Compare Lithium Phosphate and Ternary Materials in Efficiency

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Battery Technology Evolution and Objectives

Lithium-ion battery technology has undergone remarkable evolution since its commercial introduction by Sony in 1991. The journey began with lithium cobalt oxide (LCO) cathodes, which offered high energy density but suffered from safety concerns and limited cycle life. The early 2000s witnessed the emergence of lithium manganese oxide (LMO) and lithium iron phosphate (LFP) as safer alternatives, albeit with lower energy density compared to LCO.

The mid-2000s marked a significant milestone with the development of lithium nickel manganese cobalt oxide (NMC) and lithium nickel cobalt aluminum oxide (NCA), collectively known as ternary materials. These materials represented a balance between the high energy density of LCO and the improved safety characteristics of LFP, driving the widespread adoption of lithium-ion batteries in electric vehicles and energy storage systems.

Recent years have seen a technological divergence in the industry, with some manufacturers focusing on enhancing the energy density of ternary materials through increasing nickel content (NMC811, NCA+), while others have revisited LFP technology with innovations like cell-to-pack designs to compensate for its lower energy density. This bifurcation reflects different priorities in the trade-off between energy density, safety, cost, and longevity.

The efficiency comparison between LFP and ternary materials represents a critical aspect of battery technology development. While ternary materials generally offer higher energy density (180-220 Wh/kg vs. 100-160 Wh/kg for LFP), LFP batteries demonstrate superior thermal stability, longer cycle life (2000-4000 cycles vs. 1000-2000 for ternary), and better performance in extreme temperatures, particularly in cold environments.

The technological objectives in this domain are multifaceted. Short-term goals include improving the energy density of LFP batteries through advanced manufacturing techniques and novel cell designs, while enhancing the safety and reducing the cobalt content of ternary materials. Medium-term objectives focus on developing hybrid cathode materials that combine the advantages of both chemistries and improving fast-charging capabilities without compromising battery longevity.

Long-term technological aspirations include achieving solid-state battery configurations compatible with both LFP and ternary materials, potentially resolving many of the current limitations. Additionally, research is directed toward sustainable manufacturing processes, recycling technologies, and reducing dependence on critical raw materials, particularly for ternary batteries that rely on cobalt and nickel, which face supply constraints and ethical sourcing challenges.

The mid-2000s marked a significant milestone with the development of lithium nickel manganese cobalt oxide (NMC) and lithium nickel cobalt aluminum oxide (NCA), collectively known as ternary materials. These materials represented a balance between the high energy density of LCO and the improved safety characteristics of LFP, driving the widespread adoption of lithium-ion batteries in electric vehicles and energy storage systems.

Recent years have seen a technological divergence in the industry, with some manufacturers focusing on enhancing the energy density of ternary materials through increasing nickel content (NMC811, NCA+), while others have revisited LFP technology with innovations like cell-to-pack designs to compensate for its lower energy density. This bifurcation reflects different priorities in the trade-off between energy density, safety, cost, and longevity.

The efficiency comparison between LFP and ternary materials represents a critical aspect of battery technology development. While ternary materials generally offer higher energy density (180-220 Wh/kg vs. 100-160 Wh/kg for LFP), LFP batteries demonstrate superior thermal stability, longer cycle life (2000-4000 cycles vs. 1000-2000 for ternary), and better performance in extreme temperatures, particularly in cold environments.

The technological objectives in this domain are multifaceted. Short-term goals include improving the energy density of LFP batteries through advanced manufacturing techniques and novel cell designs, while enhancing the safety and reducing the cobalt content of ternary materials. Medium-term objectives focus on developing hybrid cathode materials that combine the advantages of both chemistries and improving fast-charging capabilities without compromising battery longevity.

Long-term technological aspirations include achieving solid-state battery configurations compatible with both LFP and ternary materials, potentially resolving many of the current limitations. Additionally, research is directed toward sustainable manufacturing processes, recycling technologies, and reducing dependence on critical raw materials, particularly for ternary batteries that rely on cobalt and nickel, which face supply constraints and ethical sourcing challenges.

