Comparison of Structural Ceramics with Composite Materials

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ceramics and Composites Evolution and Objectives

Structural ceramics and composite materials represent two distinct yet complementary material classes that have evolved significantly over the past century. The development of structural ceramics can be traced back to the early 20th century, with major advancements occurring during the post-World War II era when materials science emerged as a distinct discipline. Initially focused on traditional ceramics like alumina and silicon carbide, the field has progressively expanded to include advanced ceramics such as silicon nitride, zirconia, and ceramic matrix composites.

The evolution of composite materials followed a parallel but distinct trajectory, gaining significant momentum in the aerospace industry during the 1960s and 1970s. From early glass fiber reinforced polymers to today's carbon fiber composites and multi-functional hybrid materials, composites have continuously pushed the boundaries of material performance. This evolutionary path has been characterized by increasingly sophisticated manufacturing techniques and design methodologies.

The convergence of these two material classes represents a frontier in materials science, with ceramic matrix composites (CMCs) embodying the intersection of ceramic durability and composite toughness. Recent technological breakthroughs in both fields have been driven by computational materials science, allowing for unprecedented precision in predicting material behavior and optimizing compositions.

The primary objective in comparing structural ceramics with composite materials is to establish a comprehensive framework for material selection based on specific application requirements. This includes identifying the performance envelopes where each material class excels, understanding the trade-offs involved, and developing hybrid solutions that leverage the strengths of both material systems.

Additional objectives include mapping the technological readiness levels of various ceramic and composite solutions across different industrial sectors, identifying cross-pollination opportunities between the two fields, and forecasting emerging applications where these materials could enable breakthrough innovations. Of particular interest is the potential for these materials to address sustainability challenges through lightweighting, improved durability, and enhanced recyclability.

The comparison also aims to identify gaps in current manufacturing capabilities and propose research directions to overcome existing limitations. By examining the full lifecycle performance of both material classes, including production energy requirements, in-service efficiency, and end-of-life considerations, this analysis seeks to provide a holistic view of their respective environmental footprints and economic viability in various applications.

The evolution of composite materials followed a parallel but distinct trajectory, gaining significant momentum in the aerospace industry during the 1960s and 1970s. From early glass fiber reinforced polymers to today's carbon fiber composites and multi-functional hybrid materials, composites have continuously pushed the boundaries of material performance. This evolutionary path has been characterized by increasingly sophisticated manufacturing techniques and design methodologies.

The convergence of these two material classes represents a frontier in materials science, with ceramic matrix composites (CMCs) embodying the intersection of ceramic durability and composite toughness. Recent technological breakthroughs in both fields have been driven by computational materials science, allowing for unprecedented precision in predicting material behavior and optimizing compositions.

The primary objective in comparing structural ceramics with composite materials is to establish a comprehensive framework for material selection based on specific application requirements. This includes identifying the performance envelopes where each material class excels, understanding the trade-offs involved, and developing hybrid solutions that leverage the strengths of both material systems.

Additional objectives include mapping the technological readiness levels of various ceramic and composite solutions across different industrial sectors, identifying cross-pollination opportunities between the two fields, and forecasting emerging applications where these materials could enable breakthrough innovations. Of particular interest is the potential for these materials to address sustainability challenges through lightweighting, improved durability, and enhanced recyclability.

The comparison also aims to identify gaps in current manufacturing capabilities and propose research directions to overcome existing limitations. By examining the full lifecycle performance of both material classes, including production energy requirements, in-service efficiency, and end-of-life considerations, this analysis seeks to provide a holistic view of their respective environmental footprints and economic viability in various applications.

Market Applications and Demand Analysis

The market for both structural ceramics and composite materials has experienced significant growth over the past decade, driven by increasing demands for high-performance materials across multiple industries. The global structural ceramics market was valued at approximately 25 billion USD in 2022, with projections indicating growth at a compound annual rate of 6.8% through 2030. Similarly, the advanced composite materials market reached 36 billion USD in 2022 and is expected to grow at 7.5% annually over the same period.

Aerospace and defense sectors represent the largest application areas for both material types, accounting for roughly 35% of the total market share. In these industries, the demand is primarily driven by the need for lightweight, high-strength materials that can withstand extreme temperatures and harsh operating conditions. Commercial aircraft manufacturers have increased their use of composite materials from 10% to over 50% by weight in modern aircraft designs, while structural ceramics are increasingly utilized in engine components.

