How Is Microinjection Molding Used in Advanced Sensor Technology?

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microinjection Molding in Sensor Technology: Background and Objectives

Microinjection molding represents a significant advancement in manufacturing technology, evolving from traditional injection molding processes to address the growing demand for miniaturized components. This technology emerged in the late 1980s and has since undergone substantial refinement, particularly in the last two decades as the need for micro-scale precision parts has accelerated across various industries. The evolution of microinjection molding has been closely tied to advancements in material science, machine precision, and process control technologies.

The fundamental principle of microinjection molding involves the precise injection of polymer materials into micro-scale molds to produce components with features in the micrometer range. This technology has become increasingly critical in the development of advanced sensor technologies, where miniaturization, precision, and reliability are paramount. The convergence of these manufacturing capabilities with sensor technology represents a significant technological frontier with far-reaching implications.

Current technological trends indicate a continued push toward even smaller components, greater precision, and the integration of multiple materials and functionalities within single molded parts. The industry is witnessing a shift toward hybrid manufacturing approaches that combine microinjection molding with other advanced processes such as 3D printing, laser machining, and surface modification techniques to enhance sensor performance and capabilities.

The primary objective of implementing microinjection molding in sensor technology is to enable the production of highly precise, miniaturized sensor components that can be manufactured at scale while maintaining consistent quality and performance. This includes the development of microfluidic channels for lab-on-chip sensors, miniaturized housings for MEMS (Micro-Electro-Mechanical Systems) devices, and complex three-dimensional structures that enhance sensor functionality.

Additional objectives include reducing production costs through material efficiency and process optimization, improving sensor reliability through enhanced design freedom and material selection, and accelerating time-to-market for new sensor technologies. The ability to produce complex geometries at the micro-scale opens new possibilities for sensor design that were previously unattainable with conventional manufacturing methods.

Looking forward, the trajectory of microinjection molding in sensor technology points toward increased integration with digital manufacturing paradigms, including Industry 4.0 concepts such as real-time process monitoring, adaptive control systems, and predictive maintenance. These advancements aim to further enhance production efficiency, quality control, and the ability to rapidly iterate designs based on performance feedback.

The ultimate goal is to establish microinjection molding as a cornerstone technology in the development of next-generation sensors that will power applications in healthcare, environmental monitoring, industrial automation, and consumer electronics, driving innovation across multiple sectors of the global economy.

The fundamental principle of microinjection molding involves the precise injection of polymer materials into micro-scale molds to produce components with features in the micrometer range. This technology has become increasingly critical in the development of advanced sensor technologies, where miniaturization, precision, and reliability are paramount. The convergence of these manufacturing capabilities with sensor technology represents a significant technological frontier with far-reaching implications.

Current technological trends indicate a continued push toward even smaller components, greater precision, and the integration of multiple materials and functionalities within single molded parts. The industry is witnessing a shift toward hybrid manufacturing approaches that combine microinjection molding with other advanced processes such as 3D printing, laser machining, and surface modification techniques to enhance sensor performance and capabilities.

The primary objective of implementing microinjection molding in sensor technology is to enable the production of highly precise, miniaturized sensor components that can be manufactured at scale while maintaining consistent quality and performance. This includes the development of microfluidic channels for lab-on-chip sensors, miniaturized housings for MEMS (Micro-Electro-Mechanical Systems) devices, and complex three-dimensional structures that enhance sensor functionality.

Additional objectives include reducing production costs through material efficiency and process optimization, improving sensor reliability through enhanced design freedom and material selection, and accelerating time-to-market for new sensor technologies. The ability to produce complex geometries at the micro-scale opens new possibilities for sensor design that were previously unattainable with conventional manufacturing methods.

Looking forward, the trajectory of microinjection molding in sensor technology points toward increased integration with digital manufacturing paradigms, including Industry 4.0 concepts such as real-time process monitoring, adaptive control systems, and predictive maintenance. These advancements aim to further enhance production efficiency, quality control, and the ability to rapidly iterate designs based on performance feedback.

The ultimate goal is to establish microinjection molding as a cornerstone technology in the development of next-generation sensors that will power applications in healthcare, environmental monitoring, industrial automation, and consumer electronics, driving innovation across multiple sectors of the global economy.

