How Does Microinjection Molding Enhance Catalytic Processes?

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microinjection Molding in Catalysis: Background and Objectives

Microinjection molding represents a significant advancement in manufacturing technology, particularly for the production of miniaturized components with high precision. This technology emerged in the late 1980s as an extension of conventional injection molding, specifically tailored to address the growing demand for micro-scale parts in various industries. The evolution of microinjection molding has been driven by the miniaturization trend across multiple sectors, including medical devices, electronics, and more recently, catalytic systems.

The integration of microinjection molding with catalytic processes marks a pivotal intersection of manufacturing technology and chemical engineering. Historically, catalytic processes have relied on traditional catalyst support structures, often limited by surface area constraints and mass transfer inefficiencies. The advent of microinjection molding has opened new possibilities for designing and fabricating catalyst supports with unprecedented geometric complexity and precision at the micro-scale.

The technical evolution trajectory shows a clear progression from basic micro-molding capabilities to advanced multi-material and hybrid processes that enable the creation of complex catalytic structures. Early applications focused primarily on simple geometries, while recent developments have expanded to include intricate internal channels, hierarchical structures, and controlled porosity—all critical features for enhancing catalytic performance.

Current research objectives in this field center on optimizing the interface between the molded substrate and catalytic materials. This includes developing novel polymer composites that can withstand harsh reaction conditions while maintaining structural integrity, exploring surface modification techniques to improve catalyst adhesion, and engineering micro-features that maximize surface area-to-volume ratios for enhanced catalytic activity.

The potential impact of microinjection molding on catalytic processes extends beyond traditional chemical manufacturing. Emerging applications in environmental remediation, energy conversion, and sustainable chemistry highlight the transformative potential of this technology. By enabling precise control over catalyst geometry and distribution at the microscale, microinjection molding offers pathways to significantly improve reaction efficiency, selectivity, and yield.

Looking forward, the convergence of microinjection molding with other advanced manufacturing technologies, such as 3D printing and nanofabrication, promises to further expand the design space for catalytic systems. The ultimate goal is to develop scalable manufacturing processes that can translate laboratory innovations in catalyst design to industrial-scale applications, addressing global challenges in energy, environment, and sustainable chemical production.

The integration of microinjection molding with catalytic processes marks a pivotal intersection of manufacturing technology and chemical engineering. Historically, catalytic processes have relied on traditional catalyst support structures, often limited by surface area constraints and mass transfer inefficiencies. The advent of microinjection molding has opened new possibilities for designing and fabricating catalyst supports with unprecedented geometric complexity and precision at the micro-scale.

The technical evolution trajectory shows a clear progression from basic micro-molding capabilities to advanced multi-material and hybrid processes that enable the creation of complex catalytic structures. Early applications focused primarily on simple geometries, while recent developments have expanded to include intricate internal channels, hierarchical structures, and controlled porosity—all critical features for enhancing catalytic performance.

Current research objectives in this field center on optimizing the interface between the molded substrate and catalytic materials. This includes developing novel polymer composites that can withstand harsh reaction conditions while maintaining structural integrity, exploring surface modification techniques to improve catalyst adhesion, and engineering micro-features that maximize surface area-to-volume ratios for enhanced catalytic activity.

The potential impact of microinjection molding on catalytic processes extends beyond traditional chemical manufacturing. Emerging applications in environmental remediation, energy conversion, and sustainable chemistry highlight the transformative potential of this technology. By enabling precise control over catalyst geometry and distribution at the microscale, microinjection molding offers pathways to significantly improve reaction efficiency, selectivity, and yield.

Looking forward, the convergence of microinjection molding with other advanced manufacturing technologies, such as 3D printing and nanofabrication, promises to further expand the design space for catalytic systems. The ultimate goal is to develop scalable manufacturing processes that can translate laboratory innovations in catalyst design to industrial-scale applications, addressing global challenges in energy, environment, and sustainable chemical production.

Market Analysis for Microinjection-Enhanced Catalytic Systems

The global market for microinjection-enhanced catalytic systems is experiencing significant growth, driven by increasing demand for efficient and sustainable chemical processes across various industries. Current market valuation stands at approximately 3.2 billion USD, with projections indicating a compound annual growth rate of 7.8% through 2028. This growth trajectory is particularly pronounced in pharmaceutical manufacturing, fine chemicals production, and renewable energy applications.

The pharmaceutical sector represents the largest market segment, accounting for nearly 38% of the total market share. This dominance stems from the industry's need for precise catalytic reactions in drug synthesis, where microinjection molding enables controlled delivery of catalysts at microscale, resulting in higher yields and reduced waste. The fine chemicals segment follows closely at 27%, while energy applications constitute about 19% of the market.

Geographically, North America leads with 35% market share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is witnessing the fastest growth rate at 9.3% annually, primarily driven by rapid industrialization in China and India, coupled with increasing investments in advanced manufacturing technologies.