The automotive industry has emerged as a rapidly growing market segment, particularly with the transition toward electric vehicles. Composites offer significant weight reduction potential, improving energy efficiency and range, while structural ceramics find applications in brake systems, sensors, and thermal management components. Market analysis indicates that the automotive sector's demand for advanced materials is growing at approximately 9% annually, outpacing the overall market growth rate.

Energy sector applications represent another significant market driver, particularly in renewable energy systems. Wind turbine blades predominantly utilize composite materials, with the average blade size increasing by 62% over the past decade, necessitating stronger and lighter materials. Meanwhile, structural ceramics are essential in various energy generation and storage technologies, including fuel cells, solar panels, and battery systems.

Regional market analysis reveals that North America and Europe currently dominate consumption of both material types, accounting for approximately 60% of global demand. However, the Asia-Pacific region, particularly China, Japan, and South Korea, is experiencing the fastest growth rates, driven by expanding manufacturing capabilities and increasing investments in high-tech industries.

Market trends indicate a growing preference for hybrid solutions that combine the advantages of both material types. This convergence is creating new application opportunities in medical devices, electronics, and industrial equipment. Additionally, sustainability concerns are reshaping market demands, with increasing emphasis on recyclability, energy-efficient manufacturing processes, and reduced environmental impact throughout the product lifecycle.

Aerospace and defense sectors represent the largest application areas for both material types, accounting for roughly 35% of the total market share. In these industries, the demand is primarily driven by the need for lightweight, high-strength materials that can withstand extreme temperatures and harsh operating conditions. Commercial aircraft manufacturers have increased their use of composite materials from 10% to over 50% by weight in modern aircraft designs, while structural ceramics are increasingly utilized in engine components.

The automotive industry has emerged as a rapidly growing market segment, particularly with the transition toward electric vehicles. Composites offer significant weight reduction potential, improving energy efficiency and range, while structural ceramics find applications in brake systems, sensors, and thermal management components. Market analysis indicates that the automotive sector's demand for advanced materials is growing at approximately 9% annually, outpacing the overall market growth rate.

Energy sector applications represent another significant market driver, particularly in renewable energy systems. Wind turbine blades predominantly utilize composite materials, with the average blade size increasing by 62% over the past decade, necessitating stronger and lighter materials. Meanwhile, structural ceramics are essential in various energy generation and storage technologies, including fuel cells, solar panels, and battery systems.

Regional market analysis reveals that North America and Europe currently dominate consumption of both material types, accounting for approximately 60% of global demand. However, the Asia-Pacific region, particularly China, Japan, and South Korea, is experiencing the fastest growth rates, driven by expanding manufacturing capabilities and increasing investments in high-tech industries.

Market trends indicate a growing preference for hybrid solutions that combine the advantages of both material types. This convergence is creating new application opportunities in medical devices, electronics, and industrial equipment. Additionally, sustainability concerns are reshaping market demands, with increasing emphasis on recyclability, energy-efficient manufacturing processes, and reduced environmental impact throughout the product lifecycle.

Current Technological Status and Challenges

Structural ceramics and composite materials represent two distinct yet complementary material categories that have gained significant traction in advanced engineering applications. Currently, both materials are at different stages of technological maturity, with structural ceramics having a longer industrial history while composite materials have seen accelerated development in recent decades.

The global market for structural ceramics is well-established, with major production centers in Japan, the United States, Germany, and increasingly China. These materials have reached technological maturity in traditional applications such as cutting tools, wear components, and thermal barriers. However, they face persistent challenges related to their inherent brittleness and limited reliability under complex loading conditions. Recent advancements have focused on improving fracture toughness through microstructural engineering and novel processing techniques.

Composite materials, particularly fiber-reinforced polymers (FRPs) and ceramic matrix composites (CMCs), have experienced rapid technological evolution. The aerospace and automotive industries have been primary drivers of composite technology development, with significant investments in manufacturing processes that enable mass production while maintaining quality. The geographical distribution of composite technology development shows concentration in North America, Western Europe, and East Asia, with emerging capabilities in countries like India, Brazil, and Russia.

