The Evolution of Structural Ceramics for Spacecraft Shields

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Spacecraft Shield Ceramics Background and Objectives

Structural ceramics have emerged as critical materials in spacecraft shield development, evolving significantly since the early days of space exploration. Initially, spacecraft relied primarily on metallic shields, but as mission requirements became more demanding, particularly for extended space missions and protection against micrometeoroid and orbital debris (MMOD), advanced ceramic materials gained prominence. The evolution began in the 1960s with basic alumina ceramics and has progressed to sophisticated silicon carbide, boron carbide, and ceramic matrix composites that offer superior protection while minimizing mass penalties.

The technological trajectory of structural ceramics for spacecraft shields has been driven by the harsh space environment, characterized by extreme temperature fluctuations, vacuum conditions, radiation exposure, and high-velocity impacts. These conditions necessitate materials with exceptional thermal stability, mechanical strength, and impact resistance. Modern ceramic shield systems represent the culmination of decades of materials science research, combining theoretical modeling with empirical testing to optimize performance characteristics.

Current spacecraft shield ceramics incorporate multi-layered designs, often integrating different ceramic compositions to address specific threats. The Whipple shield concept, enhanced with ceramic components, has become a standard approach, utilizing the unique properties of ceramics to fragment and disperse impact energy. Recent innovations include functionally graded ceramics that provide graduated protection and self-healing ceramic systems that can partially restore integrity after minor impacts.

The primary objectives of ongoing research in spacecraft shield ceramics focus on several key areas. Weight reduction remains paramount, as launch costs are directly tied to payload mass. Researchers aim to develop lighter ceramic compositions without compromising protective capabilities. Simultaneously, there is a push toward multi-functional ceramics that serve not only as shields but also contribute to thermal management, radiation protection, or structural support.

Another critical objective is enhancing impact resistance against increasingly diverse threat profiles. As space becomes more congested with satellites and debris, the velocity and composition of potential impactors vary widely, requiring shields capable of responding to different impact scenarios. Researchers are exploring nano-engineered ceramics and ceramic composites with tailored microstructures to optimize energy absorption and crack propagation resistance.

Long-term reliability represents another significant goal, particularly for deep space missions where repair or replacement is impossible. This drives research into ceramics with predictable aging characteristics and resistance to degradation from atomic oxygen, ultraviolet radiation, and thermal cycling. The ultimate aim is to develop ceramic shield systems that maintain their protective capabilities throughout mission lifetimes that may extend for decades.

The technological trajectory of structural ceramics for spacecraft shields has been driven by the harsh space environment, characterized by extreme temperature fluctuations, vacuum conditions, radiation exposure, and high-velocity impacts. These conditions necessitate materials with exceptional thermal stability, mechanical strength, and impact resistance. Modern ceramic shield systems represent the culmination of decades of materials science research, combining theoretical modeling with empirical testing to optimize performance characteristics.

Current spacecraft shield ceramics incorporate multi-layered designs, often integrating different ceramic compositions to address specific threats. The Whipple shield concept, enhanced with ceramic components, has become a standard approach, utilizing the unique properties of ceramics to fragment and disperse impact energy. Recent innovations include functionally graded ceramics that provide graduated protection and self-healing ceramic systems that can partially restore integrity after minor impacts.

The primary objectives of ongoing research in spacecraft shield ceramics focus on several key areas. Weight reduction remains paramount, as launch costs are directly tied to payload mass. Researchers aim to develop lighter ceramic compositions without compromising protective capabilities. Simultaneously, there is a push toward multi-functional ceramics that serve not only as shields but also contribute to thermal management, radiation protection, or structural support.

Another critical objective is enhancing impact resistance against increasingly diverse threat profiles. As space becomes more congested with satellites and debris, the velocity and composition of potential impactors vary widely, requiring shields capable of responding to different impact scenarios. Researchers are exploring nano-engineered ceramics and ceramic composites with tailored microstructures to optimize energy absorption and crack propagation resistance.

