Structural Ceramics in Nuclear Energy: Challenges and Solutions

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nuclear Ceramics Background and Objectives

Structural ceramics have emerged as critical materials in nuclear energy applications due to their exceptional properties under extreme conditions. The evolution of ceramic materials in nuclear environments can be traced back to the early days of nuclear power development in the 1950s, when researchers first recognized the need for materials capable of withstanding high temperatures, intense radiation, and corrosive environments. Over subsequent decades, significant advancements in ceramic processing, characterization techniques, and computational modeling have revolutionized our understanding of these materials' behavior in nuclear applications.

The technological trajectory of structural ceramics in nuclear energy has been characterized by continuous improvements in material performance, particularly regarding radiation resistance, thermal stability, and mechanical integrity. Silicon carbide (SiC), aluminum oxide (Al₂O₃), zirconium dioxide (ZrO₂), and silicon nitride (Si₃N₄) have emerged as prominent ceramic materials, each offering unique advantages for specific nuclear applications. Recent innovations in ceramic matrix composites (CMCs) represent a significant leap forward, combining the inherent properties of ceramics with enhanced fracture toughness.

The primary technical objectives for structural ceramics in nuclear energy applications center on developing materials that can withstand increasingly demanding operational conditions while maintaining structural integrity and functional performance. Specifically, these objectives include enhancing radiation resistance to minimize swelling and embrittlement, improving thermal conductivity for efficient heat transfer, increasing mechanical strength and fracture toughness, and ensuring chemical compatibility with coolants and other reactor components.

Current research aims to address the fundamental limitations of ceramic materials, particularly their inherent brittleness and susceptibility to radiation-induced defects. Advanced manufacturing techniques, including additive manufacturing and novel sintering processes, are being explored to create ceramics with tailored microstructures that exhibit superior performance under extreme conditions. Additionally, there is growing interest in developing multi-functional ceramics that can simultaneously serve as structural components and perform secondary functions such as tritium barriers or neutron moderators.

Looking forward, the evolution of structural ceramics is expected to play a pivotal role in enabling next-generation nuclear technologies, including advanced fission reactors, fusion energy systems, and space nuclear power. The development of these materials represents not only a technological challenge but also a strategic imperative for achieving sustainable, safe, and efficient nuclear energy solutions in the coming decades.

The technological trajectory of structural ceramics in nuclear energy has been characterized by continuous improvements in material performance, particularly regarding radiation resistance, thermal stability, and mechanical integrity. Silicon carbide (SiC), aluminum oxide (Al₂O₃), zirconium dioxide (ZrO₂), and silicon nitride (Si₃N₄) have emerged as prominent ceramic materials, each offering unique advantages for specific nuclear applications. Recent innovations in ceramic matrix composites (CMCs) represent a significant leap forward, combining the inherent properties of ceramics with enhanced fracture toughness.

The primary technical objectives for structural ceramics in nuclear energy applications center on developing materials that can withstand increasingly demanding operational conditions while maintaining structural integrity and functional performance. Specifically, these objectives include enhancing radiation resistance to minimize swelling and embrittlement, improving thermal conductivity for efficient heat transfer, increasing mechanical strength and fracture toughness, and ensuring chemical compatibility with coolants and other reactor components.

Current research aims to address the fundamental limitations of ceramic materials, particularly their inherent brittleness and susceptibility to radiation-induced defects. Advanced manufacturing techniques, including additive manufacturing and novel sintering processes, are being explored to create ceramics with tailored microstructures that exhibit superior performance under extreme conditions. Additionally, there is growing interest in developing multi-functional ceramics that can simultaneously serve as structural components and perform secondary functions such as tritium barriers or neutron moderators.

Looking forward, the evolution of structural ceramics is expected to play a pivotal role in enabling next-generation nuclear technologies, including advanced fission reactors, fusion energy systems, and space nuclear power. The development of these materials represents not only a technological challenge but also a strategic imperative for achieving sustainable, safe, and efficient nuclear energy solutions in the coming decades.