Market Analysis for Miniaturized Sensor Components

The global market for miniaturized sensor components is experiencing robust growth, driven primarily by the increasing demand for smaller, more efficient sensing technologies across multiple industries. The market value reached approximately $12.5 billion in 2022 and is projected to grow at a CAGR of 8.7% through 2028, potentially reaching $20.6 billion by the end of the forecast period.

Healthcare and medical devices represent the largest application segment, accounting for nearly 32% of the market share. The demand for minimally invasive diagnostic tools, wearable health monitors, and implantable medical devices has significantly boosted the adoption of micro-molded sensor components. Continuous glucose monitoring systems alone generated $4.2 billion in revenue in 2022, with microinjection molded components being critical to their functionality.

The automotive sector follows closely, representing 27% of the market. Advanced driver assistance systems (ADAS), autonomous driving technologies, and vehicle electrification are key drivers in this segment. Pressure sensors, temperature sensors, and position sensors manufactured through microinjection molding are increasingly integrated into modern vehicles, with an average premium vehicle now containing over 100 different sensors.

Consumer electronics constitutes approximately 23% of the market, with smartphones, wearables, and IoT devices incorporating multiple miniaturized sensors. The remaining market share is distributed among industrial automation (10%), aerospace and defense (5%), and other applications (3%).

Geographically, North America leads with 38% of the market share, followed by Europe (29%) and Asia-Pacific (26%). However, Asia-Pacific is expected to witness the highest growth rate of 10.2% annually, primarily due to the expanding electronics manufacturing ecosystem in China, South Korea, Taiwan, and Japan.

Key market challenges include high initial tooling costs for microinjection molding, which can range from $15,000 to $100,000 depending on complexity, creating barriers for smaller manufacturers. Material selection constraints also limit certain applications, as not all engineering polymers are suitable for the microinjection molding process.

Supply chain vulnerabilities became evident during the COVID-19 pandemic, with 67% of manufacturers reporting disruptions in component availability. This has accelerated the trend toward regional manufacturing hubs and vertical integration among larger players in the sensor market.

The competitive landscape features both specialized microinjection molding service providers and integrated sensor manufacturers. Consolidation is increasing, with 14 significant mergers and acquisitions recorded in the past three years as companies seek to combine expertise in materials science, precision molding, and sensor design.

Healthcare and medical devices represent the largest application segment, accounting for nearly 32% of the market share. The demand for minimally invasive diagnostic tools, wearable health monitors, and implantable medical devices has significantly boosted the adoption of micro-molded sensor components. Continuous glucose monitoring systems alone generated $4.2 billion in revenue in 2022, with microinjection molded components being critical to their functionality.

The automotive sector follows closely, representing 27% of the market. Advanced driver assistance systems (ADAS), autonomous driving technologies, and vehicle electrification are key drivers in this segment. Pressure sensors, temperature sensors, and position sensors manufactured through microinjection molding are increasingly integrated into modern vehicles, with an average premium vehicle now containing over 100 different sensors.

Consumer electronics constitutes approximately 23% of the market, with smartphones, wearables, and IoT devices incorporating multiple miniaturized sensors. The remaining market share is distributed among industrial automation (10%), aerospace and defense (5%), and other applications (3%).

Geographically, North America leads with 38% of the market share, followed by Europe (29%) and Asia-Pacific (26%). However, Asia-Pacific is expected to witness the highest growth rate of 10.2% annually, primarily due to the expanding electronics manufacturing ecosystem in China, South Korea, Taiwan, and Japan.

Key market challenges include high initial tooling costs for microinjection molding, which can range from $15,000 to $100,000 depending on complexity, creating barriers for smaller manufacturers. Material selection constraints also limit certain applications, as not all engineering polymers are suitable for the microinjection molding process.

Supply chain vulnerabilities became evident during the COVID-19 pandemic, with 67% of manufacturers reporting disruptions in component availability. This has accelerated the trend toward regional manufacturing hubs and vertical integration among larger players in the sensor market.

The competitive landscape features both specialized microinjection molding service providers and integrated sensor manufacturers. Consolidation is increasing, with 14 significant mergers and acquisitions recorded in the past three years as companies seek to combine expertise in materials science, precision molding, and sensor design.