Consumer demand patterns reveal a strong preference for systems that offer enhanced energy efficiency, reduced environmental impact, and improved product quality. End-users are increasingly willing to invest in premium-priced solutions that demonstrate measurable improvements in catalytic efficiency, with surveys indicating that 72% of industrial customers prioritize performance metrics over initial acquisition costs.

Market challenges include high initial investment requirements, technical complexity in system integration, and regulatory hurdles related to nanoscale materials. The average implementation cost for a comprehensive microinjection-enhanced catalytic system ranges from 250,000 to 1.2 million USD, depending on scale and application specificity.

Emerging market opportunities are concentrated in green chemistry applications, where microinjection-enhanced catalysis offers significant advantages in reducing hazardous waste and improving atom economy. The biocatalysis segment is experiencing particularly rapid growth, with market analysts predicting a doubling of market size within the next five years.

Supply chain analysis reveals increasing vertical integration among major players, with catalyst manufacturers forming strategic partnerships with microinjection molding specialists to create comprehensive solution packages. This trend is reshaping traditional market structures and creating new entry barriers for smaller competitors while simultaneously opening niche opportunities for specialized technology providers.

The pharmaceutical sector represents the largest market segment, accounting for nearly 38% of the total market share. This dominance stems from the industry's need for precise catalytic reactions in drug synthesis, where microinjection molding enables controlled delivery of catalysts at microscale, resulting in higher yields and reduced waste. The fine chemicals segment follows closely at 27%, while energy applications constitute about 19% of the market.

Geographically, North America leads with 35% market share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is witnessing the fastest growth rate at 9.3% annually, primarily driven by rapid industrialization in China and India, coupled with increasing investments in advanced manufacturing technologies.

Consumer demand patterns reveal a strong preference for systems that offer enhanced energy efficiency, reduced environmental impact, and improved product quality. End-users are increasingly willing to invest in premium-priced solutions that demonstrate measurable improvements in catalytic efficiency, with surveys indicating that 72% of industrial customers prioritize performance metrics over initial acquisition costs.

Market challenges include high initial investment requirements, technical complexity in system integration, and regulatory hurdles related to nanoscale materials. The average implementation cost for a comprehensive microinjection-enhanced catalytic system ranges from 250,000 to 1.2 million USD, depending on scale and application specificity.

Emerging market opportunities are concentrated in green chemistry applications, where microinjection-enhanced catalysis offers significant advantages in reducing hazardous waste and improving atom economy. The biocatalysis segment is experiencing particularly rapid growth, with market analysts predicting a doubling of market size within the next five years.

Supply chain analysis reveals increasing vertical integration among major players, with catalyst manufacturers forming strategic partnerships with microinjection molding specialists to create comprehensive solution packages. This trend is reshaping traditional market structures and creating new entry barriers for smaller competitors while simultaneously opening niche opportunities for specialized technology providers.

Technical Challenges in Microinjection Molding for Catalysis

Microinjection molding for catalytic applications faces several significant technical challenges that must be addressed to fully realize its potential. The miniaturization of injection molding components to micro-scale dimensions introduces complex fluid dynamics issues that do not exist at conventional scales. When working with feature sizes below 100 micrometers, the flow behavior of polymer melts changes dramatically, exhibiting non-Newtonian characteristics that are difficult to predict and control. This results in filling inconsistencies, particularly in high aspect ratio microstructures essential for catalytic applications.

Material selection presents another critical challenge. Catalytic processes often require materials with specific chemical resistance properties and thermal stability. However, many polymers suitable for microinjection molding lack these characteristics, creating a significant materials engineering challenge. Additionally, incorporating catalytic materials directly into the polymer matrix without compromising the mechanical properties or moldability of the final component requires sophisticated compounding techniques that are still being developed.

The precision requirements for mold fabrication represent a substantial technical hurdle. Molds for catalytic microstructures must maintain tolerances in the micrometer or even sub-micrometer range, necessitating advanced manufacturing techniques such as micro-electrical discharge machining, laser ablation, or LIGA processes. These manufacturing methods are costly and time-intensive, limiting scalability and commercial viability.

Process control during microinjection molding presents unique challenges for catalytic applications. Parameters such as injection speed, pressure, temperature, and cooling rates must be controlled with exceptional precision to ensure consistent part quality. The window of optimal processing conditions is significantly narrower than in conventional injection molding, requiring sophisticated monitoring and control systems that can respond in milliseconds to process variations.

Demoulding microstructured catalytic components introduces additional complications. The increased surface area-to-volume ratio results in stronger adhesion forces between the molded part and the mold cavity, often leading to part deformation or damage during ejection. This is particularly problematic for delicate catalytic structures where surface integrity is crucial for performance.