A critical technological challenge for both material systems is the optimization of manufacturing processes to reduce costs while maintaining performance. For structural ceramics, additive manufacturing represents a promising frontier that could overcome traditional forming limitations, though challenges in achieving full density and controlling microstructure remain. For composites, automated fiber placement and out-of-autoclave processing are advancing rapidly but still face issues with consistency and scalability.

Interface engineering represents another significant challenge area. In structural ceramics, grain boundary engineering is crucial for enhancing mechanical properties, while in composites, the fiber-matrix interface determines load transfer efficiency and overall performance. Both material systems require sophisticated characterization techniques to understand these interfaces at micro and nano scales.

Sustainability concerns are increasingly shaping technological development. The energy-intensive nature of ceramic processing presents environmental challenges, while composite materials face end-of-life recycling issues, particularly for thermoset-based systems. Research into more environmentally friendly processing routes and recyclable composite formulations is gaining momentum but remains in early stages.

Standardization and qualification procedures represent another shared challenge. The anisotropic nature of composites and the statistical variation in ceramic properties necessitate complex testing protocols and design allowables. Industry-wide acceptance of new material systems requires extensive validation, which can slow technological adoption despite promising performance characteristics.

The global market for structural ceramics is well-established, with major production centers in Japan, the United States, Germany, and increasingly China. These materials have reached technological maturity in traditional applications such as cutting tools, wear components, and thermal barriers. However, they face persistent challenges related to their inherent brittleness and limited reliability under complex loading conditions. Recent advancements have focused on improving fracture toughness through microstructural engineering and novel processing techniques.

Composite materials, particularly fiber-reinforced polymers (FRPs) and ceramic matrix composites (CMCs), have experienced rapid technological evolution. The aerospace and automotive industries have been primary drivers of composite technology development, with significant investments in manufacturing processes that enable mass production while maintaining quality. The geographical distribution of composite technology development shows concentration in North America, Western Europe, and East Asia, with emerging capabilities in countries like India, Brazil, and Russia.

A critical technological challenge for both material systems is the optimization of manufacturing processes to reduce costs while maintaining performance. For structural ceramics, additive manufacturing represents a promising frontier that could overcome traditional forming limitations, though challenges in achieving full density and controlling microstructure remain. For composites, automated fiber placement and out-of-autoclave processing are advancing rapidly but still face issues with consistency and scalability.

Interface engineering represents another significant challenge area. In structural ceramics, grain boundary engineering is crucial for enhancing mechanical properties, while in composites, the fiber-matrix interface determines load transfer efficiency and overall performance. Both material systems require sophisticated characterization techniques to understand these interfaces at micro and nano scales.

Sustainability concerns are increasingly shaping technological development. The energy-intensive nature of ceramic processing presents environmental challenges, while composite materials face end-of-life recycling issues, particularly for thermoset-based systems. Research into more environmentally friendly processing routes and recyclable composite formulations is gaining momentum but remains in early stages.

Standardization and qualification procedures represent another shared challenge. The anisotropic nature of composites and the statistical variation in ceramic properties necessitate complex testing protocols and design allowables. Industry-wide acceptance of new material systems requires extensive validation, which can slow technological adoption despite promising performance characteristics.

Contemporary Material Solutions Comparison

01 Manufacturing processes for ceramic matrix composites

Various manufacturing processes are employed to produce ceramic matrix composites with enhanced structural properties. These processes include chemical vapor infiltration, polymer infiltration and pyrolysis, and melt infiltration techniques. These methods allow for the creation of composites with improved mechanical strength, thermal resistance, and durability compared to monolithic ceramics. The resulting materials often feature reinforcing fibers or particles embedded within a ceramic matrix to achieve superior performance characteristics.- Manufacturing processes for ceramic matrix composites: Various manufacturing processes are employed to produce ceramic matrix composites with enhanced structural properties. These include chemical vapor infiltration, polymer infiltration and pyrolysis, and melt infiltration techniques. These processes allow for the creation of lightweight, high-strength materials that can withstand extreme temperatures and mechanical stresses, making them suitable for aerospace and industrial applications.

- Oxide-based structural ceramics: Oxide-based ceramics such as alumina, zirconia, and silica are used as structural materials due to their excellent thermal stability and mechanical properties. These materials can be processed into various forms including dense monolithic structures or porous architectures. They offer advantages such as high hardness, wear resistance, and chemical inertness, making them suitable for applications in harsh environments.