Technical Challenges in Micro-Scale Molding for Sensors

Microinjection molding for sensor applications faces significant technical challenges due to the miniaturization requirements of modern sensing devices. The primary difficulty lies in achieving precise dimensional control at the micro-scale, where tolerances are often measured in micrometers or even nanometers. Traditional injection molding equipment and processes, designed for macro-scale production, cannot simply be scaled down without encountering fundamental physical limitations.

Material flow behavior changes dramatically at the micro-scale, with surface tension and viscosity effects becoming dominant factors. The high surface-to-volume ratio in micro-cavities causes rapid cooling of polymer melts, leading to premature solidification before the mold is completely filled. This phenomenon, known as hesitation effect, results in incomplete part formation and compromises the structural integrity of sensor components.

Tool design and fabrication present another significant hurdle. Creating mold inserts with micro-features requires specialized techniques such as micro-EDM, laser ablation, or LIGA processes. These manufacturing methods are costly and time-intensive, with limited service life of the resulting tools due to the high stresses they endure during the molding process.

Demolding challenges are particularly acute in micro-scale applications. The increased surface contact between the polymer and mold walls creates substantial adhesion forces relative to part mass, making part release difficult without damage. This necessitates sophisticated ejection systems and careful consideration of draft angles and surface treatments.

Process control represents perhaps the most complex challenge. The processing window for microinjection molding is extremely narrow, requiring precise control of numerous parameters including melt temperature, injection speed, holding pressure, and cooling time. Minor variations in these parameters can lead to significant defects in the final parts, affecting sensor performance and reliability.

Material selection is further constrained by the micro-molding process. While sensors often require materials with specific electrical, optical, or chemical properties, not all such materials exhibit suitable flow characteristics for micro-molding. Additives that enhance processability may compromise the functional properties required for sensing applications.

Post-molding operations introduce additional complexities. Techniques for quality inspection become increasingly difficult as feature sizes decrease below the resolution of conventional measurement systems. Assembly of micro-molded sensor components demands specialized handling equipment and processes to avoid damage to delicate features.

Environmental factors such as humidity, electrostatic discharge, and particulate contamination pose greater risks at the micro-scale, necessitating cleanroom conditions for both production and assembly operations. These requirements significantly increase manufacturing costs and complexity.

Material flow behavior changes dramatically at the micro-scale, with surface tension and viscosity effects becoming dominant factors. The high surface-to-volume ratio in micro-cavities causes rapid cooling of polymer melts, leading to premature solidification before the mold is completely filled. This phenomenon, known as hesitation effect, results in incomplete part formation and compromises the structural integrity of sensor components.

Tool design and fabrication present another significant hurdle. Creating mold inserts with micro-features requires specialized techniques such as micro-EDM, laser ablation, or LIGA processes. These manufacturing methods are costly and time-intensive, with limited service life of the resulting tools due to the high stresses they endure during the molding process.

Demolding challenges are particularly acute in micro-scale applications. The increased surface contact between the polymer and mold walls creates substantial adhesion forces relative to part mass, making part release difficult without damage. This necessitates sophisticated ejection systems and careful consideration of draft angles and surface treatments.

Process control represents perhaps the most complex challenge. The processing window for microinjection molding is extremely narrow, requiring precise control of numerous parameters including melt temperature, injection speed, holding pressure, and cooling time. Minor variations in these parameters can lead to significant defects in the final parts, affecting sensor performance and reliability.

Material selection is further constrained by the micro-molding process. While sensors often require materials with specific electrical, optical, or chemical properties, not all such materials exhibit suitable flow characteristics for micro-molding. Additives that enhance processability may compromise the functional properties required for sensing applications.

Post-molding operations introduce additional complexities. Techniques for quality inspection become increasingly difficult as feature sizes decrease below the resolution of conventional measurement systems. Assembly of micro-molded sensor components demands specialized handling equipment and processes to avoid damage to delicate features.

Environmental factors such as humidity, electrostatic discharge, and particulate contamination pose greater risks at the micro-scale, necessitating cleanroom conditions for both production and assembly operations. These requirements significantly increase manufacturing costs and complexity.

