Innovations in Structural Ceramics for Heat Shield Applications

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Structural Ceramics Evolution and Heat Shield Objectives

Structural ceramics have undergone significant evolution since their initial development in the mid-20th century. Early applications primarily focused on basic refractory materials with limited thermal protection capabilities. The 1960s marked a pivotal turning point with NASA's space programs driving innovation in heat shield technologies for spacecraft re-entry systems. This period saw the emergence of first-generation structural ceramics specifically designed to withstand extreme thermal environments.

The technological progression accelerated during the 1970s-1980s with the development of advanced ceramic matrix composites (CMCs) offering superior fracture toughness compared to monolithic ceramics. This breakthrough addressed the inherent brittleness that had previously limited ceramic applications in critical structural components. The 1990s witnessed further refinement with the introduction of ultra-high temperature ceramics (UHTCs) based on zirconium and hafnium compounds, capable of withstanding temperatures exceeding 2000°C.

Recent advancements have focused on multi-functional ceramic systems that combine thermal protection with additional properties such as electromagnetic shielding, self-healing capabilities, and integrated sensor functions. The current technological frontier involves nanoscale engineering of ceramic microstructures to optimize thermal conductivity, mechanical strength, and oxidation resistance simultaneously.

The primary objective in structural ceramics for heat shield applications is to develop materials capable of maintaining structural integrity under extreme thermal gradients while minimizing weight penalties. This includes withstanding temperatures ranging from -150°C to +2500°C during operational cycles. Secondary objectives encompass improving manufacturing scalability, reducing production costs, and enhancing reliability through predictable performance degradation patterns.

Long-term goals in this field include developing ceramics with programmable thermal properties that can actively respond to changing environmental conditions. This involves creating materials with variable thermal conductivity that can adapt to heat flux variations during different mission phases. Additionally, research aims to achieve seamless integration with underlying structural components to minimize thermal expansion mismatches and reduce mechanical stress concentrations.

The technological roadmap for structural ceramics in heat shield applications envisions progressive improvements in temperature capability, from current limits around 1800°C for sustained operation to future systems exceeding 3000°C. Parallel development tracks focus on improving impact resistance to mitigate damage from micrometeoroid strikes and enhancing reusability for next-generation space vehicles and hypersonic aircraft requiring multiple thermal cycles without performance degradation.

The technological progression accelerated during the 1970s-1980s with the development of advanced ceramic matrix composites (CMCs) offering superior fracture toughness compared to monolithic ceramics. This breakthrough addressed the inherent brittleness that had previously limited ceramic applications in critical structural components. The 1990s witnessed further refinement with the introduction of ultra-high temperature ceramics (UHTCs) based on zirconium and hafnium compounds, capable of withstanding temperatures exceeding 2000°C.

Recent advancements have focused on multi-functional ceramic systems that combine thermal protection with additional properties such as electromagnetic shielding, self-healing capabilities, and integrated sensor functions. The current technological frontier involves nanoscale engineering of ceramic microstructures to optimize thermal conductivity, mechanical strength, and oxidation resistance simultaneously.

The primary objective in structural ceramics for heat shield applications is to develop materials capable of maintaining structural integrity under extreme thermal gradients while minimizing weight penalties. This includes withstanding temperatures ranging from -150°C to +2500°C during operational cycles. Secondary objectives encompass improving manufacturing scalability, reducing production costs, and enhancing reliability through predictable performance degradation patterns.

Long-term goals in this field include developing ceramics with programmable thermal properties that can actively respond to changing environmental conditions. This involves creating materials with variable thermal conductivity that can adapt to heat flux variations during different mission phases. Additionally, research aims to achieve seamless integration with underlying structural components to minimize thermal expansion mismatches and reduce mechanical stress concentrations.

The technological roadmap for structural ceramics in heat shield applications envisions progressive improvements in temperature capability, from current limits around 1800°C for sustained operation to future systems exceeding 3000°C. Parallel development tracks focus on improving impact resistance to mitigate damage from micrometeoroid strikes and enhancing reusability for next-generation space vehicles and hypersonic aircraft requiring multiple thermal cycles without performance degradation.

Market Analysis for Advanced Thermal Protection Systems

The global market for Advanced Thermal Protection Systems (ATPS) has experienced significant growth over the past decade, driven primarily by expanding applications in aerospace, defense, and emerging commercial space sectors. Current market valuations place the ATPS sector at approximately $3.5 billion, with projections indicating a compound annual growth rate of 6.8% through 2030.

