Evaluating the Role of Structural Ceramics in Porous Media Filters

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Structural Ceramics in Filtration: Background and Objectives

Structural ceramics have emerged as a critical material in filtration technologies over the past several decades, evolving from simple clay-based filters to sophisticated engineered porous structures. The development trajectory of ceramic filtration media has been characterized by continuous innovation in material composition, manufacturing techniques, and structural design to enhance performance characteristics such as permeability, mechanical strength, and chemical resistance.

The evolution of structural ceramics in filtration applications began in the mid-20th century with rudimentary ceramic candles and expanded significantly in the 1970s and 1980s with the introduction of advanced ceramic processing methods. This technological progression has been driven by increasing demands for filtration efficiency across multiple industries including water treatment, chemical processing, and emissions control systems.

Current technological trends in structural ceramic filters focus on nano-engineering of pore structures, development of composite ceramic materials, and integration of catalytic functionalities within the ceramic matrix. These advancements aim to address the growing complexity of filtration requirements in both industrial and environmental applications, where removal of increasingly smaller particulates and specific chemical contaminants has become paramount.

The primary technical objectives for structural ceramics in porous media filters encompass several dimensions. First, enhancing filtration efficiency through optimized pore size distribution and interconnectivity remains a fundamental goal. Second, improving mechanical durability under thermal cycling and high-pressure conditions continues to drive material innovation. Third, developing cost-effective manufacturing processes that can produce complex geometries while maintaining precise control over microstructural features represents a significant technical challenge.

Additionally, there is growing interest in multifunctional ceramic filters that can simultaneously perform separation, catalysis, and sensing functions. This integration of capabilities requires sophisticated material design approaches that consider not only the structural aspects of ceramics but also their surface chemistry and electronic properties.

The environmental sustainability of ceramic filter production and operation has also emerged as an important consideration, with research increasingly focused on reducing energy consumption during manufacturing and extending operational lifetimes to minimize waste generation. This holistic approach to technology development reflects the evolving understanding of filtration systems as integral components of sustainable industrial processes.

As we examine the role of structural ceramics in porous media filters, it becomes evident that future advancements will likely depend on interdisciplinary collaboration between materials science, fluid dynamics, and process engineering to overcome current limitations and exploit emerging opportunities in this technologically significant domain.

The evolution of structural ceramics in filtration applications began in the mid-20th century with rudimentary ceramic candles and expanded significantly in the 1970s and 1980s with the introduction of advanced ceramic processing methods. This technological progression has been driven by increasing demands for filtration efficiency across multiple industries including water treatment, chemical processing, and emissions control systems.

Current technological trends in structural ceramic filters focus on nano-engineering of pore structures, development of composite ceramic materials, and integration of catalytic functionalities within the ceramic matrix. These advancements aim to address the growing complexity of filtration requirements in both industrial and environmental applications, where removal of increasingly smaller particulates and specific chemical contaminants has become paramount.

The primary technical objectives for structural ceramics in porous media filters encompass several dimensions. First, enhancing filtration efficiency through optimized pore size distribution and interconnectivity remains a fundamental goal. Second, improving mechanical durability under thermal cycling and high-pressure conditions continues to drive material innovation. Third, developing cost-effective manufacturing processes that can produce complex geometries while maintaining precise control over microstructural features represents a significant technical challenge.

Additionally, there is growing interest in multifunctional ceramic filters that can simultaneously perform separation, catalysis, and sensing functions. This integration of capabilities requires sophisticated material design approaches that consider not only the structural aspects of ceramics but also their surface chemistry and electronic properties.

The environmental sustainability of ceramic filter production and operation has also emerged as an important consideration, with research increasingly focused on reducing energy consumption during manufacturing and extending operational lifetimes to minimize waste generation. This holistic approach to technology development reflects the evolving understanding of filtration systems as integral components of sustainable industrial processes.

As we examine the role of structural ceramics in porous media filters, it becomes evident that future advancements will likely depend on interdisciplinary collaboration between materials science, fluid dynamics, and process engineering to overcome current limitations and exploit emerging opportunities in this technologically significant domain.

Market Analysis for Ceramic-Based Filtration Systems

The global market for ceramic-based filtration systems has experienced significant growth over the past decade, driven primarily by increasing environmental regulations, water scarcity concerns, and industrial demand for efficient separation technologies. Current market valuations place the structural ceramic filtration sector at approximately 3.2 billion USD in 2023, with projections indicating a compound annual growth rate of 7.8% through 2030.