Current Microinjection Molding Solutions for Sensor Manufacturing

01 Equipment and tooling for microinjection molding

Specialized equipment and tooling are essential for microinjection molding processes. This includes micro-molds with precise cavity designs, advanced injection units capable of delivering small, accurate material doses, and specialized clamping systems. The equipment often features high-precision components, temperature control systems, and vacuum-assisted mold filling capabilities to ensure the production of high-quality micro parts with complex geometries and tight tolerances.- Equipment and apparatus for microinjection molding: Specialized equipment and apparatus are essential for microinjection molding processes. These include precision molds, micro-scale injection units, and advanced control systems that enable the accurate formation of micro-sized components. The equipment often features high-precision positioning mechanisms, specialized heating elements, and monitoring systems to ensure consistent quality in the production of miniature parts with complex geometries.

- Materials for microinjection molding: Various materials are used in microinjection molding, including specialized polymers, biocompatible materials, and composite materials. These materials are selected based on their flow properties, mechanical strength, and ability to fill micro-cavities. Advanced formulations may include additives to enhance flow characteristics, reduce shrinkage, and improve surface finish, which are critical factors in producing high-quality micro-components.

- Biomedical applications of microinjection molding: Microinjection molding has significant applications in the biomedical field, including the production of microfluidic devices, drug delivery systems, and medical diagnostic tools. The technology enables the creation of precise microstructures for cell culture, tissue engineering, and lab-on-a-chip devices. The ability to produce small, complex components with high precision makes microinjection molding particularly valuable for creating miniaturized medical devices and implants.

- Process optimization and control in microinjection molding: Optimizing the microinjection molding process involves precise control of parameters such as injection pressure, temperature, cooling rate, and cycle time. Advanced monitoring systems and simulation tools are used to predict and control material flow behavior in micro-cavities. Process innovations include specialized venting techniques, vacuum-assisted molding, and variotherm processes to enhance part quality and reduce defects in micro-scale components.

- Novel microinjection molding techniques and innovations: Emerging techniques in microinjection molding include multi-material molding, in-mold assembly, and hybrid processes combining injection molding with other manufacturing methods. These innovations enable the production of increasingly complex micro-components with enhanced functionality. Research focuses on improving surface quality, reducing cycle times, and developing new approaches for creating high-aspect-ratio microstructures and nano-features within molded parts.

02 Materials for microinjection molding

Various materials are used in microinjection molding, including specialized polymers, biocompatible materials, and composite materials. These materials are selected based on their flow properties, shrinkage characteristics, and mechanical properties. Advanced polymer formulations with improved flow behavior at low viscosity are particularly important for filling micro-scale cavities. Material selection is critical to achieve the desired part performance, surface finish, and dimensional accuracy in micro-scale applications.Expand Specific Solutions03 Biomedical applications of microinjection molding

Microinjection molding is widely used in biomedical applications, including the production of microfluidic devices, lab-on-a-chip systems, medical implants, and drug delivery systems. The process enables the manufacturing of complex biomedical components with high precision and reproducibility. Specialized techniques have been developed to ensure biocompatibility, sterility, and compliance with medical regulations while maintaining the required micro-features and functionality.Expand Specific Solutions04 Process optimization and control in microinjection molding

Process optimization and control are crucial in microinjection molding to ensure consistent quality and high precision. This includes precise control of injection parameters such as pressure, temperature, speed, and cooling time. Advanced monitoring systems, simulation tools, and statistical process control methods are employed to optimize the molding process. Techniques such as vacuum-assisted molding, variothermal processing, and precise dosing systems help overcome challenges related to micro-scale part production.Expand Specific Solutions05 Innovative microinjection molding techniques

Innovative techniques in microinjection molding include multi-material molding, insert molding, overmolding, and in-mold assembly processes adapted for micro-scale applications. These advanced methods enable the production of complex micro-components with integrated functionalities. Other innovations include ultrasonic-assisted molding, micro-powder injection molding, and hybrid manufacturing approaches that combine microinjection molding with other micro-fabrication techniques to achieve enhanced part performance and functionality.Expand Specific Solutions

Leading Companies in Microinjection Molding for Sensors

Microinjection molding for advanced sensor technology is evolving rapidly in a growth market phase, with the global market expected to reach significant expansion due to increasing demand for miniaturized sensors across automotive, medical, and consumer electronics sectors. The technology has reached moderate maturity, with key players demonstrating varying levels of expertise. Industry leaders like Robert Bosch GmbH, Siemens AG, and Continental Automotive have established advanced capabilities in sensor miniaturization, while specialized firms such as Priamus System Technologies and KISTLER HOLDING AG offer sophisticated process control solutions. Research institutions including Fraunhofer-Gesellschaft and academic partners like University of Connecticut are driving innovation through collaborative R&D efforts with semiconductor manufacturers like Taiwan Semiconductor and Infineon Technologies, pushing boundaries in micro-scale precision molding for next-generation sensor applications.