Market Demand Analysis for High-Efficiency Battery Materials

The global battery market is experiencing unprecedented growth driven by the rapid expansion of electric vehicles (EVs), renewable energy storage systems, and portable electronics. Within this landscape, high-efficiency battery materials have become a critical focus area, with lithium phosphate (LFP) and ternary materials (NCM/NCA) emerging as the dominant chemistries. Current market analysis indicates the global lithium-ion battery market reached approximately $46 billion in 2022 and is projected to grow at a CAGR of 18-20% through 2030.

Market demand for high-efficiency battery materials is primarily segmented across automotive, grid storage, and consumer electronics sectors. The automotive segment represents the largest growth opportunity, with EV battery demand expected to increase tenfold by 2030. This surge is fueled by stringent emissions regulations, government incentives, and declining battery costs, which have fallen by over 85% since 2010.

Regional analysis reveals distinct preferences in battery chemistry adoption. Chinese manufacturers and markets show stronger preference for LFP batteries due to their cost advantages and safety profile, capturing nearly 60% of the Chinese EV battery market in 2022. Meanwhile, European and North American markets have traditionally favored ternary materials for their higher energy density, though this trend is beginning to shift as LFP technology improves.

Consumer demand patterns indicate a growing bifurcation in the market. The mass-market segment increasingly prioritizes affordability and safety, creating expanded opportunities for LFP batteries. Premium segments continue to value maximum range and performance, sustaining demand for high-nickel ternary materials despite their higher costs and supply chain vulnerabilities.

Industrial users and grid storage applications represent another significant growth vector, with projected annual growth rates exceeding 25% through 2028. These applications typically prioritize cycle life and safety over maximum energy density, creating favorable conditions for LFP chemistry adoption.

Supply chain considerations are increasingly influencing market demand patterns. Concerns about nickel and cobalt supply constraints, price volatility, and ethical sourcing issues have accelerated interest in LFP technology. Major battery manufacturers have responded by diversifying their technology portfolios, with several global players announcing significant investments in LFP production capacity outside China.

Looking forward, market signals indicate growing demand for "best of both worlds" solutions that combine the safety and longevity of LFP with energy densities approaching those of ternary materials. This has spurred research into advanced LFP formulations, silicon-enhanced anodes, and hybrid cathode designs that could reshape competitive dynamics in the high-efficiency battery materials market.

Market demand for high-efficiency battery materials is primarily segmented across automotive, grid storage, and consumer electronics sectors. The automotive segment represents the largest growth opportunity, with EV battery demand expected to increase tenfold by 2030. This surge is fueled by stringent emissions regulations, government incentives, and declining battery costs, which have fallen by over 85% since 2010.

Regional analysis reveals distinct preferences in battery chemistry adoption. Chinese manufacturers and markets show stronger preference for LFP batteries due to their cost advantages and safety profile, capturing nearly 60% of the Chinese EV battery market in 2022. Meanwhile, European and North American markets have traditionally favored ternary materials for their higher energy density, though this trend is beginning to shift as LFP technology improves.

Consumer demand patterns indicate a growing bifurcation in the market. The mass-market segment increasingly prioritizes affordability and safety, creating expanded opportunities for LFP batteries. Premium segments continue to value maximum range and performance, sustaining demand for high-nickel ternary materials despite their higher costs and supply chain vulnerabilities.

Industrial users and grid storage applications represent another significant growth vector, with projected annual growth rates exceeding 25% through 2028. These applications typically prioritize cycle life and safety over maximum energy density, creating favorable conditions for LFP chemistry adoption.

Supply chain considerations are increasingly influencing market demand patterns. Concerns about nickel and cobalt supply constraints, price volatility, and ethical sourcing issues have accelerated interest in LFP technology. Major battery manufacturers have responded by diversifying their technology portfolios, with several global players announcing significant investments in LFP production capacity outside China.

Looking forward, market signals indicate growing demand for "best of both worlds" solutions that combine the safety and longevity of LFP with energy densities approaching those of ternary materials. This has spurred research into advanced LFP formulations, silicon-enhanced anodes, and hybrid cathode designs that could reshape competitive dynamics in the high-efficiency battery materials market.