Water treatment applications represent the largest market segment, accounting for roughly 42% of ceramic filter deployments. This dominance stems from ceramics' superior chemical resistance, thermal stability, and longevity compared to polymeric alternatives, particularly in challenging environments with high temperatures or corrosive conditions. Municipal water treatment facilities increasingly favor ceramic membrane systems for their lower lifetime costs despite higher initial investments.

Industrial processing applications constitute the second-largest market segment at 28%, with particularly strong adoption in food and beverage, pharmaceutical, and chemical manufacturing sectors. These industries value ceramic filters for their ability to maintain sterility, withstand cleaning protocols, and provide consistent filtration performance over extended operational periods.

Regional analysis reveals Asia-Pacific as the fastest-growing market, expanding at nearly 9.5% annually, driven by rapid industrialization, urbanization, and increasing regulatory pressure for water reuse and emissions control in China and India. North America and Europe maintain significant market shares due to established industrial bases and stringent environmental regulations, though growth rates are more modest at 5-6% annually.

Customer demand patterns show increasing preference for customized ceramic filtration solutions with specific porosity profiles, surface treatments, and geometries tailored to particular applications. This trend has created market opportunities for specialized manufacturers capable of engineering ceramic structures with precisely controlled pore architectures.

Price sensitivity varies significantly by application segment. High-value industries such as pharmaceuticals and electronics prioritize performance consistency and contamination control over initial cost, while municipal water treatment and general industrial applications remain more price-conscious, creating distinct market tiers with different competitive dynamics.

Emerging market opportunities include advanced ceramic filters for air purification systems, particularly for removing ultrafine particulates and specific gaseous pollutants, as well as specialized biomedical applications requiring controlled molecular separation capabilities. These developing segments are projected to grow at above-market rates of 12-15% annually, though from smaller base values.

Water treatment applications represent the largest market segment, accounting for roughly 42% of ceramic filter deployments. This dominance stems from ceramics' superior chemical resistance, thermal stability, and longevity compared to polymeric alternatives, particularly in challenging environments with high temperatures or corrosive conditions. Municipal water treatment facilities increasingly favor ceramic membrane systems for their lower lifetime costs despite higher initial investments.

Industrial processing applications constitute the second-largest market segment at 28%, with particularly strong adoption in food and beverage, pharmaceutical, and chemical manufacturing sectors. These industries value ceramic filters for their ability to maintain sterility, withstand cleaning protocols, and provide consistent filtration performance over extended operational periods.

Regional analysis reveals Asia-Pacific as the fastest-growing market, expanding at nearly 9.5% annually, driven by rapid industrialization, urbanization, and increasing regulatory pressure for water reuse and emissions control in China and India. North America and Europe maintain significant market shares due to established industrial bases and stringent environmental regulations, though growth rates are more modest at 5-6% annually.

Customer demand patterns show increasing preference for customized ceramic filtration solutions with specific porosity profiles, surface treatments, and geometries tailored to particular applications. This trend has created market opportunities for specialized manufacturers capable of engineering ceramic structures with precisely controlled pore architectures.

Price sensitivity varies significantly by application segment. High-value industries such as pharmaceuticals and electronics prioritize performance consistency and contamination control over initial cost, while municipal water treatment and general industrial applications remain more price-conscious, creating distinct market tiers with different competitive dynamics.

Emerging market opportunities include advanced ceramic filters for air purification systems, particularly for removing ultrafine particulates and specific gaseous pollutants, as well as specialized biomedical applications requiring controlled molecular separation capabilities. These developing segments are projected to grow at above-market rates of 12-15% annually, though from smaller base values.

Current Challenges in Porous Ceramic Filter Technology

Despite significant advancements in porous ceramic filter technology, several critical challenges continue to impede optimal performance and widespread adoption. One of the primary obstacles remains the trade-off between porosity and mechanical strength. As porosity increases to enhance filtration efficiency, the structural integrity of ceramic filters often deteriorates, leading to reduced durability and shorter operational lifespans under demanding conditions. This fundamental contradiction necessitates innovative material compositions and manufacturing techniques to achieve an optimal balance.

