The Role of Structural Ceramics in High-Frequency Communication Systems

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Structural Ceramics Evolution and Communication Goals

Structural ceramics have undergone significant evolution since their initial development in the mid-20th century. Originally utilized primarily for their mechanical properties in high-temperature applications, these materials have transformed into critical components for modern communication systems. The progression from traditional ceramics to advanced structural ceramics has been marked by continuous improvements in material composition, processing techniques, and performance characteristics, enabling their integration into increasingly sophisticated communication technologies.

The development of structural ceramics for communication applications accelerated in the 1980s with the emergence of wireless technologies. During this period, researchers focused on enhancing dielectric properties, thermal stability, and mechanical strength to meet the demands of emerging communication systems. The introduction of advanced ceramic processing methods, including hot isostatic pressing and chemical vapor deposition, facilitated the production of ceramics with precisely controlled microstructures and properties tailored for specific communication applications.

In the context of high-frequency communication systems, structural ceramics serve multiple critical functions. They provide mechanical support for sensitive electronic components while simultaneously offering excellent electrical insulation and thermal management capabilities. As communication frequencies have increased from megahertz to gigahertz ranges, the role of structural ceramics has expanded to include electromagnetic wave management, signal filtering, and antenna substrate applications.

The primary technical goal for structural ceramics in modern communication systems is to achieve optimal balance between dielectric properties, thermal stability, and mechanical reliability. Specifically, low dielectric loss, consistent performance across wide temperature ranges, and resistance to environmental degradation are essential characteristics. Additionally, as 5G and future 6G technologies push operating frequencies into millimeter-wave bands, structural ceramics must maintain their performance at frequencies exceeding 30 GHz while accommodating miniaturization trends.

Another crucial objective is the development of ceramic materials and composites that can be integrated into complex, multi-functional communication devices through cost-effective manufacturing processes. This includes addressing challenges related to ceramic-metal interfaces, hermetic sealing, and dimensional precision at microscale levels. The ability to produce ceramics with tailored properties through precise control of composition and microstructure remains a key focus area for researchers and manufacturers.

Looking forward, the evolution of structural ceramics aims to support emerging communication paradigms such as Internet of Things (IoT), autonomous vehicles, and space-based communication networks. These applications demand ceramics with enhanced functionality, including self-diagnostic capabilities, adaptable properties, and improved sustainability profiles. The convergence of structural ceramics with other advanced materials, such as metamaterials and 2D materials, represents a promising direction for achieving these ambitious communication goals.

The development of structural ceramics for communication applications accelerated in the 1980s with the emergence of wireless technologies. During this period, researchers focused on enhancing dielectric properties, thermal stability, and mechanical strength to meet the demands of emerging communication systems. The introduction of advanced ceramic processing methods, including hot isostatic pressing and chemical vapor deposition, facilitated the production of ceramics with precisely controlled microstructures and properties tailored for specific communication applications.

In the context of high-frequency communication systems, structural ceramics serve multiple critical functions. They provide mechanical support for sensitive electronic components while simultaneously offering excellent electrical insulation and thermal management capabilities. As communication frequencies have increased from megahertz to gigahertz ranges, the role of structural ceramics has expanded to include electromagnetic wave management, signal filtering, and antenna substrate applications.

The primary technical goal for structural ceramics in modern communication systems is to achieve optimal balance between dielectric properties, thermal stability, and mechanical reliability. Specifically, low dielectric loss, consistent performance across wide temperature ranges, and resistance to environmental degradation are essential characteristics. Additionally, as 5G and future 6G technologies push operating frequencies into millimeter-wave bands, structural ceramics must maintain their performance at frequencies exceeding 30 GHz while accommodating miniaturization trends.

Another crucial objective is the development of ceramic materials and composites that can be integrated into complex, multi-functional communication devices through cost-effective manufacturing processes. This includes addressing challenges related to ceramic-metal interfaces, hermetic sealing, and dimensional precision at microscale levels. The ability to produce ceramics with tailored properties through precise control of composition and microstructure remains a key focus area for researchers and manufacturers.