Robert Bosch GmbH

Technical Solution: Bosch has developed proprietary microinjection molding techniques specifically for MEMS sensor manufacturing. Their process involves multi-component injection molding with specialized polymers that can withstand harsh automotive environments while maintaining precise dimensional tolerances down to the micrometer level. The company utilizes a two-component microinjection molding approach where a rigid thermoplastic forms the sensor housing structure while a second elastomeric material creates integrated sealing elements and vibration dampening features. This eliminates the need for separate assembly steps and improves reliability. Bosch's advanced process control systems monitor and adjust injection parameters in real-time to compensate for material variations, ensuring consistent quality across high-volume production runs.

Strengths: Vertical integration of sensor design and manufacturing capabilities allows for optimized designs specifically for microinjection molding; extensive automotive qualification expertise ensures sensors meet stringent reliability requirements. Weaknesses: Proprietary manufacturing processes may limit flexibility for custom sensor designs; higher production costs compared to standard injection molding techniques.

Priamus System Technologies

Technical Solution: Priamus has developed advanced process monitoring and control systems specifically for microinjection molding in sensor applications. Their technology utilizes miniaturized pressure and temperature sensors embedded directly within mold cavities to provide real-time data during the injection process. This allows for detection of subtle variations in material flow behavior that are critical at the microscale. Their proprietary algorithms analyze this data to automatically adjust injection parameters, ensuring consistent part quality even with challenging geometries. Priamus systems can detect and compensate for batch-to-batch material variations that would otherwise cause quality issues in precision sensor components. Their technology enables automated documentation of process parameters for each molded part, creating a digital fingerprint that supports traceability requirements in regulated industries.

Strengths: Specialized focus on process monitoring provides unmatched insight into microinjection molding dynamics; systems can be retrofitted to existing molding equipment. Weaknesses: Requires significant expertise to properly implement and interpret the data; additional capital investment compared to conventional molding equipment.

Key Patents and Innovations in Sensor Microinjection Technology

Method for monitoring and/or controlling and/or regulating functions of and in injection moulding machines

PatentWO2010017970A2

Innovation

- The use of sensors positioned just below the surface, such as in hot runners or cavities, which react sensitively to temperature and pressure changes, triggering signals in fractions of a second for monitoring and control, and are designed to avoid direct contact with the melt, ensuring they are not damaged and can be produced more cost-effectively.

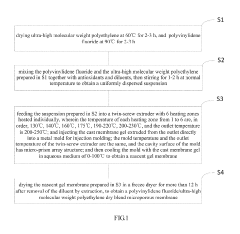

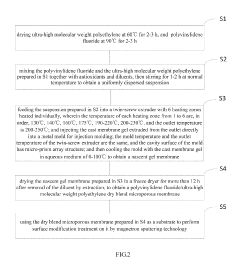

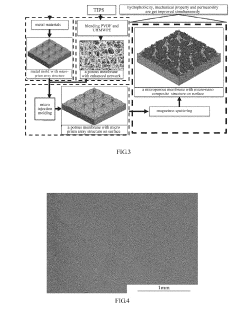

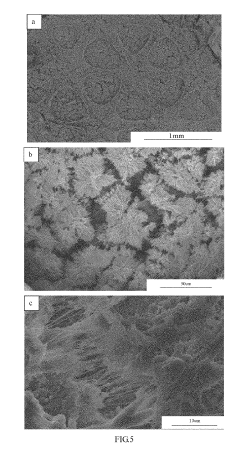

Polyvinylidene Fluoride/Ultra-high Molecular Weight Polyethylene Blend Microporous Membrane and Preparation Method Thereof

PatentActiveUS20190105611A1

Innovation

- A polyvinylidene fluoride/ultra-high molecular weight polyethylene blend microporous membrane is prepared using a combination of thermally induced phase separation and micro-injection molding, with a micro-prism array structure and surface modification by magnetron sputtering, to achieve improved hydrophobicity, mechanical strength, and permeability.

