Comparison of Conductive Adhesives vs Traditional Soldering

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Conductive Adhesives and Soldering Evolution

The evolution of joining technologies in electronics has seen significant transformations over the decades, with traditional soldering and conductive adhesives representing two major approaches. Traditional soldering, based on tin-lead alloys, has dominated the electronics industry since the early 20th century. The 1940s and 1950s marked the standardization of soldering processes in military and aerospace applications, establishing tin-lead solders as the industry standard due to their reliability and electrical conductivity.

The 1980s witnessed a pivotal shift with the introduction of surface mount technology (SMT), which demanded more precise soldering techniques and opened the door for alternative joining methods. This period also saw the first commercial applications of electrically conductive adhesives (ECAs), primarily in niche applications where traditional soldering presented limitations.

A significant evolutionary milestone occurred in the early 2000s with the implementation of the Restriction of Hazardous Substances (RoHS) directive, which mandated the elimination of lead from electronic solders. This regulatory change accelerated the development of lead-free solders and simultaneously boosted research into conductive adhesives as potential alternatives.

The 2010s marked the maturation of conductive adhesive technology, with isotropic conductive adhesives (ICAs) and anisotropic conductive adhesives (ACAs) emerging as viable solutions for specific applications. ICAs, containing high concentrations of conductive fillers, provide omnidirectional conductivity similar to traditional solders. ACAs, with lower filler content, conduct electricity only in the vertical direction when compressed, making them ideal for fine-pitch connections.

Recent developments have focused on enhancing the thermal and electrical properties of conductive adhesives through nanomaterials. Carbon nanotubes, graphene, and metallic nanoparticles have been incorporated to improve conductivity while maintaining the processing advantages of polymer-based systems. Simultaneously, lead-free solders have evolved to address reliability issues, with additions of elements like silver, copper, bismuth, and indium to improve performance.

The miniaturization trend in electronics has pushed both technologies to adapt to increasingly demanding requirements. For traditional soldering, this has meant the development of ultra-fine solder pastes and precise application methods. For conductive adhesives, innovations in polymer chemistry have yielded formulations capable of creating reliable connections in densely packed assemblies.

Looking forward, the convergence of these technologies is becoming apparent, with hybrid joining solutions emerging that combine the strengths of both approaches. These developments reflect the industry's ongoing pursuit of environmentally friendly, reliable, and cost-effective methods for creating electrical interconnections in increasingly complex electronic devices.

The 1980s witnessed a pivotal shift with the introduction of surface mount technology (SMT), which demanded more precise soldering techniques and opened the door for alternative joining methods. This period also saw the first commercial applications of electrically conductive adhesives (ECAs), primarily in niche applications where traditional soldering presented limitations.

A significant evolutionary milestone occurred in the early 2000s with the implementation of the Restriction of Hazardous Substances (RoHS) directive, which mandated the elimination of lead from electronic solders. This regulatory change accelerated the development of lead-free solders and simultaneously boosted research into conductive adhesives as potential alternatives.

The 2010s marked the maturation of conductive adhesive technology, with isotropic conductive adhesives (ICAs) and anisotropic conductive adhesives (ACAs) emerging as viable solutions for specific applications. ICAs, containing high concentrations of conductive fillers, provide omnidirectional conductivity similar to traditional solders. ACAs, with lower filler content, conduct electricity only in the vertical direction when compressed, making them ideal for fine-pitch connections.

Recent developments have focused on enhancing the thermal and electrical properties of conductive adhesives through nanomaterials. Carbon nanotubes, graphene, and metallic nanoparticles have been incorporated to improve conductivity while maintaining the processing advantages of polymer-based systems. Simultaneously, lead-free solders have evolved to address reliability issues, with additions of elements like silver, copper, bismuth, and indium to improve performance.

The miniaturization trend in electronics has pushed both technologies to adapt to increasingly demanding requirements. For traditional soldering, this has meant the development of ultra-fine solder pastes and precise application methods. For conductive adhesives, innovations in polymer chemistry have yielded formulations capable of creating reliable connections in densely packed assemblies.

Looking forward, the convergence of these technologies is becoming apparent, with hybrid joining solutions emerging that combine the strengths of both approaches. These developments reflect the industry's ongoing pursuit of environmentally friendly, reliable, and cost-effective methods for creating electrical interconnections in increasingly complex electronic devices.