Long-term reliability represents another significant goal, particularly for deep space missions where repair or replacement is impossible. This drives research into ceramics with predictable aging characteristics and resistance to degradation from atomic oxygen, ultraviolet radiation, and thermal cycling. The ultimate aim is to develop ceramic shield systems that maintain their protective capabilities throughout mission lifetimes that may extend for decades.

Market Analysis for Advanced Spacecraft Protection Systems

The global market for advanced spacecraft protection systems is experiencing significant growth, driven by increased space activities and heightened awareness of space debris threats. Current market valuations indicate the spacecraft shielding sector reached approximately $2.3 billion in 2022, with projections suggesting a compound annual growth rate of 6.8% through 2030. This growth trajectory is supported by expanding government space budgets, with NASA allocating over $500 million specifically for spacecraft protection research and implementation in its latest budget.

The commercial space sector represents the fastest-growing market segment, expanding at nearly 12% annually as private companies like SpaceX, Blue Origin, and Virgin Galactic increase their orbital activities. These commercial entities are increasingly demanding advanced ceramic shield solutions that offer superior protection while minimizing weight penalties. Market research indicates that structural ceramics now account for approximately 35% of the spacecraft protection materials market, up from just 18% a decade ago.

Regional analysis reveals North America dominates the market with approximately 42% share, followed by Europe (28%) and Asia-Pacific (22%). However, the Asia-Pacific region is demonstrating the most aggressive growth rate at 9.3% annually, primarily driven by China's ambitious space program and emerging space initiatives in India and Japan.

Customer segmentation shows distinct requirements across different market sectors. Government space agencies prioritize reliability and performance over cost considerations, while commercial satellite operators seek cost-effective solutions that maximize operational lifespan. The emerging space tourism sector represents a specialized niche with unique requirements focusing on both safety and aesthetic considerations for their protection systems.

Price sensitivity analysis indicates that while advanced ceramic solutions command premium pricing (typically 30-40% higher than traditional metallic shields), their superior performance characteristics and weight savings create compelling value propositions. Market forecasts suggest that as manufacturing technologies mature and production scales increase, price points for advanced ceramic shields will decrease by approximately 15-20% over the next five years.

Competitive landscape assessment reveals increasing consolidation among major aerospace materials suppliers, with five companies controlling approximately 68% of the structural ceramics market for space applications. However, several innovative startups specializing in novel ceramic formulations and manufacturing processes are gaining traction, particularly those leveraging advanced technologies like additive manufacturing for ceramic components.

The commercial space sector represents the fastest-growing market segment, expanding at nearly 12% annually as private companies like SpaceX, Blue Origin, and Virgin Galactic increase their orbital activities. These commercial entities are increasingly demanding advanced ceramic shield solutions that offer superior protection while minimizing weight penalties. Market research indicates that structural ceramics now account for approximately 35% of the spacecraft protection materials market, up from just 18% a decade ago.

Regional analysis reveals North America dominates the market with approximately 42% share, followed by Europe (28%) and Asia-Pacific (22%). However, the Asia-Pacific region is demonstrating the most aggressive growth rate at 9.3% annually, primarily driven by China's ambitious space program and emerging space initiatives in India and Japan.

Customer segmentation shows distinct requirements across different market sectors. Government space agencies prioritize reliability and performance over cost considerations, while commercial satellite operators seek cost-effective solutions that maximize operational lifespan. The emerging space tourism sector represents a specialized niche with unique requirements focusing on both safety and aesthetic considerations for their protection systems.

Price sensitivity analysis indicates that while advanced ceramic solutions command premium pricing (typically 30-40% higher than traditional metallic shields), their superior performance characteristics and weight savings create compelling value propositions. Market forecasts suggest that as manufacturing technologies mature and production scales increase, price points for advanced ceramic shields will decrease by approximately 15-20% over the next five years.