Looking forward, the evolution of structural ceramics aims to support emerging communication paradigms such as Internet of Things (IoT), autonomous vehicles, and space-based communication networks. These applications demand ceramics with enhanced functionality, including self-diagnostic capabilities, adaptable properties, and improved sustainability profiles. The convergence of structural ceramics with other advanced materials, such as metamaterials and 2D materials, represents a promising direction for achieving these ambitious communication goals.

High-Frequency Market Demand Analysis

The high-frequency communication market has experienced unprecedented growth in recent years, primarily driven by the rapid expansion of 5G networks, satellite communications, and advanced radar systems. According to industry reports, the global high-frequency communication systems market reached $76.2 billion in 2022 and is projected to grow at a CAGR of 17.3% through 2028, potentially reaching $196.5 billion by the end of the forecast period.

The demand for structural ceramics in this sector stems from their exceptional properties that address critical performance requirements in high-frequency applications. These materials offer superior dielectric properties, thermal stability, and mechanical strength that conventional materials cannot match at frequencies above 24 GHz, which are increasingly common in modern communication systems.

Market segmentation reveals that defense and aerospace sectors currently represent the largest application areas for structural ceramics in high-frequency systems, accounting for approximately 42% of the total market. However, commercial telecommunications is rapidly catching up, with its market share growing from 28% in 2020 to 36% in 2022, reflecting the accelerating deployment of mmWave 5G infrastructure worldwide.

Geographically, North America leads the market with a 38% share, followed by Asia-Pacific at 34%, which is experiencing the fastest growth rate due to massive infrastructure investments in China, South Korea, and Japan. European markets contribute about 22% of global demand, with particular strength in specialized defense and scientific applications.

The industry is witnessing a significant shift toward higher frequency bands (above 30 GHz) for both terrestrial and satellite communications, creating new technical challenges that structural ceramics are uniquely positioned to address. This trend is expected to intensify with the development of 6G technologies, which may operate at frequencies up to 300 GHz, further expanding the market for advanced ceramic components.

Customer requirements are evolving rapidly, with increasing emphasis on miniaturization, multi-functionality, and cost-effectiveness. System designers are seeking ceramic solutions that can integrate multiple functions (filtering, antenna elements, packaging) while maintaining performance in increasingly compact form factors. This has led to growing demand for complex-shaped ceramic components with precisely engineered electromagnetic properties.

The market also shows strong interest in ceramic-metal composites and ceramic-polymer systems that can offer tailored performance characteristics while addressing manufacturing and integration challenges. These hybrid materials are expected to represent a significant growth segment, with projected annual growth rates exceeding 20% through 2027.

The demand for structural ceramics in this sector stems from their exceptional properties that address critical performance requirements in high-frequency applications. These materials offer superior dielectric properties, thermal stability, and mechanical strength that conventional materials cannot match at frequencies above 24 GHz, which are increasingly common in modern communication systems.

Market segmentation reveals that defense and aerospace sectors currently represent the largest application areas for structural ceramics in high-frequency systems, accounting for approximately 42% of the total market. However, commercial telecommunications is rapidly catching up, with its market share growing from 28% in 2020 to 36% in 2022, reflecting the accelerating deployment of mmWave 5G infrastructure worldwide.

Geographically, North America leads the market with a 38% share, followed by Asia-Pacific at 34%, which is experiencing the fastest growth rate due to massive infrastructure investments in China, South Korea, and Japan. European markets contribute about 22% of global demand, with particular strength in specialized defense and scientific applications.

The industry is witnessing a significant shift toward higher frequency bands (above 30 GHz) for both terrestrial and satellite communications, creating new technical challenges that structural ceramics are uniquely positioned to address. This trend is expected to intensify with the development of 6G technologies, which may operate at frequencies up to 300 GHz, further expanding the market for advanced ceramic components.

Customer requirements are evolving rapidly, with increasing emphasis on miniaturization, multi-functionality, and cost-effectiveness. System designers are seeking ceramic solutions that can integrate multiple functions (filtering, antenna elements, packaging) while maintaining performance in increasingly compact form factors. This has led to growing demand for complex-shaped ceramic components with precisely engineered electromagnetic properties.

The market also shows strong interest in ceramic-metal composites and ceramic-polymer systems that can offer tailored performance characteristics while addressing manufacturing and integration challenges. These hybrid materials are expected to represent a significant growth segment, with projected annual growth rates exceeding 20% through 2027.