Material Science Advancements for Sensor Microinjection Applications

Recent advancements in material science have revolutionized the capabilities of microinjection molding for sensor applications. The development of high-performance polymers with enhanced thermal stability, mechanical strength, and chemical resistance has expanded the range of environments where microinjected sensors can operate. Materials such as liquid crystal polymers (LCPs), polyetheretherketone (PEEK), and specialized polyamides now enable sensors to function reliably in extreme conditions, including high temperatures, corrosive environments, and high-pressure applications.

Nanocomposite materials represent another significant breakthrough, incorporating nanoscale fillers like carbon nanotubes, graphene, and metal nanoparticles into polymer matrices. These additives dramatically improve electrical conductivity, thermal properties, and mechanical performance while maintaining the processability required for microinjection molding. For instance, carbon nanotube-reinforced polymers can achieve conductivity levels suitable for electromagnetic shielding while preserving the dimensional precision critical for microsensors.

Biocompatible and biodegradable polymers have opened new frontiers in medical and environmental sensing applications. Materials such as polylactic acid (PLA), polyglycolic acid (PGA), and various polycaprolactones can be microinjection molded to create implantable or disposable sensors with minimal biological impact. These materials maintain sufficient mechanical properties while offering controlled degradation profiles, essential for temporary medical monitoring devices.

Smart materials with stimuli-responsive properties represent the cutting edge of sensor material development. Shape memory polymers, piezoelectric composites, and thermochromic materials can be precisely formed through microinjection molding to create sensors that physically respond to environmental changes. These materials effectively integrate the sensing element and transducer into a single component, reducing complexity and size.

Surface modification techniques have also advanced significantly, allowing post-molding treatments that enhance sensor performance without compromising the molded geometry. Plasma treatments, chemical vapor deposition, and specialized coatings can modify surface energy, add functional groups, or create nanoscale textures that improve sensor sensitivity and selectivity.

Multi-material microinjection molding has emerged as a transformative approach, enabling the creation of complex sensor structures with integrated functions in a single manufacturing step. This technique allows the combination of rigid structural elements with flexible sensing regions, or the integration of conductive and non-conductive materials in precise spatial arrangements, eliminating assembly steps and reducing production costs.

The miniaturization trend continues to drive material innovations, with new polymer formulations specifically engineered for ultra-small feature replication and high aspect ratio structures. These specialized materials exhibit enhanced flow properties at processing temperatures while maintaining dimensional stability during cooling, critical for producing the microscale features required in advanced sensor applications.

Nanocomposite materials represent another significant breakthrough, incorporating nanoscale fillers like carbon nanotubes, graphene, and metal nanoparticles into polymer matrices. These additives dramatically improve electrical conductivity, thermal properties, and mechanical performance while maintaining the processability required for microinjection molding. For instance, carbon nanotube-reinforced polymers can achieve conductivity levels suitable for electromagnetic shielding while preserving the dimensional precision critical for microsensors.

Biocompatible and biodegradable polymers have opened new frontiers in medical and environmental sensing applications. Materials such as polylactic acid (PLA), polyglycolic acid (PGA), and various polycaprolactones can be microinjection molded to create implantable or disposable sensors with minimal biological impact. These materials maintain sufficient mechanical properties while offering controlled degradation profiles, essential for temporary medical monitoring devices.

Smart materials with stimuli-responsive properties represent the cutting edge of sensor material development. Shape memory polymers, piezoelectric composites, and thermochromic materials can be precisely formed through microinjection molding to create sensors that physically respond to environmental changes. These materials effectively integrate the sensing element and transducer into a single component, reducing complexity and size.

Surface modification techniques have also advanced significantly, allowing post-molding treatments that enhance sensor performance without compromising the molded geometry. Plasma treatments, chemical vapor deposition, and specialized coatings can modify surface energy, add functional groups, or create nanoscale textures that improve sensor sensitivity and selectivity.

Multi-material microinjection molding has emerged as a transformative approach, enabling the creation of complex sensor structures with integrated functions in a single manufacturing step. This technique allows the combination of rigid structural elements with flexible sensing regions, or the integration of conductive and non-conductive materials in precise spatial arrangements, eliminating assembly steps and reducing production costs.

The miniaturization trend continues to drive material innovations, with new polymer formulations specifically engineered for ultra-small feature replication and high aspect ratio structures. These specialized materials exhibit enhanced flow properties at processing temperatures while maintaining dimensional stability during cooling, critical for producing the microscale features required in advanced sensor applications.