Competitive landscape assessment reveals increasing consolidation among major aerospace materials suppliers, with five companies controlling approximately 68% of the structural ceramics market for space applications. However, several innovative startups specializing in novel ceramic formulations and manufacturing processes are gaining traction, particularly those leveraging advanced technologies like additive manufacturing for ceramic components.

Current Status and Challenges in Structural Ceramics

Structural ceramics for spacecraft shields have witnessed significant advancements globally, with current research primarily focused on enhancing thermal resistance, impact absorption, and weight reduction. Leading nations in this field include the United States, China, Russia, Japan, and several European countries, each contributing unique innovations to address the harsh conditions of space environments.

The state-of-the-art materials currently dominating the field include silicon carbide (SiC), aluminum oxide (Al₂O₃), boron carbide (B₄C), and ultra-high temperature ceramics (UHTCs) such as zirconium diboride (ZrB₂) and hafnium diboride (HfB₂). These materials demonstrate exceptional thermal stability at temperatures exceeding 2000°C, critical for atmospheric re-entry applications.

Despite significant progress, several technical challenges persist in structural ceramics development. The inherent brittleness of ceramic materials remains a fundamental limitation, creating vulnerability to catastrophic failure under impact conditions. Current research focuses on developing ceramic matrix composites (CMCs) that incorporate reinforcing fibers to improve fracture toughness while maintaining thermal resistance properties.

Manufacturing scalability presents another significant hurdle. Advanced fabrication techniques such as spark plasma sintering, additive manufacturing, and chemical vapor deposition enable the creation of complex geometries but face challenges in consistent quality control and cost-effectiveness at production scale. The integration of these ceramics with metallic and composite spacecraft structures also presents ongoing interface compatibility issues.

Geographical distribution of structural ceramics technology shows concentration in aerospace research centers, with NASA's Ames Research Center and Langley Research Center leading American efforts. In Europe, the European Space Agency collaborates with institutions like the German Aerospace Center (DLR) on advanced ceramic shield systems. China's rapid advancement comes through institutions like the Harbin Institute of Technology and Shanghai Institute of Ceramics.

Environmental extremes of space present unique challenges for ceramic materials, including atomic oxygen erosion in low Earth orbit, micrometeoroid impacts, and extreme temperature cycling between solar exposure and shadow. Current research addresses these issues through multi-layered ceramic systems and gradient structures that optimize performance across varying conditions.

The economic constraints of space missions further complicate development, as the high processing costs of advanced ceramics must be balanced against performance requirements. This has driven interest in preceramic polymers and other processing routes that could reduce manufacturing complexity while maintaining critical protective properties for spacecraft shields.

The state-of-the-art materials currently dominating the field include silicon carbide (SiC), aluminum oxide (Al₂O₃), boron carbide (B₄C), and ultra-high temperature ceramics (UHTCs) such as zirconium diboride (ZrB₂) and hafnium diboride (HfB₂). These materials demonstrate exceptional thermal stability at temperatures exceeding 2000°C, critical for atmospheric re-entry applications.

Despite significant progress, several technical challenges persist in structural ceramics development. The inherent brittleness of ceramic materials remains a fundamental limitation, creating vulnerability to catastrophic failure under impact conditions. Current research focuses on developing ceramic matrix composites (CMCs) that incorporate reinforcing fibers to improve fracture toughness while maintaining thermal resistance properties.

Manufacturing scalability presents another significant hurdle. Advanced fabrication techniques such as spark plasma sintering, additive manufacturing, and chemical vapor deposition enable the creation of complex geometries but face challenges in consistent quality control and cost-effectiveness at production scale. The integration of these ceramics with metallic and composite spacecraft structures also presents ongoing interface compatibility issues.

Geographical distribution of structural ceramics technology shows concentration in aerospace research centers, with NASA's Ames Research Center and Langley Research Center leading American efforts. In Europe, the European Space Agency collaborates with institutions like the German Aerospace Center (DLR) on advanced ceramic shield systems. China's rapid advancement comes through institutions like the Harbin Institute of Technology and Shanghai Institute of Ceramics.

