation.

The convergence of microinjection molding with complementary technologies such as additive manufacturing and surface functionalization represents a promising frontier, potentially enabling hybrid manufacturing approaches that combine the high throughput of injection molding with the geometric freedom of other processes.

Market Demand Analysis for High-Efficiency Microinjection Molding

The global market for microinjection molding technologies has experienced significant growth in recent years, driven primarily by increasing demand for miniaturized components across multiple industries. The market size for microinjection molding equipment and services was valued at approximately $1.5 billion in 2022 and is projected to reach $2.7 billion by 2028, representing a compound annual growth rate of 10.3% during the forecast period.

Healthcare and medical device manufacturing constitute the largest application segment, accounting for nearly 45% of the total market share. This dominance stems from the growing need for precise, small-scale medical components such as drug delivery systems, surgical instruments, implantable devices, and diagnostic equipment. The trend toward minimally invasive procedures has further accelerated demand for micro-molded components with complex geometries and tight tolerances.

Consumer electronics represents the second-largest market segment, driven by the continuous miniaturization of electronic devices and components. Manufacturers require increasingly smaller connectors, switches, and housings that maintain structural integrity while accommodating advanced functionality. This segment is expected to grow at 12.1% annually through 2028, outpacing the overall market growth rate.

Automotive applications are emerging as a rapidly expanding segment, particularly with the rise of electric vehicles and advanced driver assistance systems. These technologies require numerous precision components that benefit from high-efficiency microinjection molding processes. Market analysts predict this segment will grow from 8% of the total market share to approximately 15% by 2028.

Regional analysis reveals that Asia-Pacific dominates the market with a 42% share, followed by North America (28%) and Europe (24%). China, Japan, and South Korea are particularly significant manufacturing hubs, while Germany leads European production. The fastest growth is occurring in emerging economies such as India and Vietnam, where medical device manufacturing and electronics production are expanding rapidly.

Customer demands are increasingly focused on three key areas: production efficiency, component quality, and sustainability. End-users report willingness to invest in advanced microinjection molding technologies that reduce cycle times by at least 20% while maintaining or improving part quality. Additionally, 78% of surveyed manufacturers indicated that energy efficiency and material waste reduction are becoming critical factors in equipment purchasing decisions.

The market is also witnessing a shift toward integrated solutions that combine microinjection molding with in-line quality control systems, automated part handling, and digital process monitoring. This trend reflects the growing importance of Industry 4.0 principles in precision manufacturing and represents a significant opportunity for technology providers who can deliver comprehensive efficiency improvements.

Healthcare and medical device manufacturing constitute the largest application segment, accounting for nearly 45% of the total market share. This dominance stems from the growing need for precise, small-scale medical components such as drug delivery systems, surgical instruments, implantable devices, and diagnostic equipment. The trend toward minimally invasive procedures has further accelerated demand for micro-molded components with complex geometries and tight tolerances.

Consumer electronics represents the second-largest market segment, driven by the continuous miniaturization of electronic devices and components. Manufacturers require increasingly smaller connectors, switches, and housings that maintain structural integrity while accommodating advanced functionality. This segment is expected to grow at 12.1% annually through 2028, outpacing the overall market growth rate.

Automotive applications are emerging as a rapidly expanding segment, particularly with the rise of electric vehicles and advanced driver assistance systems. These technologies require numerous precision components that benefit from high-efficiency microinjection molding processes. Market analysts predict this segment will grow from 8% of the total market share to approximately 15% by 2028.

Regional analysis reveals that Asia-Pacific dominates the market with a 42% share, followed by North America (28%) and Europe (24%). China, Japan, and South Korea are particularly significant manufacturing hubs, while Germany leads European production. The fastest growth is occurring in emerging economies such as India and Vietnam, where medical device manufacturing and electronics production are expanding rapidly.

