Research on Structural Ceramics' Radiation Shielding Capabilities

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Radiation Shielding Ceramics Background and Objectives

Structural ceramics have emerged as a significant area of interest in radiation shielding applications over the past several decades. The evolution of this technology can be traced back to the mid-20th century when the nuclear industry began expanding rapidly, creating an urgent need for effective radiation protection materials. Initially, conventional materials such as lead and concrete dominated the field, but their limitations in extreme environments prompted researchers to explore alternative solutions.

The development trajectory of radiation shielding ceramics has been characterized by continuous innovation, moving from basic oxide ceramics to more sophisticated compositions with enhanced properties. Early research focused primarily on aluminum oxide and zirconium oxide systems, while recent advances have expanded to include boron carbide, silicon carbide, and various composite ceramic materials specifically engineered for radiation environments.

Current technological trends indicate a shift toward multifunctional ceramic materials that can simultaneously provide structural integrity, thermal stability, and radiation attenuation. This evolution is driven by increasing demands from nuclear power generation, space exploration, medical imaging, and defense applications, where materials must perform reliably under extreme conditions.

The primary objective of research in structural ceramics' radiation shielding capabilities is to develop materials that effectively attenuate various forms of radiation—including gamma rays, neutrons, and charged particles—while maintaining mechanical strength and thermal stability. Specific goals include increasing the radiation absorption efficiency per unit weight, enhancing resistance to radiation-induced degradation, and improving manufacturing processes to reduce costs and increase scalability.

Another critical aim is to understand the fundamental mechanisms of radiation interaction with ceramic microstructures, enabling the design of tailored materials with optimized performance for specific radiation environments. This includes investigating how compositional variations and microstructural features influence shielding effectiveness and long-term stability under radiation exposure.

The research also seeks to establish standardized testing methodologies and performance metrics for radiation shielding ceramics, facilitating meaningful comparisons between different materials and accelerating their adoption in practical applications. This standardization effort extends to modeling and simulation tools that can predict material behavior under various radiation conditions, reducing the need for extensive experimental testing.

Looking forward, the field aims to bridge the gap between laboratory research and industrial implementation by addressing challenges related to large-scale production, quality control, and system integration. The ultimate goal is to create ceramic-based radiation shielding solutions that outperform traditional materials across multiple performance parameters while remaining economically viable for widespread deployment.

The development trajectory of radiation shielding ceramics has been characterized by continuous innovation, moving from basic oxide ceramics to more sophisticated compositions with enhanced properties. Early research focused primarily on aluminum oxide and zirconium oxide systems, while recent advances have expanded to include boron carbide, silicon carbide, and various composite ceramic materials specifically engineered for radiation environments.

Current technological trends indicate a shift toward multifunctional ceramic materials that can simultaneously provide structural integrity, thermal stability, and radiation attenuation. This evolution is driven by increasing demands from nuclear power generation, space exploration, medical imaging, and defense applications, where materials must perform reliably under extreme conditions.

The primary objective of research in structural ceramics' radiation shielding capabilities is to develop materials that effectively attenuate various forms of radiation—including gamma rays, neutrons, and charged particles—while maintaining mechanical strength and thermal stability. Specific goals include increasing the radiation absorption efficiency per unit weight, enhancing resistance to radiation-induced degradation, and improving manufacturing processes to reduce costs and increase scalability.

Another critical aim is to understand the fundamental mechanisms of radiation interaction with ceramic microstructures, enabling the design of tailored materials with optimized performance for specific radiation environments. This includes investigating how compositional variations and microstructural features influence shielding effectiveness and long-term stability under radiation exposure.

The research also seeks to establish standardized testing methodologies and performance metrics for radiation shielding ceramics, facilitating meaningful comparisons between different materials and accelerating their adoption in practical applications. This standardization effort extends to modeling and simulation tools that can predict material behavior under various radiation conditions, reducing the need for extensive experimental testing.