Aerospace remains the dominant application segment, accounting for nearly 45% of the total market share. This is largely attributed to the increasing number of space missions, satellite deployments, and the resurgence of interest in lunar and Mars exploration programs. NASA's Artemis program and similar initiatives by other space agencies have created substantial demand for next-generation heat shield technologies capable of withstanding extreme reentry conditions.

The defense sector represents the second-largest market segment at 30%, with applications in hypersonic vehicles, missile systems, and advanced aircraft. The recent global focus on hypersonic technology development has particularly accelerated demand for innovative ceramic-based thermal protection systems that can maintain structural integrity at speeds exceeding Mach 5.

Commercial space companies have emerged as the fastest-growing market segment, expanding at 12.3% annually. This growth is fueled by the increasing frequency of commercial launches, reusable spacecraft development, and the nascent space tourism industry. Companies like SpaceX, Blue Origin, and Virgin Galactic have all invested heavily in advanced heat shield technologies to enable vehicle reusability and improve safety margins.

Geographically, North America dominates the market with approximately 42% share, followed by Europe (27%) and Asia-Pacific (21%). However, the Asia-Pacific region is experiencing the fastest growth rate, driven by China's ambitious space program and increasing investments in aerospace and defense capabilities across India, Japan, and South Korea.

Key market drivers include increasing mission complexity requiring materials that can withstand more extreme thermal environments, growing emphasis on reusability in spacecraft design, and the push toward more efficient and lightweight thermal protection systems. The trend toward miniaturization in satellite technology has also created demand for scaled thermal protection solutions that maintain effectiveness while reducing mass.

Market challenges include high material and manufacturing costs, complex certification requirements, and long development cycles. Additionally, supply chain vulnerabilities for rare earth elements and specialized ceramics present ongoing concerns for manufacturers and end-users alike.

Aerospace remains the dominant application segment, accounting for nearly 45% of the total market share. This is largely attributed to the increasing number of space missions, satellite deployments, and the resurgence of interest in lunar and Mars exploration programs. NASA's Artemis program and similar initiatives by other space agencies have created substantial demand for next-generation heat shield technologies capable of withstanding extreme reentry conditions.

The defense sector represents the second-largest market segment at 30%, with applications in hypersonic vehicles, missile systems, and advanced aircraft. The recent global focus on hypersonic technology development has particularly accelerated demand for innovative ceramic-based thermal protection systems that can maintain structural integrity at speeds exceeding Mach 5.

Commercial space companies have emerged as the fastest-growing market segment, expanding at 12.3% annually. This growth is fueled by the increasing frequency of commercial launches, reusable spacecraft development, and the nascent space tourism industry. Companies like SpaceX, Blue Origin, and Virgin Galactic have all invested heavily in advanced heat shield technologies to enable vehicle reusability and improve safety margins.

Geographically, North America dominates the market with approximately 42% share, followed by Europe (27%) and Asia-Pacific (21%). However, the Asia-Pacific region is experiencing the fastest growth rate, driven by China's ambitious space program and increasing investments in aerospace and defense capabilities across India, Japan, and South Korea.

Key market drivers include increasing mission complexity requiring materials that can withstand more extreme thermal environments, growing emphasis on reusability in spacecraft design, and the push toward more efficient and lightweight thermal protection systems. The trend toward miniaturization in satellite technology has also created demand for scaled thermal protection solutions that maintain effectiveness while reducing mass.

Market challenges include high material and manufacturing costs, complex certification requirements, and long development cycles. Additionally, supply chain vulnerabilities for rare earth elements and specialized ceramics present ongoing concerns for manufacturers and end-users alike.

Global Status and Technical Barriers in Ceramic Heat Shields

Ceramic heat shield technology has witnessed significant advancements globally, with major research centers in the United States, Europe, Japan, and China leading innovation efforts. The United States, through NASA and aerospace contractors, has developed sophisticated ceramic thermal protection systems for space vehicles, exemplified by the TUFROC (Toughened Unipiece Fibrous Reinforced Oxidation-resistant Composite) system used on the X-37B spacecraft. The European Space Agency has focused on developing ceramic matrix composites (CMCs) for re-entry vehicles, while Japan has made notable progress in ultra-high temperature ceramics (UHTCs) through the JAXA space program.

