Comparison of Conductive Adhesives for Solar Panel Efficiency

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Solar Conductive Adhesives Background and Objectives

Conductive adhesives have emerged as a critical component in solar panel manufacturing, representing a significant evolution from traditional soldering methods. Since the early 2000s, these specialized adhesives have gained prominence due to their ability to create electrical connections while maintaining mechanical bonds between solar cells and other components. The technology has progressed from simple epoxy-based formulations to sophisticated nano-enhanced composites that offer superior conductivity and durability under extreme environmental conditions.

The development trajectory of conductive adhesives has been driven by the solar industry's push toward higher efficiency, lower costs, and more environmentally sustainable manufacturing processes. Early iterations faced challenges with conductivity degradation over time, particularly when exposed to thermal cycling and humidity. Recent advancements have focused on overcoming these limitations through innovative material science approaches, including the incorporation of silver, copper, and carbon-based nanoparticles.

Current research objectives in this field center on optimizing the balance between electrical performance and mechanical reliability. Specifically, the industry aims to develop adhesives that maintain consistent conductivity throughout the 25+ year lifespan of solar panels while withstanding temperature fluctuations between -40°C and 85°C. Additionally, there is significant interest in reducing the silver content in these formulations to decrease material costs without compromising performance.

The technical goals for next-generation conductive adhesives include achieving volume resistivity below 10^-4 Ω·cm, shear strength exceeding 20 MPa, and thermal conductivity above 3 W/m·K. These parameters are essential for maximizing energy harvest in increasingly efficient photovoltaic cells. Furthermore, there is a growing emphasis on developing adhesives compatible with emerging cell technologies, particularly heterojunction and perovskite solar cells, which have different thermal budgets and surface characteristics compared to conventional silicon cells.

Environmental considerations have also become paramount in adhesive development, with regulations such as RoHS and REACH driving the transition toward lead-free and low-VOC formulations. This regulatory landscape has accelerated innovation in bio-based and recyclable adhesive technologies, aligning with the renewable energy sector's sustainability goals.

The convergence of these technical trajectories points toward a future where conductive adhesives not only enable higher solar panel efficiencies but also contribute to reduced manufacturing costs and environmental impact, ultimately supporting the broader adoption of solar energy technologies worldwide.

The development trajectory of conductive adhesives has been driven by the solar industry's push toward higher efficiency, lower costs, and more environmentally sustainable manufacturing processes. Early iterations faced challenges with conductivity degradation over time, particularly when exposed to thermal cycling and humidity. Recent advancements have focused on overcoming these limitations through innovative material science approaches, including the incorporation of silver, copper, and carbon-based nanoparticles.

Current research objectives in this field center on optimizing the balance between electrical performance and mechanical reliability. Specifically, the industry aims to develop adhesives that maintain consistent conductivity throughout the 25+ year lifespan of solar panels while withstanding temperature fluctuations between -40°C and 85°C. Additionally, there is significant interest in reducing the silver content in these formulations to decrease material costs without compromising performance.

The technical goals for next-generation conductive adhesives include achieving volume resistivity below 10^-4 Ω·cm, shear strength exceeding 20 MPa, and thermal conductivity above 3 W/m·K. These parameters are essential for maximizing energy harvest in increasingly efficient photovoltaic cells. Furthermore, there is a growing emphasis on developing adhesives compatible with emerging cell technologies, particularly heterojunction and perovskite solar cells, which have different thermal budgets and surface characteristics compared to conventional silicon cells.

Environmental considerations have also become paramount in adhesive development, with regulations such as RoHS and REACH driving the transition toward lead-free and low-VOC formulations. This regulatory landscape has accelerated innovation in bio-based and recyclable adhesive technologies, aligning with the renewable energy sector's sustainability goals.

The convergence of these technical trajectories points toward a future where conductive adhesives not only enable higher solar panel efficiencies but also contribute to reduced manufacturing costs and environmental impact, ultimately supporting the broader adoption of solar energy technologies worldwide.

