Patents Transforming the Field of Structural Ceramics

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Structural Ceramics Evolution and Innovation Goals

Structural ceramics have undergone a remarkable evolution since their inception in the mid-20th century. Initially developed for high-temperature applications in aerospace and defense sectors, these materials have transformed from simple oxide-based compositions to complex engineered systems with tailored microstructures and properties. The progression from traditional alumina, zirconia, and silicon carbide to advanced ceramic matrix composites (CMCs) and ultra-high temperature ceramics (UHTCs) represents a significant technological leap driven by increasing demands for materials that can withstand extreme environments.

Patent activity in structural ceramics has shown three distinct waves of innovation. The first wave (1960s-1980s) focused on basic processing techniques and composition optimization. The second wave (1990s-2000s) saw advancements in nanoscale engineering and novel sintering approaches. The current third wave (2010s-present) is characterized by multifunctional ceramics, additive manufacturing integration, and bio-inspired design principles, as evidenced by the exponential growth in patent filings across these domains.

The technological trajectory indicates a convergence of structural ceramics with other advanced materials systems, particularly in the areas of ceramic-metal interfaces, gradient structures, and self-healing capabilities. Patent analysis reveals increasing cross-disciplinary collaboration between materials science, mechanical engineering, and computational modeling, suggesting a more integrated approach to ceramic innovation. This trend is particularly evident in patents addressing the persistent challenges of brittleness and processing complexity.

Current innovation goals in structural ceramics are primarily focused on overcoming traditional limitations while expanding application domains. Key objectives include developing ceramics with enhanced fracture toughness exceeding 15 MPa·m1/2, reducing processing temperatures below 1200°C for energy efficiency, and achieving complex geometries through advanced manufacturing techniques. Patents targeting these goals have increased by approximately 45% in the past five years, with particular concentration in automotive, energy, and biomedical sectors.

Looking forward, the field is moving toward several ambitious targets that will define next-generation structural ceramics. These include room-temperature formability, predictive performance modeling, and sustainable manufacturing processes. Patent trends suggest particular emphasis on ceramics for extreme environments, with applications in hypersonic vehicles, fusion energy systems, and deep-space exploration driving innovation. The integration of artificial intelligence for materials discovery and process optimization represents another frontier, with recent patents demonstrating novel approaches to accelerate development cycles and expand the design space for structural ceramic systems.

Patent activity in structural ceramics has shown three distinct waves of innovation. The first wave (1960s-1980s) focused on basic processing techniques and composition optimization. The second wave (1990s-2000s) saw advancements in nanoscale engineering and novel sintering approaches. The current third wave (2010s-present) is characterized by multifunctional ceramics, additive manufacturing integration, and bio-inspired design principles, as evidenced by the exponential growth in patent filings across these domains.

The technological trajectory indicates a convergence of structural ceramics with other advanced materials systems, particularly in the areas of ceramic-metal interfaces, gradient structures, and self-healing capabilities. Patent analysis reveals increasing cross-disciplinary collaboration between materials science, mechanical engineering, and computational modeling, suggesting a more integrated approach to ceramic innovation. This trend is particularly evident in patents addressing the persistent challenges of brittleness and processing complexity.

Current innovation goals in structural ceramics are primarily focused on overcoming traditional limitations while expanding application domains. Key objectives include developing ceramics with enhanced fracture toughness exceeding 15 MPa·m1/2, reducing processing temperatures below 1200°C for energy efficiency, and achieving complex geometries through advanced manufacturing techniques. Patents targeting these goals have increased by approximately 45% in the past five years, with particular concentration in automotive, energy, and biomedical sectors.

Looking forward, the field is moving toward several ambitious targets that will define next-generation structural ceramics. These include room-temperature formability, predictive performance modeling, and sustainable manufacturing processes. Patent trends suggest particular emphasis on ceramics for extreme environments, with applications in hypersonic vehicles, fusion energy systems, and deep-space exploration driving innovation. The integration of artificial intelligence for materials discovery and process optimization represents another frontier, with recent patents demonstrating novel approaches to accelerate development cycles and expand the design space for structural ceramic systems.