China has rapidly emerged as a significant player, investing heavily in ceramic heat shield technology for hypersonic vehicles and space applications. Russian research continues to build on Soviet-era expertise in refractory ceramics, particularly zirconium-based compounds for extreme temperature applications. India, through ISRO, has developed indigenous ceramic heat shield capabilities for its growing space program.

Despite these advancements, several critical technical barriers persist in ceramic heat shield development. Material brittleness remains a fundamental challenge, as ceramics typically exhibit low fracture toughness compared to metals, making them vulnerable to impact damage and thermal shock. This limitation is particularly problematic for reusable systems that must withstand multiple thermal cycles and potential debris impacts.

Thermal expansion mismatch between different ceramic components and attachment systems creates significant stress concentrations during heating and cooling cycles, leading to potential structural failures. The manufacturing complexity of advanced ceramic systems, particularly those with complex geometries or gradient structures, presents scalability challenges and increases production costs, limiting widespread adoption.

Oxidation resistance at ultra-high temperatures (above 1600°C) remains problematic for many ceramic systems, particularly in hypersonic flight environments where atomic oxygen can rapidly degrade material performance. The limited self-healing capabilities of ceramic materials compared to some metallic systems means damage tends to propagate rather than arrest under continued thermal and mechanical stress.

Joining and integration issues between ceramic components and metallic substructures create vulnerable interfaces that can fail under thermal cycling. Additionally, there is insufficient real-world performance data for newer ceramic compositions, as laboratory testing cannot fully replicate the complex combined thermal, mechanical, and chemical environments experienced during actual missions.

The cost-effectiveness of advanced ceramic heat shields remains challenging, with high-performance systems often requiring expensive raw materials and complex processing techniques that limit their application to high-value missions where performance requirements justify the expense.

China has rapidly emerged as a significant player, investing heavily in ceramic heat shield technology for hypersonic vehicles and space applications. Russian research continues to build on Soviet-era expertise in refractory ceramics, particularly zirconium-based compounds for extreme temperature applications. India, through ISRO, has developed indigenous ceramic heat shield capabilities for its growing space program.

Despite these advancements, several critical technical barriers persist in ceramic heat shield development. Material brittleness remains a fundamental challenge, as ceramics typically exhibit low fracture toughness compared to metals, making them vulnerable to impact damage and thermal shock. This limitation is particularly problematic for reusable systems that must withstand multiple thermal cycles and potential debris impacts.

Thermal expansion mismatch between different ceramic components and attachment systems creates significant stress concentrations during heating and cooling cycles, leading to potential structural failures. The manufacturing complexity of advanced ceramic systems, particularly those with complex geometries or gradient structures, presents scalability challenges and increases production costs, limiting widespread adoption.

Oxidation resistance at ultra-high temperatures (above 1600°C) remains problematic for many ceramic systems, particularly in hypersonic flight environments where atomic oxygen can rapidly degrade material performance. The limited self-healing capabilities of ceramic materials compared to some metallic systems means damage tends to propagate rather than arrest under continued thermal and mechanical stress.

Joining and integration issues between ceramic components and metallic substructures create vulnerable interfaces that can fail under thermal cycling. Additionally, there is insufficient real-world performance data for newer ceramic compositions, as laboratory testing cannot fully replicate the complex combined thermal, mechanical, and chemical environments experienced during actual missions.

The cost-effectiveness of advanced ceramic heat shields remains challenging, with high-performance systems often requiring expensive raw materials and complex processing techniques that limit their application to high-value missions where performance requirements justify the expense.

Current Ceramic Solutions for Extreme Temperature Applications

01 Ceramic matrix composites for heat shields

Ceramic matrix composites (CMCs) are advanced materials used in heat shield applications due to their excellent thermal resistance and mechanical properties. These composites typically consist of ceramic fibers embedded in a ceramic matrix, providing superior thermal protection while maintaining structural integrity under extreme temperatures. The combination of different ceramic materials enhances the overall performance of heat shields in aerospace and industrial applications.- Ceramic matrix composites for heat shields: Ceramic matrix composites (CMCs) are advanced materials used in heat shield applications due to their excellent thermal resistance and mechanical properties. These composites typically consist of ceramic fibers embedded in a ceramic matrix, providing superior thermal protection while maintaining structural integrity under extreme temperatures. The combination of different ceramic materials enhances the overall performance of heat shields, making them suitable for aerospace and industrial high-temperature applications.