Current State and Challenges of Ceramic Materials

Structural ceramics have emerged as critical materials in high-frequency communication systems, with significant advancements in recent years. Currently, aluminum oxide (Al2O3), silicon nitride (Si3N4), and low-temperature co-fired ceramics (LTCC) dominate the market due to their excellent dielectric properties and thermal stability. These materials exhibit low dielectric loss, high Q factors, and stable temperature coefficients, making them ideal for applications in 5G and emerging 6G technologies.

The global landscape of ceramic technology development shows concentration in Japan, the United States, Germany, and increasingly China. Japanese manufacturers like Kyocera and Murata have established leadership in high-precision ceramic components, while American companies focus on integration with semiconductor technologies. European research institutions have made significant contributions to fundamental ceramic science, particularly in understanding structure-property relationships.

Despite progress, several technical challenges persist in the application of structural ceramics for high-frequency communications. The primary limitation involves achieving consistent dielectric properties at frequencies above 100 GHz, where even minor material variations can significantly impact performance. Manufacturing precision remains problematic, as the industry struggles to economically produce ceramic components with the nanoscale tolerances required for millimeter-wave applications.

Thermal management presents another significant challenge. As communication systems operate at higher frequencies and power densities, the heat dissipation capabilities of ceramic materials become increasingly critical. Current ceramic formulations often face a trade-off between excellent dielectric properties and thermal conductivity, necessitating complex system designs to manage heat effectively.

Integration complexity represents a substantial hurdle, particularly in creating reliable interfaces between ceramic components and other system elements. The coefficient of thermal expansion mismatch between ceramics and metals or polymers can lead to mechanical stress and potential failure points during thermal cycling. Additionally, achieving strong adhesion between ceramics and metallization layers without compromising RF performance remains challenging.

Scalability and cost factors continue to constrain widespread adoption. High-performance ceramic materials often require specialized processing techniques, including high-temperature sintering and precision machining, which drive up production costs. The industry faces pressure to develop more economical manufacturing methods while maintaining the stringent performance requirements of advanced communication systems.

Environmental considerations have also emerged as a constraint, with increasing regulatory pressure regarding the use of certain raw materials and processing chemicals traditionally employed in ceramic manufacturing. This has accelerated research into more sustainable formulations and production methods that maintain the required technical specifications.

The global landscape of ceramic technology development shows concentration in Japan, the United States, Germany, and increasingly China. Japanese manufacturers like Kyocera and Murata have established leadership in high-precision ceramic components, while American companies focus on integration with semiconductor technologies. European research institutions have made significant contributions to fundamental ceramic science, particularly in understanding structure-property relationships.

Despite progress, several technical challenges persist in the application of structural ceramics for high-frequency communications. The primary limitation involves achieving consistent dielectric properties at frequencies above 100 GHz, where even minor material variations can significantly impact performance. Manufacturing precision remains problematic, as the industry struggles to economically produce ceramic components with the nanoscale tolerances required for millimeter-wave applications.

Thermal management presents another significant challenge. As communication systems operate at higher frequencies and power densities, the heat dissipation capabilities of ceramic materials become increasingly critical. Current ceramic formulations often face a trade-off between excellent dielectric properties and thermal conductivity, necessitating complex system designs to manage heat effectively.

Integration complexity represents a substantial hurdle, particularly in creating reliable interfaces between ceramic components and other system elements. The coefficient of thermal expansion mismatch between ceramics and metals or polymers can lead to mechanical stress and potential failure points during thermal cycling. Additionally, achieving strong adhesion between ceramics and metallization layers without compromising RF performance remains challenging.

Scalability and cost factors continue to constrain widespread adoption. High-performance ceramic materials often require specialized processing techniques, including high-temperature sintering and precision machining, which drive up production costs. The industry faces pressure to develop more economical manufacturing methods while maintaining the stringent performance requirements of advanced communication systems.

Environmental considerations have also emerged as a constraint, with increasing regulatory pressure regarding the use of certain raw materials and processing chemicals traditionally employed in ceramic manufacturing. This has accelerated research into more sustainable formulations and production methods that maintain the required technical specifications.