Market Analysis for High-Efficiency Solar Panel Adhesives

The global market for high-efficiency solar panel adhesives has experienced significant growth in recent years, driven by the expanding solar energy sector and increasing demand for more efficient photovoltaic systems. The market size for conductive adhesives specifically used in solar applications reached approximately $2.1 billion in 2022, with projections indicating a compound annual growth rate of 8.7% through 2028.

Consumer demand patterns show a clear shift toward adhesives that can enhance overall panel efficiency while maintaining long-term reliability. Market research indicates that improvements in panel efficiency of even 0.5-1% through superior conductive adhesives can translate to significant competitive advantages for manufacturers, as end-users increasingly prioritize total lifetime energy production over initial installation costs.

Regional market analysis reveals that Asia-Pacific dominates the solar adhesives market, accounting for nearly 65% of global production, with China leading manufacturing capacity. However, North America and Europe represent the fastest-growing markets for high-performance conductive adhesives, driven by premium solar installations and stringent performance requirements.

The market segmentation shows three distinct tiers: economy adhesives (primarily silicone-based) representing 55% of volume but only 30% of revenue; mid-range products (epoxy-silver composites) at 35% of volume and 45% of revenue; and premium conductive adhesives (including nano-enhanced formulations) comprising 10% of volume but 25% of revenue. This premium segment is experiencing the most rapid growth at 12.3% annually.

Customer surveys indicate that solar panel manufacturers prioritize four key attributes in conductive adhesives: electrical conductivity (ranked highest by 78% of respondents), thermal stability (65%), weather resistance (61%), and ease of application (52%). Price sensitivity varies significantly by market segment, with utility-scale projects showing higher price sensitivity than residential or specialized applications.

Supply chain analysis reveals potential vulnerabilities, particularly regarding silver and other precious metal components used in high-performance conductive adhesives. Recent price volatility in these raw materials has created margin pressure for manufacturers, driving innovation toward alternative formulations that maintain performance while reducing dependency on costly inputs.

Market forecasts suggest that adhesives capable of enhancing panel efficiency while extending operational lifespan will command premium pricing, with customers increasingly adopting total-cost-of-ownership models for evaluation rather than focusing solely on initial material costs.

Consumer demand patterns show a clear shift toward adhesives that can enhance overall panel efficiency while maintaining long-term reliability. Market research indicates that improvements in panel efficiency of even 0.5-1% through superior conductive adhesives can translate to significant competitive advantages for manufacturers, as end-users increasingly prioritize total lifetime energy production over initial installation costs.

Regional market analysis reveals that Asia-Pacific dominates the solar adhesives market, accounting for nearly 65% of global production, with China leading manufacturing capacity. However, North America and Europe represent the fastest-growing markets for high-performance conductive adhesives, driven by premium solar installations and stringent performance requirements.

The market segmentation shows three distinct tiers: economy adhesives (primarily silicone-based) representing 55% of volume but only 30% of revenue; mid-range products (epoxy-silver composites) at 35% of volume and 45% of revenue; and premium conductive adhesives (including nano-enhanced formulations) comprising 10% of volume but 25% of revenue. This premium segment is experiencing the most rapid growth at 12.3% annually.

Customer surveys indicate that solar panel manufacturers prioritize four key attributes in conductive adhesives: electrical conductivity (ranked highest by 78% of respondents), thermal stability (65%), weather resistance (61%), and ease of application (52%). Price sensitivity varies significantly by market segment, with utility-scale projects showing higher price sensitivity than residential or specialized applications.

Supply chain analysis reveals potential vulnerabilities, particularly regarding silver and other precious metal components used in high-performance conductive adhesives. Recent price volatility in these raw materials has created margin pressure for manufacturers, driving innovation toward alternative formulations that maintain performance while reducing dependency on costly inputs.