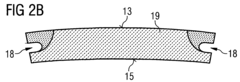

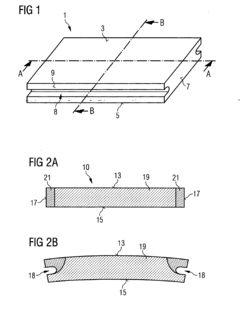

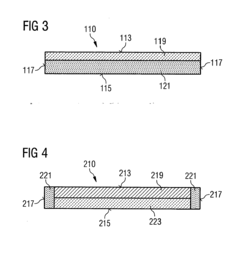

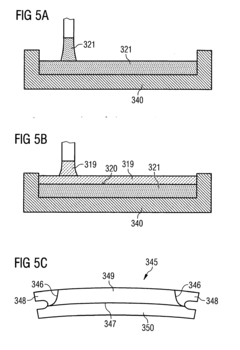

- Multi-layered ceramic thermal barrier systems: Multi-layered ceramic structures are designed to provide enhanced thermal protection by incorporating different ceramic materials with complementary properties. These systems typically include an outer layer for direct heat exposure, intermediate layers for thermal gradient management, and an inner layer bonded to the protected structure. This layered approach allows for optimized heat dissipation, thermal expansion compatibility, and improved durability under thermal cycling conditions, making them effective for applications in spacecraft re-entry shields and combustion chambers.

- Porous ceramic structures for thermal insulation: Porous ceramic materials are utilized in heat shield applications to provide enhanced thermal insulation properties. The controlled porosity within the ceramic structure creates air pockets that significantly reduce thermal conductivity while maintaining structural integrity. These materials can be engineered with specific pore sizes and distributions to optimize the balance between mechanical strength and thermal insulation performance, making them suitable for applications requiring lightweight yet effective thermal barriers.

- Ceramic coatings for metallic substrates: Specialized ceramic coatings applied to metallic substrates provide thermal protection while leveraging the structural advantages of the metal base. These coating systems typically involve plasma-sprayed or chemically bonded ceramic layers that create an effective thermal barrier. The ceramic materials used include zirconia, alumina, and silica-based compounds, which can withstand extreme temperatures while protecting the underlying metal from oxidation and thermal degradation. This approach is particularly valuable in applications where weight considerations are important alongside thermal protection.

- Ceramic heat shields with integrated cooling systems: Advanced ceramic heat shield designs incorporate integrated cooling systems to enhance thermal management capabilities. These systems may include channels or cavities within the ceramic structure that allow for the circulation of cooling fluids or gases. Some designs feature transpiration cooling where a coolant permeates through the porous ceramic material to create a protective boundary layer. This integration of active cooling with passive ceramic thermal protection provides superior performance in extreme thermal environments such as rocket engines, hypersonic vehicles, and industrial furnaces.

02 Multi-layered ceramic thermal barrier systems

Multi-layered ceramic structures are designed to provide enhanced thermal protection by incorporating different ceramic materials with complementary properties. These systems typically include an outer layer for direct heat exposure, intermediate layers for thermal gradient management, and an inner layer bonded to the protected structure. This layered approach allows for optimized heat dissipation and improved durability under thermal cycling conditions, making them suitable for spacecraft re-entry shields and high-temperature industrial applications.Expand Specific Solutions03 Porous ceramic structures for thermal insulation

Porous ceramic materials are utilized in heat shield applications to provide enhanced thermal insulation properties. The controlled porosity within the ceramic structure creates air pockets that significantly reduce thermal conductivity while maintaining structural integrity. These materials can be engineered with specific pore sizes and distributions to optimize the balance between mechanical strength and thermal insulation performance, making them ideal for applications requiring lightweight yet effective thermal barriers.Expand Specific Solutions04 High-temperature resistant ceramic coatings

Specialized ceramic coating systems are developed to protect underlying structures from extreme temperatures. These coatings typically incorporate zirconia, alumina, or other refractory ceramics with additives to enhance adhesion and thermal cycling resistance. The coatings can be applied through various methods including plasma spraying, chemical vapor deposition, or sol-gel processes, creating a protective layer that reflects and dissipates heat while preventing oxidation of the substrate material.Expand Specific Solutions05 Ceramic heat shield attachment and integration systems