Fouling and clogging represent another persistent challenge, particularly in applications involving high particulate concentrations or viscous fluids. The gradual accumulation of filtered particles within porous structures leads to diminished flow rates and increased pressure drops across the filter medium. Current regeneration methods, including backwashing and thermal treatments, often prove insufficient for complete restoration of original performance parameters, especially for deeply embedded contaminants within the ceramic matrix.

Temperature resistance limitations present significant constraints in high-temperature applications. While structural ceramics generally exhibit superior thermal stability compared to polymeric alternatives, certain ceramic compositions still experience phase transformations, sintering effects, or chemical degradation when subjected to extreme thermal cycling or prolonged exposure to elevated temperatures. These phenomena can alter pore structure and compromise filtration efficiency over time.

Chemical compatibility issues arise when ceramic filters encounter aggressive media, particularly in industrial wastewater treatment or chemical processing applications. Acid or alkaline environments can gradually erode ceramic structures, altering surface properties and pore characteristics. The development of chemically resistant ceramic compositions without sacrificing other performance attributes remains challenging.

Manufacturing consistency and scalability constitute significant hurdles for commercial implementation. Current production methods often struggle to deliver uniform pore size distribution and consistent wall thickness across large-scale ceramic filter elements. This variability leads to unpredictable performance and complicates quality control processes. Additionally, advanced ceramic manufacturing techniques capable of producing complex geometries with precisely controlled porosity typically involve high production costs, limiting economic viability.

Energy efficiency concerns persist throughout the lifecycle of ceramic filters, from energy-intensive manufacturing processes to the operational energy requirements associated with pressure drops during filtration. Reducing the environmental footprint while maintaining performance standards represents an ongoing challenge for the industry.

Lastly, the integration of smart functionality into ceramic filter systems, such as real-time monitoring capabilities or self-cleaning mechanisms, remains in nascent stages. The inherent brittleness and high-temperature processing requirements of ceramics complicate the incorporation of sensors or responsive elements that could enhance operational efficiency and extend service intervals.

Fouling and clogging represent another persistent challenge, particularly in applications involving high particulate concentrations or viscous fluids. The gradual accumulation of filtered particles within porous structures leads to diminished flow rates and increased pressure drops across the filter medium. Current regeneration methods, including backwashing and thermal treatments, often prove insufficient for complete restoration of original performance parameters, especially for deeply embedded contaminants within the ceramic matrix.

Temperature resistance limitations present significant constraints in high-temperature applications. While structural ceramics generally exhibit superior thermal stability compared to polymeric alternatives, certain ceramic compositions still experience phase transformations, sintering effects, or chemical degradation when subjected to extreme thermal cycling or prolonged exposure to elevated temperatures. These phenomena can alter pore structure and compromise filtration efficiency over time.

Chemical compatibility issues arise when ceramic filters encounter aggressive media, particularly in industrial wastewater treatment or chemical processing applications. Acid or alkaline environments can gradually erode ceramic structures, altering surface properties and pore characteristics. The development of chemically resistant ceramic compositions without sacrificing other performance attributes remains challenging.

Manufacturing consistency and scalability constitute significant hurdles for commercial implementation. Current production methods often struggle to deliver uniform pore size distribution and consistent wall thickness across large-scale ceramic filter elements. This variability leads to unpredictable performance and complicates quality control processes. Additionally, advanced ceramic manufacturing techniques capable of producing complex geometries with precisely controlled porosity typically involve high production costs, limiting economic viability.

Energy efficiency concerns persist throughout the lifecycle of ceramic filters, from energy-intensive manufacturing processes to the operational energy requirements associated with pressure drops during filtration. Reducing the environmental footprint while maintaining performance standards represents an ongoing challenge for the industry.

Lastly, the integration of smart functionality into ceramic filter systems, such as real-time monitoring capabilities or self-cleaning mechanisms, remains in nascent stages. The inherent brittleness and high-temperature processing requirements of ceramics complicate the incorporation of sensors or responsive elements that could enhance operational efficiency and extend service intervals.