Current Ceramic Solutions for High-Frequency Systems

01 Manufacturing methods for structural ceramics

Various manufacturing methods are employed to produce structural ceramics with enhanced properties. These include sintering processes, hot pressing, and specialized molding techniques. The manufacturing methods focus on achieving optimal density, strength, and microstructure control. Advanced processing techniques help in reducing defects and improving the overall performance of the ceramic components.- Manufacturing processes for structural ceramics: Various manufacturing processes are employed to produce structural ceramics with enhanced properties. These include sintering, hot pressing, and other specialized techniques that control the microstructure and properties of the final ceramic product. These processes can be optimized to achieve desired mechanical properties such as strength, hardness, and fracture toughness, which are critical for structural applications.

- Composite ceramic materials: Composite ceramic materials combine different ceramic components or ceramics with other materials to achieve superior mechanical and thermal properties. These composites often incorporate reinforcing phases such as fibers, whiskers, or particles to enhance toughness and reduce brittleness. The synergistic effect of the different components results in materials with improved performance for demanding structural applications.

- High-temperature resistant structural ceramics: Specialized structural ceramics are designed to withstand extreme temperatures while maintaining their mechanical integrity. These materials typically include silicon nitride, silicon carbide, alumina, and zirconia-based ceramics. Their high-temperature stability makes them suitable for applications in aerospace, energy generation, and other environments where conventional materials would fail due to thermal degradation.

- Surface treatments and coatings for structural ceramics: Various surface treatments and coating technologies are applied to structural ceramics to enhance their performance characteristics. These treatments can improve wear resistance, reduce friction, increase chemical stability, or provide thermal barrier properties. Techniques include glazing, chemical vapor deposition, physical vapor deposition, and the application of specialized ceramic coatings to achieve specific surface properties.

- Novel structural ceramic applications: Structural ceramics are finding new applications across various industries due to their unique combination of properties. These applications include cutting tools, biomedical implants, armor systems, electronic substrates, and components for renewable energy systems. The development of tailored ceramic materials with specific property profiles has enabled their use in increasingly demanding environments where traditional materials are inadequate.

02 Composition and materials for structural ceramics

Structural ceramics utilize various material compositions to achieve desired properties. These include silicon nitride, silicon carbide, alumina, zirconia, and other oxide and non-oxide ceramics. The composition often includes additives and sintering aids that enhance densification and mechanical properties. Multi-component systems and composite structures are developed to combine the advantages of different ceramic materials.Expand Specific Solutions03 Reinforcement techniques for structural ceramics

Reinforcement techniques are employed to improve the mechanical properties of structural ceramics. These include fiber reinforcement, whisker incorporation, and particulate additions. The reinforcement phase helps in crack deflection, bridging, and energy dissipation, leading to improved toughness and reliability. Various interface designs between the matrix and reinforcement are developed to optimize load transfer and crack propagation resistance.Expand Specific Solutions04 High-temperature applications of structural ceramics

Structural ceramics are designed for high-temperature applications where traditional materials fail. These ceramics maintain their mechanical properties at elevated temperatures, showing resistance to thermal shock, creep, and oxidation. Applications include gas turbine components, combustion engines, heat exchangers, and industrial furnace parts. Special coatings and surface treatments are often applied to enhance high-temperature performance.Expand Specific Solutions05 Novel structural ceramic systems and composites

Novel structural ceramic systems and composites are being developed to meet specialized application requirements. These include ceramic-metal composites (cermets), ceramic-ceramic composites, functionally graded materials, and nanostructured ceramics. The novel systems often feature unique combinations of properties such as electrical conductivity with high-temperature capability, or exceptional wear resistance with improved toughness. Advanced design approaches include biomimetic structures and self-healing capabilities.Expand Specific Solutions

