What Drives Material Selection in Microinjection Molding?

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microinjection Molding Materials Background and Objectives

Microinjection molding has emerged as a critical manufacturing process in the production of miniaturized components across various high-tech industries. The evolution of this technology traces back to the late 1980s, when conventional injection molding techniques were adapted to accommodate the production of increasingly smaller parts. This adaptation was primarily driven by the growing demands of the medical, electronics, and telecommunications sectors for miniaturized components with high precision and complex geometries.

The technological trajectory of microinjection molding has been characterized by continuous refinement in both equipment capabilities and material science. Initially limited by the available materials that could meet the stringent requirements of micro-scale processing, the field has witnessed significant advancements in polymer formulations specifically engineered for microinjection applications. These developments have enabled the production of components with features in the micrometer range while maintaining structural integrity and functional properties.

Material selection for microinjection molding represents a critical decision point that directly impacts product performance, manufacturing efficiency, and economic viability. The objective of material selection in this context extends beyond merely identifying polymers that can flow through micro-sized gates and cavities; it encompasses a comprehensive evaluation of how material properties influence the entire manufacturing process and end-product characteristics.

Current material selection practices are guided by a complex interplay of factors including rheological properties, thermal behavior, mechanical strength, dimensional stability, and biocompatibility (particularly for medical applications). The industry has witnessed a shift from traditional commodity plastics to high-performance engineering polymers and specialty compounds that offer enhanced flow properties and superior mechanical characteristics at the micro scale.

The primary technical goal in material selection for microinjection molding is to identify polymers that exhibit excellent flow behavior at processing temperatures while maintaining dimensional stability during cooling and solidification. This balance is particularly challenging given the high shear rates and rapid cooling conditions inherent to the microinjection process, which can significantly alter material behavior compared to conventional molding operations.

Looking forward, the field aims to develop predictive models that can accurately correlate material properties with processing parameters and final part characteristics, thereby streamlining the material selection process. Additionally, there is growing interest in sustainable and bio-based polymers that can meet the technical requirements of microinjection molding while addressing environmental concerns associated with traditional petroleum-based plastics.

The technological trajectory of microinjection molding has been characterized by continuous refinement in both equipment capabilities and material science. Initially limited by the available materials that could meet the stringent requirements of micro-scale processing, the field has witnessed significant advancements in polymer formulations specifically engineered for microinjection applications. These developments have enabled the production of components with features in the micrometer range while maintaining structural integrity and functional properties.

Material selection for microinjection molding represents a critical decision point that directly impacts product performance, manufacturing efficiency, and economic viability. The objective of material selection in this context extends beyond merely identifying polymers that can flow through micro-sized gates and cavities; it encompasses a comprehensive evaluation of how material properties influence the entire manufacturing process and end-product characteristics.

Current material selection practices are guided by a complex interplay of factors including rheological properties, thermal behavior, mechanical strength, dimensional stability, and biocompatibility (particularly for medical applications). The industry has witnessed a shift from traditional commodity plastics to high-performance engineering polymers and specialty compounds that offer enhanced flow properties and superior mechanical characteristics at the micro scale.

The primary technical goal in material selection for microinjection molding is to identify polymers that exhibit excellent flow behavior at processing temperatures while maintaining dimensional stability during cooling and solidification. This balance is particularly challenging given the high shear rates and rapid cooling conditions inherent to the microinjection process, which can significantly alter material behavior compared to conventional molding operations.

Looking forward, the field aims to develop predictive models that can accurately correlate material properties with processing parameters and final part characteristics, thereby streamlining the material selection process. Additionally, there is growing interest in sustainable and bio-based polymers that can meet the technical requirements of microinjection molding while addressing environmental concerns associated with traditional petroleum-based plastics.

Market Demand Analysis for Microinjection Molded Components

The microinjection molding market is experiencing robust growth driven by increasing demand across multiple industries. The global market for microinjection molded components was valued at approximately $1.2 billion in 2022 and is projected to reach $2.1 billion by 2028, representing a compound annual growth rate of 9.8%. This growth trajectory is primarily fueled by expanding applications in medical devices, electronics, automotive components, and telecommunications sectors.