Contemporary Ceramic Filter Design Solutions

01 Ceramic material composition for enhanced filtration

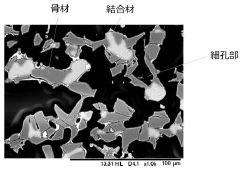

Specific ceramic material compositions can significantly enhance filtration efficiency in porous media filters. These compositions typically include alumina, silicon carbide, cordierite, or mullite, which provide optimal pore structure and mechanical strength. The chemical composition and sintering conditions of these ceramics directly influence the filter's performance characteristics such as permeability, mechanical strength, and thermal stability, resulting in improved particle capture efficiency while maintaining acceptable pressure drop across the filter.- Ceramic material composition for enhanced filtration: Specific ceramic compositions can significantly improve filtration efficiency in porous media filters. These materials include silicon carbide, alumina, and cordierite, which offer superior mechanical strength and thermal stability. The composition can be tailored to achieve desired porosity levels and pore size distribution, directly affecting the filter's ability to capture particles while maintaining adequate flow rates. Advanced ceramic formulations may incorporate additives that enhance surface properties for better particle adhesion.

- Pore structure optimization for filtration efficiency: The design and control of pore structure in ceramic filters is crucial for optimizing filtration efficiency. Techniques such as controlled sintering, template-based manufacturing, and multi-layer structures can create interconnected pore networks with specific size distributions. Gradient porosity structures allow for depth filtration capabilities, where larger particles are captured near the surface while smaller particles are trapped deeper in the filter. The relationship between pore size, tortuosity, and connectivity directly impacts both particle capture efficiency and pressure drop across the filter.

- Surface modification techniques for ceramic filters: Surface treatments and modifications of ceramic filter materials can significantly enhance filtration performance. Techniques include chemical functionalization, plasma treatment, and coating with catalytic or adsorptive materials. These modifications can increase the affinity for specific contaminants, improve hydrophilicity/hydrophobicity as needed, and provide additional functionality such as antimicrobial properties. Surface charge manipulation through various treatments can also enhance the electrostatic capture of charged particles, improving overall filtration efficiency without compromising flow characteristics.

- Advanced manufacturing methods for ceramic filters: Innovative manufacturing techniques are being developed to create ceramic filters with precisely controlled structures. These include 3D printing, freeze casting, gel casting, and template-assisted methods. Such techniques allow for the creation of complex geometries and hierarchical structures that would be impossible with traditional ceramic processing. The ability to design specific flow paths and capture zones within the filter structure leads to enhanced filtration efficiency while potentially reducing pressure drop. These manufacturing advances also enable the integration of multiple functional zones within a single filter component.

- Performance evaluation and optimization methods: Sophisticated testing and characterization methods are essential for evaluating and optimizing ceramic filter performance. Techniques include computational fluid dynamics modeling, in-situ particle tracking, accelerated fouling tests, and advanced imaging methods such as X-ray tomography. These approaches allow for quantitative assessment of filtration efficiency under various operating conditions and contaminant loads. Performance metrics typically include particle size-dependent removal efficiency, pressure drop evolution, filter capacity, and service life prediction. Such comprehensive evaluation enables targeted improvements in filter design and material selection.

02 Pore structure optimization techniques

Controlling the pore structure of ceramic filters is crucial for optimizing filtration efficiency. Various manufacturing techniques can be employed to create hierarchical pore structures with controlled pore size distribution, interconnectivity, and tortuosity. Methods such as partial sintering, use of pore-forming agents, and template-assisted fabrication allow for tailored porosity ranging from micropores to macropores. This optimization enables higher particulate matter capture efficiency while maintaining adequate flow rates and minimizing pressure drop across the filter media.Expand Specific Solutions03 Surface modification of ceramic filter media

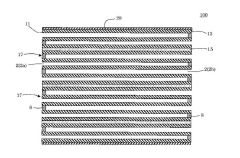

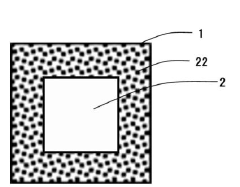

Surface modification techniques can significantly improve the filtration efficiency of ceramic porous media. These modifications include applying functional coatings, catalytic layers, or chemical treatments to the ceramic substrate. Such treatments can enhance particle adhesion, provide antimicrobial properties, or add catalytic functionality to the filter surface. Modified surfaces can also prevent fouling and extend filter lifetime by altering surface charge, hydrophilicity, or chemical reactivity, thereby improving overall filtration performance especially for challenging contaminants.Expand Specific Solutions04 Multi-layer ceramic filter structures