Current Status and Challenges in Lithium Battery Technology

Lithium-ion battery technology has witnessed significant advancements over the past decade, establishing itself as the dominant energy storage solution across multiple industries. Currently, two primary cathode materials dominate the market: lithium iron phosphate (LFP) and lithium nickel manganese cobalt oxide (NMC), commonly referred to as ternary materials. Each presents distinct advantages and limitations that influence their application scenarios.

The global lithium battery market is experiencing unprecedented growth, projected to reach $193.13 billion by 2028, with a CAGR of 23.3% from 2021. This expansion is driven primarily by electric vehicle adoption and renewable energy storage requirements. Within this landscape, LFP batteries currently hold approximately 30% market share, while ternary materials account for roughly 65%, with the remainder comprising other chemistries.

From an efficiency perspective, ternary materials demonstrate superior energy density (180-240 Wh/kg) compared to LFP (100-160 Wh/kg), allowing for greater energy storage in the same physical space. However, this advantage comes with significant trade-offs in thermal stability and safety. Recent incidents involving thermal runaway in ternary batteries have highlighted these concerns, whereas LFP chemistry demonstrates exceptional thermal stability up to 500°C.

Manufacturing challenges persist for both technologies. Ternary materials face supply chain vulnerabilities due to cobalt dependency, with over 70% of global cobalt reserves concentrated in politically unstable regions. Meanwhile, LFP production struggles with phosphate resource quality inconsistencies that affect performance uniformity. Both chemistries continue to face challenges in achieving theoretical capacity limits, with current commercial cells typically achieving only 75-85% of theoretical values.

Recycling represents another significant challenge, particularly for ternary materials where the recovery of cobalt and nickel is economically incentivized but technically complex. LFP recycling presents fewer environmental hazards but lacks economic drivers due to lower material value, resulting in recycling rates below 5% globally compared to approximately 30% for ternary batteries.

Geographically, China dominates LFP production with approximately 85% of global capacity, while South Korea and Japan lead in ternary material innovation. North American and European manufacturers are rapidly expanding capacity in both technologies to reduce dependency on Asian supply chains, with over $50 billion committed to new manufacturing facilities through 2025.

The efficiency gap between these technologies continues to narrow through innovations in electrode design, electrolyte formulations, and manufacturing processes. Recent breakthroughs in silicon-doped LFP and low-cobalt ternary materials suggest convergence in performance characteristics may be possible within the next five years, potentially resolving the current trade-off between energy density and safety.

The global lithium battery market is experiencing unprecedented growth, projected to reach $193.13 billion by 2028, with a CAGR of 23.3% from 2021. This expansion is driven primarily by electric vehicle adoption and renewable energy storage requirements. Within this landscape, LFP batteries currently hold approximately 30% market share, while ternary materials account for roughly 65%, with the remainder comprising other chemistries.

From an efficiency perspective, ternary materials demonstrate superior energy density (180-240 Wh/kg) compared to LFP (100-160 Wh/kg), allowing for greater energy storage in the same physical space. However, this advantage comes with significant trade-offs in thermal stability and safety. Recent incidents involving thermal runaway in ternary batteries have highlighted these concerns, whereas LFP chemistry demonstrates exceptional thermal stability up to 500°C.

Manufacturing challenges persist for both technologies. Ternary materials face supply chain vulnerabilities due to cobalt dependency, with over 70% of global cobalt reserves concentrated in politically unstable regions. Meanwhile, LFP production struggles with phosphate resource quality inconsistencies that affect performance uniformity. Both chemistries continue to face challenges in achieving theoretical capacity limits, with current commercial cells typically achieving only 75-85% of theoretical values.

Recycling represents another significant challenge, particularly for ternary materials where the recovery of cobalt and nickel is economically incentivized but technically complex. LFP recycling presents fewer environmental hazards but lacks economic drivers due to lower material value, resulting in recycling rates below 5% globally compared to approximately 30% for ternary batteries.

Geographically, China dominates LFP production with approximately 85% of global capacity, while South Korea and Japan lead in ternary material innovation. North American and European manufacturers are rapidly expanding capacity in both technologies to reduce dependency on Asian supply chains, with over $50 billion committed to new manufacturing facilities through 2025.

The efficiency gap between these technologies continues to narrow through innovations in electrode design, electrolyte formulations, and manufacturing processes. Recent breakthroughs in silicon-doped LFP and low-cobalt ternary materials suggest convergence in performance characteristics may be possible within the next five years, potentially resolving the current trade-off between energy density and safety.