Medical device manufacturing represents the largest market segment, accounting for nearly 40% of the total demand for microinjection molded components. The trend toward minimally invasive surgical procedures has significantly increased the need for miniaturized medical devices with complex geometries and high precision. Components such as drug delivery systems, surgical instruments, implantable devices, and diagnostic equipment all require the capabilities that microinjection molding provides.

The electronics industry follows as the second-largest consumer of microinjection molded parts, driven by the continuous miniaturization of electronic devices and components. Connectors, switches, sensors, and housings for consumer electronics, smartphones, and wearable devices all benefit from the precision and material versatility offered by microinjection molding technologies.

Automotive applications represent a rapidly growing segment, particularly with the rise of electric vehicles and advanced driver assistance systems. These applications require lightweight, high-performance components that can withstand harsh operating conditions while maintaining dimensional stability and electrical properties.

Regional analysis indicates that North America and Europe currently dominate the market due to their established medical device and automotive industries. However, the Asia-Pacific region is expected to witness the fastest growth rate, driven by expanding electronics manufacturing capabilities and increasing healthcare infrastructure development in countries like China, Japan, and South Korea.

Customer requirements are evolving toward higher precision tolerances, enhanced surface finishes, and more complex geometries. There is also growing demand for components that integrate multiple functionalities, such as electrical conductivity, thermal management, and biocompatibility, within a single molded part.

Sustainability considerations are increasingly influencing market dynamics, with growing interest in bio-based and recyclable materials for microinjection molding. This trend is particularly evident in consumer goods and packaging applications, where environmental regulations and corporate sustainability initiatives are driving material selection decisions.

The COVID-19 pandemic has accelerated certain market segments, particularly those related to medical diagnostics and personal protective equipment, while temporarily slowing others. However, the overall long-term market outlook remains positive as industries continue to seek miniaturization, weight reduction, and cost-effective manufacturing solutions.

Medical device manufacturing represents the largest market segment, accounting for nearly 40% of the total demand for microinjection molded components. The trend toward minimally invasive surgical procedures has significantly increased the need for miniaturized medical devices with complex geometries and high precision. Components such as drug delivery systems, surgical instruments, implantable devices, and diagnostic equipment all require the capabilities that microinjection molding provides.

The electronics industry follows as the second-largest consumer of microinjection molded parts, driven by the continuous miniaturization of electronic devices and components. Connectors, switches, sensors, and housings for consumer electronics, smartphones, and wearable devices all benefit from the precision and material versatility offered by microinjection molding technologies.

Automotive applications represent a rapidly growing segment, particularly with the rise of electric vehicles and advanced driver assistance systems. These applications require lightweight, high-performance components that can withstand harsh operating conditions while maintaining dimensional stability and electrical properties.

Regional analysis indicates that North America and Europe currently dominate the market due to their established medical device and automotive industries. However, the Asia-Pacific region is expected to witness the fastest growth rate, driven by expanding electronics manufacturing capabilities and increasing healthcare infrastructure development in countries like China, Japan, and South Korea.

Customer requirements are evolving toward higher precision tolerances, enhanced surface finishes, and more complex geometries. There is also growing demand for components that integrate multiple functionalities, such as electrical conductivity, thermal management, and biocompatibility, within a single molded part.

Sustainability considerations are increasingly influencing market dynamics, with growing interest in bio-based and recyclable materials for microinjection molding. This trend is particularly evident in consumer goods and packaging applications, where environmental regulations and corporate sustainability initiatives are driving material selection decisions.

The COVID-19 pandemic has accelerated certain market segments, particularly those related to medical diagnostics and personal protective equipment, while temporarily slowing others. However, the overall long-term market outlook remains positive as industries continue to seek miniaturization, weight reduction, and cost-effective manufacturing solutions.

Current Material Technologies and Challenges in Microinjection

Microinjection molding technology has evolved significantly over the past two decades, with material selection becoming increasingly sophisticated to meet the demanding requirements of miniaturized components. Currently, the industry employs a diverse range of polymers, each offering specific advantages for micro-scale applications. Thermoplastics such as polyoxymethylene (POM), liquid crystal polymers (LCP), and polyetheretherketone (PEEK) dominate the market due to their excellent flow properties and dimensional stability at the micro level.