Multi-layer ceramic filter structures offer enhanced filtration efficiency through the combination of different pore sizes and material compositions in sequential layers. These structures typically feature a gradient of porosity, with coarser pores in the inlet layers transitioning to finer pores in the outlet layers. This design enables effective capture of particles across a wide size range while maintaining acceptable flow rates and extending filter lifetime. The interface between different ceramic layers can also be engineered to optimize mechanical strength and thermal stability under operational conditions.Expand Specific Solutions05 Advanced manufacturing techniques for ceramic filters

Advanced manufacturing techniques have revolutionized the production of high-efficiency ceramic filters. Methods such as 3D printing, freeze casting, gel casting, and advanced extrusion processes enable precise control over the filter architecture. These techniques allow for complex geometries, optimized flow channels, and tailored porosity that would be impossible with conventional manufacturing methods. The resulting ceramic filters feature improved surface area to volume ratios, enhanced mechanical properties, and optimized flow dynamics, all contributing to superior filtration efficiency while maintaining structural integrity under demanding operational conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The structural ceramics market in porous media filters is currently in a growth phase, characterized by increasing demand across industrial applications. The market size is expanding steadily, driven by stringent environmental regulations and growing industrial filtration needs. Technologically, the field shows moderate maturity with ongoing innovation. Leading players include NGK Insulators and Corning, who have established strong positions through advanced ceramic technologies for filtration applications. IBIDEN and Saint-Gobain are advancing material science in this domain, while companies like LiqTech International specialize in silicon carbide ceramic membranes for liquid filtration. Asian manufacturers, particularly Japanese firms like Sumitomo Electric and DENSO, are increasingly competitive through integration of advanced manufacturing processes, creating a globally diverse competitive landscape with opportunities for technological differentiation.

NGK Insulators, Ltd.

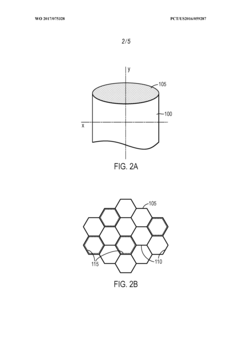

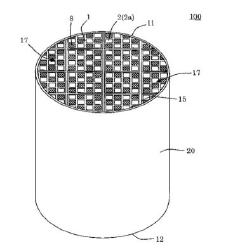

Technical Solution: NGK Insulators has developed advanced cordierite and silicon carbide ceramic filters with optimized pore structure for particulate matter filtration. Their proprietary HONEYCERAM® technology features a honeycomb structure with alternately sealed channels that force exhaust gases through porous ceramic walls. NGK's latest innovation includes nano-engineered pore structures with controlled pore size distribution (2-20μm) and porosity levels of 40-60%, enabling high filtration efficiency (>99%) while maintaining low pressure drop. The company has also developed specialized coating technologies that incorporate catalytic materials directly into the ceramic matrix, allowing for simultaneous filtration and chemical reactions in a single component. Their ceramic filters demonstrate exceptional thermal shock resistance, withstanding temperature fluctuations from ambient to 1000°C without structural degradation.

Strengths: Superior thermal durability (withstanding >1000°C), excellent chemical resistance to harsh environments, and proprietary manufacturing processes enabling precise pore structure control. Weaknesses: Higher production costs compared to metal alternatives, potential brittleness under extreme mechanical stress, and limitations in geometric complexity due to manufacturing constraints.

Corning, Inc.

Technical Solution: Corning has pioneered cellular ceramic technology with their DuraTrap® filter systems, utilizing cordierite and aluminum titanate materials specifically engineered for porous media applications. Their patented extrusion process creates honeycomb structures with wall thicknesses as thin as 50-300μm while maintaining mechanical integrity. Corning's advanced ceramic filters feature tailored porosity (45-65%) with asymmetric pore structures that optimize filtration efficiency and flow characteristics. The company has developed proprietary material formulations that enhance thermal expansion resistance, crucial for applications involving rapid temperature changes. Their latest innovation includes multi-functional ceramic filters with integrated catalyst layers that enable simultaneous particulate capture and gaseous pollutant conversion. Corning's manufacturing technology allows precise control of cell density (100-900 cells per square inch) to balance filtration performance with pressure drop requirements for specific applications.

Strengths: Industry-leading thermal shock resistance with coefficient of thermal expansion near zero, exceptional durability in cyclic operating conditions, and advanced manufacturing capabilities for complex geometries. Weaknesses: Higher initial cost compared to conventional filter materials, potential for ash clogging in certain applications requiring regular regeneration, and limitations in retrofit applications due to specific dimensional requirements.