Customer demands are increasingly focused on three key areas: production efficiency, component quality, and sustainability. End-users report willingness to invest in advanced microinjection molding technologies that reduce cycle times by at least 20% while maintaining or improving part quality. Additionally, 78% of surveyed manufacturers indicated that energy efficiency and material waste reduction are becoming critical factors in equipment purchasing decisions.

The market is also witnessing a shift toward integrated solutions that combine microinjection molding with in-line quality control systems, automated part handling, and digital process monitoring. This trend reflects the growing importance of Industry 4.0 principles in precision manufacturing and represents a significant opportunity for technology providers who can deliver comprehensive efficiency improvements.

Current Technological Limitations and Challenges in Microinjection Molding

Despite significant advancements in microinjection molding technology, several critical limitations and challenges continue to impede efficiency improvements in this field. The miniaturization of components has introduced unprecedented complexities in material flow behavior at the micro-scale. Conventional polymer flow models often fail to accurately predict material behavior when channel dimensions approach the molecular size of polymers, resulting in unpredictable filling patterns and defects. This phenomenon, known as the "scale effect," creates substantial discrepancies between simulation predictions and actual molding outcomes.

Thermal management represents another significant challenge. The rapid cooling rates in microinjection molding create extremely short processing windows, often less than one second. This limited timeframe makes it difficult to achieve complete cavity filling before material solidification occurs, particularly in high-aspect-ratio microfeatures. The resulting incomplete filling and weld lines significantly compromise part quality and mechanical properties.

Tool fabrication precision presents persistent technical barriers. Manufacturing mold inserts with microfeatures requires ultra-precision machining techniques such as micro-EDM, laser ablation, or LIGA processes. These methods face limitations in achievable aspect ratios, surface finish quality, and dimensional accuracy. Current technology struggles to consistently produce features below 10 micrometers with the required precision, creating a bottleneck in advancing to smaller component sizes.

Material limitations further constrain efficiency improvements. Standard polymers often exhibit inconsistent flow behavior at the micro-scale due to wall adhesion effects and molecular orientation phenomena. Additionally, conventional additives and fillers become problematic as their dimensions approach or exceed the size of microfeatures, causing clogging and inconsistent distribution. The industry lacks specially formulated materials optimized specifically for microinjection applications.

Process control and monitoring capabilities remain inadequate for micro-scale operations. Current sensor technologies struggle to provide real-time data on cavity pressure, temperature distribution, and flow front progression within micro-cavities. This monitoring gap prevents the implementation of advanced process control strategies that could significantly enhance production stability and part quality consistency.

Demolding challenges constitute another efficiency barrier. The increased surface-to-volume ratio in microparts intensifies adhesion forces between the polymer and mold surfaces. This often results in part deformation or breakage during ejection, necessitating specialized surface treatments or complex ejection mechanisms that add cost and complexity to the production process.

Finally, standardization deficiencies across the industry impede knowledge sharing and technology transfer. The lack of unified testing protocols, quality metrics, and design guidelines specific to microinjection molding forces manufacturers to develop proprietary approaches, slowing overall technological advancement and efficiency optimization.

Thermal management represents another significant challenge. The rapid cooling rates in microinjection molding create extremely short processing windows, often less than one second. This limited timeframe makes it difficult to achieve complete cavity filling before material solidification occurs, particularly in high-aspect-ratio microfeatures. The resulting incomplete filling and weld lines significantly compromise part quality and mechanical properties.

Tool fabrication precision presents persistent technical barriers. Manufacturing mold inserts with microfeatures requires ultra-precision machining techniques such as micro-EDM, laser ablation, or LIGA processes. These methods face limitations in achievable aspect ratios, surface finish quality, and dimensional accuracy. Current technology struggles to consistently produce features below 10 micrometers with the required precision, creating a bottleneck in advancing to smaller component sizes.