High-performance engineering plastics have gained prominence in microinjection applications, particularly in medical devices and electronics. These materials offer exceptional mechanical properties, biocompatibility, and chemical resistance at microscale dimensions. Recent advancements have also introduced specialized compounds with nano-fillers that enhance specific material properties while maintaining the processability required for microinjection.

Despite these developments, significant challenges persist in material processing for microinjection molding. The high shear rates and rapid cooling inherent to the process create unique rheological behaviors that differ substantially from conventional injection molding. Materials experience extreme conditions during microinjection, with shear rates often exceeding 10^6 s^-1 and cooling rates of several thousand degrees per second, leading to unexpected flow behaviors and property variations.

Material degradation presents another critical challenge, as the high processing temperatures and shear forces can break down polymer chains, particularly in bio-based or biodegradable materials that are increasingly demanded for sustainable applications. This degradation can compromise both mechanical properties and part functionality, necessitating careful process optimization.

The industry also faces difficulties in achieving consistent material performance across micro-features with high aspect ratios. Wall thickness variations of just a few microns can dramatically affect material flow, cooling patterns, and ultimately part quality. This challenge is particularly pronounced when molding components with mixed wall thicknesses or complex geometries.

Material-equipment compatibility represents another significant hurdle, as specialized micro-molding machines require materials with precisely tailored properties. The interaction between advanced materials and machine components, particularly at injection points and micro-cavities, can lead to unexpected wear patterns or contamination issues that affect long-term production stability.

Recent research has focused on developing predictive models for material behavior at the micro scale, but the complex interplay of molecular orientation, crystallization kinetics, and surface effects continues to challenge conventional simulation approaches. This gap between theoretical predictions and actual material performance remains one of the most pressing issues in advancing microinjection molding technology.

High-performance engineering plastics have gained prominence in microinjection applications, particularly in medical devices and electronics. These materials offer exceptional mechanical properties, biocompatibility, and chemical resistance at microscale dimensions. Recent advancements have also introduced specialized compounds with nano-fillers that enhance specific material properties while maintaining the processability required for microinjection.

Despite these developments, significant challenges persist in material processing for microinjection molding. The high shear rates and rapid cooling inherent to the process create unique rheological behaviors that differ substantially from conventional injection molding. Materials experience extreme conditions during microinjection, with shear rates often exceeding 10^6 s^-1 and cooling rates of several thousand degrees per second, leading to unexpected flow behaviors and property variations.

Material degradation presents another critical challenge, as the high processing temperatures and shear forces can break down polymer chains, particularly in bio-based or biodegradable materials that are increasingly demanded for sustainable applications. This degradation can compromise both mechanical properties and part functionality, necessitating careful process optimization.

The industry also faces difficulties in achieving consistent material performance across micro-features with high aspect ratios. Wall thickness variations of just a few microns can dramatically affect material flow, cooling patterns, and ultimately part quality. This challenge is particularly pronounced when molding components with mixed wall thicknesses or complex geometries.

Material-equipment compatibility represents another significant hurdle, as specialized micro-molding machines require materials with precisely tailored properties. The interaction between advanced materials and machine components, particularly at injection points and micro-cavities, can lead to unexpected wear patterns or contamination issues that affect long-term production stability.

Recent research has focused on developing predictive models for material behavior at the micro scale, but the complex interplay of molecular orientation, crystallization kinetics, and surface effects continues to challenge conventional simulation approaches. This gap between theoretical predictions and actual material performance remains one of the most pressing issues in advancing microinjection molding technology.

Current Material Selection Methodologies and Solutions

01 Thermoplastic polymers for microinjection molding

Thermoplastic polymers are widely used in microinjection molding due to their excellent flow properties and ability to fill micro-scale cavities. Materials such as polypropylene (PP), polyethylene (PE), polycarbonate (PC), and polymethyl methacrylate (PMMA) offer good dimensional stability and mechanical properties suitable for microinjection molding applications. These materials can be processed at relatively low temperatures and pressures, making them ideal for producing small, precise components with complex geometries.- Thermoplastic polymers for microinjection molding: Thermoplastic polymers are widely used in microinjection molding due to their excellent flow properties and ability to fill micro-scale cavities. Materials such as polypropylene (PP), polyethylene (PE), polycarbonate (PC), and polyoxymethylene (POM) offer good dimensional stability and mechanical properties suitable for microinjection applications. These materials can be processed at relatively low temperatures and pressures, making them ideal for producing small, precise components with complex geometries.