Key Patents and Innovations in Ceramic Porosity Control

Porous ceramic filters and methods for making the same

PatentWO2017075328A1

Innovation

- The development of porous ceramic filters with a nanomembrane comprising nanoparticles of inorganic oxides, such as SiO2, Al2O3, and TiO2, deposited on a porous ceramic substrate with a high porosity and specific median pore size, which enhances filtration efficiency and reduces pressure drop.

Ceramics porous body and method for producing the same, and dust collection filter

PatentActiveJP2020164408A

Innovation

- A ceramic porous body with a controlled pore volume ratio of 10 to 15 μm, comprising an aggregate, binder, and sintering aid, is developed to enhance durability and purification performance by optimizing the pore structure.

Environmental Impact and Sustainability Considerations

The environmental impact of structural ceramics in porous media filters represents a critical consideration in their development and application. These filters, while offering significant technical advantages, must be evaluated within the broader context of sustainability and environmental stewardship. The production of ceramic materials typically involves high-temperature firing processes that consume substantial energy, contributing to carbon emissions and resource depletion when powered by fossil fuels.

Manufacturing processes for structural ceramics often require raw materials that must be mined, processed, and transported, creating additional environmental footprints. However, recent advancements in green manufacturing techniques have shown promise in reducing these impacts through the use of waste materials as precursors and the implementation of more energy-efficient firing technologies.

The durability and longevity of ceramic filters present a significant environmental advantage over alternatives. With proper design and material selection, ceramic-based filtration systems can operate effectively for extended periods without replacement, reducing waste generation and resource consumption associated with frequent filter changes. This longevity factor must be quantified in lifecycle assessments to accurately represent the environmental benefits of ceramic filter technologies.

Water conservation represents another important environmental consideration. Ceramic filters often require less frequent backwashing than polymer-based alternatives, potentially reducing water consumption in operational settings. Additionally, the chemical stability of ceramics eliminates concerns about leaching of harmful substances into filtered water or the environment, addressing growing concerns about micropollutants.

End-of-life management for ceramic filters presents both challenges and opportunities. While ceramic materials are not biodegradable, they are generally inert and non-toxic when disposed of. Furthermore, emerging recycling technologies are creating pathways for reclaiming spent ceramic filter materials for use in construction materials or as precursors for new ceramic products, moving toward circular economy principles.

Carbon footprint reduction strategies for ceramic filter production include the integration of renewable energy sources for firing processes, optimization of kiln designs for improved thermal efficiency, and the development of lower-temperature sintering techniques. These approaches can significantly reduce the environmental impact of manufacturing while maintaining the essential performance characteristics of the filters.

The sustainability profile of ceramic filters must also consider their application context. In water purification systems for developing regions, the environmental benefits of providing clean water must be weighed against production impacts. Similarly, in industrial applications, the reduced use of chemical additives and improved filtration efficiency may offset manufacturing-related environmental costs.

Manufacturing processes for structural ceramics often require raw materials that must be mined, processed, and transported, creating additional environmental footprints. However, recent advancements in green manufacturing techniques have shown promise in reducing these impacts through the use of waste materials as precursors and the implementation of more energy-efficient firing technologies.

The durability and longevity of ceramic filters present a significant environmental advantage over alternatives. With proper design and material selection, ceramic-based filtration systems can operate effectively for extended periods without replacement, reducing waste generation and resource consumption associated with frequent filter changes. This longevity factor must be quantified in lifecycle assessments to accurately represent the environmental benefits of ceramic filter technologies.

Water conservation represents another important environmental consideration. Ceramic filters often require less frequent backwashing than polymer-based alternatives, potentially reducing water consumption in operational settings. Additionally, the chemical stability of ceramics eliminates concerns about leaching of harmful substances into filtered water or the environment, addressing growing concerns about micropollutants.

End-of-life management for ceramic filters presents both challenges and opportunities. While ceramic materials are not biodegradable, they are generally inert and non-toxic when disposed of. Furthermore, emerging recycling technologies are creating pathways for reclaiming spent ceramic filter materials for use in construction materials or as precursors for new ceramic products, moving toward circular economy principles.

Carbon footprint reduction strategies for ceramic filter production include the integration of renewable energy sources for firing processes, optimization of kiln designs for improved thermal efficiency, and the development of lower-temperature sintering techniques. These approaches can significantly reduce the environmental impact of manufacturing while maintaining the essential performance characteristics of the filters.