Market forecasts suggest that adhesives capable of enhancing panel efficiency while extending operational lifespan will command premium pricing, with customers increasingly adopting total-cost-of-ownership models for evaluation rather than focusing solely on initial material costs.

Current State and Challenges in Conductive Adhesive Technology

Conductive adhesives have emerged as a critical component in solar panel manufacturing, with global research efforts intensifying over the past decade. Currently, the market is dominated by silver-based conductive adhesives, which offer excellent electrical conductivity but face significant cost challenges due to silver price volatility. Alternative formulations using copper, carbon nanotubes, and graphene are gaining traction but remain in various stages of development and commercialization.

The technical landscape reveals a significant performance gap between traditional soldering methods and conductive adhesives in solar applications. While soldering provides superior electrical conductivity, conductive adhesives offer advantages in flexibility, environmental impact, and compatibility with temperature-sensitive substrates. Recent advancements have narrowed this gap, with high-performance epoxy-based adhesives achieving conductivity values approaching 80% of traditional solder connections.

A major technical challenge facing conductive adhesives in solar applications is long-term reliability under extreme environmental conditions. Solar panels experience significant temperature fluctuations, humidity exposure, and UV radiation, which can degrade adhesive performance over time. Current generation adhesives show conductivity degradation of 15-30% after accelerated aging tests equivalent to 10-15 years of field exposure, highlighting the need for improved formulations.

Geographical distribution of conductive adhesive technology development shows concentration in East Asia (particularly Japan, South Korea, and China), North America, and Western Europe. Chinese manufacturers have rapidly expanded production capacity, focusing on cost-effective formulations, while Japanese and European companies lead in high-performance specialty adhesives with enhanced durability characteristics.

Another significant challenge is the trade-off between conductivity and mechanical properties. Increasing conductive filler content improves electrical performance but often compromises adhesion strength, flexibility, and thermal cycling resistance. This balance is particularly critical for solar applications where mechanical stress from thermal expansion can lead to microcracks and connection failures.

Manufacturing scalability presents additional hurdles, as high-performance conductive adhesives often require precise mixing, controlled curing conditions, and specialized application equipment. The industry is working toward formulations with wider processing windows and compatibility with existing high-throughput manufacturing lines to enable broader adoption in large-scale solar production.

Recent research has identified interface engineering as a key focus area, with surface treatments and coupling agents showing promise in improving both electrical contact and mechanical adhesion. However, standardization of testing protocols remains inconsistent across the industry, making direct performance comparisons challenging and slowing adoption of newer technologies.

The technical landscape reveals a significant performance gap between traditional soldering methods and conductive adhesives in solar applications. While soldering provides superior electrical conductivity, conductive adhesives offer advantages in flexibility, environmental impact, and compatibility with temperature-sensitive substrates. Recent advancements have narrowed this gap, with high-performance epoxy-based adhesives achieving conductivity values approaching 80% of traditional solder connections.

A major technical challenge facing conductive adhesives in solar applications is long-term reliability under extreme environmental conditions. Solar panels experience significant temperature fluctuations, humidity exposure, and UV radiation, which can degrade adhesive performance over time. Current generation adhesives show conductivity degradation of 15-30% after accelerated aging tests equivalent to 10-15 years of field exposure, highlighting the need for improved formulations.

Geographical distribution of conductive adhesive technology development shows concentration in East Asia (particularly Japan, South Korea, and China), North America, and Western Europe. Chinese manufacturers have rapidly expanded production capacity, focusing on cost-effective formulations, while Japanese and European companies lead in high-performance specialty adhesives with enhanced durability characteristics.

Another significant challenge is the trade-off between conductivity and mechanical properties. Increasing conductive filler content improves electrical performance but often compromises adhesion strength, flexibility, and thermal cycling resistance. This balance is particularly critical for solar applications where mechanical stress from thermal expansion can lead to microcracks and connection failures.