Market Analysis for Structural Ceramics in Nuclear Applications

The global market for structural ceramics in nuclear applications is experiencing significant growth, driven by the increasing demand for advanced materials that can withstand extreme conditions in nuclear reactors. Currently valued at approximately $2.1 billion, this specialized segment is projected to grow at a compound annual growth rate of 6.8% through 2030, reaching an estimated $3.9 billion by the end of the decade.

The primary market drivers include the global push for cleaner energy sources, aging nuclear infrastructure requiring upgrades, and the development of next-generation nuclear technologies such as small modular reactors (SMRs) and Generation IV systems. These advanced reactor designs demand materials with superior performance characteristics, creating substantial opportunities for structural ceramics.

Regional analysis reveals that North America and Europe currently dominate the market, collectively accounting for over 60% of global demand. However, the Asia-Pacific region, particularly China, Japan, and South Korea, is witnessing the fastest growth rate at 8.2% annually due to ambitious nuclear expansion programs and significant investments in research and development.

By application segment, fuel cladding represents the largest market share at 38%, followed by control rod components (22%), thermal shields (18%), and various structural components (22%). Silicon carbide (SiC) composites are emerging as the fastest-growing material category, with demand increasing at 9.5% annually due to their exceptional radiation resistance and thermal properties.

The customer landscape is highly concentrated, with nuclear reactor manufacturers, nuclear power plant operators, and government research institutions constituting the primary end-users. The procurement cycle is typically long, ranging from 2-5 years, reflecting the rigorous qualification and certification processes required for nuclear-grade materials.

Price sensitivity varies significantly by application, with safety-critical components commanding premium prices regardless of cost pressures. The average selling price for advanced ceramic components has increased by 3.2% annually over the past five years, outpacing inflation due to enhanced performance requirements and limited supplier competition.

Market barriers include stringent regulatory requirements, high certification costs, and extended qualification timelines. New entrants face significant challenges in establishing credibility and securing the necessary nuclear-grade certifications, which typically require 3-7 years of testing and validation.

Future market growth will be heavily influenced by regulatory developments, particularly safety standards following the Fukushima incident, as well as the commercial viability of next-generation reactor designs that rely more extensively on advanced ceramic materials.

The primary market drivers include the global push for cleaner energy sources, aging nuclear infrastructure requiring upgrades, and the development of next-generation nuclear technologies such as small modular reactors (SMRs) and Generation IV systems. These advanced reactor designs demand materials with superior performance characteristics, creating substantial opportunities for structural ceramics.

Regional analysis reveals that North America and Europe currently dominate the market, collectively accounting for over 60% of global demand. However, the Asia-Pacific region, particularly China, Japan, and South Korea, is witnessing the fastest growth rate at 8.2% annually due to ambitious nuclear expansion programs and significant investments in research and development.

By application segment, fuel cladding represents the largest market share at 38%, followed by control rod components (22%), thermal shields (18%), and various structural components (22%). Silicon carbide (SiC) composites are emerging as the fastest-growing material category, with demand increasing at 9.5% annually due to their exceptional radiation resistance and thermal properties.

The customer landscape is highly concentrated, with nuclear reactor manufacturers, nuclear power plant operators, and government research institutions constituting the primary end-users. The procurement cycle is typically long, ranging from 2-5 years, reflecting the rigorous qualification and certification processes required for nuclear-grade materials.

Price sensitivity varies significantly by application, with safety-critical components commanding premium prices regardless of cost pressures. The average selling price for advanced ceramic components has increased by 3.2% annually over the past five years, outpacing inflation due to enhanced performance requirements and limited supplier competition.

Market barriers include stringent regulatory requirements, high certification costs, and extended qualification timelines. New entrants face significant challenges in establishing credibility and securing the necessary nuclear-grade certifications, which typically require 3-7 years of testing and validation.

Future market growth will be heavily influenced by regulatory developments, particularly safety standards following the Fukushima incident, as well as the commercial viability of next-generation reactor designs that rely more extensively on advanced ceramic materials.

Current Status and Technical Barriers in Nuclear Ceramics

Structural ceramics in nuclear energy applications have reached a significant level of technological maturity, yet face substantial challenges that limit their broader implementation. Currently, silicon carbide (SiC), aluminum oxide (Al2O3), and zirconium dioxide (ZrO2) represent the most widely utilized ceramic materials in nuclear environments, with SiC-based composites gaining particular attention for accident-tolerant fuel cladding applications.