Market Demand Analysis for Electronics Joining Technologies

The electronics industry is witnessing a significant shift in joining technologies, driven by evolving regulatory frameworks, miniaturization trends, and performance requirements. The global market for electronics joining technologies was valued at approximately $3.5 billion in 2022 and is projected to reach $5.2 billion by 2027, representing a compound annual growth rate of 8.3%. Traditional soldering has historically dominated this market, accounting for roughly 78% of all electronic connections, while conductive adhesives have been gaining traction, currently representing about 15% of the market with accelerating adoption rates.

Several key factors are driving demand for alternative joining technologies. Environmental regulations, particularly the Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE) directives, have significantly impacted traditional soldering practices by restricting lead usage. This regulatory pressure has created a substantial market opportunity for conductive adhesives, which typically offer more environmentally friendly profiles.

The miniaturization trend in electronics continues unabated, with devices becoming increasingly compact while incorporating more functionality. Traditional soldering faces limitations when dealing with ultra-fine pitch components and flexible substrates. Market research indicates that 67% of electronics manufacturers cite joining technology limitations as a significant constraint in their miniaturization efforts, creating demand for alternatives like conductive adhesives that can accommodate these advanced design requirements.

Temperature-sensitive components represent another growth segment, particularly in medical electronics, wearable technology, and certain consumer electronics applications. These components often cannot withstand the high temperatures required for traditional soldering processes (typically 220-250°C for lead-free solders). The market for temperature-sensitive electronic components is growing at 12.4% annually, outpacing the broader electronics market and driving demand for low-temperature joining solutions.

Regional analysis reveals varying adoption patterns. Asia-Pacific dominates the electronics joining technologies market with 58% share, followed by North America (22%) and Europe (17%). However, Europe leads in conductive adhesive adoption due to stricter environmental regulations and sustainability initiatives. North American markets show the fastest growth rate for conductive adhesives at 10.2% annually, driven by aerospace, defense, and medical applications.

End-user segmentation shows automotive electronics as the fastest-growing sector for advanced joining technologies (11.7% CAGR), followed by consumer electronics (9.3%) and medical devices (8.9%). The automotive sector's transition toward electric vehicles and advanced driver assistance systems has particularly accelerated demand for reliable joining technologies capable of withstanding harsh operating environments while meeting stringent safety requirements.

Several key factors are driving demand for alternative joining technologies. Environmental regulations, particularly the Restriction of Hazardous Substances (RoHS) and Waste Electrical and Electronic Equipment (WEEE) directives, have significantly impacted traditional soldering practices by restricting lead usage. This regulatory pressure has created a substantial market opportunity for conductive adhesives, which typically offer more environmentally friendly profiles.

The miniaturization trend in electronics continues unabated, with devices becoming increasingly compact while incorporating more functionality. Traditional soldering faces limitations when dealing with ultra-fine pitch components and flexible substrates. Market research indicates that 67% of electronics manufacturers cite joining technology limitations as a significant constraint in their miniaturization efforts, creating demand for alternatives like conductive adhesives that can accommodate these advanced design requirements.

Temperature-sensitive components represent another growth segment, particularly in medical electronics, wearable technology, and certain consumer electronics applications. These components often cannot withstand the high temperatures required for traditional soldering processes (typically 220-250°C for lead-free solders). The market for temperature-sensitive electronic components is growing at 12.4% annually, outpacing the broader electronics market and driving demand for low-temperature joining solutions.

Regional analysis reveals varying adoption patterns. Asia-Pacific dominates the electronics joining technologies market with 58% share, followed by North America (22%) and Europe (17%). However, Europe leads in conductive adhesive adoption due to stricter environmental regulations and sustainability initiatives. North American markets show the fastest growth rate for conductive adhesives at 10.2% annually, driven by aerospace, defense, and medical applications.

End-user segmentation shows automotive electronics as the fastest-growing sector for advanced joining technologies (11.7% CAGR), followed by consumer electronics (9.3%) and medical devices (8.9%). The automotive sector's transition toward electric vehicles and advanced driver assistance systems has particularly accelerated demand for reliable joining technologies capable of withstanding harsh operating environments while meeting stringent safety requirements.