Advanced methods for attaching and integrating ceramic heat shields to underlying structures are critical for maintaining thermal protection system integrity. These systems often incorporate flexible mounting mechanisms to accommodate thermal expansion differences between ceramics and metal substrates. Specialized joining techniques, including mechanical fastening, brazing, and adhesive bonding with strain isolation features, ensure that the ceramic components remain securely attached while allowing for thermal movement, preventing cracking and delamination during thermal cycling.Expand Specific Solutions

Leading Organizations in Ceramic Heat Shield Development

The structural ceramics for heat shield applications market is currently in a growth phase, characterized by increasing demand from aerospace, defense, and energy sectors. The global market size is estimated to exceed $5 billion, driven by advancements in hypersonic flight and space exploration. Technologically, the field is advancing rapidly with varying maturity levels across applications. Leading players include Siemens AG and Siemens Energy, focusing on industrial applications; Boeing and NASA developing aerospace solutions; and Chinese institutions like Wuhan University of Technology and Huazhong University pioneering research. Academic-industrial partnerships are accelerating innovation, with specialized companies like Hongjiu Aviation Thermal Materials and ElringKlinger AG commercializing advanced ceramic composites that offer superior thermal protection while maintaining structural integrity under extreme conditions.

The Boeing Co.

Technical Solution: Boeing has developed proprietary ceramic matrix composite (CMC) heat shield systems for aerospace applications, focusing on silicon carbide (SiC) fiber reinforced ceramic matrices. Their advanced manufacturing process involves chemical vapor infiltration (CVI) combined with polymer infiltration and pyrolysis (PIP) to create dense, high-strength ceramic structures with tailored porosity gradients. Boeing's heat shield technology incorporates multi-layered ceramic designs with functionally graded materials (FGMs) that provide optimal thermal resistance while minimizing weight. Their BSIC (Boeing Silicon-carbide Integrated Composite) system utilizes a unique fiber architecture that enhances fracture toughness while maintaining thermal stability at temperatures up to 1400°C. Boeing has also pioneered self-healing ceramic composites that can repair microcracks during thermal cycling through the incorporation of specialized healing agents within the ceramic matrix, significantly extending operational lifetimes in extreme thermal environments.

Strengths: Extensive integration experience with complex aerospace systems; advanced manufacturing capabilities for large-scale ceramic components; comprehensive testing infrastructure. Weaknesses: Higher production costs compared to traditional materials; longer manufacturing cycle times; some specialized compositions require rare or strategic materials with supply chain vulnerabilities.

Rolls-Royce Corp.

Technical Solution: Rolls-Royce has developed advanced ceramic matrix composites (CMCs) specifically engineered for extreme thermal environments in aerospace and power generation applications. Their proprietary ceramic systems utilize silicon carbide (SiC) fibers in a modified alumina matrix with zirconia stabilizers, creating heat shields capable of withstanding temperatures exceeding 1300°C while maintaining structural integrity. Rolls-Royce's manufacturing process employs a unique slurry infiltration technique combined with controlled sintering to achieve precise microstructural control. Their ceramic heat shields incorporate innovative cooling channel architectures that maximize thermal gradient management while minimizing mass. Recent innovations include their "CeraTough" technology, which introduces controlled microcracking mechanisms that enhance thermal shock resistance by up to 40% compared to conventional ceramics. Rolls-Royce has also pioneered hybrid ceramic systems that combine the thermal resistance of ceramics with the damage tolerance of metallic substrates through specialized bonding techniques that accommodate differential thermal expansion.

Strengths: Exceptional expertise in high-temperature applications for turbine engines; sophisticated thermal modeling capabilities; established production infrastructure for complex ceramic components. Weaknesses: Higher manufacturing costs compared to traditional materials; longer production lead times; some compositions have limited repairability in field conditions.

Breakthrough Patents in Structural Ceramic Heat Shields

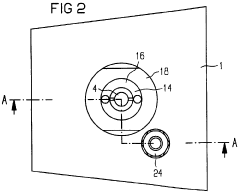

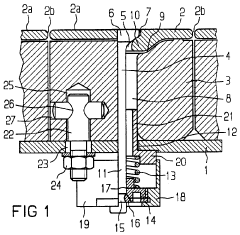

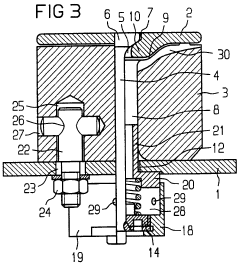

Heat-shield arrangement, especially for structural components of gas turbine plants

PatentWO1997047925A1

Innovation

- A heat shield arrangement with a layered structure featuring erosion- and corrosion-resistant heat shield elements made of structural ceramics, such as silicon carbide or silicon nitride, and thermal insulation between elements, allowing for separate material selection for protection and insulation, reducing coolant consumption, and minimizing nitrogen oxide emissions by operating closer to the ideal air ratio.