Key Industry Players and Competition Landscape

The structural ceramics market in high-frequency communication systems is currently in a growth phase, with increasing demand driven by 5G deployment and advanced wireless technologies. The global market is estimated to reach several billion dollars by 2025, expanding at a CAGR of 7-9%. Leading players include established ceramic manufacturers like Murata Manufacturing, Kyocera, and NGK Insulators, who leverage decades of materials expertise. Technology maturity varies across applications, with companies like DuPont, SCHOTT AG, and Samsung Electro-Mechanics advancing ceramic substrate technologies for higher frequencies. Research institutions including University of Electronic Science & Technology of China and The Aerospace Corp. are developing next-generation ceramic materials with enhanced dielectric properties, while telecommunications giants like NEC and Fujitsu integrate these components into comprehensive communication systems.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata has developed advanced Low Temperature Co-fired Ceramic (LTCC) technology specifically optimized for high-frequency communication systems. Their structural ceramic solutions incorporate multilayer designs with embedded passive components that enable miniaturization while maintaining signal integrity at frequencies up to 110 GHz. Murata's proprietary ceramic formulations feature controlled dielectric constants (ranging from 4.5 to 9.5) and extremely low loss tangents (<0.001 at 60 GHz), making them ideal for 5G mmWave applications. Their ceramic filters, duplexers, and antenna modules utilize precise metallization techniques and innovative cavity structures to achieve exceptional Q factors exceeding 10,000 at high frequencies. Murata has also pioneered temperature-stable ceramic resonators with temperature coefficients below ±2 ppm/°C, ensuring consistent performance across operating conditions in base stations and mobile devices.

Strengths: Industry-leading miniaturization capabilities through advanced LTCC technology; exceptional high-frequency performance with minimal signal loss; comprehensive integration of passive components. Weaknesses: Higher production costs compared to conventional materials; limited flexibility in post-production modifications; requires specialized manufacturing equipment.

Samsung Electro-Mechanics Co., Ltd.

Technical Solution: Samsung Electro-Mechanics has developed advanced multilayer ceramic technology specifically optimized for high-frequency communication systems. Their proprietary FBAR (Film Bulk Acoustic Resonator) filters utilize piezoelectric ceramic thin films with precisely controlled thicknesses (±0.01μm) to achieve exceptional frequency selectivity at bands up to 7 GHz. Samsung's ceramic-based antenna modules incorporate low-loss dielectric materials (tanδ <0.0012 at 28 GHz) with embedded radiating elements that enable compact, high-efficiency designs for 5G smartphones. Their high-frequency MLCC (Multi-Layer Ceramic Capacitor) technology features ultra-thin dielectric layers (<0.5μm) and specialized electrode materials that maintain stable capacitance values at frequencies exceeding 10 GHz. Samsung has also pioneered ceramic-based EMI shielding solutions that combine high electrical conductivity with excellent thermal management properties, addressing critical interference challenges in densely packed communication devices. Their ceramic substrates for RF modules feature tailored coefficient of thermal expansion values (6-8 ppm/°C) that closely match semiconductor materials, enhancing long-term reliability.

Strengths: Extensive vertical integration enabling optimized material-component-system solutions; advanced mass production capabilities ensuring consistent quality; comprehensive design expertise spanning materials to complete modules. Weaknesses: Proprietary technologies limiting cross-platform compatibility; higher initial development costs; challenges in rapid customization for specialized applications.

Core Patents and Innovations in Ceramic Technology

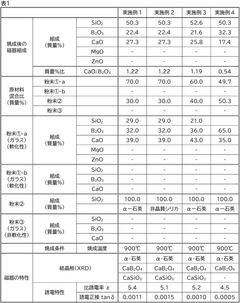

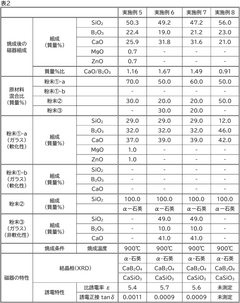

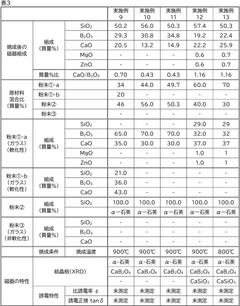

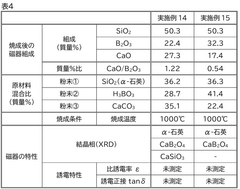

Material for high-frequency dielectric ceramic production

PatentWO2024195810A1

Innovation

- A material composition comprising SiO2, B2O3, and CaO, with specific ratios of inorganic oxide powders including glass and non-softening filler powders, is used to produce high-frequency dielectric ceramics that can be fired at 800 to 1000°C, achieving a dielectric constant of 4.0 to 6.0 and a dielectric loss tangent of 0.0001 to 0.0020 at 10 GHz.