Technical Challenges in Modern Electronics Assembly

Modern electronics assembly faces numerous technical challenges as the industry continues to evolve toward miniaturization, higher performance, and environmental sustainability. Traditional soldering techniques, which have been the backbone of electronics manufacturing for decades, are increasingly being challenged by alternative methods such as conductive adhesives.

The primary technical hurdles in soldering include the formation of reliable interconnections at ever-decreasing sizes. As component pitches shrink below 0.4mm, conventional soldering processes struggle with issues like bridging between adjacent pads, insufficient solder volume, and voiding. These challenges are exacerbated by the industry's transition to lead-free solders, which typically require higher processing temperatures (30-40°C higher than traditional tin-lead solders), potentially causing thermal damage to sensitive components.

Temperature management represents another significant challenge. Modern printed circuit boards (PCBs) often combine temperature-sensitive components with those requiring high soldering temperatures, creating a complex thermal management problem. This is particularly evident in flexible electronics and wearable technology applications, where substrate materials may have lower thermal tolerance.

Conductive adhesives present their own set of technical difficulties. While they offer lower processing temperatures (typically 120-150°C compared to 217-250°C for lead-free solders), they generally exhibit higher electrical resistance than metallic solders. This resistance can lead to performance degradation, especially in high-frequency applications or power electronics where minimal electrical losses are critical.

Reliability under environmental stress constitutes another major challenge. Both soldering and conductive adhesive technologies must withstand thermal cycling, mechanical shock, vibration, and humidity. Traditional solders typically excel in thermal cycling resistance due to their metallic nature, while conductive adhesives may experience performance degradation under prolonged environmental stress, particularly in high-humidity environments.

Manufacturing process compatibility presents additional complications. Existing production lines optimized for soldering require significant modification to accommodate conductive adhesive processes. The curing requirements for adhesives (typically requiring longer processing times than soldering) can create production bottlenecks and reduce throughput in high-volume manufacturing environments.

Quality control and inspection methodologies also differ substantially between these technologies. While X-ray inspection and automated optical inspection (AOI) are well-established for solder joint evaluation, conductive adhesive connections may require different inspection parameters and acceptance criteria, necessitating new quality assurance protocols and equipment investments.

The primary technical hurdles in soldering include the formation of reliable interconnections at ever-decreasing sizes. As component pitches shrink below 0.4mm, conventional soldering processes struggle with issues like bridging between adjacent pads, insufficient solder volume, and voiding. These challenges are exacerbated by the industry's transition to lead-free solders, which typically require higher processing temperatures (30-40°C higher than traditional tin-lead solders), potentially causing thermal damage to sensitive components.

Temperature management represents another significant challenge. Modern printed circuit boards (PCBs) often combine temperature-sensitive components with those requiring high soldering temperatures, creating a complex thermal management problem. This is particularly evident in flexible electronics and wearable technology applications, where substrate materials may have lower thermal tolerance.

Conductive adhesives present their own set of technical difficulties. While they offer lower processing temperatures (typically 120-150°C compared to 217-250°C for lead-free solders), they generally exhibit higher electrical resistance than metallic solders. This resistance can lead to performance degradation, especially in high-frequency applications or power electronics where minimal electrical losses are critical.

Reliability under environmental stress constitutes another major challenge. Both soldering and conductive adhesive technologies must withstand thermal cycling, mechanical shock, vibration, and humidity. Traditional solders typically excel in thermal cycling resistance due to their metallic nature, while conductive adhesives may experience performance degradation under prolonged environmental stress, particularly in high-humidity environments.

Manufacturing process compatibility presents additional complications. Existing production lines optimized for soldering require significant modification to accommodate conductive adhesive processes. The curing requirements for adhesives (typically requiring longer processing times than soldering) can create production bottlenecks and reduce throughput in high-volume manufacturing environments.

Quality control and inspection methodologies also differ substantially between these technologies. While X-ray inspection and automated optical inspection (AOI) are well-established for solder joint evaluation, conductive adhesive connections may require different inspection parameters and acceptance criteria, necessitating new quality assurance protocols and equipment investments.

