Microinjection Molding for High-Performance Coatings: A Study

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microinjection Molding Technology Evolution and Objectives

Microinjection molding technology emerged in the late 1980s as a specialized adaptation of conventional injection molding processes, designed specifically to produce micro-scale components with high precision. The initial development was driven by the electronics industry's demand for increasingly miniaturized components. By the early 1990s, pioneering work at institutions like the Institute for Microtechnology in Mainz, Germany, established the fundamental principles that would guide the field's evolution.

The technology underwent significant advancement in the early 2000s with the introduction of specialized equipment capable of handling small shot volumes and providing precise control over process parameters. This period marked a crucial transition from experimental techniques to commercially viable manufacturing processes, enabling mass production of micro-components with consistent quality.

A pivotal evolution occurred around 2010 when microinjection molding began to be explored for advanced coating applications. Researchers discovered that the precise control offered by microinjection processes could be leveraged to create uniform, high-performance coatings with tailored surface properties. This opened new possibilities for industries requiring specialized surface treatments, including automotive, aerospace, and medical devices.

The integration of computational fluid dynamics (CFD) and finite element analysis (FEA) into the design process represents another significant milestone. These simulation tools have enabled engineers to predict material flow behavior at the micro-scale, optimize mold designs, and reduce development cycles. The ability to simulate the complex rheological behavior of polymers under extreme processing conditions has been particularly valuable for coating applications.

Recent technological advancements have focused on multi-material microinjection molding, allowing for the creation of composite coatings with gradient properties. This capability has proven essential for applications requiring both mechanical durability and specific surface functionalities, such as hydrophobicity, antimicrobial properties, or enhanced wear resistance.

The primary objective of current microinjection molding research for high-performance coatings is to develop processes capable of producing uniform, defect-free coatings at commercially viable production rates. Additional goals include expanding the range of compatible materials, particularly high-performance polymers and polymer-nanoparticle composites, to meet demanding application requirements.

Looking forward, the field aims to achieve greater precision in controlling coating thickness variability (targeting <1% variation), enhancing adhesion between coating and substrate materials, and developing in-line quality control methods suitable for high-volume production environments. The ultimate goal is to establish microinjection molding as a preferred method for applying complex, multi-functional coatings across diverse industrial sectors.

The technology underwent significant advancement in the early 2000s with the introduction of specialized equipment capable of handling small shot volumes and providing precise control over process parameters. This period marked a crucial transition from experimental techniques to commercially viable manufacturing processes, enabling mass production of micro-components with consistent quality.

A pivotal evolution occurred around 2010 when microinjection molding began to be explored for advanced coating applications. Researchers discovered that the precise control offered by microinjection processes could be leveraged to create uniform, high-performance coatings with tailored surface properties. This opened new possibilities for industries requiring specialized surface treatments, including automotive, aerospace, and medical devices.

The integration of computational fluid dynamics (CFD) and finite element analysis (FEA) into the design process represents another significant milestone. These simulation tools have enabled engineers to predict material flow behavior at the micro-scale, optimize mold designs, and reduce development cycles. The ability to simulate the complex rheological behavior of polymers under extreme processing conditions has been particularly valuable for coating applications.

Recent technological advancements have focused on multi-material microinjection molding, allowing for the creation of composite coatings with gradient properties. This capability has proven essential for applications requiring both mechanical durability and specific surface functionalities, such as hydrophobicity, antimicrobial properties, or enhanced wear resistance.

The primary objective of current microinjection molding research for high-performance coatings is to develop processes capable of producing uniform, defect-free coatings at commercially viable production rates. Additional goals include expanding the range of compatible materials, particularly high-performance polymers and polymer-nanoparticle composites, to meet demanding application requirements.

Looking forward, the field aims to achieve greater precision in controlling coating thickness variability (targeting <1% variation), enhancing adhesion between coating and substrate materials, and developing in-line quality control methods suitable for high-volume production environments. The ultimate goal is to establish microinjection molding as a preferred method for applying complex, multi-functional coatings across diverse industrial sectors.