The global landscape of nuclear ceramic development shows concentration in advanced nuclear nations, with the United States, Japan, France, and China leading research efforts. Recent advancements have focused on improving manufacturing processes, particularly through additive manufacturing techniques that allow for more complex geometries and potentially reduced production costs.

Despite progress, several critical technical barriers persist. Irradiation-induced swelling and creep remain significant challenges, with most ceramic materials experiencing dimensional changes under neutron bombardment that can compromise structural integrity. This is particularly problematic at the high neutron fluences experienced in reactor environments, where accumulated damage can lead to property degradation over time.

Thermal shock resistance presents another major limitation, as the inherent brittleness of ceramic materials makes them vulnerable to rapid temperature changes that occur during operational transients or accident scenarios. This characteristic significantly restricts their application in certain reactor components where thermal cycling is common.

Manufacturing scalability constitutes a persistent obstacle, with current production methods for advanced ceramic composites being costly and difficult to scale to industrial levels. The complex processing requirements for achieving consistent microstructural properties across large components remain particularly challenging.

Joint and connection technologies represent another unresolved area, as the integration of ceramic components with metallic structures in reactor systems requires specialized joining techniques that can withstand the extreme operational conditions while maintaining hermeticity and structural integrity.

Performance prediction models also remain inadequate, with current computational tools unable to accurately simulate the long-term behavior of ceramic materials under the combined effects of irradiation, temperature, and mechanical stress. This limitation hampers the qualification process for new ceramic materials in regulatory frameworks.

The economic viability of ceramic solutions versus traditional materials continues to be questioned, with the higher initial costs of advanced ceramics requiring clear demonstration of lifecycle cost benefits through enhanced performance or extended operational lifetimes to justify widespread adoption in commercial nuclear facilities.

The global landscape of nuclear ceramic development shows concentration in advanced nuclear nations, with the United States, Japan, France, and China leading research efforts. Recent advancements have focused on improving manufacturing processes, particularly through additive manufacturing techniques that allow for more complex geometries and potentially reduced production costs.

Despite progress, several critical technical barriers persist. Irradiation-induced swelling and creep remain significant challenges, with most ceramic materials experiencing dimensional changes under neutron bombardment that can compromise structural integrity. This is particularly problematic at the high neutron fluences experienced in reactor environments, where accumulated damage can lead to property degradation over time.

Thermal shock resistance presents another major limitation, as the inherent brittleness of ceramic materials makes them vulnerable to rapid temperature changes that occur during operational transients or accident scenarios. This characteristic significantly restricts their application in certain reactor components where thermal cycling is common.

Manufacturing scalability constitutes a persistent obstacle, with current production methods for advanced ceramic composites being costly and difficult to scale to industrial levels. The complex processing requirements for achieving consistent microstructural properties across large components remain particularly challenging.

Joint and connection technologies represent another unresolved area, as the integration of ceramic components with metallic structures in reactor systems requires specialized joining techniques that can withstand the extreme operational conditions while maintaining hermeticity and structural integrity.

Performance prediction models also remain inadequate, with current computational tools unable to accurately simulate the long-term behavior of ceramic materials under the combined effects of irradiation, temperature, and mechanical stress. This limitation hampers the qualification process for new ceramic materials in regulatory frameworks.

The economic viability of ceramic solutions versus traditional materials continues to be questioned, with the higher initial costs of advanced ceramics requiring clear demonstration of lifecycle cost benefits through enhanced performance or extended operational lifetimes to justify widespread adoption in commercial nuclear facilities.

Existing Technical Solutions for Nuclear-Grade Ceramics

01 Manufacturing methods for structural ceramics

Various manufacturing techniques are employed to produce structural ceramics with enhanced properties. These methods include sintering, hot pressing, and chemical vapor deposition, which can control the microstructure and properties of the final ceramic product. Advanced processing techniques help to minimize defects and improve the mechanical strength, thermal resistance, and overall performance of structural ceramic components.- Manufacturing processes for structural ceramics: Various manufacturing processes are employed to produce structural ceramics with enhanced properties. These include sintering, hot pressing, and other specialized techniques that control the microstructure and density of the ceramic materials. These processes can be optimized to improve mechanical strength, thermal resistance, and overall performance of the ceramic components for structural applications.