Environmental extremes of space present unique challenges for ceramic materials, including atomic oxygen erosion in low Earth orbit, micrometeoroid impacts, and extreme temperature cycling between solar exposure and shadow. Current research addresses these issues through multi-layered ceramic systems and gradient structures that optimize performance across varying conditions.

The economic constraints of space missions further complicate development, as the high processing costs of advanced ceramics must be balanced against performance requirements. This has driven interest in preceramic polymers and other processing routes that could reduce manufacturing complexity while maintaining critical protective properties for spacecraft shields.

Current Structural Ceramic Shield Technologies

01 Manufacturing methods for structural ceramics

Various manufacturing methods are employed to produce structural ceramics with enhanced properties. These include sintering processes, hot pressing, and specialized molding techniques that control the microstructure and density of the final ceramic product. Advanced manufacturing approaches can incorporate reinforcement phases or create composite structures to improve mechanical properties such as strength, toughness, and thermal shock resistance.- Manufacturing methods for structural ceramics: Various manufacturing methods are employed to produce structural ceramics with enhanced properties. These methods include sintering processes, hot pressing techniques, and specialized molding approaches. The manufacturing processes are designed to control the microstructure and density of the ceramic materials, which directly influence their mechanical properties such as strength, hardness, and fracture toughness. Advanced processing techniques help in reducing defects and improving the overall performance of structural ceramic components.

- Composition and materials for structural ceramics: Structural ceramics are composed of various materials including silicon nitride, silicon carbide, alumina, zirconia, and other oxide and non-oxide ceramics. These materials can be combined with additives and reinforcements to create composites with tailored properties. The composition directly affects the thermal stability, chemical resistance, and mechanical performance of the ceramic components. Selection of appropriate materials and their proportions is crucial for developing structural ceramics suitable for specific applications under demanding conditions.

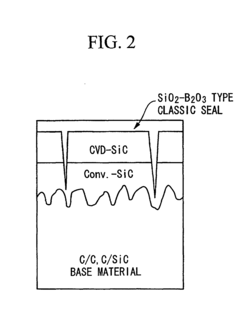

- Surface treatments and coatings for structural ceramics: Surface treatments and coatings are applied to structural ceramics to enhance their performance characteristics. These treatments can improve wear resistance, reduce friction, increase chemical stability, and provide protection against environmental degradation. Techniques such as glazing, chemical vapor deposition, physical vapor deposition, and plasma spraying are commonly used. Surface modifications can also improve the bonding between ceramic components and other materials in composite structures.

- Applications of structural ceramics in high-temperature environments: Structural ceramics are widely used in high-temperature applications due to their excellent thermal stability and resistance to thermal shock. These materials maintain their mechanical properties at elevated temperatures where metals and polymers would fail. Applications include components for gas turbines, combustion engines, heat exchangers, and industrial furnaces. The ability of structural ceramics to withstand extreme temperatures while maintaining dimensional stability makes them invaluable in aerospace, automotive, and energy generation sectors.

- Reinforcement techniques for improving mechanical properties: Various reinforcement techniques are employed to enhance the mechanical properties of structural ceramics, particularly to overcome their inherent brittleness. These include fiber reinforcement, particle dispersion, whisker incorporation, and the development of ceramic matrix composites. Reinforcement strategies aim to improve fracture toughness, impact resistance, and overall reliability of ceramic components. The introduction of secondary phases or structures can create mechanisms for crack deflection and energy absorption, significantly improving the durability of structural ceramic parts under mechanical stress.