Looking forward, the field aims to bridge the gap between laboratory research and industrial implementation by addressing challenges related to large-scale production, quality control, and system integration. The ultimate goal is to create ceramic-based radiation shielding solutions that outperform traditional materials across multiple performance parameters while remaining economically viable for widespread deployment.

Market Analysis for Radiation-Resistant Structural Ceramics

The global market for radiation-resistant structural ceramics is experiencing significant growth, driven by expanding applications in nuclear power, aerospace, medical equipment, and defense sectors. Current market valuation stands at approximately 3.2 billion USD with projections indicating a compound annual growth rate of 6.8% through 2030, substantially outpacing traditional construction materials.

Nuclear energy represents the largest market segment, accounting for roughly 42% of demand. With over 440 operational nuclear reactors worldwide and 50+ new facilities under construction, the need for advanced radiation shielding materials continues to expand. China, Russia, and India lead in new reactor development, creating substantial regional demand centers.

Healthcare applications constitute the fastest-growing segment at 9.3% annual growth. The proliferation of advanced radiotherapy equipment, diagnostic imaging systems, and radiopharmaceutical production facilities drives demand for specialized ceramic shielding solutions that offer superior performance compared to traditional lead-based alternatives.

Aerospace and defense applications represent approximately 18% of the market. As satellite deployment accelerates and space exploration missions increase, the demand for lightweight yet effective radiation shielding materials grows proportionally. Military applications, particularly in naval nuclear propulsion and tactical equipment protection, further bolster market expansion.

Geographically, North America currently dominates with 36% market share, followed by Europe (28%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the highest growth trajectory, expected to capture over 30% of the global market by 2028 due to aggressive nuclear power development and healthcare infrastructure expansion.

Customer requirements are evolving toward multi-functional ceramics that combine radiation shielding with structural integrity, thermal resistance, and reduced weight. This trend creates premium market segments where advanced ceramic composites command price premiums of 30-50% over conventional shielding materials.

Supply chain considerations significantly impact market dynamics. Critical raw materials for advanced ceramics, including rare earth elements and specialized boron compounds, face supply constraints. Countries with established ceramic manufacturing capabilities like Japan, Germany, and the United States maintain competitive advantages, though China is rapidly developing domestic production capacity.

Regulatory frameworks heavily influence market adoption patterns. Stringent safety standards in nuclear and medical applications create high barriers to entry but also establish stable demand for certified materials. Recent regulatory shifts toward replacing toxic shielding materials (particularly lead) with environmentally sustainable alternatives further accelerate ceramic adoption in multiple sectors.

Nuclear energy represents the largest market segment, accounting for roughly 42% of demand. With over 440 operational nuclear reactors worldwide and 50+ new facilities under construction, the need for advanced radiation shielding materials continues to expand. China, Russia, and India lead in new reactor development, creating substantial regional demand centers.

Healthcare applications constitute the fastest-growing segment at 9.3% annual growth. The proliferation of advanced radiotherapy equipment, diagnostic imaging systems, and radiopharmaceutical production facilities drives demand for specialized ceramic shielding solutions that offer superior performance compared to traditional lead-based alternatives.

Aerospace and defense applications represent approximately 18% of the market. As satellite deployment accelerates and space exploration missions increase, the demand for lightweight yet effective radiation shielding materials grows proportionally. Military applications, particularly in naval nuclear propulsion and tactical equipment protection, further bolster market expansion.

Geographically, North America currently dominates with 36% market share, followed by Europe (28%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the highest growth trajectory, expected to capture over 30% of the global market by 2028 due to aggressive nuclear power development and healthcare infrastructure expansion.

Customer requirements are evolving toward multi-functional ceramics that combine radiation shielding with structural integrity, thermal resistance, and reduced weight. This trend creates premium market segments where advanced ceramic composites command price premiums of 30-50% over conventional shielding materials.