Quality assurance and characterization of microinjected catalytic components present further technical obstacles. Traditional inspection methods lack sufficient resolution to detect defects at the microscale. Advanced techniques such as micro-CT scanning, electron microscopy, and atomic force microscopy are required but are expensive and time-consuming, making 100% inspection impractical for mass production.

Integration challenges also exist when incorporating microinjected catalytic components into larger systems. Establishing reliable connections between micro and macro components while maintaining catalytic efficiency requires innovative interface designs and assembly techniques that are still evolving in this field.

Material selection presents another critical challenge. Catalytic processes often require materials with specific chemical resistance properties and thermal stability. However, many polymers suitable for microinjection molding lack these characteristics, creating a significant materials engineering challenge. Additionally, incorporating catalytic materials directly into the polymer matrix without compromising the mechanical properties or moldability of the final component requires sophisticated compounding techniques that are still being developed.

The precision requirements for mold fabrication represent a substantial technical hurdle. Molds for catalytic microstructures must maintain tolerances in the micrometer or even sub-micrometer range, necessitating advanced manufacturing techniques such as micro-electrical discharge machining, laser ablation, or LIGA processes. These manufacturing methods are costly and time-intensive, limiting scalability and commercial viability.

Process control during microinjection molding presents unique challenges for catalytic applications. Parameters such as injection speed, pressure, temperature, and cooling rates must be controlled with exceptional precision to ensure consistent part quality. The window of optimal processing conditions is significantly narrower than in conventional injection molding, requiring sophisticated monitoring and control systems that can respond in milliseconds to process variations.

Demoulding microstructured catalytic components introduces additional complications. The increased surface area-to-volume ratio results in stronger adhesion forces between the molded part and the mold cavity, often leading to part deformation or damage during ejection. This is particularly problematic for delicate catalytic structures where surface integrity is crucial for performance.

Quality assurance and characterization of microinjected catalytic components present further technical obstacles. Traditional inspection methods lack sufficient resolution to detect defects at the microscale. Advanced techniques such as micro-CT scanning, electron microscopy, and atomic force microscopy are required but are expensive and time-consuming, making 100% inspection impractical for mass production.

Integration challenges also exist when incorporating microinjected catalytic components into larger systems. Establishing reliable connections between micro and macro components while maintaining catalytic efficiency requires innovative interface designs and assembly techniques that are still evolving in this field.

Current Microinjection Molding Solutions for Catalytic Processes

01 Microinjection molding techniques for catalytic components

Microinjection molding techniques are used to produce small-scale catalytic components with high precision. These techniques involve the injection of catalytic materials into micro-molds to create structures with specific geometries that enhance catalytic performance. The process allows for the production of catalysts with increased surface area and improved reactivity, which is beneficial for various chemical processes.- Microinjection molding techniques for catalytic components: Microinjection molding can be used to produce small-scale catalytic components with precise dimensions and structures. This technique allows for the creation of microreactors and catalytic devices with high surface-to-volume ratios, enhancing catalytic efficiency. The process typically involves injecting polymer or metal materials containing catalytic agents into micro-molds under controlled conditions to create components with specific geometries optimized for catalytic reactions.

- Catalytic materials for microinjection molding processes: Various catalytic materials can be incorporated into the feedstock for microinjection molding to enhance the molding process or to create parts with catalytic properties. These materials include metal catalysts, enzymes, and polymer-supported catalysts that can be uniformly distributed throughout the molded component. The selection of appropriate catalytic materials depends on the intended application, processing conditions, and compatibility with the base material being molded.

- Process optimization for catalytic microinjection molding: Optimization of microinjection molding parameters is crucial for successful catalytic processes. This includes controlling temperature, pressure, injection speed, and cooling rates to ensure proper distribution of catalytic agents and to maintain their activity. Advanced process monitoring and control systems can be implemented to achieve consistent quality in catalytically active microcomponents, while minimizing material waste and cycle times.

- Biocatalytic applications in microinjection molding: Biocatalysts such as enzymes can be incorporated into microinjection molding processes to create bioactive components for medical, pharmaceutical, or environmental applications. These biocatalytic systems can be designed to perform specific reactions under mild conditions, offering advantages in selectivity and efficiency. Special processing techniques are required to preserve the activity of biological catalysts during the high-temperature and high-pressure conditions typically associated with injection molding.

- Hybrid catalytic systems for enhanced microinjection molding: Hybrid catalytic systems combining different types of catalysts (such as metal catalysts with enzymes or homogeneous with heterogeneous catalysts) can be employed in microinjection molding to achieve synergistic effects. These hybrid systems can enhance reaction rates, improve selectivity, and extend the range of possible applications. The development of such systems requires careful consideration of compatibility between different catalytic components and the base materials used in the molding process.