- Non-oxide ceramic composites: Non-oxide ceramics including silicon carbide, silicon nitride, and boron carbide are utilized in structural applications requiring exceptional mechanical properties. These materials can be reinforced with fibers or whiskers to improve toughness and crack resistance. The resulting composites offer superior strength-to-weight ratios, thermal shock resistance, and performance at elevated temperatures compared to traditional materials.

- Ceramic-metal hybrid composites: Ceramic-metal hybrid composites combine the high-temperature capabilities of ceramics with the ductility and toughness of metals. These materials are created through various joining techniques such as brazing, diffusion bonding, or co-sintering. The resulting composites exhibit improved fracture toughness, thermal cycling resistance, and damage tolerance, making them suitable for applications in aerospace, defense, and energy sectors.

- Advanced applications of structural ceramics: Structural ceramics and composite materials find applications in various high-performance sectors including aerospace components, thermal protection systems, armor, cutting tools, and biomedical implants. These materials are engineered to meet specific requirements such as lightweight construction, thermal insulation, ballistic protection, or biocompatibility. Recent developments focus on tailoring microstructures and compositions to optimize performance for specific end-use applications.

02 High-temperature applications of structural ceramics

Structural ceramics and ceramic composites are specifically designed for high-temperature applications where conventional materials would fail. These materials maintain their mechanical properties and structural integrity at elevated temperatures, making them suitable for use in aerospace components, gas turbine engines, thermal protection systems, and industrial furnaces. Their resistance to thermal shock, creep, and oxidation at extreme temperatures provides significant advantages in demanding thermal environments.Expand Specific Solutions03 Reinforcement techniques for ceramic composites

Various reinforcement techniques are employed to enhance the mechanical properties of ceramic composites. These include the incorporation of fibers, whiskers, particles, or platelets into the ceramic matrix. The reinforcement materials can be made from carbon, silicon carbide, alumina, or other ceramics. These reinforcements help to improve fracture toughness, strength, and damage tolerance by creating mechanisms for crack deflection and energy absorption, overcoming the inherent brittleness of traditional ceramics.Expand Specific Solutions04 Novel ceramic compositions and microstructures

Innovative ceramic compositions and engineered microstructures are developed to achieve specific performance characteristics. These include multi-phase ceramics, nanostructured ceramics, and functionally graded materials. By controlling the chemical composition, grain size, porosity, and phase distribution, researchers can tailor the properties of structural ceramics for specific applications. These advanced materials often exhibit superior combinations of hardness, toughness, wear resistance, and thermal stability.Expand Specific Solutions05 Joining and integration techniques for ceramic systems

Specialized techniques for joining and integrating ceramic components are essential for creating complex structures and systems. These methods include brazing, diffusion bonding, reactive joining, and mechanical fastening adapted for ceramic materials. The development of reliable joining techniques enables the creation of larger and more complex ceramic structures while maintaining the integrity and performance of the material at the joint interfaces. These techniques are crucial for the practical application of structural ceramics in engineered systems.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The structural ceramics and composite materials market is currently in a growth phase, characterized by increasing adoption across aerospace, automotive, and industrial sectors. The global market size is expanding rapidly, driven by demand for lightweight, high-performance materials. Technologically, structural ceramics have reached maturity with established players like Saint-Gobain Ceramics, TOTO Ltd., and Kyocera leading commercial applications, while composite materials continue evolving with Boeing, Lockheed Martin, and Mitsubishi Heavy Industries pushing innovation boundaries. The competitive landscape shows aerospace giants focusing on advanced composites for weight reduction, while ceramic specialists emphasize thermal and wear resistance properties. Universities like Jilin University and New York University are bridging fundamental research gaps between these complementary material systems, accelerating cross-material innovation.

Saint-Gobain Ceramics & Plastics, Inc.

Technical Solution: Saint-Gobain's approach to structural ceramics vs. composites centers on their proprietary CeramCool® technology, which combines advanced silicon carbide and silicon nitride ceramics with tailored microstructures. Their technical solution involves precision-engineered ceramic matrices with controlled porosity (typically 2-5%) that enhance thermal shock resistance while maintaining structural integrity. The company has developed a hybrid manufacturing process that integrates traditional ceramic forming techniques with advanced composite layering methodologies, allowing for gradient material properties across components. Their materials achieve flexural strengths exceeding 500 MPa while maintaining thermal conductivity values up to 180 W/mK, significantly outperforming traditional composites in high-temperature applications (>1000°C). Saint-Gobain's comparative analysis demonstrates that their structural ceramics offer superior chemical inertness and temperature resistance compared to polymer matrix composites, while addressing traditional ceramic brittleness through microstructural engineering and strategic reinforcement.