Technical Comparison of LFP and Ternary Cathode Materials

01 Lithium phosphate battery efficiency improvements

Various methods have been developed to enhance the efficiency of lithium phosphate batteries. These include optimizing electrode materials, improving the crystal structure of lithium iron phosphate, and developing novel synthesis methods. These improvements lead to higher energy density, better rate capability, and longer cycle life for lithium phosphate batteries, making them more competitive in the energy storage market.- Lithium phosphate battery efficiency improvements: Various methods have been developed to enhance the efficiency of lithium phosphate batteries, including optimized electrode structures, improved manufacturing processes, and novel material compositions. These innovations focus on increasing energy density, extending cycle life, and improving charge-discharge rates. Advanced coating technologies and particle size control are also employed to enhance the electrochemical performance of lithium phosphate batteries.

- Ternary cathode material advancements: Ternary cathode materials (typically nickel-cobalt-manganese or nickel-cobalt-aluminum compounds) have been improved through doping, surface modification, and structural engineering. These advancements aim to increase energy density, thermal stability, and cycling performance. Research has focused on reducing cobalt content while maintaining or improving electrochemical properties, as well as developing novel synthesis methods that enhance uniformity and performance.

- Comparative performance between lithium phosphate and ternary materials: Studies comparing lithium phosphate and ternary materials have evaluated their respective advantages in terms of safety, cost, energy density, and temperature performance. While lithium phosphate offers superior thermal stability and longer cycle life, ternary materials generally provide higher energy density. Research has focused on optimizing both material types for specific applications and developing hybrid systems that leverage the strengths of each technology.

- Manufacturing processes for efficiency enhancement: Advanced manufacturing techniques have been developed to improve the efficiency of both lithium phosphate and ternary materials. These include precise control of synthesis parameters, innovative coating methods, and optimized production processes. Techniques such as spray drying, sol-gel methods, and hydrothermal synthesis have been refined to produce materials with superior electrochemical performance, uniformity, and scalability.

- Battery management systems for optimizing material efficiency: Advanced battery management systems have been developed to maximize the efficiency of both lithium phosphate and ternary material batteries. These systems incorporate sophisticated algorithms for state-of-charge estimation, thermal management, and cell balancing. By optimizing charging protocols and monitoring battery health in real-time, these management systems can extend battery life, improve safety, and enhance overall energy efficiency for different battery chemistries.

02 Ternary cathode material advancements

Ternary cathode materials (typically nickel-cobalt-manganese or nickel-cobalt-aluminum based) have been improved through various approaches including doping, surface modification, and gradient concentration designs. These advancements help overcome issues like structural instability, capacity fading, and thermal runaway, resulting in ternary materials with higher energy density and better safety characteristics.Expand Specific Solutions03 Manufacturing process optimization for battery materials

Innovations in manufacturing processes for both lithium phosphate and ternary materials focus on energy-efficient production methods, reduced waste generation, and improved material consistency. Advanced techniques include precise temperature control during synthesis, optimized particle size distribution, and environmentally friendly processing methods that reduce the carbon footprint while maintaining or improving battery performance.Expand Specific Solutions04 Composite and hybrid battery systems

Hybrid battery systems combining lithium phosphate and ternary materials leverage the advantages of both chemistries. These composite systems utilize the high stability and safety of lithium phosphate with the high energy density of ternary materials. Various approaches include layered electrodes, blended active materials, and dual-chemistry battery packs that optimize performance based on specific application requirements.Expand Specific Solutions05 Recycling and sustainability of battery materials

Efficient recycling methods for lithium phosphate and ternary materials have been developed to address sustainability concerns. These include hydrometallurgical processes, direct recycling approaches, and regeneration techniques that recover valuable metals while minimizing environmental impact. Advanced recycling technologies improve the overall efficiency of the battery lifecycle by reducing the need for virgin material extraction and processing.Expand Specific Solutions