Material limitations further constrain efficiency improvements. Standard polymers often exhibit inconsistent flow behavior at the micro-scale due to wall adhesion effects and molecular orientation phenomena. Additionally, conventional additives and fillers become problematic as their dimensions approach or exceed the size of microfeatures, causing clogging and inconsistent distribution. The industry lacks specially formulated materials optimized specifically for microinjection applications.

Process control and monitoring capabilities remain inadequate for micro-scale operations. Current sensor technologies struggle to provide real-time data on cavity pressure, temperature distribution, and flow front progression within micro-cavities. This monitoring gap prevents the implementation of advanced process control strategies that could significantly enhance production stability and part quality consistency.

Demolding challenges constitute another efficiency barrier. The increased surface-to-volume ratio in microparts intensifies adhesion forces between the polymer and mold surfaces. This often results in part deformation or breakage during ejection, necessitating specialized surface treatments or complex ejection mechanisms that add cost and complexity to the production process.

Finally, standardization deficiencies across the industry impede knowledge sharing and technology transfer. The lack of unified testing protocols, quality metrics, and design guidelines specific to microinjection molding forces manufacturers to develop proprietary approaches, slowing overall technological advancement and efficiency optimization.

Current Efficiency Enhancement Solutions in Microinjection Molding

01 Advanced mold design for microinjection molding

Advanced mold designs significantly improve microinjection molding efficiency. These designs incorporate precise cavity structures, optimized runner systems, and innovative gating solutions that enhance material flow and reduce cycle times. Features such as conformal cooling channels and vacuum-assisted mold filling help achieve better part quality while minimizing production time. These technological advancements in mold design are crucial for high-precision microcomponents manufacturing with improved throughput.- Advanced mold design for microinjection molding: Advanced mold designs significantly improve microinjection molding efficiency. These designs incorporate precise cavity structures, optimized runner systems, and innovative gating solutions that enhance material flow and reduce cycle times. Features such as conformal cooling channels and vacuum-assisted mold filling help achieve better part quality while minimizing production time. The integration of sensors for real-time monitoring and control further improves process stability and reduces defects.

- Process parameter optimization techniques: Optimizing process parameters is crucial for microinjection molding efficiency. This includes precise control of injection speed, pressure profiles, melt temperature, and cooling time. Advanced algorithms and simulation tools help determine optimal parameter combinations for specific materials and part geometries. Adaptive process control systems can make real-time adjustments to maintain consistency and reduce cycle times. These optimization techniques significantly reduce material waste, energy consumption, and production costs.

- Novel material formulations for improved flow: Specialized material formulations enhance microinjection molding efficiency by improving flow characteristics at the micro scale. These include polymer blends with optimized rheological properties, nanocomposites with reduced viscosity, and additives that enhance mold filling and release. Materials engineered specifically for microinjection applications can process at lower temperatures, reducing cycle times and energy consumption while maintaining mechanical properties and dimensional stability of the final parts.

- Automation and robotics integration: Integration of automation and robotics significantly enhances microinjection molding efficiency. Automated systems for part handling, quality inspection, and mold changeover reduce production downtime and labor costs. Robotic systems with high precision capabilities ensure consistent part removal without damage to delicate microfeatures. Advanced vision systems automatically detect defects and provide feedback for process adjustment. The implementation of Industry 4.0 concepts enables continuous monitoring and optimization of the entire production line.

- Hybrid and multi-material microinjection techniques: Hybrid and multi-material microinjection molding techniques improve production efficiency by combining multiple manufacturing steps into a single process. These include overmolding, insert molding, and multi-component injection that eliminate assembly operations. Advanced techniques such as combining microinjection with other processes like 3D printing or hot embossing create complex microstructures in fewer steps. These hybrid approaches reduce production time, improve part consistency, and enable novel functionalities that would be difficult to achieve with conventional methods.