Current Joining Solutions Comparison

01 Composition of conductive adhesives

Conductive adhesives are typically composed of a polymer matrix filled with conductive particles. These adhesives provide electrical conductivity while maintaining adhesive properties. The polymer matrix can be epoxy, silicone, or other resins, while the conductive fillers often include silver, copper, or carbon particles. The ratio of conductive fillers to polymer matrix significantly affects both the electrical conductivity and mechanical strength of the adhesive.- Conductive adhesive compositions: Conductive adhesives are formulated with specific materials to provide electrical conductivity while maintaining adhesive properties. These compositions typically include conductive fillers such as metal particles, carbon materials, or other conductive elements dispersed in a polymer matrix. The formulation can be adjusted to achieve desired conductivity levels, adhesion strength, and curing properties. These adhesives offer alternatives to traditional soldering in various electronic applications, particularly where temperature sensitivity is a concern.

- Comparison between conductive adhesives and traditional soldering: Conductive adhesives and traditional soldering represent different approaches to creating electrical connections. Traditional soldering involves melting metal alloys to form conductive joints, typically requiring higher temperatures than adhesives. Conductive adhesives offer advantages including lower processing temperatures, flexibility, and environmental benefits due to reduced or eliminated lead content. However, traditional soldering often provides superior electrical conductivity, thermal conductivity, and long-term reliability. The choice between these technologies depends on specific application requirements, environmental conditions, and manufacturing constraints.

- Manufacturing processes and application techniques: The application and curing processes for conductive adhesives differ significantly from traditional soldering methods. Conductive adhesives can be applied through dispensing, printing, or stenciling techniques and typically require thermal or chemical curing. Traditional soldering involves flux application, preheating, solder application, and cooling phases. Each method requires specific equipment and process controls to ensure reliable connections. Manufacturing considerations include production speed, compatibility with existing processes, and quality control measures to ensure consistent electrical performance and mechanical strength.

- Environmental and health considerations: Environmental and health factors significantly influence the choice between conductive adhesives and traditional soldering. Traditional soldering often involves lead-based alloys and flux chemicals that pose environmental and health risks, though lead-free alternatives have been developed to address these concerns. Conductive adhesives typically offer reduced environmental impact with lower volatile organic compound emissions and elimination of lead. However, some conductive adhesives contain their own set of potentially hazardous materials. Regulatory requirements increasingly favor technologies with reduced environmental impact and improved worker safety profiles.

- Specialized applications and emerging technologies: Both conductive adhesives and traditional soldering have specialized applications where their unique properties are advantageous. Conductive adhesives excel in temperature-sensitive applications, flexible electronics, and miniaturized devices where traditional soldering might cause damage. Traditional soldering remains preferred for high-reliability applications requiring excellent electrical and thermal conductivity. Emerging technologies combine aspects of both methods or introduce novel approaches such as low-temperature soldering alloys or hybrid bonding techniques. These innovations aim to address limitations of conventional methods while maintaining or improving performance characteristics.

02 Environmental advantages of conductive adhesives over traditional soldering

Conductive adhesives offer significant environmental benefits compared to traditional soldering methods. They typically operate at lower temperatures, reducing energy consumption during the assembly process. Additionally, many conductive adhesives are lead-free, eliminating the toxic heavy metals commonly found in traditional solder. This makes them compliant with environmental regulations such as RoHS and WEEE directives, while also reducing workplace hazards associated with solder fumes.Expand Specific Solutions03 Application techniques for conductive adhesives

Various application techniques are used for conductive adhesives in electronic assembly. These include screen printing, stencil printing, dispensing, and jet printing. Each method offers different advantages in terms of precision, volume control, and production speed. The selection of the appropriate application technique depends on factors such as component density, required bond line thickness, and production volume. Proper curing conditions, including temperature and time, are crucial for achieving optimal electrical and mechanical performance.Expand Specific Solutions04 Hybrid joining technologies combining adhesives and soldering

Hybrid joining technologies combine the advantages of both conductive adhesives and traditional soldering. These approaches may use adhesives for mechanical bonding while relying on solder for electrical connections, or incorporate solder particles within adhesive formulations. Such hybrid technologies can offer improved reliability, thermal cycling resistance, and mechanical strength compared to either method alone. They are particularly valuable in applications requiring both strong mechanical attachment and reliable electrical connections under challenging environmental conditions.Expand Specific Solutions05 Reliability comparison between conductive adhesives and traditional soldering