- Composite structural ceramics: Composite structural ceramics combine ceramic materials with other substances to enhance specific properties. These composites often incorporate reinforcing elements such as fibers, whiskers, or particles to improve toughness and crack resistance. The resulting materials offer superior mechanical properties compared to monolithic ceramics, making them suitable for demanding structural applications in various industries.

- High-temperature structural ceramics: Specialized structural ceramics designed for high-temperature applications can withstand extreme thermal conditions while maintaining their mechanical integrity. These materials often include silicon nitride, silicon carbide, and zirconia-based ceramics that exhibit excellent thermal shock resistance and creep resistance at elevated temperatures. They are particularly valuable in aerospace, energy generation, and other industries requiring components that can function in harsh thermal environments.

- Structural ceramic coatings: Ceramic coatings applied to structural components provide protection against wear, corrosion, and thermal degradation. These coatings can be applied through various methods including plasma spraying, chemical vapor deposition, and sol-gel techniques. The coatings enhance the durability and performance of the underlying materials, extending the service life of components in demanding environments.

- Novel structural ceramic materials: Innovative ceramic materials with unique compositions and microstructures are being developed to meet specific structural requirements. These include ultra-high temperature ceramics, transparent ceramics, and bioinspired ceramic structures. Research focuses on tailoring the chemical composition and processing conditions to achieve desired combinations of properties such as lightweight strength, electrical conductivity, or biocompatibility for specialized applications.

02 Composite structural ceramics

Composite structural ceramics combine different ceramic materials or ceramics with metals or polymers to achieve superior properties. These composites often feature reinforcement phases such as fibers, whiskers, or particles embedded in a ceramic matrix. The resulting materials exhibit improved fracture toughness, thermal shock resistance, and mechanical strength compared to monolithic ceramics, making them suitable for demanding applications in aerospace, automotive, and energy sectors.Expand Specific Solutions03 High-temperature structural ceramics

Specialized structural ceramics designed for high-temperature applications can withstand extreme thermal conditions while maintaining their mechanical integrity. These materials, including silicon carbide, silicon nitride, and zirconia-based ceramics, feature strong atomic bonds and stable crystal structures that resist thermal degradation. Their exceptional thermal stability makes them ideal for use in gas turbines, combustion engines, furnace components, and other high-temperature industrial environments.Expand Specific Solutions04 Structural ceramics with enhanced mechanical properties

Advanced structural ceramics are engineered to overcome the inherent brittleness of traditional ceramic materials. Through careful control of composition, grain size, and microstructure, these ceramics achieve improved mechanical properties including higher fracture toughness, flexural strength, and impact resistance. Techniques such as transformation toughening, grain boundary engineering, and incorporation of secondary phases contribute to the development of ceramics with superior mechanical performance for structural applications.Expand Specific Solutions05 Applications of structural ceramics

Structural ceramics find diverse applications across multiple industries due to their unique combination of properties. They are used in cutting tools, wear-resistant components, biomedical implants, electronic substrates, armor systems, and thermal barrier coatings. Their excellent hardness, wear resistance, chemical inertness, and thermal stability make them invaluable in environments where metals and polymers would fail, enabling technological advancements in fields ranging from manufacturing to healthcare and defense.Expand Specific Solutions