Market Analysis for High-Performance Coating Applications

The high-performance coatings market is experiencing robust growth, driven by increasing demand across multiple industries including automotive, aerospace, electronics, medical devices, and construction. The global market for high-performance coatings was valued at approximately 89.5 billion USD in 2022 and is projected to reach 132.7 billion USD by 2028, representing a compound annual growth rate (CAGR) of 6.7% during the forecast period.

Microinjection molding technology is creating significant opportunities within this market, particularly for applications requiring precise, thin-layer coatings with enhanced durability and functionality. The automotive sector represents the largest application segment, accounting for roughly 28% of the high-performance coatings market, where these coatings provide corrosion resistance, thermal stability, and aesthetic appeal.

The aerospace industry follows closely, with a market share of approximately 22%, driven by the need for lightweight, durable coatings that can withstand extreme conditions. The electronics sector is the fastest-growing application segment, with a projected CAGR of 8.3% through 2028, as miniaturization trends increase demand for precision coatings on microelectronic components.

Regional analysis indicates that Asia-Pacific dominates the high-performance coatings market with a 41% share, led by China, Japan, and South Korea's manufacturing sectors. North America and Europe follow with market shares of 27% and 23% respectively, with particular strength in advanced coating technologies for specialized applications.

Consumer preferences are increasingly shifting toward environmentally friendly coating solutions, with water-based and powder coatings gaining market share over traditional solvent-based formulations. This trend is reinforced by stringent environmental regulations in developed markets, particularly regarding volatile organic compound (VOC) emissions.

The microinjection molding process for high-performance coatings offers significant cost advantages for mass production scenarios, with potential material savings of 15-30% compared to conventional coating methods. Market research indicates that manufacturers can achieve ROI within 18-24 months when implementing these advanced coating technologies at scale.

Emerging applications in medical devices and implantable technologies represent a high-growth niche market, with specialized coatings for biocompatibility and antimicrobial properties commanding premium pricing. This segment is projected to grow at 9.2% annually through 2028, outpacing the broader market.

Microinjection molding technology is creating significant opportunities within this market, particularly for applications requiring precise, thin-layer coatings with enhanced durability and functionality. The automotive sector represents the largest application segment, accounting for roughly 28% of the high-performance coatings market, where these coatings provide corrosion resistance, thermal stability, and aesthetic appeal.

The aerospace industry follows closely, with a market share of approximately 22%, driven by the need for lightweight, durable coatings that can withstand extreme conditions. The electronics sector is the fastest-growing application segment, with a projected CAGR of 8.3% through 2028, as miniaturization trends increase demand for precision coatings on microelectronic components.

Regional analysis indicates that Asia-Pacific dominates the high-performance coatings market with a 41% share, led by China, Japan, and South Korea's manufacturing sectors. North America and Europe follow with market shares of 27% and 23% respectively, with particular strength in advanced coating technologies for specialized applications.

Consumer preferences are increasingly shifting toward environmentally friendly coating solutions, with water-based and powder coatings gaining market share over traditional solvent-based formulations. This trend is reinforced by stringent environmental regulations in developed markets, particularly regarding volatile organic compound (VOC) emissions.

The microinjection molding process for high-performance coatings offers significant cost advantages for mass production scenarios, with potential material savings of 15-30% compared to conventional coating methods. Market research indicates that manufacturers can achieve ROI within 18-24 months when implementing these advanced coating technologies at scale.

Emerging applications in medical devices and implantable technologies represent a high-growth niche market, with specialized coatings for biocompatibility and antimicrobial properties commanding premium pricing. This segment is projected to grow at 9.2% annually through 2028, outpacing the broader market.

Technical Challenges in Microinjection Molding Processes

Microinjection molding processes face several significant technical challenges that impede optimal performance and widespread adoption. The miniaturization inherent in microinjection molding creates unique difficulties not encountered in conventional injection molding. One primary challenge is achieving precise melt flow control at the microscale. When dealing with micro-features, even minor variations in melt viscosity or flow rate can lead to substantial defects, making process control exponentially more difficult than in traditional molding operations.