02 Silicon-based structural ceramics

Silicon-based ceramics, including silicon carbide (SiC), silicon nitride (Si3N4), and sialon ceramics, form a significant category of structural ceramics. These materials offer excellent high-temperature strength, thermal shock resistance, and chemical stability. They are particularly valuable in applications requiring resistance to oxidation and corrosion under extreme conditions, such as turbine components, cutting tools, and high-temperature bearings.Expand Specific Solutions03 Ceramic matrix composites (CMCs)

Ceramic matrix composites incorporate reinforcing elements such as fibers, whiskers, or particles within a ceramic matrix to overcome the inherent brittleness of monolithic ceramics. These composites exhibit improved fracture toughness, damage tolerance, and reliability. The reinforcement phase can deflect cracks and absorb energy, preventing catastrophic failure and enabling applications in aerospace, defense, and energy generation sectors.Expand Specific Solutions04 Functional structural ceramics

Functional structural ceramics combine load-bearing capabilities with additional properties such as electrical conductivity, piezoelectric behavior, or magnetic characteristics. These multifunctional materials enable the development of smart structures and integrated systems. Applications include sensors, actuators, electronic substrates, and components that must operate in harsh environments while providing both structural support and functional performance.Expand Specific Solutions05 Oxide-based structural ceramics

Oxide-based structural ceramics, including alumina (Al2O3), zirconia (ZrO2), and various mixed oxides, offer excellent wear resistance, high-temperature stability, and biocompatibility. These materials can be tailored through composition and processing to achieve specific properties such as transformation toughening in zirconia or high hardness in alumina. They find applications in cutting tools, wear components, biomedical implants, and thermal barrier coatings.Expand Specific Solutions

Leading Organizations in Aerospace Ceramic Development

The structural ceramics market for spacecraft shields is in a growth phase, with increasing demand driven by expanding space exploration and satellite deployment activities. The market is characterized by a blend of established aerospace giants like Boeing, Northrop Grumman, and Mitsubishi Heavy Industries alongside specialized research institutions such as the Aerospace Research Institute of Materials and Processing Technology. Technical maturity varies across applications, with traditional ceramics well-established while advanced composites remain in development. Leading companies like Corning, NGK Insulators, and Kyocera are pushing innovation boundaries in high-temperature ceramics and impact-resistant materials. Academic-industry partnerships, particularly involving institutions like Harbin Institute of Technology and Korea Advanced Institute of Science & Technology, are accelerating development of next-generation ceramic shield technologies with enhanced thermal and mechanical properties.

The Boeing Co.

Technical Solution: Boeing has developed advanced structural ceramic composite shields for spacecraft that combine silicon carbide (SiC) and boron nitride (BN) in a multi-layered configuration. Their proprietary Ceramic Matrix Composite (CMC) technology incorporates reinforced fibers within a ceramic matrix to create shields with exceptional thermal resistance up to 1650°C while maintaining structural integrity. Boeing's PICA-X (Phenolic Impregnated Carbon Ablator-X) system represents a significant advancement, featuring a carbon fiber substrate impregnated with phenolic resin that chars during atmospheric entry, dissipating heat through ablation. Their latest innovation includes self-healing ceramic composites that can repair microcracks at high temperatures through embedded healing agents that activate when damage occurs, extending shield lifespan during multiple mission cycles.

Strengths: Superior thermal protection combined with structural load-bearing capabilities; reduced weight compared to traditional metallic shields; self-healing properties extend operational lifespan. Weaknesses: Higher production costs compared to conventional materials; complex manufacturing process requiring specialized facilities; potential brittleness under extreme impact conditions.

Northrop Grumman Systems Corp.

Technical Solution: Northrop Grumman has pioneered Ultra-High Temperature Ceramic (UHTC) shield systems incorporating zirconium diboride (ZrB2) and hafnium diboride (HfB2) composites that withstand temperatures exceeding 2000°C. Their patented multi-phase ceramic technology combines these materials with silicon carbide (SiC) to create shields with exceptional oxidation resistance and thermal stability. The company has developed a gradient-structured ceramic shield system where composition transitions from dense outer layers to more porous inner layers, optimizing both thermal protection and weight. Northrop's recent innovation includes nano-engineered ceramic interfaces that significantly improve impact resistance by deflecting and absorbing kinetic energy from micrometeoroid strikes. Their manufacturing process utilizes advanced sintering techniques and 3D printing to create complex geometries with precisely controlled microstructures.