Manufacturing scalability presents additional hurdles, as high-performance conductive adhesives often require precise mixing, controlled curing conditions, and specialized application equipment. The industry is working toward formulations with wider processing windows and compatibility with existing high-throughput manufacturing lines to enable broader adoption in large-scale solar production.

Recent research has identified interface engineering as a key focus area, with surface treatments and coupling agents showing promise in improving both electrical contact and mechanical adhesion. However, standardization of testing protocols remains inconsistent across the industry, making direct performance comparisons challenging and slowing adoption of newer technologies.

Comparative Analysis of Current Conductive Adhesive Solutions

01 Metal-filled conductive adhesives

Metal-filled conductive adhesives incorporate metallic particles such as silver, gold, copper, or nickel to enhance electrical conductivity. These particles create conductive pathways within the adhesive matrix, allowing for efficient electron transfer. The size, shape, and concentration of metal fillers significantly impact the adhesive's conductivity and overall performance. These adhesives are widely used in electronics assembly for applications requiring both mechanical bonding and electrical connectivity.- Conductive fillers for enhanced electrical conductivity: Various conductive fillers can be incorporated into adhesive formulations to enhance electrical conductivity. These fillers include metal particles, carbon-based materials like graphene or carbon nanotubes, and metallic nanowires. The type, size, shape, and concentration of these fillers significantly impact the overall conductivity of the adhesive. Optimizing the dispersion of these fillers within the polymer matrix is crucial for achieving uniform conductivity throughout the adhesive.

- Polymer matrix selection for conductive adhesives: The selection of appropriate polymer matrices is critical for conductive adhesive performance. Epoxy resins, silicones, acrylics, and polyurethanes are commonly used as base materials. These polymers provide the adhesive properties while allowing for the incorporation of conductive fillers. The polymer matrix affects not only the mechanical properties but also how well the conductive fillers can be dispersed and maintained in position. Compatibility between the polymer and conductive fillers is essential for achieving optimal electrical conductivity while maintaining adhesive strength.

- Thermal management in conductive adhesives: Thermal management is a critical aspect of conductive adhesive efficiency. Adhesives with high thermal conductivity can effectively dissipate heat generated during electrical operation, preventing performance degradation and extending device lifespan. Incorporating thermally conductive fillers such as ceramic particles, boron nitride, or aluminum oxide alongside electrically conductive materials can create adhesives with dual functionality. The balance between thermal and electrical conductivity must be carefully optimized based on the specific application requirements.

- Processing techniques for improved conductivity: Various processing techniques can significantly enhance the efficiency of conductive adhesives. These include specialized mixing methods to ensure uniform dispersion of conductive fillers, surface treatment of fillers to improve compatibility with the polymer matrix, and curing protocols optimized for electrical performance. Advanced techniques such as ultrasonic dispersion, high-shear mixing, and controlled curing environments can prevent agglomeration of conductive particles and ensure consistent electrical pathways throughout the adhesive matrix.

- Application-specific conductive adhesive formulations: Conductive adhesives can be specifically formulated for different applications to maximize efficiency. For electronics assembly, adhesives with precise conductivity and fine-pitch capability are developed. For EMI shielding applications, adhesives with high shielding effectiveness are formulated. For flexible electronics, stretchable conductive adhesives that maintain conductivity under deformation are created. Tailoring the adhesive properties such as viscosity, cure temperature, and bond strength to specific application requirements ensures optimal performance in the intended use case.