- Biocompatible and biodegradable materials: For medical and biomedical microinjection molding applications, biocompatible and biodegradable materials are essential. These include polymers such as polylactic acid (PLA), polyglycolic acid (PGA), and their copolymers, which can be safely used in contact with biological tissues. These materials offer controlled degradation profiles and can be formulated to provide specific mechanical properties while ensuring compatibility with biological systems, making them suitable for applications such as drug delivery devices, implantable components, and medical diagnostics.

- High-performance engineering polymers: High-performance engineering polymers are selected for microinjection molding applications requiring exceptional mechanical properties, thermal resistance, and chemical stability. Materials such as polyetheretherketone (PEEK), polyetherimide (PEI), liquid crystal polymers (LCP), and high-performance polyamides offer superior strength-to-weight ratios and can withstand extreme operating conditions. These materials are particularly valuable for microcomponents used in automotive, aerospace, and electronic applications where reliability under harsh conditions is critical.

- Polymer blends and composites: Polymer blends and composites offer enhanced properties for microinjection molding by combining the advantages of multiple materials. These formulations often incorporate fillers such as glass fibers, carbon fibers, or ceramic particles to improve mechanical strength, dimensional stability, and thermal conductivity. Nano-reinforced polymers with carbon nanotubes or nanoclays can significantly enhance mechanical and barrier properties while maintaining good flow characteristics necessary for filling micro-scale features. These materials enable the production of high-performance microcomponents with tailored property profiles.

- Metal and ceramic injection molding materials: Metal and ceramic injection molding (MIM and CIM) materials are increasingly used in microinjection applications requiring high strength, hardness, and temperature resistance. These materials consist of metal or ceramic powders mixed with binder systems that enable injection molding processing. After molding, the binders are removed through debinding processes, and the components are sintered to achieve full density. Materials include stainless steel, titanium alloys, tungsten carbide, and various technical ceramics, enabling the production of micro-components with properties approaching those of conventionally processed metals and ceramics.

02 Biocompatible materials for medical applications

For microinjection molding of medical devices and components, biocompatible materials are essential. These include medical-grade polymers such as polyetheretherketone (PEEK), polyetherimide (PEI), and certain grades of polylactic acid (PLA). These materials offer excellent biocompatibility, chemical resistance, and sterilization capabilities, making them suitable for implantable devices, drug delivery systems, and diagnostic tools. The selection of these materials ensures compliance with regulatory requirements while maintaining the precision needed for microinjection molded medical components.Expand Specific Solutions03 Ceramic and metal powder injection molding materials

Powder injection molding (PIM) techniques adapted for micro-scale applications utilize metal and ceramic powders mixed with binder systems. These materials enable the production of high-strength, high-precision microcomponents that cannot be achieved with polymers alone. The process involves injecting the powder-binder mixture followed by debinding and sintering steps to create dense metal or ceramic parts. Common materials include stainless steel, titanium, alumina, and zirconia powders, which provide excellent mechanical properties, thermal stability, and wear resistance for microcomponents.Expand Specific Solutions04 Multi-material and composite formulations

Advanced microinjection molding applications often require multi-material or composite formulations to achieve specific functional properties. These include polymer blends, polymer-matrix composites reinforced with nanoparticles, fibers, or fillers, and overmolded combinations. Such material systems can provide enhanced mechanical properties, electrical conductivity, thermal management, or optical characteristics while maintaining the processability required for micro-scale molding. The careful selection of compatible materials and processing parameters is crucial for successful multi-material microinjection molding.Expand Specific Solutions05 Specialized additives for improved processing and performance

Various additives are incorporated into base materials to enhance processability and final part performance in microinjection molding. These include flow enhancers to improve cavity filling, nucleating agents for controlled crystallization, release agents for easier demolding, and stabilizers to prevent degradation during processing. Additionally, functional additives such as conductive fillers, antimicrobial agents, or UV stabilizers can be incorporated to impart specific properties to the microinjection molded parts. The careful selection and concentration of these additives is critical for achieving optimal results in micro-scale applications.Expand Specific Solutions