02 Process parameter optimization for microinjection efficiency

Optimizing process parameters is essential for enhancing microinjection molding efficiency. Key parameters include injection speed, pressure profiles, melt and mold temperatures, cooling time, and holding pressure. Advanced control systems enable real-time adjustment of these parameters to achieve optimal processing conditions. This optimization reduces cycle times, minimizes material waste, and improves part quality consistency, resulting in significant efficiency gains in microinjection molding operations.Expand Specific Solutions03 Automation and robotics integration in microinjection systems

Integration of automation and robotics technologies in microinjection molding systems dramatically improves production efficiency. Automated part removal, quality inspection, and material handling reduce cycle times and labor costs. Robotic systems ensure precise and consistent operations, minimizing human error and enabling continuous production. Smart manufacturing principles and Industry 4.0 technologies further enhance efficiency through data-driven process control and predictive maintenance approaches.Expand Specific Solutions04 Novel material formulations for improved flow characteristics

Specialized material formulations enhance microinjection molding efficiency by improving flow characteristics at the micro scale. These formulations include modified polymers with optimized melt flow indices, nano-additives that reduce viscosity, and compounds designed specifically for rapid cooling. Advanced materials enable faster injection speeds, lower processing temperatures, and reduced cycle times while maintaining or improving mechanical properties of the final microcomponents.Expand Specific Solutions05 Micro and nano-structured surface technologies

Micro and nano-structured surface technologies applied to mold cavities significantly improve demolding efficiency in microinjection processes. These surface treatments reduce friction between the polymer and mold surface, enabling faster and more reliable part ejection. Technologies include specialized coatings, laser-textured surfaces, and plasma treatments that prevent sticking and minimize cycle times. These innovations are particularly valuable for high-aspect-ratio microfeatures and complex geometries where traditional demolding can be challenging.Expand Specific Solutions

Key Industry Players and Competitive Landscape Analysis

Microinjection molding technology is currently in a growth phase, with the market expected to reach significant expansion due to increasing demand for miniaturized components across medical, automotive, and consumer electronics sectors. The global market size is projected to grow substantially, driven by precision requirements in these industries. Technologically, the field is advancing rapidly with companies at different maturity levels. Industry leaders like Husky Injection Molding Systems and FANUC Corp. have established sophisticated automation and control systems, while Murata Manufacturing and Robert Bosch focus on specialized applications. Academic institutions such as Beijing University of Chemical Technology and Tiangong University are contributing fundamental research, creating a competitive landscape where collaboration between industry and academia is accelerating efficiency improvements in microinjection molding processes.

Husky Injection Molding Systems Ltd.

Technical Solution: Husky has developed advanced HyPET HPP5 systems specifically optimized for micro-injection molding applications. Their technology incorporates precise servo-electric drives with positioning accuracy of ±0.01mm and ultra-fast injection speeds up to 350mm/s. The system features an integrated hot runner technology with valve gate control allowing for gate opening/closing times under 8ms, significantly reducing cycle times by up to 40% compared to conventional systems. Husky's patented Active Cooling Technology enables rapid mold temperature control with heating/cooling cycles under 3 seconds, critical for micro-feature replication. Their Ultra Packaging (UP) platform integrates real-time process monitoring with pressure sensors capable of detecting variations as small as 0.5 bar, ensuring consistent part quality for micro-components with tolerances as tight as ±5μm.

Strengths: Industry-leading injection speed and precision control; integrated hot runner systems specifically designed for micro-molding; comprehensive process monitoring capabilities. Weaknesses: Higher initial capital investment compared to conventional systems; requires specialized operator training; system complexity may increase maintenance requirements.

FANUC Corp.