Strengths: Exceptional thermal stability and chemical resistance in extreme environments; precision manufacturing capabilities allowing complex geometries; superior wear resistance compared to most composites. Weaknesses: Higher production costs than conventional composites; greater density leading to weight penalties in certain applications; more limited design flexibility compared to fiber-reinforced composites.

The Boeing Co.

Technical Solution: Boeing's technical approach to comparing structural ceramics with composite materials focuses on their proprietary Ceramic Matrix Composite (CMC) technology for aerospace applications. Their solution integrates silicon carbide fibers within ceramic matrices to create materials that combine the heat resistance of ceramics (withstanding temperatures exceeding 2000°F) with the mechanical durability of composites. Boeing has developed specialized manufacturing processes that overcome traditional ceramic brittleness by incorporating continuous fiber reinforcement architectures that enable damage tolerance mechanisms similar to those in polymer composites. Their comparative testing demonstrates that these advanced CMCs maintain structural integrity under thermal cycling conditions that would degrade traditional composites, while offering 30-40% weight reduction compared to superalloys in high-temperature applications. Boeing's technical solution includes proprietary fiber-matrix interface coatings that control crack propagation, resulting in graceful failure modes rather than catastrophic fracture typical of monolithic ceramics. This approach has been implemented in next-generation aircraft engine components and thermal protection systems where the material's temperature capability, oxidation resistance, and weight advantages provide critical performance improvements.

Strengths: Superior high-temperature performance compared to polymer composites; excellent strength-to-weight ratio; better damage tolerance than monolithic ceramics; proven performance in extreme aerospace environments. Weaknesses: Significantly higher manufacturing costs; complex processing requirements; limited repairability in field conditions; challenges in joining and integration with metallic structures.

Key Patents and Scientific Breakthroughs

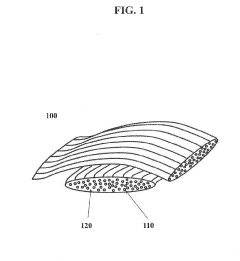

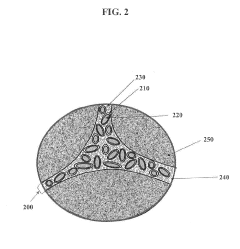

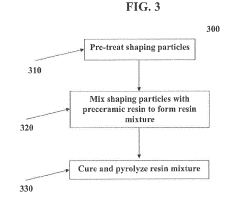

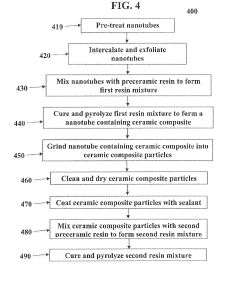

Engineered Micro-voids for Toughening Ceramic Composites

PatentActiveUS20190276371A1

Innovation

- A ceramic composite material with a closed cell structure is developed, incorporating shaping particles with nanostructures and void spaces, which are engineered to enhance strain to failure characteristics and corrosion resistance. The method involves treating nanofibers, mixing with preceramic resin, curing, pyrolyzing, grinding, and coating to create a ceramic composite with irregular, non-uniform voids that prevent crack propagation and corrosion.

Method of producing composite materials including metallic matrix composite reinforcements

PatentInactiveUS5854966A

Innovation

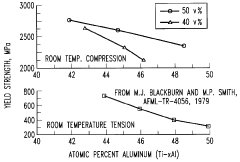

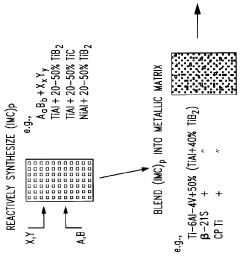

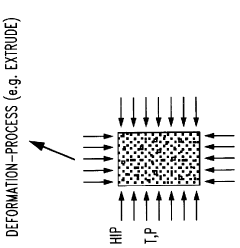

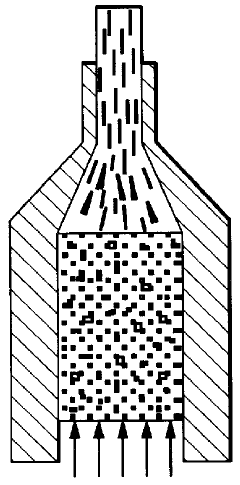

- Development of composite materials with a continuous metallic matrix and intermetallic matrix composite reinforcements, where the intermetallic matrix has a lower melting temperature than the continuous matrix, allowing for stable and high-strength composites with in-situ formed ceramic particles, such as TiB2, that are thermodynamically stable and processable at elevated temperatures.