Key Industry Players in Microinjection Molding Materials

The microinjection molding material selection landscape is currently in a growth phase, with the market expected to reach significant expansion due to increasing demand in medical, automotive, and consumer electronics sectors. The technology has reached moderate maturity, with established players like Husky Injection Molding Systems and Robert Bosch GmbH leading commercial applications, while academic institutions such as Jiangsu University and Sichuan University drive fundamental research. Companies including Stratasys, Weidmann Plastics Technology, and LG Electronics are advancing specialized applications through proprietary material formulations. The competitive environment is characterized by a balance between large multinational corporations with extensive resources and specialized firms focusing on niche applications, with collaboration between industry and academic institutions accelerating innovation in biocompatible materials and micro-feature replication.

Husky Injection Molding Systems Ltd.

Technical Solution: Husky's material selection approach for microinjection molding centers on their Ultra Packaging (UP) technology platform, which incorporates advanced material characterization techniques to optimize polymer selection. Their system analyzes rheological properties at high shear rates (>10^6 s^-1) typical in microinjection processes, enabling precise prediction of material flow behavior in micro-cavities. Husky employs a comprehensive material database that catalogs over 600 polymers specifically characterized for micro-scale applications, including specialized medical-grade materials, high-performance engineering thermoplastics, and bio-compatible polymers. Their material selection methodology incorporates multi-parameter optimization algorithms that balance mechanical properties, flow characteristics, shrinkage behavior, and part ejection requirements for micro-components with wall thicknesses below 100μm.

Strengths: Extensive material database specifically characterized for micro-applications; proprietary simulation tools for accurate flow prediction in micro-cavities; integrated material-machine optimization approach. Weaknesses: Higher implementation costs compared to conventional systems; requires specialized training for operators; some proprietary materials may limit customer flexibility in supplier selection.

Robert Bosch GmbH

Technical Solution: Bosch's approach to material selection in microinjection molding is driven by their Micro-Systems Technology (MST) platform, which integrates material science with precision manufacturing. Their methodology employs a systematic evaluation framework that assesses polymers based on five critical parameters: flow length-to-thickness ratio capability, dimensional stability, mechanical property retention at micro-scale, surface quality, and process consistency. Bosch has developed proprietary polymer blends specifically engineered for microinjection applications in automotive sensors and microfluidic devices, featuring modified rheological profiles that maintain consistent viscosity even at extreme shear rates. Their material selection process incorporates in-line quality monitoring systems that analyze material behavior during processing, enabling real-time adjustments to processing parameters to compensate for batch-to-batch material variations. This approach has enabled successful commercialization of micro-components with features below 50μm using both amorphous and semi-crystalline engineering thermoplastics.

Strengths: Highly integrated approach connecting material properties to end-product performance; sophisticated in-line monitoring capabilities; extensive experience with automotive-grade materials requiring tight tolerances. Weaknesses: Solutions often optimized for automotive applications may require adaptation for other industries; proprietary nature of some material formulations limits broader application.

Critical Material Properties and Performance Analysis

Methods of injection molding

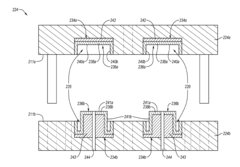

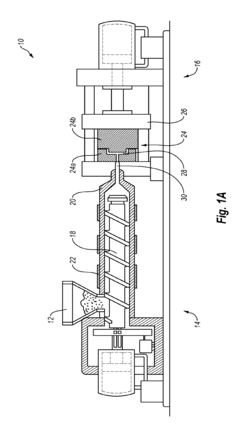

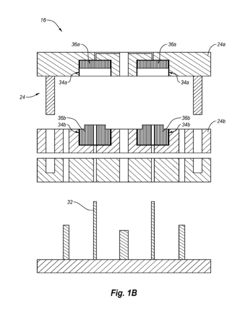

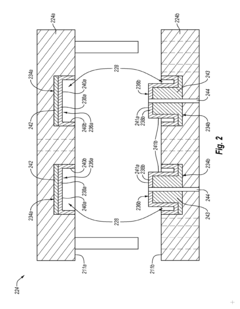

PatentInactiveUS20140145373A1

Innovation

- The use of superhard materials, such as polycrystalline diamond and cemented tungsten carbide, in injection mold assemblies and inserts to form at least a portion of the mold cavity, providing increased wear resistance and extending the lifecycle of the molds, while also allowing for the formation of mold cavities of various sizes and configurations through the combination of multiple segments.