Supply chain considerations significantly impact market dynamics. Critical raw materials for advanced ceramics, including rare earth elements and specialized boron compounds, face supply constraints. Countries with established ceramic manufacturing capabilities like Japan, Germany, and the United States maintain competitive advantages, though China is rapidly developing domestic production capacity.

Regulatory frameworks heavily influence market adoption patterns. Stringent safety standards in nuclear and medical applications create high barriers to entry but also establish stable demand for certified materials. Recent regulatory shifts toward replacing toxic shielding materials (particularly lead) with environmentally sustainable alternatives further accelerate ceramic adoption in multiple sectors.

Current Status and Technical Barriers in Ceramic Shielding

The global landscape of ceramic radiation shielding technology has witnessed significant advancements in recent years, with structural ceramics emerging as promising materials for radiation protection applications. Currently, boron carbide (B4C), silicon carbide (SiC), and alumina (Al2O3) represent the most widely utilized ceramic materials for radiation shielding. These materials have demonstrated exceptional capabilities in neutron absorption and gamma ray attenuation, particularly in nuclear power plants, space applications, and medical facilities.

Despite these advancements, the field faces several critical technical challenges. The inherent brittleness of ceramic materials remains a significant limitation, as it compromises structural integrity under mechanical stress and impact scenarios. This characteristic restricts their application in environments requiring both radiation protection and mechanical resilience. Additionally, the manufacturing processes for high-performance ceramic shields involve complex sintering techniques that often result in microstructural defects, compromising their shielding effectiveness.

The geographical distribution of ceramic shielding technology development shows concentration in countries with advanced nuclear programs. The United States, Japan, Russia, France, and increasingly China lead research efforts, with specialized research institutions focusing on overcoming current limitations. This concentration creates disparities in access to advanced shielding solutions globally.

A persistent technical barrier involves the trade-off between density and weight. While higher density ceramics typically offer superior radiation attenuation properties, they simultaneously increase the overall weight of shielding systems, creating design challenges for applications with strict weight constraints, such as aerospace systems and portable medical equipment.

The integration of ceramic shields with other structural components presents another significant challenge. Current joining techniques often create weak interfaces that can compromise both structural integrity and shielding continuity. Research into novel bonding methods and composite structures is ongoing but has yet to yield fully satisfactory solutions for all application scenarios.

Cost factors also present substantial barriers to widespread adoption. The complex manufacturing processes, specialized equipment requirements, and high-purity raw materials contribute to elevated production costs. This economic constraint limits the application of advanced ceramic shields primarily to high-value sectors where performance requirements justify the increased expenditure.

Recent research has begun addressing these challenges through innovative approaches, including the development of ceramic-matrix composites (CMCs) that incorporate secondary phases to enhance toughness while maintaining shielding properties. Additionally, additive manufacturing techniques are being explored to create geometrically optimized structures that maximize shielding effectiveness while minimizing material usage.

Despite these advancements, the field faces several critical technical challenges. The inherent brittleness of ceramic materials remains a significant limitation, as it compromises structural integrity under mechanical stress and impact scenarios. This characteristic restricts their application in environments requiring both radiation protection and mechanical resilience. Additionally, the manufacturing processes for high-performance ceramic shields involve complex sintering techniques that often result in microstructural defects, compromising their shielding effectiveness.

The geographical distribution of ceramic shielding technology development shows concentration in countries with advanced nuclear programs. The United States, Japan, Russia, France, and increasingly China lead research efforts, with specialized research institutions focusing on overcoming current limitations. This concentration creates disparities in access to advanced shielding solutions globally.

A persistent technical barrier involves the trade-off between density and weight. While higher density ceramics typically offer superior radiation attenuation properties, they simultaneously increase the overall weight of shielding systems, creating design challenges for applications with strict weight constraints, such as aerospace systems and portable medical equipment.

The integration of ceramic shields with other structural components presents another significant challenge. Current joining techniques often create weak interfaces that can compromise both structural integrity and shielding continuity. Research into novel bonding methods and composite structures is ongoing but has yet to yield fully satisfactory solutions for all application scenarios.