Leading Organizations in Nuclear Ceramic Materials Development

The structural ceramics market in nuclear energy is currently in a growth phase, characterized by increasing demand for advanced materials that can withstand extreme conditions. The global market is expanding as nuclear power gains renewed attention as a low-carbon energy source. Key players represent a diverse ecosystem spanning government research institutions (CEA, Rosatom, CNRS), established industrial giants (Westinghouse, Siemens, Framatome), specialized materials companies (IBIDEN, SCHOTT), and emerging innovators (Last Energy, Advanced Reactor Concepts). Technical maturity varies significantly across applications, with traditional structural ceramics being well-established while advanced ceramic composites for next-generation reactors remain in developmental stages. Chinese institutions (China Nuclear Power Research Institute, Harbin Institute of Technology) are rapidly advancing capabilities, challenging traditional Western and Japanese dominance in this specialized field.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The French Alternative Energies and Atomic Energy Commission (CEA) has developed advanced silicon carbide (SiC) ceramic matrix composites (CMCs) specifically engineered for nuclear applications. Their technology focuses on creating multi-layered SiC-based fuel cladding that can withstand extreme radiation environments while maintaining structural integrity. CEA's approach involves a triplex structure with an inner monolithic SiC layer for fission product retention, a middle SiC fiber-reinforced composite layer for mechanical strength, and an outer environmental barrier coating to protect against coolant interaction. This design has demonstrated exceptional resistance to neutron irradiation up to 10 dpa (displacements per atom) while maintaining thermal conductivity values above 10 W/m·K at operating temperatures. Their manufacturing process employs chemical vapor infiltration (CVI) techniques combined with nano-powder sintering to achieve near-theoretical density in critical components, significantly reducing permeability issues common in ceramic materials used in nuclear environments.

Strengths: Superior radiation resistance compared to metallic alternatives; excellent high-temperature mechanical properties; enhanced accident tolerance capabilities; reduced hydrogen generation during accident scenarios. Weaknesses: Higher manufacturing costs compared to traditional zirconium alloys; challenges in achieving hermetic sealing at end-caps; limited industrial-scale production capacity; requires specialized joining techniques for system integration.

Westinghouse Electric Co. LLC

Technical Solution: Westinghouse has pioneered the development of Accident Tolerant Fuel (ATF) systems incorporating advanced structural ceramics, particularly their EnCore® fuel technology. Their silicon carbide-based cladding system utilizes a proprietary manufacturing process that creates a composite structure with exceptional dimensional stability under irradiation. The technology employs a multi-layered approach with an inner metallic liner for hermeticity, a middle SiC composite layer for strength, and an outer environmental barrier coating. Westinghouse's innovation lies in their specialized fiber architecture and interface coating that allows for controlled micro-cracking without catastrophic failure, addressing the inherent brittleness of ceramic materials. Their SiC-based fuel cladding has demonstrated a 30% reduction in oxidation rates at high temperatures compared to traditional zirconium alloys, significantly enhancing safety margins during beyond-design-basis accidents. The company has successfully tested prototype assemblies in commercial reactors, accumulating over 18 months of in-reactor performance data showing minimal degradation under normal operating conditions.

Strengths: Extensive nuclear licensing experience; established supply chain for nuclear-grade materials; demonstrated in-reactor performance data; integrated fuel system approach considering both materials and reactor operations. Weaknesses: Higher production costs compared to traditional zirconium-based systems; challenges in scaling manufacturing to commercial quantities; joining technology for end-caps still under development; requires modifications to existing fuel handling equipment.

Critical Patents and Research in Nuclear Ceramic Materials

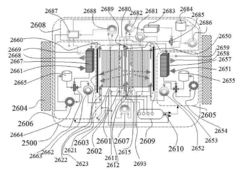

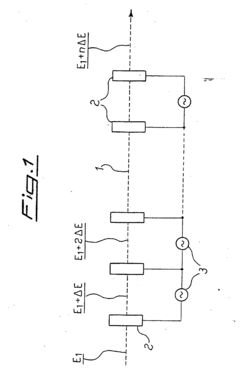

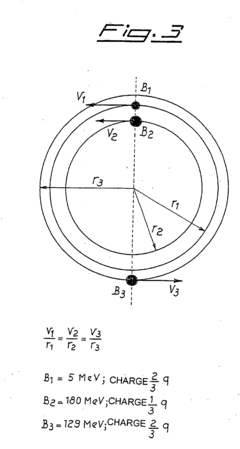

Method and device for direct nuclear energy conversion in electricity in fusion and transmutation processes

PatentInactiveUS20130121449A1

Innovation

- A method utilizing inter-atomic field modifications within nano-structures to control nuclear entanglement and quantum non-local nuclear cross-sections, allowing for adjustable nuclear reaction rates, combined with a device that converts nuclear energy into electricity using a super-capacitor assembly and direct conversion units.