02 Carbon-based conductive fillers

Carbon-based materials such as carbon nanotubes, graphene, and carbon black are incorporated into adhesives to improve conductivity while maintaining flexibility. These carbon structures create efficient electron pathways through the adhesive matrix. Carbon-based conductive adhesives often offer advantages in terms of weight reduction, flexibility, and resistance to corrosion compared to metal-filled alternatives. They are particularly useful in applications where lightweight and flexible conductive bonding is required.Expand Specific Solutions03 Thermal management in conductive adhesives

Conductive adhesives can be formulated to enhance thermal conductivity alongside electrical conductivity, improving heat dissipation in electronic assemblies. This dual functionality is achieved through specific fillers and matrix materials that facilitate both electron and phonon transfer. Improved thermal management prevents overheating of components, enhances reliability, and extends the lifespan of electronic devices. These thermally conductive adhesives are crucial for high-power electronic applications where heat management is essential.Expand Specific Solutions04 Curing methods for conductive adhesives

Various curing methods, including thermal, UV, and moisture curing, significantly impact the final conductivity and mechanical properties of conductive adhesives. The curing process affects the formation of conductive networks within the adhesive matrix and determines the strength of bonds between the adhesive and substrates. Optimized curing protocols can enhance conductivity efficiency by ensuring proper particle alignment and minimizing voids or defects in the adhesive layer. Advanced curing techniques can reduce processing time while improving the overall performance of the conductive adhesive.Expand Specific Solutions05 Novel formulations for enhanced conductivity

Innovative adhesive formulations incorporate hybrid fillers, specialized polymers, and surface-modified particles to achieve superior conductivity. These advanced formulations often combine different types of conductive materials to create synergistic effects that enhance overall performance. Novel approaches include the use of self-assembling conductive networks, anisotropic conductive properties, and stimuli-responsive conductivity. These cutting-edge adhesives offer improved reliability, higher conductivity, and better performance in challenging environmental conditions compared to conventional conductive adhesives.Expand Specific Solutions

Key Manufacturers and Competitive Landscape Analysis

The conductive adhesives market for solar panel efficiency is in a growth phase, with increasing demand driven by the expanding solar energy sector. The market size is projected to grow significantly as solar installations continue to rise globally. Technologically, the field is advancing rapidly with companies at different maturity levels. Industry leaders like Henkel AG and RESONAC CORP have established mature conductive adhesive technologies, while specialized players such as Daejoo Electronic Materials and Wuxi DK Electronic Materials are developing innovative formulations specifically for solar applications. Companies like Trina Solar and JA Solar are integrating these advanced adhesives into their high-efficiency panels, while research organizations like Fraunhofer-Gesellschaft are pushing boundaries with next-generation conductive materials that promise higher conductivity and durability under extreme conditions.

Dexerials Corp.

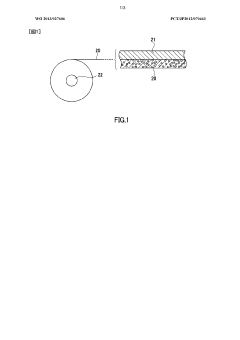

Technical Solution: Dexerials Corporation has developed specialized anisotropic conductive films (ACFs) and pastes (ACPs) for solar panel applications, focusing on high-reliability interconnections for crystalline silicon and thin-film solar technologies. Their proprietary conductive adhesive technology features precisely controlled conductive particle distribution with uniform particle sizes ranging from 3-10μm and optimized spacing to prevent electrical shorts while ensuring consistent conductivity. Dexerials' solar-specific adhesives incorporate UV and moisture resistance additives that extend operational lifetime in outdoor environments to match the 25+ year lifespan of modern solar panels. Their latest innovation includes a hybrid metal-polymer composite adhesive system that achieves electrical conductivity comparable to solder (>10^5 S/cm) while maintaining flexibility through temperature cycling from -40°C to +85°C. The company has also developed specialized low-temperature curing formulations (120-150°C) specifically designed for temperature-sensitive cell architectures like heterojunction technology (HJT).