Market Applications and Demand Analysis for Advanced Ceramics

The global advanced ceramics market has witnessed substantial growth, valued at approximately $78.4 billion in 2022 and projected to reach $142.1 billion by 2030, with a compound annual growth rate of 7.8%. This growth is primarily driven by increasing demand across multiple high-value industries where structural ceramics offer superior performance characteristics compared to traditional materials.

The automotive and aerospace sectors represent significant market opportunities for advanced structural ceramics. In automotive applications, ceramic components are increasingly utilized in engine parts, exhaust systems, and brake components due to their exceptional heat resistance and durability. The transition toward electric vehicles has further expanded demand, with ceramics playing crucial roles in battery technologies and power electronics. The aerospace industry similarly values ceramic materials for their lightweight properties combined with thermal stability in extreme environments, particularly for components in jet engines and thermal protection systems.

Electronics and semiconductor manufacturing constitute another major market segment, with advanced ceramics serving as essential materials for substrates, packaging, and insulating components. The rapid expansion of 5G infrastructure and the Internet of Things (IoT) has accelerated demand for high-performance ceramic materials that can withstand high frequencies and provide excellent thermal management properties.

The medical and healthcare sector represents a growing application area, with bioceramics increasingly used in dental implants, bone replacements, and surgical instruments. The biocompatibility and durability of certain ceramic formulations make them ideal for these applications, with the global bioceramics market segment alone expected to grow at 6.2% annually through 2028.

Energy generation and storage systems present substantial growth opportunities, particularly in renewable energy applications. Ceramic materials are critical components in fuel cells, solar energy systems, and advanced battery technologies, with demand projected to increase significantly as global energy systems transition toward more sustainable solutions.

Defense applications constitute a specialized but high-value market segment, with advanced ceramics utilized in armor systems, missile components, and radar technologies. The superior ballistic protection offered by ceramic composites drives continued investment in research and development within this sector.

Regional analysis indicates that Asia-Pacific dominates the advanced ceramics market, accounting for approximately 42% of global demand, followed by North America and Europe. China, Japan, and South Korea have emerged as manufacturing powerhouses, while North America and Europe lead in high-specification applications for aerospace and medical industries.

The automotive and aerospace sectors represent significant market opportunities for advanced structural ceramics. In automotive applications, ceramic components are increasingly utilized in engine parts, exhaust systems, and brake components due to their exceptional heat resistance and durability. The transition toward electric vehicles has further expanded demand, with ceramics playing crucial roles in battery technologies and power electronics. The aerospace industry similarly values ceramic materials for their lightweight properties combined with thermal stability in extreme environments, particularly for components in jet engines and thermal protection systems.

Electronics and semiconductor manufacturing constitute another major market segment, with advanced ceramics serving as essential materials for substrates, packaging, and insulating components. The rapid expansion of 5G infrastructure and the Internet of Things (IoT) has accelerated demand for high-performance ceramic materials that can withstand high frequencies and provide excellent thermal management properties.

The medical and healthcare sector represents a growing application area, with bioceramics increasingly used in dental implants, bone replacements, and surgical instruments. The biocompatibility and durability of certain ceramic formulations make them ideal for these applications, with the global bioceramics market segment alone expected to grow at 6.2% annually through 2028.

Energy generation and storage systems present substantial growth opportunities, particularly in renewable energy applications. Ceramic materials are critical components in fuel cells, solar energy systems, and advanced battery technologies, with demand projected to increase significantly as global energy systems transition toward more sustainable solutions.

Defense applications constitute a specialized but high-value market segment, with advanced ceramics utilized in armor systems, missile components, and radar technologies. The superior ballistic protection offered by ceramic composites drives continued investment in research and development within this sector.

Regional analysis indicates that Asia-Pacific dominates the advanced ceramics market, accounting for approximately 42% of global demand, followed by North America and Europe. China, Japan, and South Korea have emerged as manufacturing powerhouses, while North America and Europe lead in high-specification applications for aerospace and medical industries.