High-frequency ceramic substrate and high-frequency semiconductor element housing package

PatentWO2018003332A1

Innovation

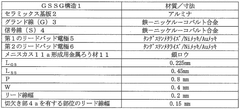

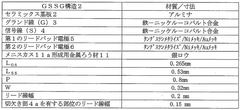

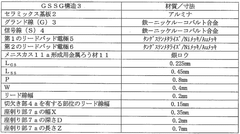

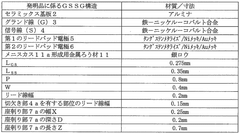

- A high-frequency ceramic substrate design featuring a GSSG structure with strategically placed recesses and bent lines, optimized lead pad electrode configurations, and adjusted intervals to minimize recess volume and enhance bonding strength, ensuring improved impedance matching and reduced thermal stress.

Thermal Management Strategies for Ceramic Components

Effective thermal management is critical for structural ceramics in high-frequency communication systems, as these components often operate under extreme conditions that generate significant heat. The thermal conductivity properties of advanced ceramics such as aluminum nitride (AlN), silicon carbide (SiC), and beryllium oxide (BeO) make them excellent candidates for heat dissipation in communication equipment. These materials exhibit thermal conductivity values ranging from 30 to 300 W/m·K, significantly outperforming traditional polymer-based substrates.

Current thermal management strategies for ceramic components in high-frequency systems employ multi-layered approaches. The primary strategy involves the integration of ceramic heat spreaders directly into circuit designs, allowing for immediate heat transfer away from sensitive electronic components. These spreaders are typically manufactured with precisely engineered microstructures to optimize thermal pathways while maintaining the necessary dielectric properties for signal integrity.

Active cooling solutions represent another critical thermal management approach. Micro-channel cooling systems embedded within ceramic substrates allow for liquid coolant circulation, dramatically enhancing heat dissipation capabilities. Recent advancements have produced ceramic components with integrated cooling channels as small as 200 microns in diameter, enabling more efficient thermal management without compromising the structural integrity or electrical performance of the system.

Surface treatment technologies have emerged as an important complementary strategy. Specialized ceramic coatings with enhanced thermal emissivity properties can increase radiative heat transfer by up to 40% compared to untreated surfaces. Additionally, interface materials designed specifically for ceramic-to-metal junctions have reduced thermal boundary resistance by nearly 30% in the latest generation of high-frequency communication systems.

Computational thermal modeling has become an essential tool in developing effective thermal management strategies. Finite element analysis and computational fluid dynamics simulations allow engineers to predict hotspots and optimize component geometry before physical prototyping. These models have become increasingly sophisticated, incorporating factors such as thermal expansion coefficients, phase transitions, and anisotropic thermal conductivity properties unique to advanced ceramic materials.

Future thermal management strategies are focusing on adaptive systems that can respond dynamically to changing thermal loads. Emerging technologies include phase-change ceramic composites that absorb heat during peak operation periods and thermally-responsive ceramic structures that can alter their thermal conductivity pathways based on temperature gradients. These innovations promise to further enhance the reliability and performance of ceramic components in next-generation high-frequency communication systems.

Current thermal management strategies for ceramic components in high-frequency systems employ multi-layered approaches. The primary strategy involves the integration of ceramic heat spreaders directly into circuit designs, allowing for immediate heat transfer away from sensitive electronic components. These spreaders are typically manufactured with precisely engineered microstructures to optimize thermal pathways while maintaining the necessary dielectric properties for signal integrity.

Active cooling solutions represent another critical thermal management approach. Micro-channel cooling systems embedded within ceramic substrates allow for liquid coolant circulation, dramatically enhancing heat dissipation capabilities. Recent advancements have produced ceramic components with integrated cooling channels as small as 200 microns in diameter, enabling more efficient thermal management without compromising the structural integrity or electrical performance of the system.

Surface treatment technologies have emerged as an important complementary strategy. Specialized ceramic coatings with enhanced thermal emissivity properties can increase radiative heat transfer by up to 40% compared to untreated surfaces. Additionally, interface materials designed specifically for ceramic-to-metal junctions have reduced thermal boundary resistance by nearly 30% in the latest generation of high-frequency communication systems.