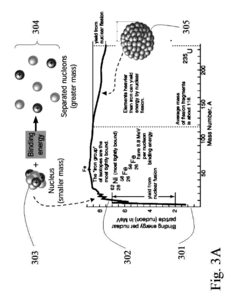

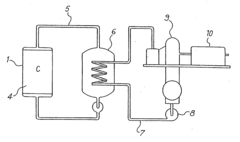

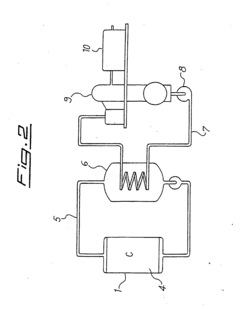

Process and apparatus for the production of clean nuclear energy

PatentInactiveUS20060008044A1

Innovation

- Employing light atoms like helium, lithium, and carbon for nuclear fission, leveraging a novel electromagnetic force theory to achieve a 'clean' energy production method using a linear resonating accelerator and cadmium moderation to control the chain reaction.

Safety and Regulatory Framework for Nuclear Ceramic Components

The regulatory landscape for structural ceramics in nuclear applications is exceptionally stringent, reflecting the critical safety requirements of nuclear energy systems. The Nuclear Regulatory Commission (NRC) in the United States and equivalent bodies worldwide have established comprehensive frameworks that govern the qualification, testing, and implementation of ceramic components in nuclear facilities. These frameworks typically require extensive material characterization, performance validation under normal and accident conditions, and long-term reliability assessments.

Ceramic components must demonstrate compliance with standards such as ASME Boiler and Pressure Vessel Code Section III for nuclear components, which has been expanded to include specific provisions for advanced materials including ceramics. The qualification process involves rigorous testing protocols to verify mechanical properties, thermal stability, radiation resistance, and chemical compatibility with coolants and other reactor materials.

Safety assessment methodologies for ceramic components differ significantly from those for traditional metallic materials. The brittle nature of ceramics necessitates probabilistic approaches to failure analysis rather than the deterministic methods typically applied to metals. Weibull statistics are commonly employed to characterize the strength distribution and reliability of ceramic components, accounting for their sensitivity to microscopic flaws and manufacturing variations.

Regulatory bodies require demonstration of ceramic component integrity throughout the entire lifecycle of nuclear facilities, including normal operation, anticipated operational occurrences, design basis accidents, and beyond design basis events. This involves accelerated aging tests, simulated accident condition exposure, and post-irradiation examination to validate performance models and safety margins.

International harmonization of standards remains a challenge, with variations in regulatory approaches across different countries creating barriers to global deployment of ceramic-based nuclear technologies. Organizations such as the International Atomic Energy Agency (IAEA) are working to develop consensus standards and guidelines to facilitate international acceptance of structural ceramic components in nuclear applications.

Recent regulatory developments have begun to address advanced reactor designs that incorporate novel ceramic materials. The NRC's non-light water reactor vision and strategy includes pathways for qualifying and licensing new materials, while initiatives like the ASME's Section III, Division 5 for high-temperature reactors provide specific guidance for ceramic composite materials in high-temperature applications.

Ceramic components must demonstrate compliance with standards such as ASME Boiler and Pressure Vessel Code Section III for nuclear components, which has been expanded to include specific provisions for advanced materials including ceramics. The qualification process involves rigorous testing protocols to verify mechanical properties, thermal stability, radiation resistance, and chemical compatibility with coolants and other reactor materials.

Safety assessment methodologies for ceramic components differ significantly from those for traditional metallic materials. The brittle nature of ceramics necessitates probabilistic approaches to failure analysis rather than the deterministic methods typically applied to metals. Weibull statistics are commonly employed to characterize the strength distribution and reliability of ceramic components, accounting for their sensitivity to microscopic flaws and manufacturing variations.

Regulatory bodies require demonstration of ceramic component integrity throughout the entire lifecycle of nuclear facilities, including normal operation, anticipated operational occurrences, design basis accidents, and beyond design basis events. This involves accelerated aging tests, simulated accident condition exposure, and post-irradiation examination to validate performance models and safety margins.