Material behavior at the microscale presents another critical challenge. Polymers exhibit different rheological properties when forced through micro-channels and cavities. The high shear rates experienced during microinjection can cause unexpected material degradation, while the rapid cooling rates in micro-cavities may prevent complete polymer chain relaxation, resulting in high residual stresses and part warpage.

Tooling precision represents perhaps the most formidable technical barrier. Manufacturing mold inserts with micro-features requires ultra-precision machining techniques such as micro-EDM, laser ablation, or LIGA processes. These techniques demand exceptional accuracy, often requiring tolerances measured in single-digit micrometers. The wear characteristics of these micro-tooling components also present ongoing challenges, as even minimal wear can significantly impact part quality in ways that would be negligible in conventional molding.

The demolding phase introduces additional complexities. As part dimensions decrease, surface forces become increasingly dominant compared to volumetric forces. This phenomenon creates substantial demolding challenges, as micro-parts tend to adhere to mold surfaces due to increased surface-to-volume ratios. Specialized surface treatments or coatings are often necessary to facilitate clean part release without damage.

Process monitoring and quality control systems face significant limitations in microinjection molding. Conventional sensors may lack the sensitivity required to detect the subtle variations that can affect micro-part quality. The development of specialized in-mold sensors capable of monitoring cavity pressure, temperature, and flow front position at the microscale remains an ongoing challenge.

When specifically applied to high-performance coatings, microinjection molding faces additional material-specific challenges. The high-performance polymers typically used for these applications, such as PEEK, PPS, or liquid crystal polymers, exhibit narrow processing windows and are highly sensitive to thermal history. Achieving consistent coating thickness and adhesion properties requires exceptional process stability that is difficult to maintain at the microscale.

Furthermore, the incorporation of functional additives (such as conductive fillers or reinforcing nanoparticles) into high-performance coating formulations introduces additional complexities in flow behavior and material homogeneity. These additives often experience significant orientation effects during high-shear microinjection processes, potentially creating anisotropic properties in the final coating that may be undesirable for certain applications.

Material behavior at the microscale presents another critical challenge. Polymers exhibit different rheological properties when forced through micro-channels and cavities. The high shear rates experienced during microinjection can cause unexpected material degradation, while the rapid cooling rates in micro-cavities may prevent complete polymer chain relaxation, resulting in high residual stresses and part warpage.

Tooling precision represents perhaps the most formidable technical barrier. Manufacturing mold inserts with micro-features requires ultra-precision machining techniques such as micro-EDM, laser ablation, or LIGA processes. These techniques demand exceptional accuracy, often requiring tolerances measured in single-digit micrometers. The wear characteristics of these micro-tooling components also present ongoing challenges, as even minimal wear can significantly impact part quality in ways that would be negligible in conventional molding.

The demolding phase introduces additional complexities. As part dimensions decrease, surface forces become increasingly dominant compared to volumetric forces. This phenomenon creates substantial demolding challenges, as micro-parts tend to adhere to mold surfaces due to increased surface-to-volume ratios. Specialized surface treatments or coatings are often necessary to facilitate clean part release without damage.

Process monitoring and quality control systems face significant limitations in microinjection molding. Conventional sensors may lack the sensitivity required to detect the subtle variations that can affect micro-part quality. The development of specialized in-mold sensors capable of monitoring cavity pressure, temperature, and flow front position at the microscale remains an ongoing challenge.

When specifically applied to high-performance coatings, microinjection molding faces additional material-specific challenges. The high-performance polymers typically used for these applications, such as PEEK, PPS, or liquid crystal polymers, exhibit narrow processing windows and are highly sensitive to thermal history. Achieving consistent coating thickness and adhesion properties requires exceptional process stability that is difficult to maintain at the microscale.

Furthermore, the incorporation of functional additives (such as conductive fillers or reinforcing nanoparticles) into high-performance coating formulations introduces additional complexities in flow behavior and material homogeneity. These additives often experience significant orientation effects during high-shear microinjection processes, potentially creating anisotropic properties in the final coating that may be undesirable for certain applications.