Strengths: Exceptional thermal resistance suitable for extreme reentry conditions; superior oxidation protection in oxygen-rich environments; customizable properties through gradient structures. Weaknesses: High material and processing costs; challenges in scaling production for larger spacecraft components; potential thermal expansion mismatch issues at material interfaces.

Key Innovations in Spacecraft Ceramic Shield Patents

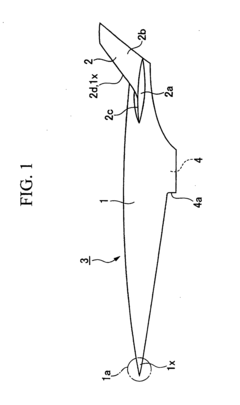

HEAT−RESISTANT MATERIAL AND HOT STRUCTURE MEMBER BOTH FOR SPACE SHUTTLE, SPACE SHUTTLE, AND METHOD FOR PRODUCING HEAT−RESISTANT MATERIAL FOR SPACE SHUTTLE

PatentInactiveEP1460048A1

Innovation

- A ceramic material containing silicon carbide in zirconium boride is used, forming a thick zirconium oxide oxidation layer that acts as an anti-oxidation protection layer, allowing for higher heat resistance and the ability to be molded into desired shapes using a normal pressure sintering method, rather than the conventional hot pressing method.

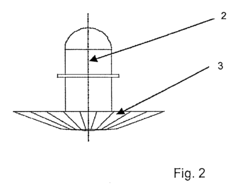

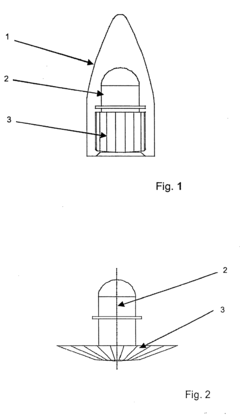

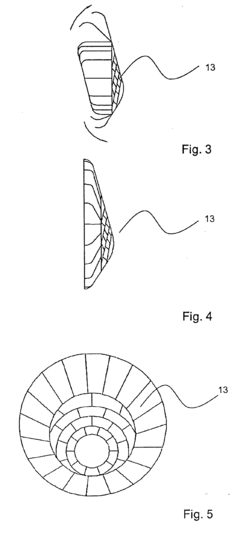

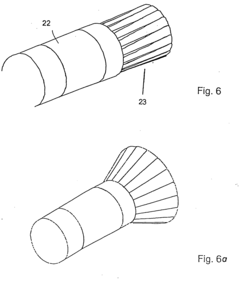

Deployable braking structure for space vehicles

PatentInactiveEP1905691A1

Innovation

- A deployable shield made of ultra-lightweight, high-temperature-resistant fiber-reinforced ceramic panels that can be mounted to the spacecraft's outer structure, allowing for a 50% weight reduction and compact storage, enabling safe deployment as a self-stiffening aerodynamic braking shield without ablative materials.

Space Environment Impact Assessment

The space environment presents unique and extreme challenges for spacecraft materials, particularly for structural ceramics used in protective shields. Spacecraft in orbit face a barrage of hazards including micrometeoroids, orbital debris, extreme temperature fluctuations, atomic oxygen, ultraviolet radiation, and charged particles. These environmental factors significantly influence the performance requirements and degradation mechanisms of ceramic shield materials.

Micrometeoroids and orbital debris (MMOD) represent perhaps the most immediate physical threat, with impact velocities averaging 10-15 km/s in low Earth orbit. Such hypervelocity impacts create extreme localized pressures exceeding 100 GPa and temperatures above 10,000°C, conditions that test the limits of even advanced ceramic materials. The Whipple shield design, incorporating ceramic components, has evolved specifically to address these threats through multi-layer protection systems.