Technical Solution: FANUC has developed the ROBOSHOT α-S15iA micro-injection molding system featuring their AI Mold Protection technology that provides ultra-precise control with force sensitivity as low as 0.3kN. The system incorporates a high-precision servo-electric drive with positioning accuracy of ±0.0005mm and acceleration/deceleration times under 50ms. FANUC's Precise Metering Control (PMC) technology achieves volumetric accuracy of ±0.01% through closed-loop control of the screw position during plasticization. Their system features specialized micro-nozzles with diameters as small as 0.8mm and precision-ground non-return valves with clearances under 0.01mm to prevent material leakage. The ROBOSHOT platform integrates with FANUC's comprehensive factory automation systems, enabling fully automated micro-molding cells with cycle time reductions of approximately 35% compared to manual operations. Their AI Backflow Monitor provides real-time detection of material consistency variations as small as 0.05cc, ensuring part quality consistency.

Strengths: Exceptional precision and repeatability; seamless integration with robotic automation systems; comprehensive AI-driven process monitoring. Weaknesses: Less specialized in pure micro-molding compared to dedicated micro-molding equipment manufacturers; higher complexity in setup and programming; premium pricing structure.

Critical Patents and Technical Innovations in Process Optimization

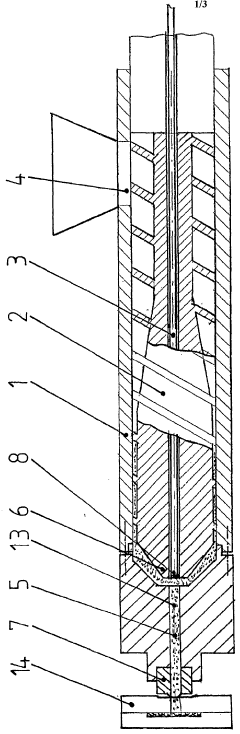

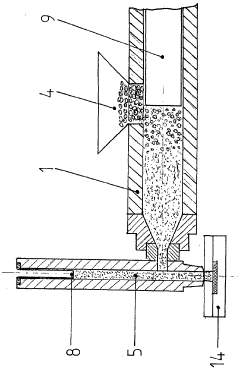

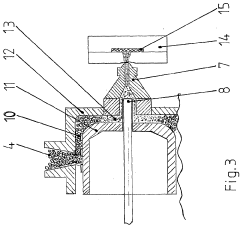

Methods for microcellular injection molding

PatentActiveUS20120061870A1

Innovation

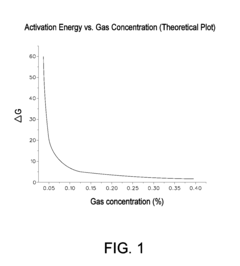

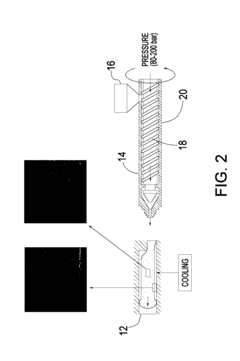

- The method involves processing a polymer with a supercritical fluid to create a single-phase polymer-gas solution, adjusting conditions to control the weight and surface characteristics of the plastic part, and injecting the mixture into a mold where pressure drop causes nucleation of bubbles, reducing SCF concentrations to minimize surface irregularities and enhance dimensional stability.

Method for injection moulding shaped parts from plastics

PatentWO2002051612A1

Innovation

- The method involves injecting the melt directly into the mold using a gaseous or liquid medium, eliminating the need for mechanically movable assemblies and allowing for a sprue-free production with improved stability and reduced cooling time, applicable to various injection molding machines with different plasticizing and injection devices.

Material Advancements for Improved Microinjection Performance

Recent advancements in material science have significantly contributed to enhancing microinjection molding efficiency. Traditional polymers used in microinjection molding often face challenges related to flow behavior, solidification rates, and surface finish quality. However, the development of specialized polymer blends with optimized rheological properties has revolutionized the field, allowing for faster cycle times and improved part quality.

Nano-composite materials represent a breakthrough in microinjection molding technology. By incorporating nanoparticles such as carbon nanotubes, graphene, or nano-clays into polymer matrices, manufacturers can achieve enhanced mechanical properties while maintaining excellent flow characteristics. These materials demonstrate lower viscosity at processing temperatures, enabling faster filling of micro-cavities and more precise replication of micro-features.