Current Microinjection Methods for High-Performance Coatings

01 Process optimization for microinjection molding

Optimization of process parameters is crucial for achieving high performance in microinjection molding. This includes controlling injection speed, pressure, temperature, and cooling time to ensure proper filling of micro-cavities and achieving desired part quality. Advanced process control systems can be implemented to maintain consistent performance and reduce defects in micro-molded parts.- Materials for microinjection molding: Various materials can be used in microinjection molding to achieve optimal performance. These include specialized polymers, composites, and biocompatible materials that offer improved flow properties at the micro scale. The selection of appropriate materials significantly impacts the quality of microinjection molded parts, affecting aspects such as surface finish, dimensional accuracy, and mechanical properties. Advanced materials formulated specifically for microinjection molding can enhance process reliability and product performance.

- Process optimization techniques: Optimizing microinjection molding processes involves precise control of parameters such as injection speed, pressure, temperature, and cooling time. Advanced techniques include vacuum-assisted molding, variotherm processes, and specialized runner systems designed for micro-scale applications. Process optimization helps overcome challenges related to material flow in micro-cavities, reduces cycle times, and improves part quality. Simulation tools can be employed to predict and optimize the molding process before actual production.

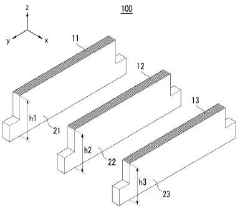

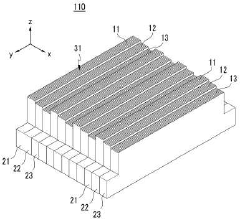

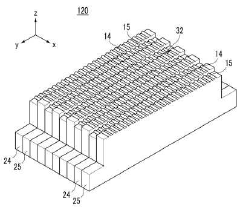

- Equipment and tooling innovations: Specialized equipment and tooling are essential for high-performance microinjection molding. This includes precision micro-molds with advanced surface treatments, high-precision injection units capable of metering small shot volumes, and integrated monitoring systems. Innovations in mold design, such as conformal cooling channels and specialized ejection systems, contribute to improved part quality and cycle times. Advanced micro-tooling manufacturing techniques enable the production of complex micro-features with high accuracy.

- Quality control and measurement systems: Ensuring consistent quality in microinjection molding requires specialized measurement and inspection systems. Advanced optical and mechanical metrology tools enable the verification of micro-features with high precision. In-line monitoring systems can detect process variations and quality issues during production. Statistical process control methods adapted for micro-scale manufacturing help maintain consistent part quality. Non-destructive testing techniques provide valuable data for process optimization and quality assurance.

- Applications in biomedical and microfluidic devices: Microinjection molding is particularly valuable for producing biomedical and microfluidic devices. The process enables the manufacturing of complex micro-components with biocompatible materials for medical applications such as drug delivery systems, diagnostic devices, and implantable components. For microfluidic applications, microinjection molding can create precise channel geometries and surface features necessary for fluid control at the micro scale. The technology allows for cost-effective mass production of these specialized components while maintaining high precision and repeatability.

02 Material selection and formulation for microinjection molding

The choice of polymer materials significantly impacts microinjection molding performance. Materials need specific rheological properties to flow into micro-features while maintaining dimensional stability after cooling. Specialized polymer formulations with additives can enhance flow characteristics, reduce viscosity, and improve surface finish of micro-molded components. High-performance engineering polymers and polymer blends are often used to meet the demanding requirements of microinjection applications.Expand Specific Solutions03 Tooling and mold design for microinjection applications

Advanced tooling and mold design are essential for successful microinjection molding. This includes precision micro-cavities, optimized gate locations, runner systems, and venting. Micro-structured mold surfaces can be created using techniques such as laser ablation, micro-machining, or LIGA processes. Proper mold temperature control systems are implemented to ensure uniform cooling and prevent defects in micro-parts.Expand Specific Solutions04 Equipment and machinery for high-precision microinjection molding