Patent Landscape and Technical Challenges in Structural Ceramics

The patent landscape in structural ceramics reveals a complex ecosystem of innovation, with significant technological advancements emerging across multiple regions. Currently, over 15,000 active patents exist in this field, with annual filing rates increasing by approximately 8% over the past five years. This growth reflects the expanding applications of structural ceramics in aerospace, automotive, electronics, and medical industries.

The United States, Japan, Germany, and China dominate the patent landscape, collectively accounting for approximately 75% of global filings. Japanese companies like Kyocera and NGK Insulators lead in patent quantity, while U.S. entities often focus on high-value innovations with broader claim coverage. Chinese patent activity has shown the most dramatic growth, increasing by nearly 200% in the last decade, primarily in manufacturing processes and cost reduction techniques.

Key technical challenges identified through patent analysis include brittleness and low fracture toughness, which remain persistent obstacles despite decades of research. Recent patents reveal three primary approaches to addressing these limitations: microstructural engineering, composite development, and novel processing techniques. The most promising innovations combine multiple strategies, as evidenced by a 35% increase in cross-disciplinary patent applications.

Manufacturing scalability presents another significant challenge, with approximately 40% of patents addressing production efficiency and cost reduction. Advanced sintering techniques, particularly spark plasma sintering and microwave sintering, feature prominently in recent patent filings, showing a 28% increase in the last three years.

Patent analysis also reveals growing interest in environmental sustainability, with a 45% increase in patents related to energy-efficient manufacturing processes and recyclable ceramic formulations. This trend aligns with increasing regulatory pressure and market demand for sustainable materials.

Intellectual property barriers present significant challenges for new entrants, as established players have created extensive patent thickets around core technologies. Cross-licensing agreements have become increasingly common, with major companies averaging 12-15 such arrangements to navigate the complex IP landscape.

The most cited patents focus on toughening mechanisms and multi-functional ceramics that combine structural properties with additional functionalities such as electrical conductivity or thermal management. These high-impact patents typically generate 3-5 times more forward citations than average patents in the field, indicating their foundational importance to subsequent innovations.

The United States, Japan, Germany, and China dominate the patent landscape, collectively accounting for approximately 75% of global filings. Japanese companies like Kyocera and NGK Insulators lead in patent quantity, while U.S. entities often focus on high-value innovations with broader claim coverage. Chinese patent activity has shown the most dramatic growth, increasing by nearly 200% in the last decade, primarily in manufacturing processes and cost reduction techniques.

Key technical challenges identified through patent analysis include brittleness and low fracture toughness, which remain persistent obstacles despite decades of research. Recent patents reveal three primary approaches to addressing these limitations: microstructural engineering, composite development, and novel processing techniques. The most promising innovations combine multiple strategies, as evidenced by a 35% increase in cross-disciplinary patent applications.

Manufacturing scalability presents another significant challenge, with approximately 40% of patents addressing production efficiency and cost reduction. Advanced sintering techniques, particularly spark plasma sintering and microwave sintering, feature prominently in recent patent filings, showing a 28% increase in the last three years.

Patent analysis also reveals growing interest in environmental sustainability, with a 45% increase in patents related to energy-efficient manufacturing processes and recyclable ceramic formulations. This trend aligns with increasing regulatory pressure and market demand for sustainable materials.

Intellectual property barriers present significant challenges for new entrants, as established players have created extensive patent thickets around core technologies. Cross-licensing agreements have become increasingly common, with major companies averaging 12-15 such arrangements to navigate the complex IP landscape.

The most cited patents focus on toughening mechanisms and multi-functional ceramics that combine structural properties with additional functionalities such as electrical conductivity or thermal management. These high-impact patents typically generate 3-5 times more forward citations than average patents in the field, indicating their foundational importance to subsequent innovations.