Cost factors also present substantial barriers to widespread adoption. The complex manufacturing processes, specialized equipment requirements, and high-purity raw materials contribute to elevated production costs. This economic constraint limits the application of advanced ceramic shields primarily to high-value sectors where performance requirements justify the increased expenditure.

Recent research has begun addressing these challenges through innovative approaches, including the development of ceramic-matrix composites (CMCs) that incorporate secondary phases to enhance toughness while maintaining shielding properties. Additionally, additive manufacturing techniques are being explored to create geometrically optimized structures that maximize shielding effectiveness while minimizing material usage.

Contemporary Ceramic Shielding Solutions and Implementations

01 Boron-containing ceramic composites for radiation shielding

Boron-containing ceramic composites are effective for radiation shielding due to boron's high neutron absorption capability. These materials combine boron compounds with ceramic matrices to create lightweight yet durable shields that can attenuate various forms of radiation. The incorporation of boron carbide, boron nitride, or other boron-rich compounds enhances the neutron capture properties while maintaining structural integrity under radiation exposure.- Boron-containing ceramic composites for radiation shielding: Ceramic composites containing boron compounds are effective for radiation shielding, particularly against neutron radiation. These materials combine boron's excellent neutron absorption properties with the structural integrity of ceramics. The composites can be formulated with varying concentrations of boron to optimize shielding effectiveness while maintaining mechanical strength. These materials are particularly useful in nuclear facilities, spacecraft, and medical applications where radiation protection is critical.

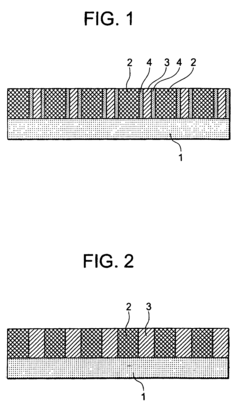

- Multi-layered ceramic structures for enhanced radiation protection: Multi-layered ceramic structures provide superior radiation shielding by combining different materials that can attenuate various types of radiation. These structures typically consist of layers designed to block specific radiation types - heavy elements for gamma rays, hydrogen-rich materials for neutrons, and specialized ceramics for charged particles. The layered approach allows for optimization of weight, thickness, and shielding effectiveness. These structures can be engineered to meet specific radiation protection requirements while maintaining structural integrity under extreme conditions.

- Metal oxide-doped ceramics for improved radiation attenuation: Ceramics doped with metal oxides demonstrate enhanced radiation shielding capabilities. Heavy metal oxides such as lead oxide, bismuth oxide, and tungsten oxide incorporated into ceramic matrices can significantly improve gamma radiation attenuation. These materials combine the structural advantages of ceramics with the high atomic number elements' ability to block radiation. The concentration and distribution of metal oxide dopants can be tailored to achieve specific shielding requirements while maintaining the ceramic's structural properties.

- Rare earth element-incorporated ceramic shields: Ceramics incorporating rare earth elements offer exceptional radiation shielding properties. Elements such as gadolinium, samarium, and europium have high neutron capture cross-sections and can be effectively integrated into ceramic matrices. These materials provide dual functionality - structural support and radiation protection. The rare earth elements can be distributed uniformly throughout the ceramic or concentrated in specific regions to optimize shielding performance. These advanced ceramics are particularly valuable in high-radiation environments where material stability is crucial.