Integration Challenges with Other Sensor Manufacturing Processes

The integration of microinjection molding with other sensor manufacturing processes presents significant challenges that require careful consideration and innovative solutions. When incorporating microinjection molded components into advanced sensor systems, manufacturers face dimensional compatibility issues due to the microscale nature of these parts. Even minor variations in dimensions can lead to misalignment or improper fitting with components produced through other manufacturing methods such as MEMS fabrication, thin-film deposition, or laser micromachining.

Material compatibility represents another critical challenge. The polymers used in microinjection molding may have different thermal expansion coefficients, chemical resistances, and mechanical properties compared to materials used in other sensor manufacturing processes. These differences can create interface problems, especially when sensors must operate across wide temperature ranges or in harsh chemical environments.

Process sequencing and thermal management also pose significant integration hurdles. Microinjection molded components may have lower temperature tolerances than ceramic or metallic sensor elements, limiting subsequent processing options. Manufacturers must carefully design the assembly sequence to ensure that high-temperature processes do not damage previously molded components, often requiring complex fixturing and handling systems.

Surface treatment and bonding between microinjection molded parts and other sensor components present additional challenges. Creating reliable electrical connections between polymer components and conductive elements requires specialized techniques such as selective metallization, conductive adhesives, or ultrasonic welding. The microscale nature of these connections makes traditional bonding methods difficult to implement with the necessary precision.

Cleanroom compatibility issues further complicate integration efforts. While semiconductor and MEMS processes typically require stringent cleanroom environments, microinjection molding equipment may generate particles or outgassing that can contaminate sensitive sensor elements. This necessitates careful process isolation or specialized molding equipment designed for cleanroom compatibility.

Quality control across integrated processes represents perhaps the most persistent challenge. Different manufacturing methods require different inspection techniques, making it difficult to implement unified quality standards. Non-destructive testing methods that work well for silicon wafers may be ineffective for polymer microstructures, requiring manufacturers to develop comprehensive multi-modal inspection protocols that can validate the integrity of the complete sensor assembly.

Addressing these integration challenges requires cross-disciplinary expertise and often leads to compromises in design or performance. However, successful integration strategies can yield sensors with unique capabilities that combine the advantages of microinjection molding—such as complex 3D geometries and cost-effective mass production—with the precision and functionality of other advanced manufacturing techniques.

Material compatibility represents another critical challenge. The polymers used in microinjection molding may have different thermal expansion coefficients, chemical resistances, and mechanical properties compared to materials used in other sensor manufacturing processes. These differences can create interface problems, especially when sensors must operate across wide temperature ranges or in harsh chemical environments.

Process sequencing and thermal management also pose significant integration hurdles. Microinjection molded components may have lower temperature tolerances than ceramic or metallic sensor elements, limiting subsequent processing options. Manufacturers must carefully design the assembly sequence to ensure that high-temperature processes do not damage previously molded components, often requiring complex fixturing and handling systems.

Surface treatment and bonding between microinjection molded parts and other sensor components present additional challenges. Creating reliable electrical connections between polymer components and conductive elements requires specialized techniques such as selective metallization, conductive adhesives, or ultrasonic welding. The microscale nature of these connections makes traditional bonding methods difficult to implement with the necessary precision.

Cleanroom compatibility issues further complicate integration efforts. While semiconductor and MEMS processes typically require stringent cleanroom environments, microinjection molding equipment may generate particles or outgassing that can contaminate sensitive sensor elements. This necessitates careful process isolation or specialized molding equipment designed for cleanroom compatibility.

Quality control across integrated processes represents perhaps the most persistent challenge. Different manufacturing methods require different inspection techniques, making it difficult to implement unified quality standards. Non-destructive testing methods that work well for silicon wafers may be ineffective for polymer microstructures, requiring manufacturers to develop comprehensive multi-modal inspection protocols that can validate the integrity of the complete sensor assembly.

Addressing these integration challenges requires cross-disciplinary expertise and often leads to compromises in design or performance. However, successful integration strategies can yield sensors with unique capabilities that combine the advantages of microinjection molding—such as complex 3D geometries and cost-effective mass production—with the precision and functionality of other advanced manufacturing techniques.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!