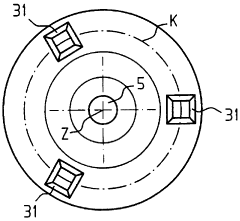

Heat shield element, method for manufacturing the same, heat shield and combustor

PatentInactiveEP1666797A1

Innovation

- Designing heat shield elements with material areas having different thermal expansion coefficients, where areas exposed to high temperatures have lower coefficients and those exposed to low temperatures have higher coefficients, and using a method to adjust these coefficients during production, such as changing base material mixtures or post-treating regions, to minimize stress and ensure smooth transitions.

Environmental Impact and Sustainability of Ceramic Materials

The environmental impact of ceramic materials used in heat shield applications has become increasingly important as industries strive for sustainability alongside performance. Traditional ceramic manufacturing processes are energy-intensive, requiring high-temperature kilns that consume substantial fossil fuels and generate significant carbon emissions. Recent life cycle assessments indicate that the production of advanced structural ceramics can generate between 5-15 kg CO2 equivalent per kilogram of material, depending on manufacturing methods and energy sources.

However, innovations in manufacturing technologies are progressively reducing this environmental footprint. Low-temperature synthesis routes, microwave-assisted sintering, and spark plasma sintering techniques have demonstrated energy savings of up to 60% compared to conventional methods. These approaches not only reduce carbon emissions but also minimize the release of harmful particulates and nitrogen oxides associated with high-temperature processing.

Raw material sourcing presents another critical environmental consideration. Many advanced ceramics require rare earth elements and specialized minerals that involve environmentally destructive mining practices. The development of alternative formulations using more abundant materials represents a promising direction for sustainability improvement. Research into biogenic silica sources from agricultural waste, for example, has shown potential for creating eco-friendly ceramic precursors with reduced mining impact.

The durability and longevity of ceramic heat shields contribute positively to their sustainability profile. With service lifespans often exceeding 20 years in aerospace applications, ceramic heat shields significantly outperform metallic alternatives that may require frequent replacement. This extended operational life translates to reduced material consumption and waste generation over time, partially offsetting the initial environmental costs of production.

End-of-life considerations for ceramic materials have historically been problematic due to their chemical stability and resistance to degradation. However, recent advances in ceramic recycling technologies have shown promise. Mechanical processing of used ceramics can produce valuable secondary materials for construction applications, while chemical recovery methods are being developed to reclaim rare elements from specialized compositions, creating a more circular material economy.

Water usage in ceramic processing represents another environmental challenge, with traditional wet processing methods consuming 5-10 liters of water per kilogram of ceramic produced. Dry processing techniques and closed-loop water systems are increasingly being implemented, reducing freshwater consumption by up to 80% in modern manufacturing facilities while simultaneously preventing the discharge of contaminated effluents into natural water systems.

However, innovations in manufacturing technologies are progressively reducing this environmental footprint. Low-temperature synthesis routes, microwave-assisted sintering, and spark plasma sintering techniques have demonstrated energy savings of up to 60% compared to conventional methods. These approaches not only reduce carbon emissions but also minimize the release of harmful particulates and nitrogen oxides associated with high-temperature processing.

Raw material sourcing presents another critical environmental consideration. Many advanced ceramics require rare earth elements and specialized minerals that involve environmentally destructive mining practices. The development of alternative formulations using more abundant materials represents a promising direction for sustainability improvement. Research into biogenic silica sources from agricultural waste, for example, has shown potential for creating eco-friendly ceramic precursors with reduced mining impact.

The durability and longevity of ceramic heat shields contribute positively to their sustainability profile. With service lifespans often exceeding 20 years in aerospace applications, ceramic heat shields significantly outperform metallic alternatives that may require frequent replacement. This extended operational life translates to reduced material consumption and waste generation over time, partially offsetting the initial environmental costs of production.

End-of-life considerations for ceramic materials have historically been problematic due to their chemical stability and resistance to degradation. However, recent advances in ceramic recycling technologies have shown promise. Mechanical processing of used ceramics can produce valuable secondary materials for construction applications, while chemical recovery methods are being developed to reclaim rare elements from specialized compositions, creating a more circular material economy.