Strengths: Excellent thermal cycling reliability, compatibility with advanced cell architectures including HJT and IBC cells, reduced microcracks due to lower processing temperatures, and consistent performance in varying environmental conditions. Weaknesses: Higher material costs compared to traditional interconnection methods, specialized application equipment requirements, and potential for increased contact resistance over extended field exposure.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed advanced electrically conductive adhesives (ECAs) specifically designed for solar applications, with their LOCTITE ABLESTIK ECAs offering superior performance for cell interconnection. Their technology utilizes silver-filled epoxy formulations that provide excellent electrical conductivity while maintaining flexibility to withstand thermal cycling. Henkel's conductive adhesives eliminate the need for high-temperature soldering processes, reducing thermal stress on solar cells and minimizing microcracks. Their latest generation products feature nano-silver technology that achieves conductivity comparable to traditional soldering (>10^4 S/cm) while using up to 30% less silver content. The company has also developed specialized adhesives for specific solar panel architectures, including heterojunction (HJT) and IBC (Interdigitated Back Contact) cells, where traditional soldering methods are problematic due to temperature sensitivity.

Strengths: Lower processing temperatures (150-180°C vs. 240-250°C for soldering), reduced cell breakage rates, excellent thermal cycling durability, and compatibility with temperature-sensitive cell technologies. Weaknesses: Higher material costs compared to traditional soldering, potential for increased contact resistance over time, and more complex processing requirements including controlled curing environments.

Critical Patents and Technical Innovations in Conductive Adhesives

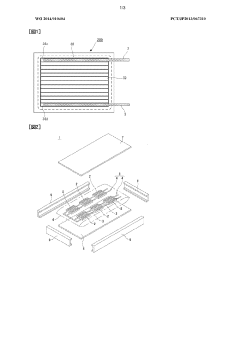

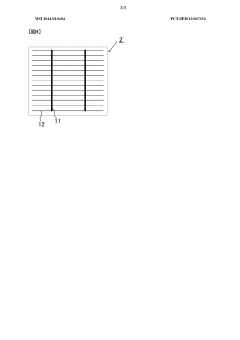

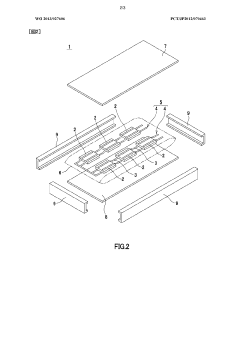

Conductive adhesive for solar cell, solar cell module, and manufacturing method thereof

PatentWO2014010404A1

Innovation

- A conductive adhesive comprising fluorene-type phenoxy resin, fluorene-type epoxy resin, a curing agent, and conductive particles, with a specific mass ratio and particle content, which provides high adhesion and connection reliability by using silver-coated copper powder and a curing process that ensures storage modulus and tan δ peak values suitable for solar cell modules.

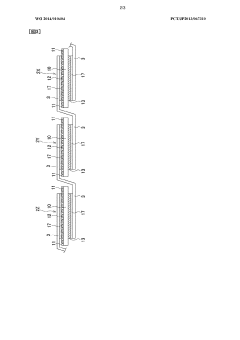

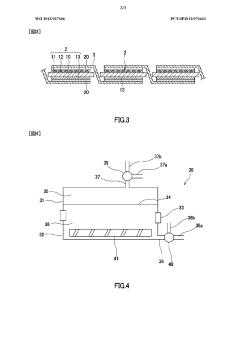

Conductive adhesive and solar cell module

PatentWO2013027606A1

Innovation

- A conductive adhesive comprising an acrylic resin, radical polymerization initiator, and conductive particles with a glass transition temperature of 150°C or higher and a tan δ peak value between 0.25 and 0.60, providing enhanced heat resistance and connection reliability through thermocompression bonding.

Environmental Impact and Sustainability Considerations

The environmental impact of conductive adhesives in solar panel manufacturing represents a critical consideration as the industry strives toward greater sustainability. Traditional soldering methods using lead-based materials pose significant environmental hazards through toxic waste generation and energy-intensive processing. In contrast, many conductive adhesives offer reduced environmental footprints through lower curing temperatures, resulting in decreased energy consumption during manufacturing processes. This energy reduction can range from 30-60% compared to conventional soldering methods, contributing significantly to reduced carbon emissions in production facilities.