Thermal cycling poses another significant challenge, with temperature swings from +150°C in direct sunlight to -150°C in Earth's shadow during each orbital period. These rapid and extreme fluctuations induce thermal stresses that can lead to microcracking and progressive degradation of ceramic materials over time. Advanced structural ceramics must maintain their protective capabilities despite thousands of such cycles during a typical mission lifetime.

Atomic oxygen, prevalent in low Earth orbit at altitudes of 200-700 km, aggressively erodes many materials through oxidation reactions. While ceramics generally offer better resistance than polymers or metals, certain compositions may still experience surface degradation, affecting optical properties and potentially compromising shield integrity over extended missions.

Radiation effects, including ultraviolet, X-ray, gamma, and particle radiation, can alter the microstructure and properties of ceramic materials. Displacement damage from high-energy particles can create defects in the crystal structure, while ionizing radiation may induce color centers that affect thermal and optical properties. These effects accumulate over mission duration and must be accounted for in material selection and shield design.

The combined and synergistic effects of these environmental factors often produce degradation mechanisms more severe than would be predicted by considering each factor in isolation. For example, pre-existing radiation damage may significantly reduce a ceramic's resistance to micrometeoroid impact, while thermal cycling can accelerate atomic oxygen erosion by creating new surface pathways for reaction.

Assessment methodologies have evolved from simple ground-based testing to sophisticated combined-environment simulation facilities and in-space exposure experiments. The Materials International Space Station Experiment (MISSE) series has provided valuable real-world performance data for ceramic materials in the actual space environment, helping to validate laboratory predictions and refine material selection criteria.

Micrometeoroids and orbital debris (MMOD) represent perhaps the most immediate physical threat, with impact velocities averaging 10-15 km/s in low Earth orbit. Such hypervelocity impacts create extreme localized pressures exceeding 100 GPa and temperatures above 10,000°C, conditions that test the limits of even advanced ceramic materials. The Whipple shield design, incorporating ceramic components, has evolved specifically to address these threats through multi-layer protection systems.

Thermal cycling poses another significant challenge, with temperature swings from +150°C in direct sunlight to -150°C in Earth's shadow during each orbital period. These rapid and extreme fluctuations induce thermal stresses that can lead to microcracking and progressive degradation of ceramic materials over time. Advanced structural ceramics must maintain their protective capabilities despite thousands of such cycles during a typical mission lifetime.

Atomic oxygen, prevalent in low Earth orbit at altitudes of 200-700 km, aggressively erodes many materials through oxidation reactions. While ceramics generally offer better resistance than polymers or metals, certain compositions may still experience surface degradation, affecting optical properties and potentially compromising shield integrity over extended missions.

Radiation effects, including ultraviolet, X-ray, gamma, and particle radiation, can alter the microstructure and properties of ceramic materials. Displacement damage from high-energy particles can create defects in the crystal structure, while ionizing radiation may induce color centers that affect thermal and optical properties. These effects accumulate over mission duration and must be accounted for in material selection and shield design.

The combined and synergistic effects of these environmental factors often produce degradation mechanisms more severe than would be predicted by considering each factor in isolation. For example, pre-existing radiation damage may significantly reduce a ceramic's resistance to micrometeoroid impact, while thermal cycling can accelerate atomic oxygen erosion by creating new surface pathways for reaction.

Assessment methodologies have evolved from simple ground-based testing to sophisticated combined-environment simulation facilities and in-space exposure experiments. The Materials International Space Station Experiment (MISSE) series has provided valuable real-world performance data for ceramic materials in the actual space environment, helping to validate laboratory predictions and refine material selection criteria.