Performance Metrics and Testing Standards

Performance metrics and testing standards for structural ceramics and composite materials are essential for objective comparison and quality assurance across industries. The evaluation framework for these materials encompasses mechanical, thermal, and environmental performance parameters that must be systematically assessed through standardized testing protocols.

Mechanical performance metrics include compressive strength, tensile strength, flexural strength, fracture toughness, and impact resistance. For structural ceramics, ASTM C1161 provides guidelines for flexural strength testing, while ASTM C1421 addresses fracture toughness. Composite materials are typically evaluated using ASTM D3039 for tensile properties and ASTM D7264 for flexural properties. The significant difference in testing approaches reflects the inherent anisotropic nature of composites versus the more isotropic behavior of ceramics.

Thermal performance evaluation includes thermal conductivity, thermal expansion coefficient, and thermal shock resistance. ISO 22007 series standards apply to both material categories for thermal conductivity measurements, while ASTM C1470 specifically addresses thermal shock resistance in ceramics. Composites require additional consideration of matrix-reinforcement interfaces under thermal cycling, as outlined in ASTM D7791.

Environmental durability metrics encompass chemical resistance, moisture absorption, and aging characteristics. ASTM C1663 provides guidelines for assessing the chemical resistance of ceramics, while ASTM D5229 addresses moisture absorption in composite materials. Long-term performance prediction often requires accelerated aging tests, with ceramics following ASTM C1368 protocols and composites utilizing ASTM D3045.

Industry-specific standards further refine testing requirements. Aerospace applications follow more stringent protocols such as RTCA DO-160 for environmental conditions and MIL-STD-810 for military applications. The medical industry relies on ISO 10993 series for biocompatibility testing of both ceramics and composites used in implantable devices.

Recent developments in testing methodologies include non-destructive evaluation techniques such as acoustic emission, thermography, and digital image correlation, which allow for real-time monitoring of material performance. These advanced techniques are increasingly being incorporated into standards like ASTM E2533 and ISO 18249, enabling more comprehensive material characterization without specimen destruction.

The harmonization of international standards remains an ongoing challenge, with efforts by ISO, ASTM, and regional organizations to develop globally accepted testing protocols that facilitate material comparison across different regulatory frameworks and application domains.

Mechanical performance metrics include compressive strength, tensile strength, flexural strength, fracture toughness, and impact resistance. For structural ceramics, ASTM C1161 provides guidelines for flexural strength testing, while ASTM C1421 addresses fracture toughness. Composite materials are typically evaluated using ASTM D3039 for tensile properties and ASTM D7264 for flexural properties. The significant difference in testing approaches reflects the inherent anisotropic nature of composites versus the more isotropic behavior of ceramics.

Thermal performance evaluation includes thermal conductivity, thermal expansion coefficient, and thermal shock resistance. ISO 22007 series standards apply to both material categories for thermal conductivity measurements, while ASTM C1470 specifically addresses thermal shock resistance in ceramics. Composites require additional consideration of matrix-reinforcement interfaces under thermal cycling, as outlined in ASTM D7791.

Environmental durability metrics encompass chemical resistance, moisture absorption, and aging characteristics. ASTM C1663 provides guidelines for assessing the chemical resistance of ceramics, while ASTM D5229 addresses moisture absorption in composite materials. Long-term performance prediction often requires accelerated aging tests, with ceramics following ASTM C1368 protocols and composites utilizing ASTM D3045.

Industry-specific standards further refine testing requirements. Aerospace applications follow more stringent protocols such as RTCA DO-160 for environmental conditions and MIL-STD-810 for military applications. The medical industry relies on ISO 10993 series for biocompatibility testing of both ceramics and composites used in implantable devices.