Material composition of conductive adhesives directly influences their environmental profile. Silver-based conductive adhesives, while highly efficient, raise sustainability concerns due to silver mining's environmental impact and resource scarcity. Alternative formulations incorporating copper, carbon, or graphene demonstrate promising environmental advantages despite current efficiency limitations. Notably, bio-based conductive adhesives derived from renewable resources represent an emerging category with potentially transformative environmental benefits, though they currently face performance and durability challenges in commercial applications.

End-of-life considerations reveal substantial differences between adhesive types. Isotropic conductive adhesives (ICAs) often contain thermosetting polymers that complicate recycling processes, while anisotropic conductive adhesives (ACAs) may offer improved recyclability depending on their specific formulation. Recent research indicates that nano-enhanced conductive adhesives can be designed with disassembly mechanisms that facilitate component separation and material recovery, potentially increasing solar panel recyclability rates by 15-25% compared to conventional methods.

Regulatory frameworks increasingly influence adhesive selection, with global initiatives like RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) driving manufacturers toward less toxic formulations. Several leading conductive adhesive manufacturers have implemented life cycle assessment (LCA) methodologies to quantify environmental impacts across production, use, and disposal phases, providing valuable comparative data for sustainability-focused decision-making.

Water consumption presents another critical environmental factor, with certain conductive adhesive manufacturing processes requiring significant water resources for production and cleaning. Advanced water-efficient formulations have emerged that reduce water usage by up to 40% compared to conventional manufacturing methods, addressing growing concerns about water scarcity in manufacturing regions.

Human toxicity profiles vary significantly among adhesive formulations, with newer generations increasingly designed to minimize workplace exposure risks and associated health impacts. This evolution reflects broader industry recognition that environmental sustainability must encompass both ecological and human health considerations throughout the product lifecycle.

Material composition of conductive adhesives directly influences their environmental profile. Silver-based conductive adhesives, while highly efficient, raise sustainability concerns due to silver mining's environmental impact and resource scarcity. Alternative formulations incorporating copper, carbon, or graphene demonstrate promising environmental advantages despite current efficiency limitations. Notably, bio-based conductive adhesives derived from renewable resources represent an emerging category with potentially transformative environmental benefits, though they currently face performance and durability challenges in commercial applications.

End-of-life considerations reveal substantial differences between adhesive types. Isotropic conductive adhesives (ICAs) often contain thermosetting polymers that complicate recycling processes, while anisotropic conductive adhesives (ACAs) may offer improved recyclability depending on their specific formulation. Recent research indicates that nano-enhanced conductive adhesives can be designed with disassembly mechanisms that facilitate component separation and material recovery, potentially increasing solar panel recyclability rates by 15-25% compared to conventional methods.

Regulatory frameworks increasingly influence adhesive selection, with global initiatives like RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) driving manufacturers toward less toxic formulations. Several leading conductive adhesive manufacturers have implemented life cycle assessment (LCA) methodologies to quantify environmental impacts across production, use, and disposal phases, providing valuable comparative data for sustainability-focused decision-making.

Water consumption presents another critical environmental factor, with certain conductive adhesive manufacturing processes requiring significant water resources for production and cleaning. Advanced water-efficient formulations have emerged that reduce water usage by up to 40% compared to conventional manufacturing methods, addressing growing concerns about water scarcity in manufacturing regions.

Human toxicity profiles vary significantly among adhesive formulations, with newer generations increasingly designed to minimize workplace exposure risks and associated health impacts. This evolution reflects broader industry recognition that environmental sustainability must encompass both ecological and human health considerations throughout the product lifecycle.

Reliability Testing and Performance Standards

Reliability testing and performance standards are critical components in evaluating conductive adhesives for solar panel applications. The International Electrotechnical Commission (IEC) has established several standards specifically for photovoltaic systems, including IEC 61215 and IEC 61730, which provide frameworks for testing the durability and safety of solar modules. When assessing conductive adhesives, these standards must be adapted to focus on electrical connectivity, mechanical strength, and environmental resistance.