02 Catalytic materials for microinjection molding processes

Various catalytic materials can be incorporated into microinjection molding processes to create functional components. These materials include metal catalysts, enzymes, and polymer-supported catalysts that can be formulated for specific reactions. The selection of appropriate catalytic materials is crucial for achieving desired reaction rates and selectivity in the final molded products.Expand Specific Solutions03 Process optimization for catalytic microinjection molding

Optimization of microinjection molding processes for catalytic applications involves controlling parameters such as temperature, pressure, and injection speed. These factors significantly influence the distribution and activity of catalytic components within the molded structure. Advanced process control methods and simulation tools are employed to achieve optimal catalytic performance in the final products.Expand Specific Solutions04 Biocatalytic applications in microinjection molding

Microinjection molding techniques are applied to create biocatalytic systems by incorporating enzymes or other biological catalysts into polymer matrices. These systems can be used for biosensing, bioremediation, and pharmaceutical applications. The microinjection process allows for precise control over the spatial distribution of biocatalysts, enhancing their stability and activity in various environments.Expand Specific Solutions05 Hybrid catalytic systems produced by microinjection molding

Hybrid catalytic systems combine different types of catalysts (e.g., metallic and enzymatic) in a single microinjection-molded component. These systems leverage synergistic effects between different catalytic mechanisms to enhance overall performance. The microinjection molding process enables the creation of complex structures with multiple catalytic domains, allowing for cascade reactions or multifunctional catalytic processes.Expand Specific Solutions

Leading Companies and Research Institutions in the Field

Microinjection molding for catalytic processes is evolving rapidly in a market transitioning from early development to commercial growth. The global market is expanding as industries recognize the technology's potential to enhance catalytic efficiency through precise microstructure control. From a technical maturity perspective, leading players demonstrate varying specialization levels. Companies like Husky Injection Molding Systems and BASF have established strong positions in equipment manufacturing and chemical applications respectively, while research institutions including Wisconsin Alumni Research Foundation and Xi'an Jiaotong University drive fundamental innovation. China Petroleum & Chemical Corp. and Robert Bosch GmbH are leveraging their industrial scale to implement these technologies in commercial applications, creating a competitive landscape balanced between established manufacturers and emerging research-driven entities.

Husky Injection Molding Systems Ltd.

Technical Solution: Husky Injection Molding Systems has developed specialized microinjection molding equipment and processes specifically optimized for catalytic applications. Their HyCAT™ platform integrates precision molding capabilities with advanced material handling systems designed for catalyst-loaded feedstocks. The technology utilizes ultra-precise screw designs with L/D ratios exceeding 30:1 and specialized mixing sections that ensure homogeneous distribution of catalytic particles within polymer matrices. Husky's systems can process materials at temperatures up to 450°C and injection pressures of 3000 bar, enabling the molding of high-performance polymers (PEEK, PEI, LCP) with catalytic loadings up to 65% by weight. The resulting microstructured components feature channel dimensions as small as 30 micrometers with aspect ratios exceeding 20:1, creating exceptional surface area for catalytic reactions. Their patented vario-thermal mold technology enables rapid temperature cycling (up to 80°C/second) to optimize both filling and crystallization phases of the molding process[5]. This approach has been successfully implemented in microreactor systems for fine chemical synthesis, demonstrating 200-300% increases in space-time yield compared to conventional batch processes.

Strengths: Industry-leading precision in microfeature replication; excellent material versatility; high throughput production capability; superior part-to-part consistency. Weaknesses: Significant capital investment required; complex process parameter optimization; challenges with high-viscosity catalyst-loaded materials; limited in-house catalytic expertise.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has pioneered micro-reactor technology utilizing microinjection molding for enhanced catalytic cracking processes. Their approach involves creating micro-structured reactor components with feature sizes ranging from 50-500 micrometers that dramatically increase surface-to-volume ratios. Sinopec's proprietary MicroCat™ system employs specialized high-temperature resistant polymers (PEEK, PPS) infused with zeolite and metal catalyst particles that are precision-molded to create intricate internal geometries. The molding process operates under carefully controlled conditions (300-350°C, 1500-2000 bar) to ensure uniform catalyst distribution throughout the microstructures. These components are then assembled into modular reactor systems that have demonstrated 25-35% higher conversion rates and 15-20% improved selectivity in hydrocarbon processing applications[2]. The technology enables precise control of residence time distribution and eliminates hot spots common in traditional packed-bed reactors, resulting in extended catalyst lifetime and reduced coking.

Strengths: Exceptional heat and mass transfer characteristics; modular design allows for easy scaling and maintenance; significant improvement in reaction selectivity. Weaknesses: Higher manufacturing complexity; potential for channel clogging in long-term operation; limited to certain reaction types due to material constraints.