The reliability of conductive adhesives compared to traditional soldering varies depending on application conditions. While traditional soldering typically offers superior electrical conductivity and thermal performance, conductive adhesives may provide better mechanical flexibility and stress absorption. Conductive adhesives can be more susceptible to moisture absorption and oxidation over time, potentially leading to increased contact resistance. However, they often perform better in applications subject to vibration or thermal cycling, where rigid solder joints might crack or fatigue.Expand Specific Solutions

Key Industry Players in Conductive Adhesives and Soldering

The conductive adhesives market is in a growth phase, with increasing adoption as an alternative to traditional soldering due to environmental regulations and miniaturization trends. The global market is expanding at a CAGR of approximately 8-10%, driven by electronics, automotive, and renewable energy applications. Leading players include Henkel AG & Co. KGaA, which dominates with comprehensive adhesive technology solutions, and Namics Corporation, specializing in high-performance conductive materials. Other significant competitors include Dexerials Corp., Dow Silicones, and Panasonic Holdings, each leveraging proprietary technologies. While traditional soldering remains prevalent in high-reliability applications, conductive adhesives are gaining traction in flexible electronics, wearables, and automotive sectors where environmental concerns and thermal sensitivity are critical factors.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed advanced electrically conductive adhesives (ECAs) as alternatives to traditional soldering, particularly their LOCTITE ABLESTIK series. These adhesives utilize silver particles suspended in polymer matrices to create electrical connections while providing mechanical bonding. Their latest formulations incorporate nano-silver particles that enable lower processing temperatures (150°C vs. 220°C+ for lead-free solders) while maintaining conductivity comparable to traditional solders. Henkel's ECAs feature customizable rheology properties allowing for various application methods including screen printing, stencil printing, and jet dispensing. The company has also developed specialized formulations for specific applications such as die-attach in semiconductor packaging and surface mount technology on temperature-sensitive substrates like flexible circuits and plastic films.

Strengths: Lower processing temperatures reduce energy consumption and enable use with temperature-sensitive components; environmentally friendly (no lead or flux cleaning required); excellent mechanical properties including vibration resistance and flexibility. Weaknesses: Higher material costs compared to traditional solders; typically lower electrical conductivity than metallic solders; some formulations have limited shelf life requiring refrigerated storage.

Dow Silicones Corp.

Technical Solution: Dow Silicones has pioneered silicone-based conductive adhesive technologies that combine the thermal stability and flexibility of silicones with electrical conductivity. Their DOWSIL EA series features hybrid organic-silicone matrices filled with silver or silver-coated particles that provide stable electrical performance across wide temperature ranges (-55°C to +200°C). Dow's proprietary cross-linking chemistry enables these adhesives to maintain conductivity even under thermal cycling and high humidity conditions. The company has developed both one-part and two-part systems with varying cure profiles, allowing manufacturers to select formulations based on process requirements. Their latest innovations include optically clear conductive adhesives for display applications and thermally conductive variants that simultaneously manage heat dissipation while providing electrical connections for power electronics.

Strengths: Exceptional thermal stability and reliability in harsh environments; excellent adhesion to diverse substrates including metals, ceramics, and many plastics; good resistance to moisture and chemicals. Weaknesses: Generally higher cost than epoxy-based conductive adhesives; some formulations require longer cure times than competing technologies; may require surface treatments for optimal adhesion to certain substrates.

Critical Patents and Research in Conductive Joining

Low stress conductive adhesive

PatentActiveEP1701361A1

Innovation

- A low stress isotropic conductive film or paste adhesive comprising functional acrylic copolymers, epoxy, and conductive fillers, with optional adhesion promoters, curing agents, and rheology modifiers, providing higher adhesion strength and reduced stress compared to traditional flexible and high adhesion strength films.

Conductive adhesive and circuit comprising it

PatentWO2004022663A1

Innovation

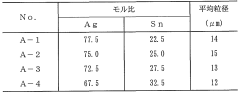

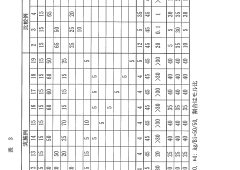

- A conductive adhesive with a silver-tin composition ratio of 77.5:22.5 to 0:100, where silver and tin powders are combined to prevent migration and maintain high conductivity, even at elevated temperatures, replacing traditional solder methods.