Key Industry Players in Battery Material Manufacturing

The lithium battery market is experiencing rapid growth, currently in a mature expansion phase with an estimated global market size exceeding $50 billion. Lithium phosphate (LFP) and ternary materials represent the two dominant cathode technologies, with efficiency comparisons showing trade-offs between energy density and safety. Leading players like Contemporary Amperex Technology (CATL) and BYD have established significant advantages in LFP technology, offering superior thermal stability and longer cycle life, while companies such as LG Energy Solution and Beijing Easpring focus on high-energy-density ternary materials. The competitive landscape is evolving as manufacturers like Ningbo Ronbay and XTC New Energy Materials develop advanced formulations to address the efficiency gap between these technologies, with increasing focus on hybrid approaches that combine the strengths of both material systems.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: Contemporary Amperex Technology (CATL) has developed advanced lithium phosphate (LFP) and ternary lithium batteries with distinct efficiency profiles. Their LFP technology features cell-to-pack (CTP) integration that achieves energy densities of 160-170 Wh/kg, significantly closing the gap with ternary materials. CATL's third-generation CTP technology eliminates conventional module components, increasing volume utilization by 15-20% and energy density by 10-15%. For ternary materials, CATL employs nickel-rich NCM (nickel-cobalt-manganese) cathodes achieving energy densities of 240-280 Wh/kg. Their proprietary gradient concentration technology creates optimized ion transport channels, enhancing rate capability while maintaining structural stability during cycling. CATL has also pioneered hybrid battery packs combining both chemistries to leverage their complementary advantages.

Strengths: Industry-leading energy density in LFP batteries through CTP technology; advanced manufacturing capabilities allowing cost-effective mass production; strong R&D pipeline for next-generation materials. Weaknesses: Ternary materials still face thermal stability challenges at high nickel content; LFP batteries have lower energy density than ternary despite improvements; temperature sensitivity affects low-temperature performance.

BYD Co., Ltd.

Technical Solution: BYD has revolutionized lithium battery technology with its proprietary Blade Battery, a novel LFP cell design that arranges long, thin cells in arrays to optimize space utilization and thermal management. This design achieves volumetric energy densities approaching 450 Wh/L, significantly higher than conventional LFP packs. The Blade Battery demonstrates exceptional safety with minimal temperature rise during nail penetration tests compared to ternary batteries that typically experience thermal runaway. For ternary materials, BYD employs their advanced NCM technology with silicon-carbon composite anodes, achieving gravimetric energy densities of 260-300 Wh/kg. Their integrated manufacturing approach spans the entire supply chain from raw materials to finished vehicles, enabling tight quality control and cost optimization. BYD's dual-chemistry strategy allows them to deploy different battery technologies based on specific vehicle requirements.

Strengths: Industry-leading safety performance in LFP technology; vertical integration from raw materials to vehicles enables cost advantages; innovative cell-to-pack structural designs maximize energy density. Weaknesses: LFP chemistry still has inherent energy density limitations compared to highest-nickel ternary materials; cold weather performance remains challenging for LFP batteries; higher initial manufacturing investment required for blade battery production.

Core Patents and Research in Battery Efficiency Enhancement

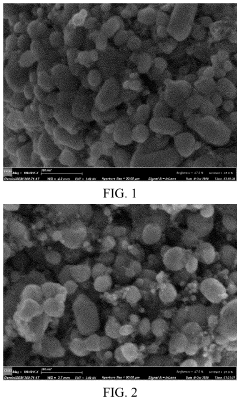

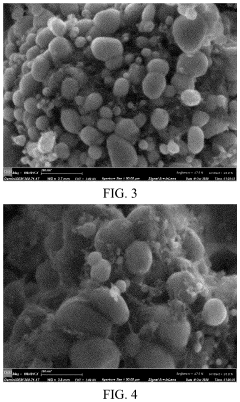

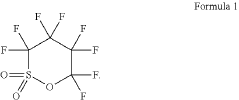

Lithium iron phosphate positive electrode material, preparation method thereof, and lithium ion battery

PatentPendingUS20240079573A1

Innovation

- A lithium iron phosphate positive electrode material with a formula of LiFe1-xMxPO4/C, where 0<x≤0.05, and M is selected from elements like Mg, Al, Zr, Ti, Co, V, Mn, W, Sn, Nb, and Mo, is synthesized using a method involving hydrothermal reaction, sand milling, and sintering, with the addition of a dispersant and grain growth inhibitor to control particle size and conductivity.