International harmonization of standards remains a challenge, with variations in regulatory approaches across different countries creating barriers to global deployment of ceramic-based nuclear technologies. Organizations such as the International Atomic Energy Agency (IAEA) are working to develop consensus standards and guidelines to facilitate international acceptance of structural ceramic components in nuclear applications.

Recent regulatory developments have begun to address advanced reactor designs that incorporate novel ceramic materials. The NRC's non-light water reactor vision and strategy includes pathways for qualifying and licensing new materials, while initiatives like the ASME's Section III, Division 5 for high-temperature reactors provide specific guidance for ceramic composite materials in high-temperature applications.

Environmental Impact and Waste Management Considerations

The environmental footprint of structural ceramics in nuclear energy extends throughout their lifecycle, from raw material extraction to disposal. Mining operations for ceramic materials like silicon carbide and aluminum oxide create significant land disturbances and generate particulate emissions. Manufacturing processes require high temperatures, consuming substantial energy and producing greenhouse gases, particularly when fossil fuels power these operations.

During operational phases, structural ceramics offer environmental advantages over traditional materials. Their superior durability reduces replacement frequency, minimizing waste generation and resource consumption. Additionally, ceramics enable higher operating temperatures in nuclear reactors, potentially increasing thermal efficiency and reducing cooling water requirements, which lessens thermal pollution in aquatic ecosystems.

Waste management presents unique challenges for ceramic components exposed to neutron radiation. These materials become activated during service, requiring specialized handling and disposal protocols. Unlike metallic waste that can be recycled through melting, ceramics typically resist conventional recycling methods due to their chemical stability and potential for containing radionuclides.

Current disposal strategies for radioactive ceramic waste include vitrification, where waste is incorporated into glass matrices, and deep geological repositories. Research into advanced waste management techniques focuses on selective leaching processes to separate radioactive elements from ceramic matrices and novel encapsulation methods using geopolymers that provide additional containment barriers.

Regulatory frameworks governing ceramic waste disposal vary internationally, with most nuclear nations adopting a tiered approach based on radioactivity levels. Low-level ceramic waste may undergo near-surface disposal, while intermediate and high-level waste requires more robust containment solutions. The long half-lives of certain activated ceramic components necessitate disposal planning on millennial timescales.

Emerging research explores the potential for designing ceramics with reduced activation characteristics through careful selection of constituent elements. Materials engineered to minimize the formation of long-lived radioisotopes could significantly reduce long-term waste management burdens. Additionally, developments in transmutation technologies may eventually offer pathways to convert problematic radioisotopes in ceramic waste into more manageable forms.

During operational phases, structural ceramics offer environmental advantages over traditional materials. Their superior durability reduces replacement frequency, minimizing waste generation and resource consumption. Additionally, ceramics enable higher operating temperatures in nuclear reactors, potentially increasing thermal efficiency and reducing cooling water requirements, which lessens thermal pollution in aquatic ecosystems.

Waste management presents unique challenges for ceramic components exposed to neutron radiation. These materials become activated during service, requiring specialized handling and disposal protocols. Unlike metallic waste that can be recycled through melting, ceramics typically resist conventional recycling methods due to their chemical stability and potential for containing radionuclides.

Current disposal strategies for radioactive ceramic waste include vitrification, where waste is incorporated into glass matrices, and deep geological repositories. Research into advanced waste management techniques focuses on selective leaching processes to separate radioactive elements from ceramic matrices and novel encapsulation methods using geopolymers that provide additional containment barriers.

Regulatory frameworks governing ceramic waste disposal vary internationally, with most nuclear nations adopting a tiered approach based on radioactivity levels. Low-level ceramic waste may undergo near-surface disposal, while intermediate and high-level waste requires more robust containment solutions. The long half-lives of certain activated ceramic components necessitate disposal planning on millennial timescales.

Emerging research explores the potential for designing ceramics with reduced activation characteristics through careful selection of constituent elements. Materials engineered to minimize the formation of long-lived radioisotopes could significantly reduce long-term waste management burdens. Additionally, developments in transmutation technologies may eventually offer pathways to convert problematic radioisotopes in ceramic waste into more manageable forms.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!