Key Patents and Technical Innovations in Micro-Catalytic Systems

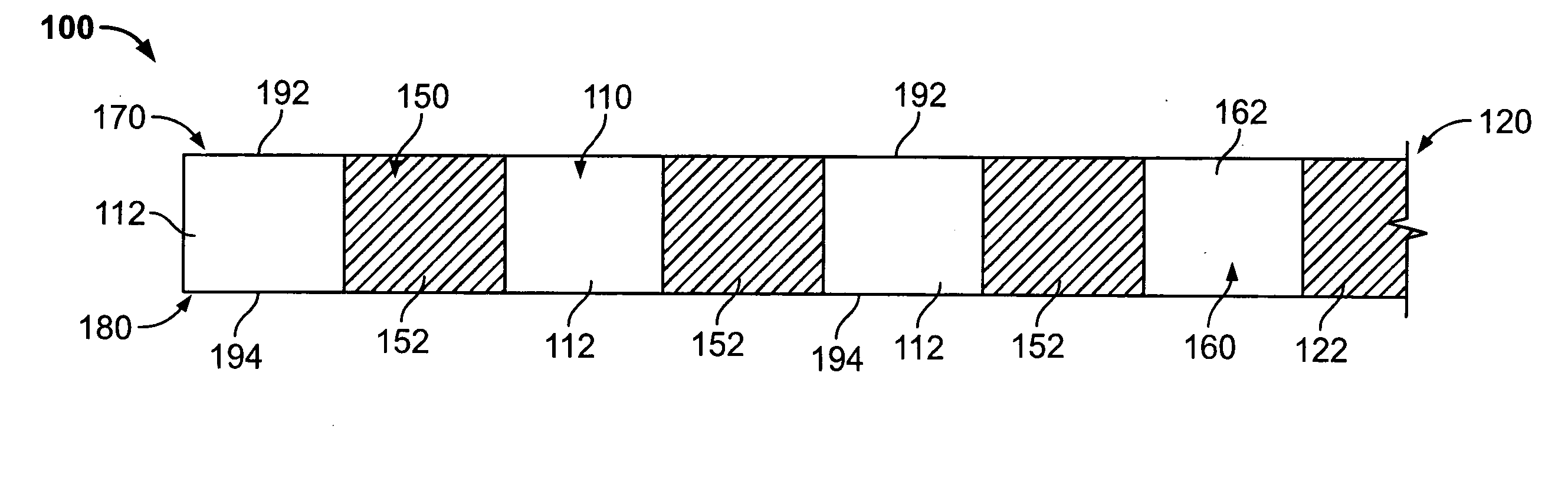

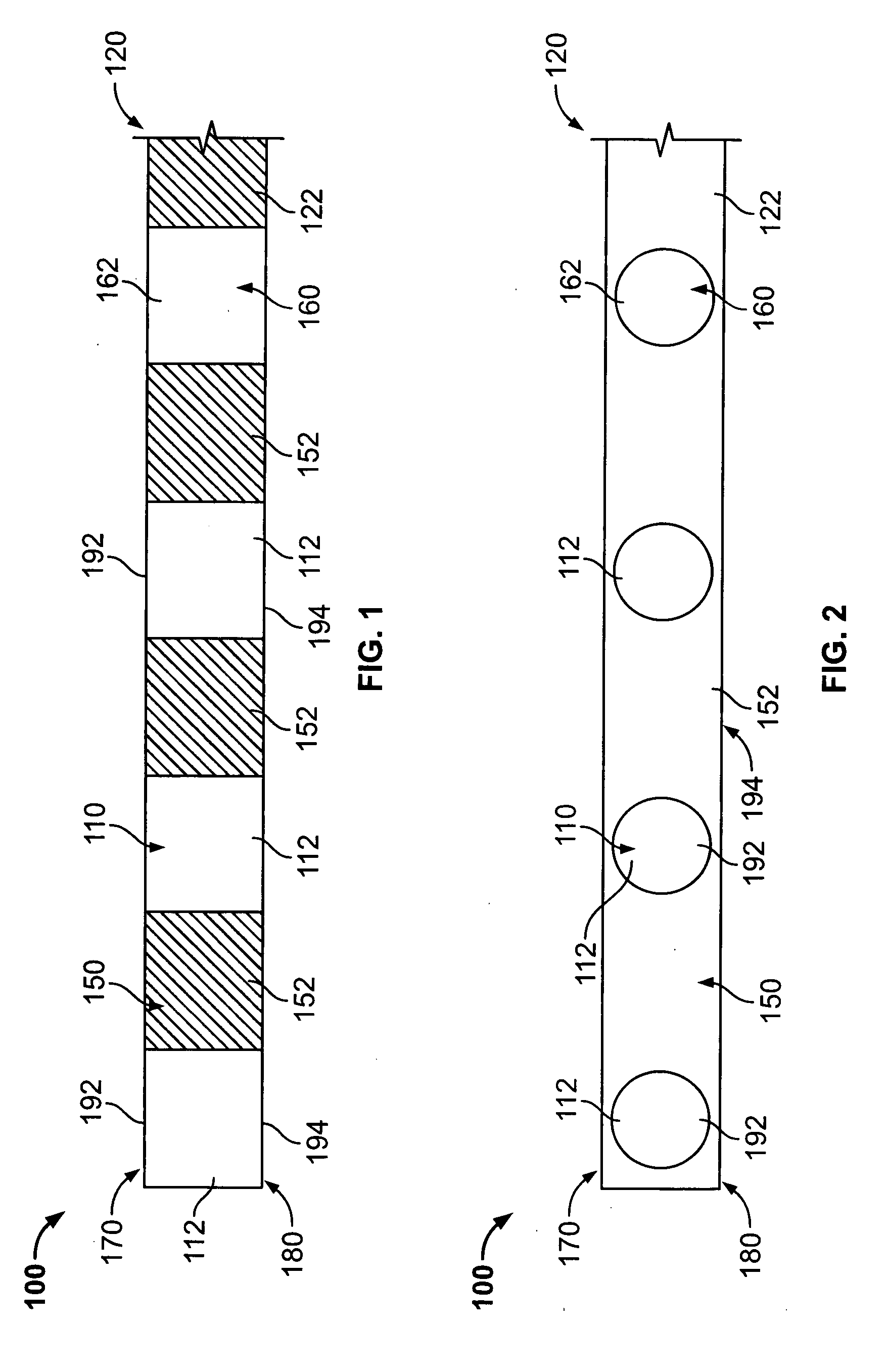

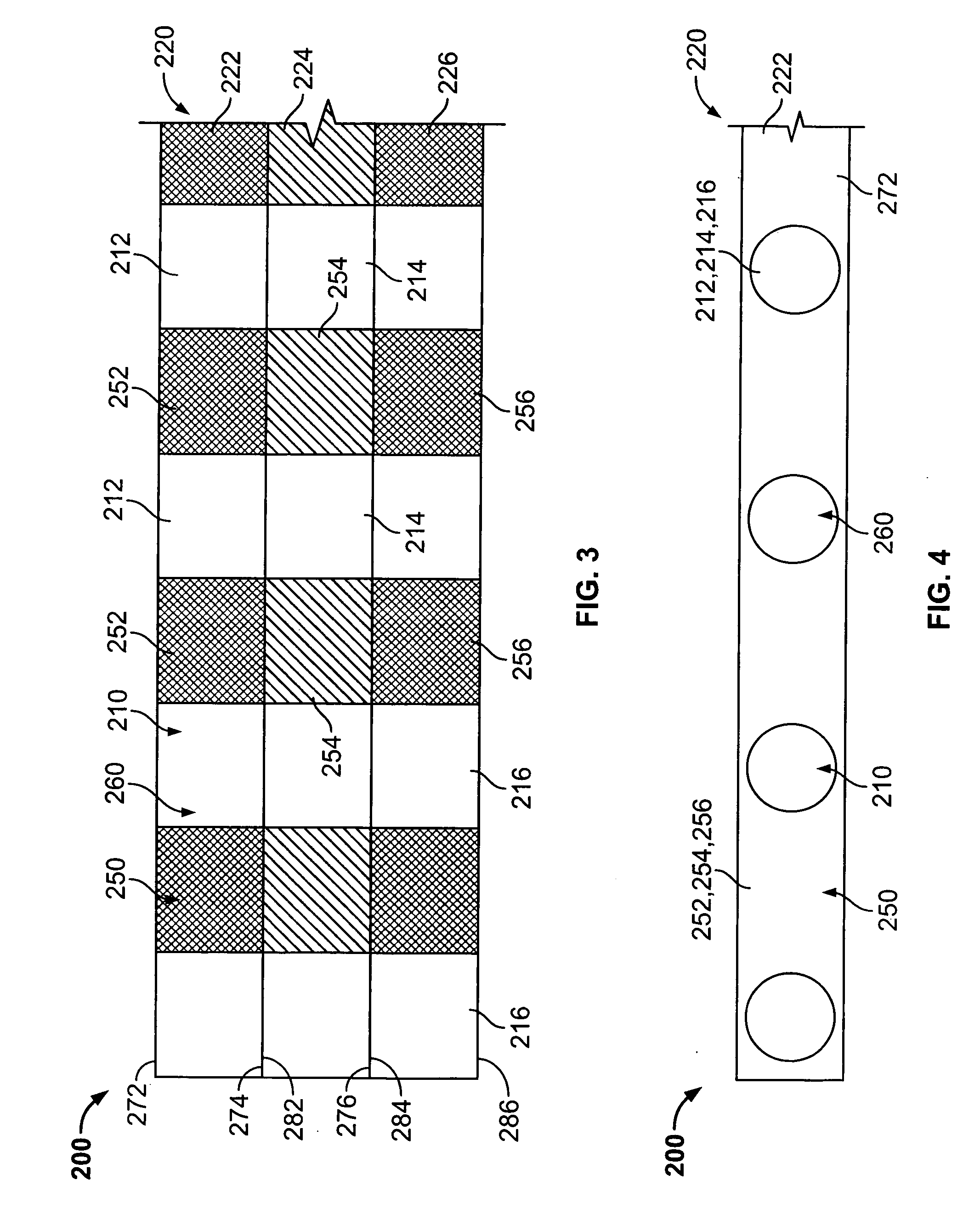

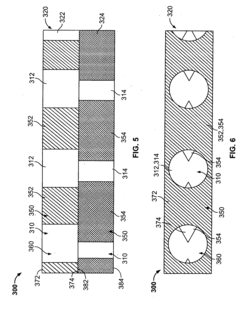

System and method of micromolded filtration microstructure and devices

PatentInactiveUS20070151920A1

Innovation

- The use of injection micromolding technology with advanced tool micro-machining techniques like EDM, MEDM, or laser beam machining to create precise filtration microstructures with a one-shot or multi-shot molding process, allowing for the production of filters with varying channel configurations and rigid structures that maintain consistency and efficiency.

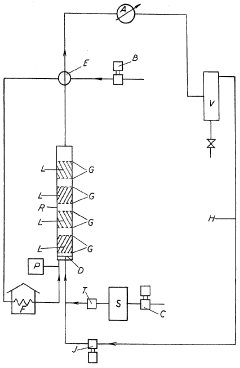

Improvements in or relating to heterogeneous catalytic processes

PatentInactiveGB839066A

Innovation

- Implementing a process where the linear velocity of the liquid reagent in a reactor is periodically and alternately increased and decreased by a superimposed force, ensuring intimate contact between the three phases and enhancing diffusion rates, thereby reducing gas consumption and catalyst deactivation.

Environmental Impact and Sustainability Considerations

Microinjection molding in catalytic processes presents significant environmental advantages compared to traditional manufacturing methods. The precision and efficiency of this technology directly contribute to reduced material waste, as the exact amount of polymer or catalyst material is used without excess. This waste reduction is particularly important when working with precious metals and rare earth elements commonly used as catalysts, conserving these limited natural resources.