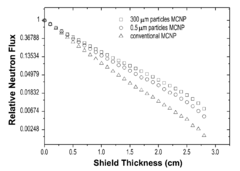

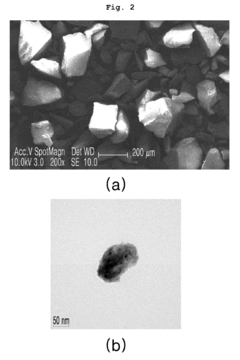

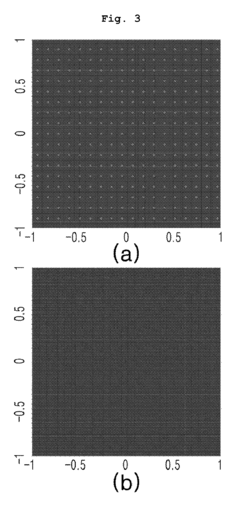

- Nanostructured ceramics for radiation shielding: Nanostructured ceramics represent a cutting-edge approach to radiation shielding. By engineering ceramics at the nanoscale, interfaces and grain boundaries can be optimized to enhance radiation absorption and scattering. These materials can incorporate nanoparticles of high-Z elements or specialized compounds that interact effectively with radiation. The nanostructuring also improves mechanical properties such as fracture toughness while maintaining lightweight characteristics. These advanced ceramics offer superior radiation protection with reduced thickness and weight compared to conventional shielding materials.

02 Multi-layered ceramic structures for enhanced radiation protection

Multi-layered ceramic structures provide comprehensive radiation shielding by combining different ceramic materials with complementary protective properties. These structures typically feature layers designed to attenuate specific types of radiation, such as gamma rays, neutrons, or charged particles. The strategic arrangement of ceramic layers with varying densities and compositions creates an effective barrier against multiple radiation forms while maintaining structural integrity and thermal stability.Expand Specific Solutions03 Metal-ceramic composites for radiation shielding applications

Metal-ceramic composites combine the structural strength of ceramics with the radiation attenuation properties of metals to create effective shielding materials. These composites typically incorporate high-Z elements like tungsten, lead, or bismuth within a ceramic matrix to enhance gamma radiation shielding while maintaining structural integrity. The ceramic component provides thermal stability and mechanical strength, while the metallic elements increase radiation absorption capacity.Expand Specific Solutions04 Rare earth-doped ceramic materials for radiation shielding

Ceramic materials doped with rare earth elements exhibit enhanced radiation shielding capabilities due to the high atomic numbers and electron densities of rare earth elements. These materials can effectively attenuate gamma and X-ray radiation while maintaining structural integrity. The incorporation of elements such as gadolinium, ytterbium, or europium into ceramic matrices creates shielding materials that combine structural strength with superior radiation absorption properties.Expand Specific Solutions05 Nanostructured ceramics for improved radiation resistance

Nanostructured ceramic materials offer improved radiation resistance through their unique microstructural features. The high density of grain boundaries and interfaces in these materials serves as effective sinks for radiation-induced defects, enhancing their ability to withstand prolonged radiation exposure without significant degradation. These advanced ceramics incorporate nanoscale features that trap and recombine point defects, maintaining structural integrity and mechanical properties even under intense radiation conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions Analysis

The structural ceramics radiation shielding market is in a growth phase, driven by increasing applications in nuclear, aerospace, and medical sectors. The market is expected to expand significantly due to rising safety concerns and technological advancements. Leading players include specialized ceramics manufacturers like MTK Co. with their "Rashix" radiation shielding ceramics, alongside diversified industrial ceramics companies such as NGK Insulators, Proterial Ltd., and IBIDEN. Academic institutions including Harbin Institute of Technology, University of Florida, and Sichuan University are advancing research in this field. The technology is reaching maturity with commercial applications emerging, though continued R&D by companies like Corning and JFE Steel is enhancing performance characteristics and expanding potential applications.