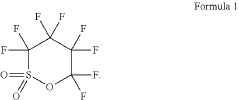

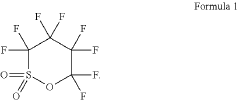

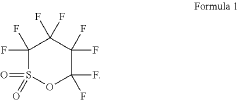

Electrolyte and Lithium-ion Battery

PatentPendingUS20230411690A1

Innovation

- Incorporating a fluorosultones compound as an additive in the electrolyte to form a protective film on the cathode and negative electrodes, along with lithium bis(oxalate) borate to suppress manganese dissolution and enhance the electrolyte's wettability and internal resistance, and using a specific combination of organic solvents and lithium salts to improve the battery's electrochemical performance.

Environmental Impact and Sustainability Assessment

The environmental impact of battery technologies has become a critical consideration in the sustainable development of electric vehicles and energy storage systems. When comparing lithium phosphate (LFP) and ternary lithium-ion batteries (NMC/NCA), significant differences emerge in their ecological footprints throughout their lifecycle.

LFP batteries demonstrate superior environmental credentials in several key aspects. The mining and processing of phosphate involves substantially lower environmental degradation compared to the extraction of nickel, cobalt, and manganese required for ternary materials. Phosphate resources are more abundant and geographically distributed, reducing the environmental impacts associated with concentrated mining operations and long-distance transportation.

The manufacturing process for LFP batteries consumes approximately 14% less energy than ternary alternatives, resulting in lower carbon emissions during production. Studies indicate that LFP battery production generates approximately 30% fewer greenhouse gas emissions compared to equivalent capacity ternary batteries. This advantage is particularly significant when considering large-scale manufacturing operations.

During the operational phase, both technologies demonstrate similar efficiency profiles, though the environmental benefits of LFP extend to safety considerations. The thermal stability of LFP reduces the risk of thermal runaway events, which can release toxic substances into the environment and pose significant safety hazards.

End-of-life management presents another area where LFP demonstrates environmental advantages. The absence of cobalt and nickel in LFP batteries simplifies recycling processes and reduces the potential for toxic leaching in landfill scenarios. Recent advancements in hydrometallurgical recycling techniques have achieved recovery rates exceeding 95% for lithium and phosphate from spent LFP batteries.

Life cycle assessment (LCA) studies comparing both technologies reveal that LFP batteries typically have a 15-20% lower global warming potential over their complete lifecycle. Water consumption metrics similarly favor LFP, with approximately 25% reduction in water usage across mining, processing, and manufacturing stages.

The sustainability profile of both technologies continues to evolve with technological advancements. Innovations in ternary material composition are progressively reducing cobalt content, while improvements in LFP energy density are narrowing performance gaps. However, current environmental assessments consistently identify LFP as the more sustainable option when considering comprehensive ecological impacts, resource depletion, and long-term environmental health considerations.

LFP batteries demonstrate superior environmental credentials in several key aspects. The mining and processing of phosphate involves substantially lower environmental degradation compared to the extraction of nickel, cobalt, and manganese required for ternary materials. Phosphate resources are more abundant and geographically distributed, reducing the environmental impacts associated with concentrated mining operations and long-distance transportation.

The manufacturing process for LFP batteries consumes approximately 14% less energy than ternary alternatives, resulting in lower carbon emissions during production. Studies indicate that LFP battery production generates approximately 30% fewer greenhouse gas emissions compared to equivalent capacity ternary batteries. This advantage is particularly significant when considering large-scale manufacturing operations.

During the operational phase, both technologies demonstrate similar efficiency profiles, though the environmental benefits of LFP extend to safety considerations. The thermal stability of LFP reduces the risk of thermal runaway events, which can release toxic substances into the environment and pose significant safety hazards.

End-of-life management presents another area where LFP demonstrates environmental advantages. The absence of cobalt and nickel in LFP batteries simplifies recycling processes and reduces the potential for toxic leaching in landfill scenarios. Recent advancements in hydrometallurgical recycling techniques have achieved recovery rates exceeding 95% for lithium and phosphate from spent LFP batteries.