Specialized equipment designed specifically for microinjection molding offers enhanced precision and control. These machines feature high-resolution position control, precise dosing systems, and advanced injection units capable of extremely small shot sizes. Integration of sensors and monitoring systems allows for real-time process control and quality assurance. Hybrid manufacturing systems combining microinjection with other processes can further enhance production capabilities.Expand Specific Solutions05 Quality control and performance evaluation methods

Specialized techniques for evaluating microinjection molded parts include high-resolution imaging, dimensional metrology, and mechanical testing at the micro-scale. Non-destructive testing methods such as micro-CT scanning can be used to detect internal defects. Statistical process control methodologies are implemented to monitor and maintain consistent quality in high-volume production. Performance evaluation includes testing for mechanical properties, optical characteristics, and functional performance of micro-molded components.Expand Specific Solutions

Industry Leaders in Microinjection Molding Equipment

Microinjection molding for high-performance coatings is currently in a growth phase, with the market expanding due to increasing demand for precision components in automotive, electronics, and medical industries. The global market size is estimated to reach $1.2 billion by 2025, growing at a CAGR of 11%. Technologically, the field shows varying maturity levels across applications. Industry leaders like KraussMaffei Technologies and Husky Injection Molding Systems have established advanced capabilities in equipment manufacturing, while companies such as 3M Innovative Properties, PPG Industries, and Oerlikon Surface Solutions are driving coating technology innovation. Asian manufacturers including LG Electronics, Seiko Epson, and Hyundai Motor are rapidly advancing their technological capabilities, particularly in consumer electronics and automotive applications, creating a competitive landscape that balances established Western expertise with emerging Eastern innovation.

KraussMaffei Technologies GmbH

Technical Solution: KraussMaffei has developed advanced microinjection molding systems specifically designed for high-performance coating applications. Their technology utilizes a precision-controlled injection process with micro-dosing capabilities that can achieve layer thicknesses down to 0.1mm. The company's PX series micro-molding machines incorporate specialized screw designs that ensure homogeneous melting and precise material distribution, critical for coating uniformity. KraussMaffei's systems feature adaptive process control that continuously monitors and adjusts parameters during the injection cycle to maintain coating quality. Their technology also includes multi-component capabilities allowing for the creation of complex multi-layer coatings with different functional properties in a single production step. The company has integrated their APC plus (Adaptive Process Control) technology to compensate for batch fluctuations in raw materials, ensuring consistent coating performance.

Strengths: Superior precision control allowing for extremely thin yet uniform coatings; integrated quality monitoring systems that reduce defect rates; versatility in handling multiple materials. Weaknesses: Higher initial investment costs compared to conventional systems; requires specialized operator training; limited to certain polymer types for optimal performance.

3M Innovative Properties Co.

Technical Solution: 3M has developed a proprietary microinjection molding process for creating high-performance optical and protective coatings. Their technology utilizes micro-replication techniques to create precisely structured surfaces with functional properties. The process involves the injection of specially formulated polymer blends into micro-patterned molds with feature sizes down to 1 micron. 3M's approach combines material science expertise with precision molding to create films and coatings with controlled optical properties, including light management, anti-reflective characteristics, and enhanced durability. Their Precision Microreplication Technology creates microscopic prism structures that can be used for brightness enhancement films and light-directing applications. The company has also developed specialized release coatings for the mold surfaces that enable the production of ultra-smooth finishes required for optical applications. 3M's process allows for the integration of multiple functional layers in a single molding step, creating composite coatings with combined properties such as abrasion resistance, UV protection, and optical enhancement.

Strengths: Exceptional optical performance capabilities; ability to create functional microstructures that enhance coating performance; scalable manufacturing process suitable for high-volume production. Weaknesses: Highly specialized equipment requirements; limited to certain polymer types compatible with optical applications; challenging quality control for the smallest feature sizes.

Key Patents in Microinjection Molding Surface Technologies

A micro-injection forming technology for production of high-precision plastic parts materials

PatentInactiveTW200740586A

Innovation

- Employing micro-injection molding technology to produce high-precision plastic parts using plastic steel (POM or Acetal) and nylon, controlling accuracy within 0.02mm, replacing traditional CNC milling and metal powder injection methods.