Bio-based polymers have emerged as sustainable alternatives that also offer performance advantages. Materials such as PLA (polylactic acid) and PHB (polyhydroxybutyrate) with tailored additives demonstrate improved flow properties and reduced cycle times compared to their conventional counterparts. These materials respond well to high-speed injection processes while maintaining dimensional stability in micro-scale applications.

The development of low-friction internal additives has been particularly impactful for microinjection efficiency. These additives reduce the interaction between polymer melts and mold surfaces, decreasing the force required for ejection and minimizing wear on delicate mold components. This advancement has enabled the design of thinner walls and more complex geometries while reducing cycle times by up to 15%.

High-performance liquid crystal polymers (LCPs) have gained prominence in microinjection applications requiring extreme precision. These materials exhibit exceptional flow properties in the melt state while maintaining dimensional stability during cooling. Their self-reinforcing molecular structure eliminates the need for fiber reinforcement in many applications, simplifying processing and reducing wear on equipment.

Metal-polymer hybrid materials represent another frontier in microinjection molding. These composites combine the flowability of polymers with the enhanced thermal conductivity of metallic particles, allowing for more rapid heat transfer during cooling phases. The accelerated cooling results in shorter cycle times and improved surface quality, particularly beneficial for micro-components with high aspect ratios.

Advancements in polymer processing aids have also contributed significantly to efficiency improvements. Modern nucleating agents promote faster and more uniform crystallization, reducing cooling time requirements. Similarly, new mold release agents specifically formulated for micro-scale applications minimize sticking issues that previously caused production delays and quality problems in microinjection processes.

Nano-composite materials represent a breakthrough in microinjection molding technology. By incorporating nanoparticles such as carbon nanotubes, graphene, or nano-clays into polymer matrices, manufacturers can achieve enhanced mechanical properties while maintaining excellent flow characteristics. These materials demonstrate lower viscosity at processing temperatures, enabling faster filling of micro-cavities and more precise replication of micro-features.

Bio-based polymers have emerged as sustainable alternatives that also offer performance advantages. Materials such as PLA (polylactic acid) and PHB (polyhydroxybutyrate) with tailored additives demonstrate improved flow properties and reduced cycle times compared to their conventional counterparts. These materials respond well to high-speed injection processes while maintaining dimensional stability in micro-scale applications.

The development of low-friction internal additives has been particularly impactful for microinjection efficiency. These additives reduce the interaction between polymer melts and mold surfaces, decreasing the force required for ejection and minimizing wear on delicate mold components. This advancement has enabled the design of thinner walls and more complex geometries while reducing cycle times by up to 15%.

High-performance liquid crystal polymers (LCPs) have gained prominence in microinjection applications requiring extreme precision. These materials exhibit exceptional flow properties in the melt state while maintaining dimensional stability during cooling. Their self-reinforcing molecular structure eliminates the need for fiber reinforcement in many applications, simplifying processing and reducing wear on equipment.

Metal-polymer hybrid materials represent another frontier in microinjection molding. These composites combine the flowability of polymers with the enhanced thermal conductivity of metallic particles, allowing for more rapid heat transfer during cooling phases. The accelerated cooling results in shorter cycle times and improved surface quality, particularly beneficial for micro-components with high aspect ratios.

Advancements in polymer processing aids have also contributed significantly to efficiency improvements. Modern nucleating agents promote faster and more uniform crystallization, reducing cooling time requirements. Similarly, new mold release agents specifically formulated for micro-scale applications minimize sticking issues that previously caused production delays and quality problems in microinjection processes.

Sustainability and Energy Efficiency Considerations

Sustainability and energy efficiency have become critical considerations in modern manufacturing processes, including microinjection molding techniques. The miniaturization trend in various industries has led to increased demand for micro-components, yet this production method traditionally consumes significant energy resources. Recent advancements in microinjection molding have focused on reducing environmental impact while maintaining or improving production efficiency.