Temperature cycling tests represent one of the most crucial reliability assessments for conductive adhesives in solar applications. These tests typically involve exposing adhesive samples to temperature extremes ranging from -40°C to +85°C for 200-1000 cycles, simulating years of field exposure. The adhesive must maintain consistent electrical conductivity and mechanical integrity throughout these cycles to be considered reliable for long-term solar panel deployment.

Humidity testing presents another essential evaluation parameter, with damp heat tests (85°C/85% relative humidity) conducted for 1000+ hours to assess moisture resistance. This test is particularly relevant for conductive adhesives as moisture ingress can significantly degrade both adhesion strength and electrical conductivity, leading to increased contact resistance and potential power losses in solar panels.

Mechanical stress testing includes pull and shear strength measurements before and after environmental exposure. Industry standards typically require conductive adhesives to maintain at least 80% of their initial mechanical strength after environmental conditioning. For solar applications, adhesives should demonstrate shear strengths exceeding 15 MPa and pull strengths above 5 MPa to ensure long-term reliability in field conditions.

Electrical performance standards focus on volume resistivity measurements, with high-performance conductive adhesives expected to maintain resistivity below 10^-4 Ω·cm throughout their service life. Contact resistance stability is equally important, with changes limited to less than 20% after environmental exposure to ensure consistent power output from solar panels.

Accelerated UV exposure testing has become increasingly important for solar applications, with standards requiring 500-1000 hours of exposure to simulate decades of field deployment. This test is particularly relevant for adhesives used in the front-side connections of solar cells, where direct sunlight exposure occurs.

Corrosion resistance testing, including salt spray exposure (ASTM B117) and mixed flowing gas tests, evaluates the adhesive's ability to protect metal interfaces from environmental degradation. For solar applications in coastal or industrial environments, adhesives must demonstrate minimal corrosion after 500+ hours of salt spray exposure to be considered suitable for deployment.

Temperature cycling tests represent one of the most crucial reliability assessments for conductive adhesives in solar applications. These tests typically involve exposing adhesive samples to temperature extremes ranging from -40°C to +85°C for 200-1000 cycles, simulating years of field exposure. The adhesive must maintain consistent electrical conductivity and mechanical integrity throughout these cycles to be considered reliable for long-term solar panel deployment.

Humidity testing presents another essential evaluation parameter, with damp heat tests (85°C/85% relative humidity) conducted for 1000+ hours to assess moisture resistance. This test is particularly relevant for conductive adhesives as moisture ingress can significantly degrade both adhesion strength and electrical conductivity, leading to increased contact resistance and potential power losses in solar panels.

Mechanical stress testing includes pull and shear strength measurements before and after environmental exposure. Industry standards typically require conductive adhesives to maintain at least 80% of their initial mechanical strength after environmental conditioning. For solar applications, adhesives should demonstrate shear strengths exceeding 15 MPa and pull strengths above 5 MPa to ensure long-term reliability in field conditions.

Electrical performance standards focus on volume resistivity measurements, with high-performance conductive adhesives expected to maintain resistivity below 10^-4 Ω·cm throughout their service life. Contact resistance stability is equally important, with changes limited to less than 20% after environmental exposure to ensure consistent power output from solar panels.

Accelerated UV exposure testing has become increasingly important for solar applications, with standards requiring 500-1000 hours of exposure to simulate decades of field deployment. This test is particularly relevant for adhesives used in the front-side connections of solar cells, where direct sunlight exposure occurs.

Corrosion resistance testing, including salt spray exposure (ASTM B117) and mixed flowing gas tests, evaluates the adhesive's ability to protect metal interfaces from environmental degradation. For solar applications in coastal or industrial environments, adhesives must demonstrate minimal corrosion after 500+ hours of salt spray exposure to be considered suitable for deployment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!