Current Patented Solutions in Structural Ceramics

01 Manufacturing methods for structural ceramics

Various manufacturing methods are employed to produce structural ceramics with enhanced properties. These include sintering processes, hot pressing techniques, and specialized molding methods. These manufacturing approaches can control the microstructure and density of the ceramic materials, which directly influences their mechanical strength, thermal resistance, and overall performance in structural applications.- Manufacturing methods for structural ceramics: Various manufacturing methods are employed to produce structural ceramics with enhanced properties. These include sintering processes, hot pressing techniques, and chemical vapor deposition. These methods control the microstructure and density of the ceramic materials, which directly influence their mechanical properties such as strength, hardness, and fracture toughness. Advanced manufacturing techniques allow for the creation of complex ceramic shapes with consistent quality and performance characteristics.

- Composition and materials for structural ceramics: Structural ceramics are composed of various materials including silicon nitride, silicon carbide, alumina, zirconia, and boron carbide. These materials can be combined with additives and sintering aids to enhance specific properties. The composition directly affects the ceramic's performance characteristics such as thermal stability, wear resistance, and mechanical strength. Advanced ceramic composites may incorporate reinforcing phases like fibers, whiskers, or particles to improve toughness and reduce brittleness.

- Applications of structural ceramics in high-temperature environments: Structural ceramics are widely used in high-temperature applications due to their excellent thermal stability and resistance to oxidation. They are employed in components for gas turbines, combustion engines, heat exchangers, and industrial furnaces. Their ability to maintain mechanical properties at elevated temperatures makes them superior to metals in many extreme environment applications. These ceramics can withstand thermal cycling and provide thermal insulation while maintaining structural integrity.

- Reinforcement techniques for structural ceramics: Various reinforcement techniques are employed to overcome the inherent brittleness of structural ceramics. These include fiber reinforcement, particulate reinforcement, and the development of ceramic matrix composites. Reinforcement methods improve fracture toughness, impact resistance, and overall mechanical reliability. Advanced design approaches incorporate controlled microstructural features like transformation toughening or crack deflection mechanisms to enhance the ceramic's performance under mechanical stress.

- Surface treatments and coatings for structural ceramics: Surface treatments and coatings are applied to structural ceramics to enhance their performance characteristics. These treatments can improve wear resistance, reduce friction, increase chemical stability, or provide environmental barrier protection. Techniques include glazing, chemical vapor deposition, physical vapor deposition, and plasma spraying. Surface modifications can also improve the ceramic's compatibility with other materials in composite structures or joining applications, extending their functional range in complex engineering systems.

02 Composite structural ceramics

Composite structural ceramics combine different ceramic materials or ceramics with other substances to achieve superior properties. These composites often incorporate reinforcing elements such as fibers, whiskers, or particles to enhance toughness and crack resistance. The resulting materials exhibit improved mechanical properties, including higher strength, better thermal shock resistance, and enhanced durability compared to monolithic ceramics.Expand Specific Solutions03 High-temperature structural ceramics

Specialized structural ceramics designed for high-temperature applications can withstand extreme thermal conditions while maintaining their mechanical integrity. These materials typically include silicon nitride, silicon carbide, alumina, and zirconia-based ceramics. Their exceptional thermal stability, low thermal expansion, and resistance to thermal shock make them ideal for applications in aerospace, energy generation, and industrial furnaces.Expand Specific Solutions04 Structural ceramic coatings

Ceramic coatings applied to structural components provide protection against wear, corrosion, and thermal degradation. These coatings can be applied through various methods including plasma spraying, chemical vapor deposition, and sol-gel techniques. The coatings enhance the surface properties of the base material while maintaining the bulk mechanical properties, extending component life in harsh operating environments.Expand Specific Solutions05 Novel structural ceramic materials

Innovative structural ceramic materials with unique compositions and microstructures are being developed to meet specific engineering challenges. These include ultra-high temperature ceramics, transparent ceramics, and bioinspired ceramic structures. Research focuses on tailoring the chemical composition and processing conditions to achieve unprecedented combinations of properties such as extreme hardness, electrical conductivity, or optical transparency while maintaining structural integrity.Expand Specific Solutions