Harbin Institute of Technology

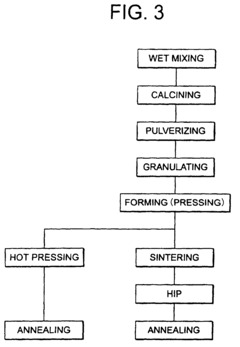

Technical Solution: Harbin Institute of Technology (HIT) has developed advanced boron carbide (B4C) and silicon carbide (SiC) based structural ceramics with enhanced radiation shielding properties. Their research focuses on multi-layered ceramic composites that combine neutron absorption capabilities of boron-rich materials with the gamma radiation attenuation properties of high-density ceramics. HIT has pioneered a novel hot-pressing sintering technique that achieves near-theoretical density (>99%) in these ceramics while maintaining excellent mechanical properties. Their materials demonstrate superior radiation resistance in high-temperature environments (up to 1200°C) with minimal degradation of mechanical properties after exposure to neutron fluences of 10^20 n/cm². Recent developments include SiC-B4C-rare earth oxide composites that provide comprehensive shielding against multiple radiation types while maintaining structural integrity.

Strengths: Exceptional high-temperature performance and mechanical stability after radiation exposure; comprehensive shielding against multiple radiation types. Weakness: Manufacturing process is energy-intensive and costly; potential challenges in scaling production for large structural applications.

NGK Insulators, Ltd.

Technical Solution: NGK Insulators has developed proprietary ceramic materials specifically engineered for radiation shielding in nuclear environments. Their flagship technology involves aluminum oxide (Al2O3) and zirconium oxide (ZrO2) based ceramics with controlled porosity and specialized dopants that enhance radiation absorption while maintaining structural integrity. NGK's manufacturing process employs advanced sintering techniques that create a hierarchical microstructure optimized for both neutron moderation and gamma attenuation. Their ceramics demonstrate less than 5% degradation in mechanical properties after exposure to radiation doses exceeding 10^9 Gy. NGK has successfully implemented these materials in critical components for nuclear power plants, with documented service lifetimes exceeding 40 years under continuous radiation exposure. Recent innovations include self-healing ceramic composites that can recover from radiation-induced microstructural damage through engineered phase transformations.

Strengths: Exceptional long-term stability under radiation exposure; proven track record in nuclear industry applications with documented performance data. Weakness: Higher production costs compared to conventional shielding materials; limited flexibility in complex geometrical applications.

Critical Patents and Research in Ceramic Radiation Protection

Ceramic radiation shield and radiation detector using same

PatentInactiveEP1089091B1

Innovation

- Sintered ceramic radiation shields with a composition of rare-earth and alkaline-earth oxides, along with V, Ta, and Nb oxides, providing high radiation shielding and light reflecting capabilities, are used between scintillators, eliminating the need for separate light reflecting films and improving manufacturing ease.

Radiation shielding members including nano-particles as a radiation shielding material and method for preparing the same

PatentActiveUS8318045B2

Innovation

- A radiation shielding member is created by homogeneously dispersing nano-particles in a polymer or metal matrix, reducing particle size through mechanical pulverization and surface activation, which increases collision probability and reduces mean free path of radiation, thereby enhancing shielding efficiency while minimizing weight and porosity.

Safety Standards and Regulatory Framework for Shielding Materials

The regulatory landscape governing radiation shielding materials is complex and multifaceted, with standards varying across different regions and applications. For structural ceramics used in radiation shielding, compliance with international standards is paramount to ensure safety and effectiveness. The International Atomic Energy Agency (IAEA) provides comprehensive guidelines through its Safety Standards Series, particularly the General Safety Requirements Part 3 (GSR Part 3) which establishes fundamental radiation protection principles.

In the United States, the Nuclear Regulatory Commission (NRC) enforces 10 CFR Part 20, which specifies radiation protection requirements including shielding material performance criteria. These regulations mandate that shielding materials must demonstrate specific attenuation capabilities depending on the radiation type and energy levels. For structural ceramics, ASTM C1275 provides standard test methods for evaluating monotonic tensile behavior of ceramic matrix composites, which is critical when these materials serve dual structural and shielding functions.

The European Union implements radiation protection standards through the Euratom Basic Safety Standards Directive (2013/59/Euratom), which establishes uniform safety requirements across member states. Additionally, ISO 16637:2016 outlines monitoring and internal dosimetry requirements that influence shielding material specifications.