Water usage in ceramic processing represents another environmental challenge, with traditional wet processing methods consuming 5-10 liters of water per kilogram of ceramic produced. Dry processing techniques and closed-loop water systems are increasingly being implemented, reducing freshwater consumption by up to 80% in modern manufacturing facilities while simultaneously preventing the discharge of contaminated effluents into natural water systems.

Manufacturing Processes and Scalability Challenges

The manufacturing of advanced structural ceramics for heat shield applications presents unique challenges that must be addressed to enable widespread adoption. Traditional ceramic processing methods such as slip casting, tape casting, and dry pressing have been adapted for heat shield ceramics, but often struggle with the complex geometries and precise microstructural control required for optimal thermal protection systems.

Additive manufacturing has emerged as a promising approach, with techniques like robocasting, stereolithography, and selective laser sintering enabling the production of complex ceramic components with tailored porosity gradients. These methods allow for the creation of optimized thermal barrier structures that would be impossible to produce using conventional techniques. However, challenges remain in achieving consistent material properties throughout the printed structure and managing post-processing shrinkage.

Sintering represents a critical step in ceramic heat shield manufacturing, with the need to balance densification against the preservation of engineered porosity. Advanced sintering techniques such as spark plasma sintering and microwave sintering have demonstrated potential for reducing processing times while maintaining microstructural control. These methods can produce ceramics with superior thermal shock resistance by creating controlled grain boundaries and defect structures.

Scalability remains a significant hurdle for next-generation ceramic heat shields. Laboratory-scale innovations often face difficulties in transitioning to industrial production volumes. Key challenges include maintaining quality consistency across larger components, reducing cycle times, and managing the high energy costs associated with high-temperature processing. The development of continuous manufacturing processes, rather than batch operations, represents a promising direction for cost-effective scaling.

Quality control methodologies have evolved to address the stringent requirements of aerospace and defense applications. Non-destructive testing techniques including ultrasonic inspection, X-ray computed tomography, and infrared thermography have been adapted specifically for ceramic heat shield components. These methods enable the detection of critical defects such as delaminations, cracks, and porosity variations that could compromise performance under extreme conditions.

Cost considerations continue to drive manufacturing innovation, with efforts focused on reducing energy consumption, minimizing material waste, and shortening production cycles. The integration of computational modeling with manufacturing processes has enabled process optimization, reducing the need for costly trial-and-error approaches. Additionally, the development of near-net-shape forming techniques has significantly reduced machining requirements for complex geometries, further improving economic viability.

Additive manufacturing has emerged as a promising approach, with techniques like robocasting, stereolithography, and selective laser sintering enabling the production of complex ceramic components with tailored porosity gradients. These methods allow for the creation of optimized thermal barrier structures that would be impossible to produce using conventional techniques. However, challenges remain in achieving consistent material properties throughout the printed structure and managing post-processing shrinkage.

Sintering represents a critical step in ceramic heat shield manufacturing, with the need to balance densification against the preservation of engineered porosity. Advanced sintering techniques such as spark plasma sintering and microwave sintering have demonstrated potential for reducing processing times while maintaining microstructural control. These methods can produce ceramics with superior thermal shock resistance by creating controlled grain boundaries and defect structures.

Scalability remains a significant hurdle for next-generation ceramic heat shields. Laboratory-scale innovations often face difficulties in transitioning to industrial production volumes. Key challenges include maintaining quality consistency across larger components, reducing cycle times, and managing the high energy costs associated with high-temperature processing. The development of continuous manufacturing processes, rather than batch operations, represents a promising direction for cost-effective scaling.

Quality control methodologies have evolved to address the stringent requirements of aerospace and defense applications. Non-destructive testing techniques including ultrasonic inspection, X-ray computed tomography, and infrared thermography have been adapted specifically for ceramic heat shield components. These methods enable the detection of critical defects such as delaminations, cracks, and porosity variations that could compromise performance under extreme conditions.

Cost considerations continue to drive manufacturing innovation, with efforts focused on reducing energy consumption, minimizing material waste, and shortening production cycles. The integration of computational modeling with manufacturing processes has enabled process optimization, reducing the need for costly trial-and-error approaches. Additionally, the development of near-net-shape forming techniques has significantly reduced machining requirements for complex geometries, further improving economic viability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!