Recent developments in testing methodologies include non-destructive evaluation techniques such as acoustic emission, thermography, and digital image correlation, which allow for real-time monitoring of material performance. These advanced techniques are increasingly being incorporated into standards like ASTM E2533 and ISO 18249, enabling more comprehensive material characterization without specimen destruction.

The harmonization of international standards remains an ongoing challenge, with efforts by ISO, ASTM, and regional organizations to develop globally accepted testing protocols that facilitate material comparison across different regulatory frameworks and application domains.

Environmental Impact and Sustainability Considerations

The environmental impact of materials selection has become increasingly critical in engineering design decisions, with both structural ceramics and composite materials presenting distinct sustainability profiles. Structural ceramics generally require high-temperature processing (1400-1700°C), resulting in substantial energy consumption during manufacturing. However, their exceptional durability and chemical stability contribute to extended service lifespans, potentially offsetting initial environmental costs through reduced replacement frequency.

Composite materials, particularly polymer-matrix composites, typically require lower processing temperatures (120-180°C), resulting in reduced energy consumption during manufacturing. However, the environmental challenge lies in their complex multi-material nature, which often combines synthetic resins with reinforcement materials that are difficult to separate at end-of-life.

Life cycle assessment (LCA) studies indicate that ceramic materials generally exhibit higher embodied energy during production but demonstrate superior environmental performance during operational phases due to their resistance to degradation. For instance, silicon nitride ceramics in turbine applications can withstand extreme temperatures without cooling systems, improving overall system efficiency and reducing operational emissions.

Recyclability presents contrasting challenges for both material classes. Structural ceramics, being primarily inorganic, can potentially be downcycled into construction aggregates but rarely return to their original high-performance applications. Composite materials, particularly those with thermoset matrices, present significant recycling difficulties due to the chemical crosslinking that prevents simple remelting and reforming.

Recent innovations are addressing these sustainability concerns. Bio-derived composite materials utilizing natural fibers (flax, hemp) and bio-based resins offer reduced environmental impact while maintaining competitive mechanical properties for non-critical applications. Similarly, advances in low-temperature ceramic processing techniques, including cold sintering processes, are reducing the energy intensity of ceramic manufacturing.

Water consumption patterns also differ significantly between these material classes. Ceramic processing typically requires substantial water for slurry preparation and processing, while composite manufacturing generally has lower direct water requirements but may have hidden water footprints in the production of constituent materials, particularly synthetic fibers and resins.

Carbon footprint comparisons reveal that the selection between ceramics and composites must be application-specific, with transportation applications generally favoring lightweight composites for operational efficiency, while static structural applications may benefit from the durability and longevity of ceramics despite their higher initial production emissions.

Composite materials, particularly polymer-matrix composites, typically require lower processing temperatures (120-180°C), resulting in reduced energy consumption during manufacturing. However, the environmental challenge lies in their complex multi-material nature, which often combines synthetic resins with reinforcement materials that are difficult to separate at end-of-life.

Life cycle assessment (LCA) studies indicate that ceramic materials generally exhibit higher embodied energy during production but demonstrate superior environmental performance during operational phases due to their resistance to degradation. For instance, silicon nitride ceramics in turbine applications can withstand extreme temperatures without cooling systems, improving overall system efficiency and reducing operational emissions.

Recyclability presents contrasting challenges for both material classes. Structural ceramics, being primarily inorganic, can potentially be downcycled into construction aggregates but rarely return to their original high-performance applications. Composite materials, particularly those with thermoset matrices, present significant recycling difficulties due to the chemical crosslinking that prevents simple remelting and reforming.

Recent innovations are addressing these sustainability concerns. Bio-derived composite materials utilizing natural fibers (flax, hemp) and bio-based resins offer reduced environmental impact while maintaining competitive mechanical properties for non-critical applications. Similarly, advances in low-temperature ceramic processing techniques, including cold sintering processes, are reducing the energy intensity of ceramic manufacturing.

Water consumption patterns also differ significantly between these material classes. Ceramic processing typically requires substantial water for slurry preparation and processing, while composite manufacturing generally has lower direct water requirements but may have hidden water footprints in the production of constituent materials, particularly synthetic fibers and resins.

Carbon footprint comparisons reveal that the selection between ceramics and composites must be application-specific, with transportation applications generally favoring lightweight composites for operational efficiency, while static structural applications may benefit from the durability and longevity of ceramics despite their higher initial production emissions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!