Computational thermal modeling has become an essential tool in developing effective thermal management strategies. Finite element analysis and computational fluid dynamics simulations allow engineers to predict hotspots and optimize component geometry before physical prototyping. These models have become increasingly sophisticated, incorporating factors such as thermal expansion coefficients, phase transitions, and anisotropic thermal conductivity properties unique to advanced ceramic materials.

Future thermal management strategies are focusing on adaptive systems that can respond dynamically to changing thermal loads. Emerging technologies include phase-change ceramic composites that absorb heat during peak operation periods and thermally-responsive ceramic structures that can alter their thermal conductivity pathways based on temperature gradients. These innovations promise to further enhance the reliability and performance of ceramic components in next-generation high-frequency communication systems.

Environmental Impact and Sustainability Considerations

The integration of structural ceramics in high-frequency communication systems presents significant environmental and sustainability considerations that warrant careful examination. Advanced ceramic materials, while offering superior technical performance, involve complex manufacturing processes that can generate substantial environmental footprints. The production of high-purity structural ceramics typically requires energy-intensive sintering at temperatures exceeding 1500°C, contributing to considerable carbon emissions when powered by fossil fuels.

Material extraction represents another environmental challenge, as rare earth elements and specialized minerals often used in advanced ceramic formulations may involve environmentally disruptive mining practices. The limited geographical distribution of these resources further raises concerns about supply chain sustainability and geopolitical dependencies that could impact long-term viability of ceramic-based communication technologies.

Waste management throughout the lifecycle of ceramic components presents both challenges and opportunities. While ceramic materials are generally non-biodegradable, their exceptional durability translates to longer service lives compared to conventional materials, potentially reducing replacement frequency and associated resource consumption. Additionally, recent advances in ceramic recycling technologies show promise for recovering valuable materials from end-of-life components, though commercial-scale implementation remains limited.

Water usage in ceramic processing represents another significant environmental consideration. Wet processing methods commonly employed in advanced ceramic manufacturing can consume substantial water resources and generate contaminated wastewater requiring specialized treatment. Industry leaders are increasingly implementing closed-loop water systems and dry processing alternatives to address these concerns.

From a sustainability perspective, the superior performance characteristics of structural ceramics in high-frequency applications may offer indirect environmental benefits. Their excellent thermal management properties can reduce cooling requirements in communication infrastructure, while their electrical efficiency minimizes energy losses during operation. These operational advantages could potentially offset manufacturing-related environmental impacts over the full lifecycle of communication systems.

Regulatory frameworks governing environmental aspects of ceramic manufacturing vary significantly across regions, creating challenges for global supply chains. Forward-thinking manufacturers are increasingly adopting voluntary sustainability certifications and transparent lifecycle assessment practices to demonstrate environmental responsibility beyond minimum compliance requirements.

Material extraction represents another environmental challenge, as rare earth elements and specialized minerals often used in advanced ceramic formulations may involve environmentally disruptive mining practices. The limited geographical distribution of these resources further raises concerns about supply chain sustainability and geopolitical dependencies that could impact long-term viability of ceramic-based communication technologies.

Waste management throughout the lifecycle of ceramic components presents both challenges and opportunities. While ceramic materials are generally non-biodegradable, their exceptional durability translates to longer service lives compared to conventional materials, potentially reducing replacement frequency and associated resource consumption. Additionally, recent advances in ceramic recycling technologies show promise for recovering valuable materials from end-of-life components, though commercial-scale implementation remains limited.

Water usage in ceramic processing represents another significant environmental consideration. Wet processing methods commonly employed in advanced ceramic manufacturing can consume substantial water resources and generate contaminated wastewater requiring specialized treatment. Industry leaders are increasingly implementing closed-loop water systems and dry processing alternatives to address these concerns.

From a sustainability perspective, the superior performance characteristics of structural ceramics in high-frequency applications may offer indirect environmental benefits. Their excellent thermal management properties can reduce cooling requirements in communication infrastructure, while their electrical efficiency minimizes energy losses during operation. These operational advantages could potentially offset manufacturing-related environmental impacts over the full lifecycle of communication systems.

Regulatory frameworks governing environmental aspects of ceramic manufacturing vary significantly across regions, creating challenges for global supply chains. Forward-thinking manufacturers are increasingly adopting voluntary sustainability certifications and transparent lifecycle assessment practices to demonstrate environmental responsibility beyond minimum compliance requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!