Environmental Impact Assessment

The environmental impact of electronics manufacturing processes has become increasingly important as global sustainability concerns grow. When comparing conductive adhesives with traditional soldering methods, several significant environmental factors must be considered across their entire lifecycle.

Traditional soldering processes, particularly those using lead-based alloys, present substantial environmental hazards. Despite regulations like RoHS (Restriction of Hazardous Substances) driving the transition to lead-free alternatives, even these newer soldering materials contain metals like silver, copper, and tin that require energy-intensive mining operations. The soldering process itself typically demands high temperatures (often exceeding 200°C), resulting in considerable energy consumption and associated carbon emissions.

Conductive adhesives, by contrast, offer several environmental advantages. Most significantly, they can be cured at lower temperatures (often between 80-150°C), reducing energy requirements by up to 70% compared to traditional soldering processes. This temperature reduction translates directly to decreased carbon footprint in manufacturing operations. Additionally, many conductive adhesives are formulated without heavy metals or other substances of high environmental concern.

Waste management represents another critical environmental consideration. Soldering processes generate hazardous waste including flux residues, dross, and spent solder materials that require specialized disposal procedures. The manufacturing of solder itself produces mining tailings and processing byproducts with significant environmental impacts. Conductive adhesives generally produce less hazardous waste and many formulations are designed with end-of-life considerations in mind.

Water usage and pollution profiles also differ significantly between these technologies. Traditional soldering often involves water-intensive cleaning processes to remove flux residues, potentially introducing contaminants into wastewater streams. Conductive adhesives typically require less intensive cleaning procedures, reducing both water consumption and potential contamination.

Lifecycle assessment studies indicate that conductive adhesives may offer 30-45% reduction in overall environmental impact compared to traditional soldering when considering the complete product lifecycle. However, this advantage must be balanced against potential durability concerns, as premature product failure would negate environmental benefits through increased replacement and waste generation.

Recent innovations in bio-based conductive adhesives derived from renewable resources represent a promising development for further reducing environmental impact. These formulations incorporate plant-based components that can reduce reliance on petrochemical feedstocks while maintaining necessary performance characteristics for electronics applications.

Traditional soldering processes, particularly those using lead-based alloys, present substantial environmental hazards. Despite regulations like RoHS (Restriction of Hazardous Substances) driving the transition to lead-free alternatives, even these newer soldering materials contain metals like silver, copper, and tin that require energy-intensive mining operations. The soldering process itself typically demands high temperatures (often exceeding 200°C), resulting in considerable energy consumption and associated carbon emissions.

Conductive adhesives, by contrast, offer several environmental advantages. Most significantly, they can be cured at lower temperatures (often between 80-150°C), reducing energy requirements by up to 70% compared to traditional soldering processes. This temperature reduction translates directly to decreased carbon footprint in manufacturing operations. Additionally, many conductive adhesives are formulated without heavy metals or other substances of high environmental concern.

Waste management represents another critical environmental consideration. Soldering processes generate hazardous waste including flux residues, dross, and spent solder materials that require specialized disposal procedures. The manufacturing of solder itself produces mining tailings and processing byproducts with significant environmental impacts. Conductive adhesives generally produce less hazardous waste and many formulations are designed with end-of-life considerations in mind.

Water usage and pollution profiles also differ significantly between these technologies. Traditional soldering often involves water-intensive cleaning processes to remove flux residues, potentially introducing contaminants into wastewater streams. Conductive adhesives typically require less intensive cleaning procedures, reducing both water consumption and potential contamination.

Lifecycle assessment studies indicate that conductive adhesives may offer 30-45% reduction in overall environmental impact compared to traditional soldering when considering the complete product lifecycle. However, this advantage must be balanced against potential durability concerns, as premature product failure would negate environmental benefits through increased replacement and waste generation.

Recent innovations in bio-based conductive adhesives derived from renewable resources represent a promising development for further reducing environmental impact. These formulations incorporate plant-based components that can reduce reliance on petrochemical feedstocks while maintaining necessary performance characteristics for electronics applications.