The sustainability profile of ceramic filters must also consider their application context. In water purification systems for developing regions, the environmental benefits of providing clean water must be weighed against production impacts. Similarly, in industrial applications, the reduced use of chemical additives and improved filtration efficiency may offset manufacturing-related environmental costs.

Performance Metrics and Testing Standards

The evaluation of structural ceramics in porous media filters requires standardized performance metrics and testing protocols to ensure consistent quality assessment. The filtration efficiency, measured as the percentage of particles captured by the filter, stands as a primary metric, typically determined through particle counting before and after filtration using laser particle analyzers or gravimetric methods. This parameter varies significantly based on particle size distribution, with most standards requiring efficiency measurements across multiple particle size ranges.

Pressure drop represents another critical performance indicator, measuring the resistance to flow across the filter media. This metric directly impacts energy consumption in filtration systems and is typically measured in pascals or bar under standardized flow conditions. The relationship between pressure drop and filtration efficiency often presents a trade-off that manufacturers must optimize according to application requirements.

Mechanical strength parameters, including compressive strength, flexural strength, and Young's modulus, are essential for evaluating structural integrity under operational conditions. ASTM C1674 and similar standards provide testing methodologies specifically designed for ceramic materials used in filtration applications. These tests simulate the mechanical stresses experienced during operation, including thermal cycling and pressure fluctuations.

Chemical resistance testing follows protocols such as ASTM C1662, which evaluates material degradation when exposed to acids, bases, and other corrosive substances commonly encountered in industrial environments. This includes measurements of weight loss, dimensional changes, and strength retention after controlled exposure periods.

Thermal stability assessment involves cyclic heating and cooling tests to evaluate material performance under temperature fluctuations. Standards like ISO 10081 provide guidelines for refractory ceramics testing, with modifications applicable to porous filter media. These tests typically measure thermal expansion coefficients, thermal shock resistance, and structural integrity after multiple thermal cycles.

Longevity metrics, including service life prediction models based on accelerated aging tests, help quantify the expected operational duration under various conditions. The dust holding capacity, measured in grams per square meter, indicates how much particulate matter a filter can accumulate before requiring regeneration or replacement.

International standards organizations, including ISO, ASTM, and DIN, have developed specific testing protocols for ceramic filter media. Notable examples include ISO 29463 for high-efficiency filters, ASTM F1252 for porous ceramic filters, and DIN 71460 for automotive applications. These standards ensure consistency in performance evaluation across different manufacturers and applications, facilitating meaningful comparisons and quality assurance.

Pressure drop represents another critical performance indicator, measuring the resistance to flow across the filter media. This metric directly impacts energy consumption in filtration systems and is typically measured in pascals or bar under standardized flow conditions. The relationship between pressure drop and filtration efficiency often presents a trade-off that manufacturers must optimize according to application requirements.

Mechanical strength parameters, including compressive strength, flexural strength, and Young's modulus, are essential for evaluating structural integrity under operational conditions. ASTM C1674 and similar standards provide testing methodologies specifically designed for ceramic materials used in filtration applications. These tests simulate the mechanical stresses experienced during operation, including thermal cycling and pressure fluctuations.

Chemical resistance testing follows protocols such as ASTM C1662, which evaluates material degradation when exposed to acids, bases, and other corrosive substances commonly encountered in industrial environments. This includes measurements of weight loss, dimensional changes, and strength retention after controlled exposure periods.

Thermal stability assessment involves cyclic heating and cooling tests to evaluate material performance under temperature fluctuations. Standards like ISO 10081 provide guidelines for refractory ceramics testing, with modifications applicable to porous filter media. These tests typically measure thermal expansion coefficients, thermal shock resistance, and structural integrity after multiple thermal cycles.

Longevity metrics, including service life prediction models based on accelerated aging tests, help quantify the expected operational duration under various conditions. The dust holding capacity, measured in grams per square meter, indicates how much particulate matter a filter can accumulate before requiring regeneration or replacement.

International standards organizations, including ISO, ASTM, and DIN, have developed specific testing protocols for ceramic filter media. Notable examples include ISO 29463 for high-efficiency filters, ASTM F1252 for porous ceramic filters, and DIN 71460 for automotive applications. These standards ensure consistency in performance evaluation across different manufacturers and applications, facilitating meaningful comparisons and quality assurance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!