The producing methodology of precise mould and high precise injection products

PatentInactiveKR1020200121976A

Innovation

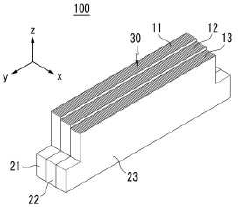

- A micro mold system comprising at least two types of base molds with different heights and fine irregularities, which can be combined to form multi-scale molding surfaces, allowing for the production of complex micro-precision parts through injection molding.

Material Science Advancements for Microinjection Coatings

Recent advancements in material science have significantly transformed the landscape of microinjection molding for high-performance coatings. The development of novel polymeric materials with enhanced thermal stability, mechanical strength, and chemical resistance has expanded the application scope of microinjection-molded coatings across various industries. Particularly noteworthy is the emergence of nanocomposite materials that incorporate functionalized nanoparticles within polymer matrices, resulting in coatings with superior barrier properties and durability.

The integration of smart materials, such as shape memory polymers and self-healing compounds, represents another frontier in coating technology. These materials can respond to environmental stimuli like temperature, pH, or mechanical stress, enabling coatings that adapt to changing conditions and repair minor damage autonomously. This functionality is especially valuable in harsh operating environments where maintenance access is limited.

Biodegradable and sustainable materials have gained significant traction in recent years, addressing growing environmental concerns. Research into bio-based polymers derived from renewable resources has yielded promising alternatives to petroleum-based materials traditionally used in microinjection molding. These eco-friendly options maintain comparable performance characteristics while reducing environmental impact throughout their lifecycle.

Surface modification techniques have evolved to enhance the interfacial properties of microinjection-molded coatings. Plasma treatment, chemical functionalization, and physical texturing methods have been refined to improve adhesion, wettability, and surface energy characteristics. These advancements enable better compatibility between coating layers and substrates, resulting in more durable and effective protective systems.

Multi-material microinjection molding represents a significant technological breakthrough, allowing for the creation of gradient coatings with tailored properties across different regions. This approach enables the development of coatings with optimized performance characteristics, such as combining high wear resistance in one area with flexibility in another, all within a single manufacturing process.

Computational materials science has accelerated innovation through predictive modeling and simulation of material behavior at multiple scales. Machine learning algorithms now facilitate the discovery of novel material formulations by analyzing vast datasets of structure-property relationships. This data-driven approach has shortened development cycles and identified promising material candidates that might otherwise remain undiscovered through conventional experimental methods.

The integration of smart materials, such as shape memory polymers and self-healing compounds, represents another frontier in coating technology. These materials can respond to environmental stimuli like temperature, pH, or mechanical stress, enabling coatings that adapt to changing conditions and repair minor damage autonomously. This functionality is especially valuable in harsh operating environments where maintenance access is limited.

Biodegradable and sustainable materials have gained significant traction in recent years, addressing growing environmental concerns. Research into bio-based polymers derived from renewable resources has yielded promising alternatives to petroleum-based materials traditionally used in microinjection molding. These eco-friendly options maintain comparable performance characteristics while reducing environmental impact throughout their lifecycle.

Surface modification techniques have evolved to enhance the interfacial properties of microinjection-molded coatings. Plasma treatment, chemical functionalization, and physical texturing methods have been refined to improve adhesion, wettability, and surface energy characteristics. These advancements enable better compatibility between coating layers and substrates, resulting in more durable and effective protective systems.

Multi-material microinjection molding represents a significant technological breakthrough, allowing for the creation of gradient coatings with tailored properties across different regions. This approach enables the development of coatings with optimized performance characteristics, such as combining high wear resistance in one area with flexibility in another, all within a single manufacturing process.

Computational materials science has accelerated innovation through predictive modeling and simulation of material behavior at multiple scales. Machine learning algorithms now facilitate the discovery of novel material formulations by analyzing vast datasets of structure-property relationships. This data-driven approach has shortened development cycles and identified promising material candidates that might otherwise remain undiscovered through conventional experimental methods.