Life cycle assessment (LCA) studies comparing both technologies reveal that LFP batteries typically have a 15-20% lower global warming potential over their complete lifecycle. Water consumption metrics similarly favor LFP, with approximately 25% reduction in water usage across mining, processing, and manufacturing stages.

The sustainability profile of both technologies continues to evolve with technological advancements. Innovations in ternary material composition are progressively reducing cobalt content, while improvements in LFP energy density are narrowing performance gaps. However, current environmental assessments consistently identify LFP as the more sustainable option when considering comprehensive ecological impacts, resource depletion, and long-term environmental health considerations.

Cost-Performance Analysis of Battery Technologies

The cost-performance analysis of lithium phosphate (LFP) and ternary lithium-ion (NMC/NCA) battery technologies reveals significant differences that impact their market adoption across various applications. When examining efficiency versus cost metrics, LFP batteries demonstrate superior cost advantages with prices approximately 20-30% lower than their ternary counterparts, primarily due to the absence of expensive cobalt and reduced nickel content.

From a performance perspective, ternary materials offer higher energy density (180-220 Wh/kg) compared to LFP (120-160 Wh/kg), translating to extended range capabilities in electric vehicles. However, this advantage comes with trade-offs in thermal stability and safety characteristics, where LFP batteries excel with significantly lower thermal runaway risks.

Lifecycle economics analysis indicates LFP batteries typically achieve 3,000-4,000 charge cycles before capacity degrades to 80%, substantially outperforming ternary batteries that generally reach 1,000-2,000 cycles. This extended operational lifespan effectively reduces the total cost of ownership despite the initial energy density disadvantage.

Manufacturing efficiency comparisons show LFP production processes require approximately 15-20% less energy input per kWh of battery capacity produced. The simplified supply chain for phosphate-based cathodes further enhances cost efficiency, with raw materials sourced from more geopolitically diverse regions compared to cobalt-dependent ternary materials.

Environmental impact assessments reveal LFP batteries generate approximately 30% lower carbon emissions during production phases. Additionally, the recyclability factor favors LFP with recovery rates of key materials reaching 90-95%, compared to more complex separation processes required for ternary materials.

Market segmentation analysis demonstrates LFP batteries dominating cost-sensitive applications including energy storage systems and commercial electric vehicles, while ternary materials maintain advantages in premium consumer electronics and high-performance electric vehicles where range anxiety remains a primary concern.

Forward-looking economic projections indicate the cost gap between these technologies will narrow as manufacturing scales increase, with LFP expected to maintain a 10-15% cost advantage through 2030. However, technological improvements in ternary materials, particularly in reducing cobalt content while maintaining performance, may alter this trajectory.

From a performance perspective, ternary materials offer higher energy density (180-220 Wh/kg) compared to LFP (120-160 Wh/kg), translating to extended range capabilities in electric vehicles. However, this advantage comes with trade-offs in thermal stability and safety characteristics, where LFP batteries excel with significantly lower thermal runaway risks.

Lifecycle economics analysis indicates LFP batteries typically achieve 3,000-4,000 charge cycles before capacity degrades to 80%, substantially outperforming ternary batteries that generally reach 1,000-2,000 cycles. This extended operational lifespan effectively reduces the total cost of ownership despite the initial energy density disadvantage.

Manufacturing efficiency comparisons show LFP production processes require approximately 15-20% less energy input per kWh of battery capacity produced. The simplified supply chain for phosphate-based cathodes further enhances cost efficiency, with raw materials sourced from more geopolitically diverse regions compared to cobalt-dependent ternary materials.

Environmental impact assessments reveal LFP batteries generate approximately 30% lower carbon emissions during production phases. Additionally, the recyclability factor favors LFP with recovery rates of key materials reaching 90-95%, compared to more complex separation processes required for ternary materials.

Market segmentation analysis demonstrates LFP batteries dominating cost-sensitive applications including energy storage systems and commercial electric vehicles, while ternary materials maintain advantages in premium consumer electronics and high-performance electric vehicles where range anxiety remains a primary concern.

Forward-looking economic projections indicate the cost gap between these technologies will narrow as manufacturing scales increase, with LFP expected to maintain a 10-15% cost advantage through 2030. However, technological improvements in ternary materials, particularly in reducing cobalt content while maintaining performance, may alter this trajectory.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!