Sustainability Considerations in Material Selection

Sustainability has emerged as a critical factor in material selection for microinjection molding processes, driven by increasing environmental regulations, corporate social responsibility initiatives, and consumer demand for eco-friendly products. The miniaturization trend in various industries necessitates a careful balance between technical performance requirements and environmental considerations throughout the product lifecycle.

Material recyclability represents a primary sustainability concern in microinjection molding. Thermoplastics such as polypropylene (PP) and polyethylene (PE) offer significant advantages due to their ability to be melted and reformed multiple times with minimal property degradation. Conversely, thermosets and certain high-performance polymers present recycling challenges due to their cross-linked molecular structures, which resist reprocessing.

Bio-based and biodegradable materials are gaining traction in microinjection applications. Polylactic acid (PLA), polyhydroxyalkanoates (PHA), and cellulose-derived polymers offer promising alternatives to petroleum-based plastics. However, these materials often require specialized processing parameters and may exhibit different shrinkage behaviors and mechanical properties compared to conventional polymers, necessitating careful process optimization.

Energy consumption during processing represents another significant sustainability aspect. Materials with lower melting temperatures and narrower processing windows generally require less energy during injection molding. For instance, selecting a material that processes at 180°C versus one requiring 320°C can yield substantial energy savings over production runs, particularly in high-volume microinjection applications.

Regulatory compliance increasingly influences material selection decisions. Restrictions on substances like phthalates, bisphenol A, and certain flame retardants have prompted manufacturers to seek alternative formulations. The medical and food packaging sectors face particularly stringent requirements regarding material composition and leachable compounds.

Life cycle assessment (LCA) methodologies are becoming essential tools for evaluating the environmental impact of materials across their entire lifespan. These assessments consider raw material extraction, manufacturing processes, transportation, use phase, and end-of-life scenarios. Comprehensive LCA data enables more informed material selection decisions that balance performance requirements with environmental considerations.

Supply chain sustainability also factors into material selection. Materials sourced from certified sustainable operations or those with transparent environmental practices are increasingly preferred. Additionally, locally sourced materials can reduce transportation-related carbon emissions, though this must be balanced against technical performance requirements specific to microinjection applications.

Material recyclability represents a primary sustainability concern in microinjection molding. Thermoplastics such as polypropylene (PP) and polyethylene (PE) offer significant advantages due to their ability to be melted and reformed multiple times with minimal property degradation. Conversely, thermosets and certain high-performance polymers present recycling challenges due to their cross-linked molecular structures, which resist reprocessing.

Bio-based and biodegradable materials are gaining traction in microinjection applications. Polylactic acid (PLA), polyhydroxyalkanoates (PHA), and cellulose-derived polymers offer promising alternatives to petroleum-based plastics. However, these materials often require specialized processing parameters and may exhibit different shrinkage behaviors and mechanical properties compared to conventional polymers, necessitating careful process optimization.

Energy consumption during processing represents another significant sustainability aspect. Materials with lower melting temperatures and narrower processing windows generally require less energy during injection molding. For instance, selecting a material that processes at 180°C versus one requiring 320°C can yield substantial energy savings over production runs, particularly in high-volume microinjection applications.

Regulatory compliance increasingly influences material selection decisions. Restrictions on substances like phthalates, bisphenol A, and certain flame retardants have prompted manufacturers to seek alternative formulations. The medical and food packaging sectors face particularly stringent requirements regarding material composition and leachable compounds.

Life cycle assessment (LCA) methodologies are becoming essential tools for evaluating the environmental impact of materials across their entire lifespan. These assessments consider raw material extraction, manufacturing processes, transportation, use phase, and end-of-life scenarios. Comprehensive LCA data enables more informed material selection decisions that balance performance requirements with environmental considerations.