Energy consumption in microinjection molding primarily occurs during material heating, injection, and cooling phases. Innovative approaches have emerged to optimize these energy-intensive stages. Variable-frequency drives for hydraulic pumps have demonstrated energy savings of 30-50% compared to conventional systems by adjusting power output based on real-time process requirements. Similarly, all-electric injection molding machines have shown energy efficiency improvements of up to 70% over hydraulic systems, with the added benefit of reduced noise pollution and elimination of hydraulic oil disposal concerns.

Material innovations also contribute significantly to sustainability improvements. Bio-based and biodegradable polymers are increasingly being adapted for microinjection molding applications, reducing dependency on petroleum-based materials. These alternatives often require lower processing temperatures, further reducing energy consumption. Additionally, advanced material formulations with improved flow characteristics enable lower injection pressures and temperatures while maintaining part quality.

Process optimization techniques have evolved to enhance both sustainability and production efficiency. Rapid heating and cooling technologies, such as conformal cooling channels created through additive manufacturing, can reduce cycle times by up to 40% while decreasing energy consumption. Simulation software advancements allow for virtual optimization of process parameters before physical implementation, minimizing material waste and energy consumption during setup and production.

Waste reduction strategies complement energy efficiency improvements in creating more sustainable microinjection molding operations. Hot runner systems eliminate or significantly reduce sprue and runner waste, particularly valuable when working with expensive engineering polymers or medical-grade materials. Closed-loop production systems that incorporate in-line quality monitoring reduce defect rates and associated material waste, while enabling the recycling of process scrap.

The economic benefits of these sustainability improvements extend beyond reduced environmental impact. Lower energy consumption translates directly to cost savings, with some manufacturers reporting 15-25% reduction in operational costs after implementing energy-efficient technologies. Additionally, sustainable manufacturing practices increasingly influence purchasing decisions, providing market advantages for companies that adopt environmentally responsible production methods.

Energy consumption in microinjection molding primarily occurs during material heating, injection, and cooling phases. Innovative approaches have emerged to optimize these energy-intensive stages. Variable-frequency drives for hydraulic pumps have demonstrated energy savings of 30-50% compared to conventional systems by adjusting power output based on real-time process requirements. Similarly, all-electric injection molding machines have shown energy efficiency improvements of up to 70% over hydraulic systems, with the added benefit of reduced noise pollution and elimination of hydraulic oil disposal concerns.

Material innovations also contribute significantly to sustainability improvements. Bio-based and biodegradable polymers are increasingly being adapted for microinjection molding applications, reducing dependency on petroleum-based materials. These alternatives often require lower processing temperatures, further reducing energy consumption. Additionally, advanced material formulations with improved flow characteristics enable lower injection pressures and temperatures while maintaining part quality.

Process optimization techniques have evolved to enhance both sustainability and production efficiency. Rapid heating and cooling technologies, such as conformal cooling channels created through additive manufacturing, can reduce cycle times by up to 40% while decreasing energy consumption. Simulation software advancements allow for virtual optimization of process parameters before physical implementation, minimizing material waste and energy consumption during setup and production.

Waste reduction strategies complement energy efficiency improvements in creating more sustainable microinjection molding operations. Hot runner systems eliminate or significantly reduce sprue and runner waste, particularly valuable when working with expensive engineering polymers or medical-grade materials. Closed-loop production systems that incorporate in-line quality monitoring reduce defect rates and associated material waste, while enabling the recycling of process scrap.

The economic benefits of these sustainability improvements extend beyond reduced environmental impact. Lower energy consumption translates directly to cost savings, with some manufacturers reporting 15-25% reduction in operational costs after implementing energy-efficient technologies. Additionally, sustainable manufacturing practices increasingly influence purchasing decisions, providing market advantages for companies that adopt environmentally responsible production methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!