Energy consumption represents another critical environmental consideration. Microinjection molding typically requires less energy than conventional manufacturing processes due to smaller material volumes and more efficient heating and cooling cycles. When applied to catalytic processes, this energy efficiency extends throughout the product lifecycle, as precisely engineered catalytic structures often operate at lower temperatures or pressures than their conventional counterparts.

The miniaturization enabled by microinjection molding contributes to sustainability through material dematerialization - achieving the same or enhanced catalytic performance with significantly less material input. This approach aligns with circular economy principles by maximizing resource efficiency while maintaining or improving functional performance. Additionally, the precise control over catalyst geometry and distribution can extend catalyst lifespan, reducing replacement frequency and associated environmental impacts.

Water conservation represents another environmental benefit, as microinjection processes typically require less cooling water than traditional manufacturing methods. This aspect becomes increasingly important as water scarcity affects more regions globally. Furthermore, the controlled nature of the microinjection process minimizes the release of potentially harmful chemicals during manufacturing, reducing pollution risks.

From a lifecycle perspective, catalysts produced via microinjection molding often demonstrate extended operational lifespans due to optimized structures that resist degradation mechanisms like sintering or poisoning. This longevity reduces the environmental footprint associated with catalyst replacement and disposal. The technology also enables easier recovery of precious metals from spent catalysts through designed-in features that facilitate end-of-life processing.