Supply chain sustainability also factors into material selection. Materials sourced from certified sustainable operations or those with transparent environmental practices are increasingly preferred. Additionally, locally sourced materials can reduce transportation-related carbon emissions, though this must be balanced against technical performance requirements specific to microinjection applications.

Quality Control and Testing Protocols for Microinjection Materials

Quality control and testing protocols are essential components in the microinjection molding process, particularly when evaluating material performance and ensuring consistent product quality. These protocols must be tailored specifically to the microscale nature of the components being produced, as traditional testing methods often prove inadequate at this level.

Material characterization forms the foundation of quality control in microinjection molding. This includes rheological testing to determine flow behavior under high shear rates typical in microinjection processes. Capillary rheometers and specialized micro-rheology instruments provide critical data on material behavior at the microscale, enabling manufacturers to predict how materials will perform during actual molding operations.

Dimensional accuracy testing represents another crucial aspect of quality control. Given the tight tolerances required in microinjection molded parts (often in the micrometer range), advanced measurement technologies such as confocal microscopy, white light interferometry, and micro-CT scanning have become standard tools. These technologies allow for non-destructive evaluation of internal features that would be impossible to inspect using conventional methods.

Mechanical property verification ensures that microinjection molded components meet performance requirements. Micro-tensile testing, nanoindentation, and dynamic mechanical analysis provide insights into material strength, modulus, and other critical properties at the microscale. These tests must account for size effects, as material behavior can differ significantly at microscale compared to macroscale properties.

Surface quality assessment protocols are particularly important for microinjection molded parts where surface-to-volume ratios are high. Atomic force microscopy and scanning electron microscopy enable evaluation of surface roughness, defects, and morphology at nanometer resolution. These assessments are vital for applications requiring specific surface characteristics, such as medical devices or optical components.

Process validation protocols must be established to ensure repeatability and reproducibility. Statistical process control methods, adapted for microinjection molding, help manufacturers identify process drift before it affects part quality. In-line monitoring systems that track parameters such as injection pressure, velocity profiles, and melt temperature provide real-time data for quality assurance.

Accelerated aging and environmental testing protocols evaluate long-term material performance under various conditions. These tests are particularly important for materials used in medical, automotive, or aerospace applications where reliability over time is critical. Custom testing chambers that simulate specific environmental conditions help predict material behavior throughout the product lifecycle.

Material characterization forms the foundation of quality control in microinjection molding. This includes rheological testing to determine flow behavior under high shear rates typical in microinjection processes. Capillary rheometers and specialized micro-rheology instruments provide critical data on material behavior at the microscale, enabling manufacturers to predict how materials will perform during actual molding operations.

Dimensional accuracy testing represents another crucial aspect of quality control. Given the tight tolerances required in microinjection molded parts (often in the micrometer range), advanced measurement technologies such as confocal microscopy, white light interferometry, and micro-CT scanning have become standard tools. These technologies allow for non-destructive evaluation of internal features that would be impossible to inspect using conventional methods.

Mechanical property verification ensures that microinjection molded components meet performance requirements. Micro-tensile testing, nanoindentation, and dynamic mechanical analysis provide insights into material strength, modulus, and other critical properties at the microscale. These tests must account for size effects, as material behavior can differ significantly at microscale compared to macroscale properties.

Surface quality assessment protocols are particularly important for microinjection molded parts where surface-to-volume ratios are high. Atomic force microscopy and scanning electron microscopy enable evaluation of surface roughness, defects, and morphology at nanometer resolution. These assessments are vital for applications requiring specific surface characteristics, such as medical devices or optical components.

Process validation protocols must be established to ensure repeatability and reproducibility. Statistical process control methods, adapted for microinjection molding, help manufacturers identify process drift before it affects part quality. In-line monitoring systems that track parameters such as injection pressure, velocity profiles, and melt temperature provide real-time data for quality assurance.

Accelerated aging and environmental testing protocols evaluate long-term material performance under various conditions. These tests are particularly important for materials used in medical, automotive, or aerospace applications where reliability over time is critical. Custom testing chambers that simulate specific environmental conditions help predict material behavior throughout the product lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!