Manufacturing Processes and Scalability Analysis

The manufacturing of structural ceramics for spacecraft shields has evolved significantly over the past decades, transitioning from laboratory-scale production to industrial-scale manufacturing. Traditional ceramic processing methods such as slip casting, tape casting, and dry pressing have been adapted and enhanced to meet the stringent requirements of aerospace applications. These methods have been supplemented by advanced techniques including hot isostatic pressing (HIP), spark plasma sintering (SPS), and additive manufacturing, which enable the production of complex geometries with controlled microstructures.

Scalability remains a critical challenge in the production of ceramic shields. While laboratory prototypes demonstrate excellent performance, scaling up to full-size spacecraft components introduces variables that can compromise structural integrity. The transition from small-scale to large-scale production often results in increased defect rates, dimensional inconsistencies, and performance variability. Manufacturers have addressed these issues through process optimization, statistical quality control, and the implementation of in-line inspection technologies.

Cost considerations significantly impact manufacturing decisions. High-performance ceramics like silicon carbide, boron carbide, and aluminum oxide composites require specialized equipment and processing conditions, driving up production expenses. Economic analyses indicate that batch processing optimizations and material recycling strategies can reduce costs by 15-30%, making advanced ceramic shields more economically viable for broader spacecraft applications.

Recent innovations in manufacturing technology have focused on reducing processing temperatures and times. Microwave sintering, for example, has demonstrated the ability to consolidate ceramic materials at lower temperatures and in shorter timeframes compared to conventional sintering methods. This approach not only reduces energy consumption but also minimizes grain growth, resulting in finer microstructures with enhanced mechanical properties.

Quality control protocols have become increasingly sophisticated, incorporating non-destructive evaluation techniques such as ultrasonic testing, X-ray computed tomography, and infrared thermography. These methods allow manufacturers to detect internal defects, verify dimensional accuracy, and ensure consistent material properties throughout the ceramic components. The integration of artificial intelligence and machine learning algorithms has further enhanced defect detection capabilities, reducing rejection rates and improving overall manufacturing yield.

Environmental considerations are gaining prominence in ceramic manufacturing processes. Sustainable practices, including closed-loop water systems, energy recovery, and reduced emissions, are being implemented across the industry. These initiatives not only address regulatory requirements but also contribute to cost reduction through improved resource utilization and waste management.

Scalability remains a critical challenge in the production of ceramic shields. While laboratory prototypes demonstrate excellent performance, scaling up to full-size spacecraft components introduces variables that can compromise structural integrity. The transition from small-scale to large-scale production often results in increased defect rates, dimensional inconsistencies, and performance variability. Manufacturers have addressed these issues through process optimization, statistical quality control, and the implementation of in-line inspection technologies.

Cost considerations significantly impact manufacturing decisions. High-performance ceramics like silicon carbide, boron carbide, and aluminum oxide composites require specialized equipment and processing conditions, driving up production expenses. Economic analyses indicate that batch processing optimizations and material recycling strategies can reduce costs by 15-30%, making advanced ceramic shields more economically viable for broader spacecraft applications.

Recent innovations in manufacturing technology have focused on reducing processing temperatures and times. Microwave sintering, for example, has demonstrated the ability to consolidate ceramic materials at lower temperatures and in shorter timeframes compared to conventional sintering methods. This approach not only reduces energy consumption but also minimizes grain growth, resulting in finer microstructures with enhanced mechanical properties.

Quality control protocols have become increasingly sophisticated, incorporating non-destructive evaluation techniques such as ultrasonic testing, X-ray computed tomography, and infrared thermography. These methods allow manufacturers to detect internal defects, verify dimensional accuracy, and ensure consistent material properties throughout the ceramic components. The integration of artificial intelligence and machine learning algorithms has further enhanced defect detection capabilities, reducing rejection rates and improving overall manufacturing yield.

Environmental considerations are gaining prominence in ceramic manufacturing processes. Sustainable practices, including closed-loop water systems, energy recovery, and reduced emissions, are being implemented across the industry. These initiatives not only address regulatory requirements but also contribute to cost reduction through improved resource utilization and waste management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!