Looking forward, microinjection molding offers promising pathways toward more sustainable catalytic processes through bio-based polymer supports, biodegradable catalyst carriers, and designs that facilitate material recovery. As regulatory frameworks increasingly emphasize environmental performance, these sustainability advantages position microinjection molding as a strategically important technology for future catalytic applications across industries ranging from renewable energy to pharmaceutical manufacturing.

Energy consumption represents another critical environmental consideration. Microinjection molding typically requires less energy than conventional manufacturing processes due to smaller material volumes and more efficient heating and cooling cycles. When applied to catalytic processes, this energy efficiency extends throughout the product lifecycle, as precisely engineered catalytic structures often operate at lower temperatures or pressures than their conventional counterparts.

The miniaturization enabled by microinjection molding contributes to sustainability through material dematerialization - achieving the same or enhanced catalytic performance with significantly less material input. This approach aligns with circular economy principles by maximizing resource efficiency while maintaining or improving functional performance. Additionally, the precise control over catalyst geometry and distribution can extend catalyst lifespan, reducing replacement frequency and associated environmental impacts.

Water conservation represents another environmental benefit, as microinjection processes typically require less cooling water than traditional manufacturing methods. This aspect becomes increasingly important as water scarcity affects more regions globally. Furthermore, the controlled nature of the microinjection process minimizes the release of potentially harmful chemicals during manufacturing, reducing pollution risks.