Reliability and Performance Testing Methodologies

Reliability and performance testing methodologies for conductive adhesives and traditional soldering require comprehensive evaluation frameworks to ensure electronic assembly integrity across diverse operating conditions. The testing protocols typically encompass several critical dimensions that assess both immediate performance characteristics and long-term reliability factors.

Thermal cycling tests represent a cornerstone methodology, subjecting assemblies to repeated temperature extremes (-65°C to +150°C) to evaluate joint stability under thermal stress. For conductive adhesives, these tests are particularly crucial as they often exhibit different coefficient of thermal expansion (CTE) characteristics compared to traditional solder joints, potentially leading to earlier mechanical fatigue.

Mechanical shock and vibration testing protocols simulate real-world physical stresses, with standardized procedures including drop tests (JEDEC JESD22-B111) and vibration tests (MIL-STD-810G). These methodologies reveal significant differences between the two joining technologies, with traditional soldering generally demonstrating superior mechanical robustness while conductive adhesives offer advantages in applications requiring flexibility.

Humidity and environmental exposure tests evaluate resistance to moisture ingress and corrosion. Standard methodologies include temperature-humidity-bias (THB) testing and highly accelerated stress testing (HAST), typically conducted at 85°C/85% relative humidity. Conductive adhesives often require specialized formulations to match the environmental resistance inherent to traditional solder alloys.

Electrical performance testing methodologies focus on conductivity stability over time, with four-point probe measurements tracking resistance changes under various conditions. High-frequency signal integrity testing has become increasingly important, with vector network analyzers employed to measure insertion loss and return loss characteristics up to millimeter-wave frequencies.

Accelerated aging methodologies attempt to compress time-dependent degradation mechanisms, with high-temperature storage tests (typically at 125°C or 150°C) serving as standard protocols. These tests often reveal different failure modes between the two technologies, with conductive adhesives potentially showing earlier degradation in electrical performance while maintaining mechanical integrity longer in certain conditions.

Specialized testing methodologies have emerged for specific application environments, including automotive-grade testing (AEC-Q100), medical device reliability testing (ISO 10993), and aerospace qualification testing (NASA-STD-8739.1). These application-specific protocols have driven the development of customized test matrices that combine multiple stress factors to better predict field performance.

Thermal cycling tests represent a cornerstone methodology, subjecting assemblies to repeated temperature extremes (-65°C to +150°C) to evaluate joint stability under thermal stress. For conductive adhesives, these tests are particularly crucial as they often exhibit different coefficient of thermal expansion (CTE) characteristics compared to traditional solder joints, potentially leading to earlier mechanical fatigue.

Mechanical shock and vibration testing protocols simulate real-world physical stresses, with standardized procedures including drop tests (JEDEC JESD22-B111) and vibration tests (MIL-STD-810G). These methodologies reveal significant differences between the two joining technologies, with traditional soldering generally demonstrating superior mechanical robustness while conductive adhesives offer advantages in applications requiring flexibility.

Humidity and environmental exposure tests evaluate resistance to moisture ingress and corrosion. Standard methodologies include temperature-humidity-bias (THB) testing and highly accelerated stress testing (HAST), typically conducted at 85°C/85% relative humidity. Conductive adhesives often require specialized formulations to match the environmental resistance inherent to traditional solder alloys.

Electrical performance testing methodologies focus on conductivity stability over time, with four-point probe measurements tracking resistance changes under various conditions. High-frequency signal integrity testing has become increasingly important, with vector network analyzers employed to measure insertion loss and return loss characteristics up to millimeter-wave frequencies.

Accelerated aging methodologies attempt to compress time-dependent degradation mechanisms, with high-temperature storage tests (typically at 125°C or 150°C) serving as standard protocols. These tests often reveal different failure modes between the two technologies, with conductive adhesives potentially showing earlier degradation in electrical performance while maintaining mechanical integrity longer in certain conditions.

Specialized testing methodologies have emerged for specific application environments, including automotive-grade testing (AEC-Q100), medical device reliability testing (ISO 10993), and aerospace qualification testing (NASA-STD-8739.1). These application-specific protocols have driven the development of customized test matrices that combine multiple stress factors to better predict field performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!