For structural ceramics specifically, material certification processes typically require demonstration of both mechanical integrity and radiation attenuation properties. The International Commission on Radiological Protection (ICRP) recommendations, particularly Publications 103 and 116, inform dose limitation principles that directly impact shielding material requirements. These publications establish the ALARA principle (As Low As Reasonably Achievable), which drives continuous improvement in shielding technology.

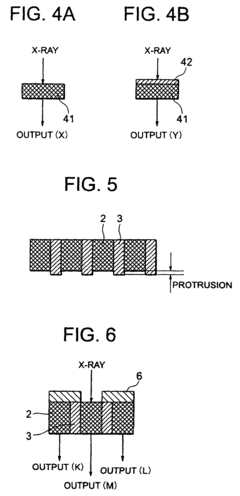

Testing protocols for ceramic radiation shields must adhere to standardized methodologies. IEC 61331 series standards specify test methods for determining protective capabilities against X-radiation, while ASTM E2002 addresses standard test methods for determining neutron attenuation properties. Compliance with these standards requires sophisticated testing facilities and precise measurement techniques.

Regulatory frameworks also address long-term performance considerations. Shielding materials must maintain their protective capabilities throughout their service life, necessitating accelerated aging tests and performance degradation assessments. Standards such as ASTM C1663 provide guidance for assessing radiation effects on ceramic materials, which is essential for predicting long-term shielding effectiveness.

Emerging regulations increasingly focus on multi-hazard protection, requiring shielding materials to provide protection against radiation while maintaining structural integrity during seismic events or fire scenarios. This trend particularly benefits structural ceramics, which often exhibit superior high-temperature stability compared to traditional shielding materials.

In the United States, the Nuclear Regulatory Commission (NRC) enforces 10 CFR Part 20, which specifies radiation protection requirements including shielding material performance criteria. These regulations mandate that shielding materials must demonstrate specific attenuation capabilities depending on the radiation type and energy levels. For structural ceramics, ASTM C1275 provides standard test methods for evaluating monotonic tensile behavior of ceramic matrix composites, which is critical when these materials serve dual structural and shielding functions.

The European Union implements radiation protection standards through the Euratom Basic Safety Standards Directive (2013/59/Euratom), which establishes uniform safety requirements across member states. Additionally, ISO 16637:2016 outlines monitoring and internal dosimetry requirements that influence shielding material specifications.

For structural ceramics specifically, material certification processes typically require demonstration of both mechanical integrity and radiation attenuation properties. The International Commission on Radiological Protection (ICRP) recommendations, particularly Publications 103 and 116, inform dose limitation principles that directly impact shielding material requirements. These publications establish the ALARA principle (As Low As Reasonably Achievable), which drives continuous improvement in shielding technology.

Testing protocols for ceramic radiation shields must adhere to standardized methodologies. IEC 61331 series standards specify test methods for determining protective capabilities against X-radiation, while ASTM E2002 addresses standard test methods for determining neutron attenuation properties. Compliance with these standards requires sophisticated testing facilities and precise measurement techniques.

Regulatory frameworks also address long-term performance considerations. Shielding materials must maintain their protective capabilities throughout their service life, necessitating accelerated aging tests and performance degradation assessments. Standards such as ASTM C1663 provide guidance for assessing radiation effects on ceramic materials, which is essential for predicting long-term shielding effectiveness.

Emerging regulations increasingly focus on multi-hazard protection, requiring shielding materials to provide protection against radiation while maintaining structural integrity during seismic events or fire scenarios. This trend particularly benefits structural ceramics, which often exhibit superior high-temperature stability compared to traditional shielding materials.

Environmental Impact and Lifecycle Assessment of Shielding Ceramics

The environmental footprint of radiation shielding ceramics represents a critical consideration in their development and deployment. Traditional shielding materials like lead and concrete pose significant environmental challenges throughout their lifecycle, making structural ceramics an increasingly attractive alternative from a sustainability perspective.