Environmental Impact and Sustainability Considerations

Microinjection molding for high-performance coatings represents a significant advancement in manufacturing technology, yet its environmental implications warrant careful consideration. The process typically involves the use of polymers and additives that may pose environmental challenges throughout their lifecycle. Traditional coating materials often contain volatile organic compounds (VOCs) and hazardous substances that contribute to air pollution and pose health risks. In contrast, microinjection molding techniques can potentially reduce material waste through precise application and minimal overspray, offering a more environmentally responsible alternative.

Energy consumption remains a critical environmental factor in microinjection molding operations. The high-precision nature of the process requires substantial energy inputs for heating, cooling, and maintaining precise pressure conditions. Recent innovations have focused on developing more energy-efficient equipment, including electric and hybrid machines that demonstrate up to 30-50% reduction in energy consumption compared to conventional hydraulic systems. These advancements significantly contribute to reducing the carbon footprint associated with coating production.

Material selection plays a pivotal role in determining the sustainability profile of microinjection-molded coatings. The industry has witnessed a gradual shift toward bio-based polymers and recyclable materials that maintain high-performance characteristics while minimizing environmental impact. Research indicates that incorporating recycled content into coating formulations can reduce greenhouse gas emissions by approximately 25-40% compared to virgin material production, without compromising coating integrity or performance properties.

End-of-life considerations present both challenges and opportunities for microinjection-molded coatings. The durability of high-performance coatings extends product lifecycles, reducing replacement frequency and associated resource consumption. However, the complex composition of these coatings can complicate recycling efforts. Emerging technologies for coating removal and material recovery show promise, with chemical delamination techniques achieving recovery rates of up to 85% for certain polymer types.

Water usage and contamination concerns also merit attention in sustainability assessments. Closed-loop water systems in microinjection facilities can reduce freshwater consumption by up to 90% compared to conventional coating processes. Additionally, the elimination of solvent-based carriers in many microinjection applications substantially reduces wastewater treatment requirements and associated environmental burdens.

Regulatory frameworks increasingly influence the development trajectory of coating technologies. The European Union's REACH regulations and similar initiatives worldwide have accelerated the transition toward more environmentally benign coating formulations. Companies investing in sustainable microinjection molding technologies often gain competitive advantages through regulatory compliance readiness and positive brand perception among environmentally conscious consumers and industrial clients.

Energy consumption remains a critical environmental factor in microinjection molding operations. The high-precision nature of the process requires substantial energy inputs for heating, cooling, and maintaining precise pressure conditions. Recent innovations have focused on developing more energy-efficient equipment, including electric and hybrid machines that demonstrate up to 30-50% reduction in energy consumption compared to conventional hydraulic systems. These advancements significantly contribute to reducing the carbon footprint associated with coating production.

Material selection plays a pivotal role in determining the sustainability profile of microinjection-molded coatings. The industry has witnessed a gradual shift toward bio-based polymers and recyclable materials that maintain high-performance characteristics while minimizing environmental impact. Research indicates that incorporating recycled content into coating formulations can reduce greenhouse gas emissions by approximately 25-40% compared to virgin material production, without compromising coating integrity or performance properties.

End-of-life considerations present both challenges and opportunities for microinjection-molded coatings. The durability of high-performance coatings extends product lifecycles, reducing replacement frequency and associated resource consumption. However, the complex composition of these coatings can complicate recycling efforts. Emerging technologies for coating removal and material recovery show promise, with chemical delamination techniques achieving recovery rates of up to 85% for certain polymer types.

Water usage and contamination concerns also merit attention in sustainability assessments. Closed-loop water systems in microinjection facilities can reduce freshwater consumption by up to 90% compared to conventional coating processes. Additionally, the elimination of solvent-based carriers in many microinjection applications substantially reduces wastewater treatment requirements and associated environmental burdens.

Regulatory frameworks increasingly influence the development trajectory of coating technologies. The European Union's REACH regulations and similar initiatives worldwide have accelerated the transition toward more environmentally benign coating formulations. Companies investing in sustainable microinjection molding technologies often gain competitive advantages through regulatory compliance readiness and positive brand perception among environmentally conscious consumers and industrial clients.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!