From a lifecycle perspective, catalysts produced via microinjection molding often demonstrate extended operational lifespans due to optimized structures that resist degradation mechanisms like sintering or poisoning. This longevity reduces the environmental footprint associated with catalyst replacement and disposal. The technology also enables easier recovery of precious metals from spent catalysts through designed-in features that facilitate end-of-life processing.

Looking forward, microinjection molding offers promising pathways toward more sustainable catalytic processes through bio-based polymer supports, biodegradable catalyst carriers, and designs that facilitate material recovery. As regulatory frameworks increasingly emphasize environmental performance, these sustainability advantages position microinjection molding as a strategically important technology for future catalytic applications across industries ranging from renewable energy to pharmaceutical manufacturing.

Scale-up Challenges and Industrial Implementation Strategies

Scaling up microinjection molding for catalytic processes from laboratory to industrial scale presents significant challenges that require strategic approaches. The miniaturization inherent in microinjection molding creates unique obstacles when transitioning to mass production environments. One primary challenge is maintaining precise dimensional control and surface quality across larger production volumes, as microscale features critical for catalytic efficiency can be compromised during scale-up.

Equipment adaptation represents another substantial hurdle. Conventional injection molding machinery often lacks the precision required for microfeatures that enhance catalytic processes. Industrial implementation typically necessitates specialized equipment with advanced control systems capable of ultra-precise dosing, injection pressures, and temperature regulation to ensure consistent catalyst substrate production.

Material behavior also changes significantly during scale-up. Polymers that perform well in laboratory settings may exhibit different flow characteristics, cooling rates, and shrinkage patterns when processed at industrial volumes. This variability can directly impact the catalytic performance of the final components by altering surface area, porosity, and active site distribution.

Quality control methodologies must evolve substantially for industrial implementation. Traditional inspection methods prove inadequate for verifying microscale features that influence catalytic activity. Advanced metrology systems, including automated optical inspection and in-line process monitoring, become essential for maintaining quality standards across production batches.

Economic considerations further complicate scale-up efforts. The capital investment required for specialized microinjection equipment must be balanced against production volume and value-added benefits of enhanced catalytic performance. Manufacturers must develop comprehensive cost models that account for reduced material usage, improved catalytic efficiency, and potential energy savings to justify implementation costs.

Successful industrial implementation strategies typically involve a phased approach. Initial pilot production allows for process optimization before full-scale deployment. Cross-functional teams comprising polymer scientists, process engineers, and catalysis experts are essential for addressing interdisciplinary challenges. Additionally, developing robust design for manufacturing (DFM) guidelines specific to catalytic microstructures helps ensure reproducibility across production environments.

Strategic partnerships between research institutions and manufacturing entities have proven effective in bridging the laboratory-to-industry gap. These collaborations facilitate knowledge transfer and shared resources, accelerating the implementation timeline while distributing development risks. As the technology matures, standardization efforts will become increasingly important to establish industry-wide best practices for microinjection molding in catalytic applications.

Equipment adaptation represents another substantial hurdle. Conventional injection molding machinery often lacks the precision required for microfeatures that enhance catalytic processes. Industrial implementation typically necessitates specialized equipment with advanced control systems capable of ultra-precise dosing, injection pressures, and temperature regulation to ensure consistent catalyst substrate production.

Material behavior also changes significantly during scale-up. Polymers that perform well in laboratory settings may exhibit different flow characteristics, cooling rates, and shrinkage patterns when processed at industrial volumes. This variability can directly impact the catalytic performance of the final components by altering surface area, porosity, and active site distribution.

Quality control methodologies must evolve substantially for industrial implementation. Traditional inspection methods prove inadequate for verifying microscale features that influence catalytic activity. Advanced metrology systems, including automated optical inspection and in-line process monitoring, become essential for maintaining quality standards across production batches.

Economic considerations further complicate scale-up efforts. The capital investment required for specialized microinjection equipment must be balanced against production volume and value-added benefits of enhanced catalytic performance. Manufacturers must develop comprehensive cost models that account for reduced material usage, improved catalytic efficiency, and potential energy savings to justify implementation costs.

Successful industrial implementation strategies typically involve a phased approach. Initial pilot production allows for process optimization before full-scale deployment. Cross-functional teams comprising polymer scientists, process engineers, and catalysis experts are essential for addressing interdisciplinary challenges. Additionally, developing robust design for manufacturing (DFM) guidelines specific to catalytic microstructures helps ensure reproducibility across production environments.

Strategic partnerships between research institutions and manufacturing entities have proven effective in bridging the laboratory-to-industry gap. These collaborations facilitate knowledge transfer and shared resources, accelerating the implementation timeline while distributing development risks. As the technology matures, standardization efforts will become increasingly important to establish industry-wide best practices for microinjection molding in catalytic applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!