Manufacturing processes for structural ceramics with radiation shielding capabilities typically require high-temperature firing (1400-1700°C), resulting in substantial energy consumption and associated carbon emissions. However, recent advancements in sintering technologies, particularly microwave and spark plasma sintering, have demonstrated energy reductions of 30-40% compared to conventional methods, significantly lowering the carbon footprint of production.

Raw material extraction for shielding ceramics presents varying environmental impacts depending on composition. Boron-based ceramics require mining operations that can disturb ecosystems, while rare earth element incorporation may involve environmentally intensive extraction processes. Conversely, ceramics utilizing industrial byproducts or waste materials as radiation-absorbing fillers represent a circular economy approach that reduces overall environmental burden.

Water consumption during ceramic processing remains a concern, with traditional wet processing methods requiring 2-5 liters per kilogram of finished product. Dry processing alternatives have emerged, reducing water requirements by up to 80%, though often with trade-offs in material homogeneity that can affect shielding performance.

The durability of structural ceramics offers significant lifecycle advantages. With service lifespans typically exceeding 50 years without degradation of shielding properties, these materials require less frequent replacement than alternatives, reducing cumulative environmental impact. Their chemical stability also minimizes leaching concerns in various environmental conditions, addressing a major drawback of lead-based shields.

End-of-life considerations reveal further environmental benefits. Unlike lead shields requiring specialized disposal protocols, many ceramic compositions are non-toxic and can be safely landfilled. Research indicates that approximately 60-70% of radiation shielding ceramics can potentially be recycled into new ceramic products or as aggregates in construction materials, though specialized recycling infrastructure remains limited.

Lifecycle assessment studies comparing borosilicate ceramic shields to lead alternatives have demonstrated 40-60% reductions in global warming potential when accounting for full lifecycle impacts. However, these benefits must be balanced against potentially higher impacts in categories such as resource depletion, particularly when rare earth elements are incorporated into ceramic formulations.

Manufacturing processes for structural ceramics with radiation shielding capabilities typically require high-temperature firing (1400-1700°C), resulting in substantial energy consumption and associated carbon emissions. However, recent advancements in sintering technologies, particularly microwave and spark plasma sintering, have demonstrated energy reductions of 30-40% compared to conventional methods, significantly lowering the carbon footprint of production.

Raw material extraction for shielding ceramics presents varying environmental impacts depending on composition. Boron-based ceramics require mining operations that can disturb ecosystems, while rare earth element incorporation may involve environmentally intensive extraction processes. Conversely, ceramics utilizing industrial byproducts or waste materials as radiation-absorbing fillers represent a circular economy approach that reduces overall environmental burden.

Water consumption during ceramic processing remains a concern, with traditional wet processing methods requiring 2-5 liters per kilogram of finished product. Dry processing alternatives have emerged, reducing water requirements by up to 80%, though often with trade-offs in material homogeneity that can affect shielding performance.

The durability of structural ceramics offers significant lifecycle advantages. With service lifespans typically exceeding 50 years without degradation of shielding properties, these materials require less frequent replacement than alternatives, reducing cumulative environmental impact. Their chemical stability also minimizes leaching concerns in various environmental conditions, addressing a major drawback of lead-based shields.

End-of-life considerations reveal further environmental benefits. Unlike lead shields requiring specialized disposal protocols, many ceramic compositions are non-toxic and can be safely landfilled. Research indicates that approximately 60-70% of radiation shielding ceramics can potentially be recycled into new ceramic products or as aggregates in construction materials, though specialized recycling infrastructure remains limited.

Lifecycle assessment studies comparing borosilicate ceramic shields to lead alternatives have demonstrated 40-60% reductions in global warming potential when accounting for full lifecycle impacts. However, these benefits must be balanced against potentially higher impacts in categories such as resource depletion, particularly when rare earth elements are incorporated into ceramic formulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!