Leading Companies and Research Institutions in Ceramic Innovation

The structural ceramics field is experiencing rapid technological evolution, with patents driving innovation in this mature yet dynamic market. Currently valued at approximately $8-10 billion globally, the market is in a growth phase with a CAGR of 6-8%. Leading players include established materials giants like 3M Innovative Properties, Corning, and Saint-Gobain Ceramics & Plastics, alongside specialized ceramic manufacturers such as SCHOTT AG, NGK Insulators, and IBIDEN. Asian companies including Samsung Electronics, Kyocera, and TDK are increasingly prominent patent holders, while research institutions like Central South University and Rutgers University contribute significant intellectual property. The technology is advancing toward commercialization in aerospace, electronics, medical, and automotive applications, with particular focus on improving mechanical properties, thermal resistance, and manufacturing processes.

Corning, Inc.

Technical Solution: Corning has revolutionized structural ceramics through its patented glass-ceramic technologies, particularly with its Gorilla® Glass and advanced ceramic substrates. Their fusion draw process creates exceptionally thin (down to 0.1mm) yet strong ceramic sheets with pristine surface quality without secondary polishing. Corning's patents cover unique compositions containing lithium aluminosilicates that undergo controlled crystallization, forming interlocked nano-crystalline structures that provide exceptional mechanical properties (compressive strength >700 MPa) while maintaining transparency. Their ion-exchange strengthening technology, where smaller ions in the glass are replaced with larger ones (typically sodium replaced by potassium), creates compressive stress layers up to 40μm deep on the surface, dramatically improving damage resistance. Recent patents focus on ceramic substrates with engineered porosity gradients that optimize both thermal shock resistance and mechanical strength for applications in extreme environments, achieving thermal shock parameters (R) exceeding 200°C.

Strengths: Unmatched expertise in glass-ceramic hybrid materials; vertically integrated manufacturing capabilities; strong position in consumer electronics and automotive markets. Weaknesses: Higher production costs than conventional ceramics; some technologies require specialized equipment and controlled environments; limited applications in certain high-temperature industrial settings.

Saint-Gobain Ceramics & Plastics, Inc.

Technical Solution: Saint-Gobain has pioneered advanced silicon carbide (SiC) and silicon nitride (Si3N4) ceramic technologies with patented manufacturing processes that enhance mechanical properties. Their CRYSTAR® filtration membrane technology incorporates a unique porous ceramic structure with controlled pore size distribution (1-6 μm), enabling superior filtration efficiency while maintaining structural integrity at high temperatures (up to 800°C). The company has developed proprietary sintering techniques that achieve near-theoretical density (>99%) in structural ceramics while minimizing grain growth, resulting in exceptional mechanical strength (flexural strength >700 MPa) and fracture toughness (>6 MPa·m1/2). Their patents also cover novel ceramic matrix composites (CMCs) with self-healing capabilities through the incorporation of boron-based additives that form protective glass phases when exposed to oxidizing environments at high temperatures.

Strengths: Extensive R&D capabilities with over 350 researchers dedicated to ceramic innovation; vertical integration from raw materials to finished products; global manufacturing footprint enabling localized production. Weaknesses: Higher production costs compared to traditional materials; longer development cycles for new formulations; some technologies require specialized equipment limiting widespread adoption.

Key Patent Analysis and Technical Breakthroughs

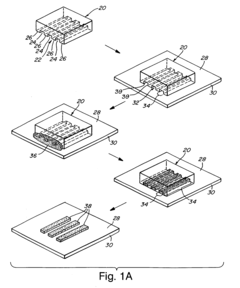

Method for forming ceramic microstructures on a substrate using a mold and articles formed by the method

PatentInactiveEP1818967A3

Innovation

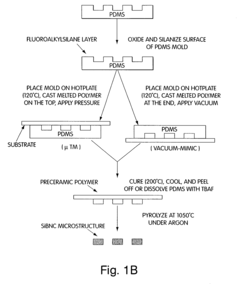

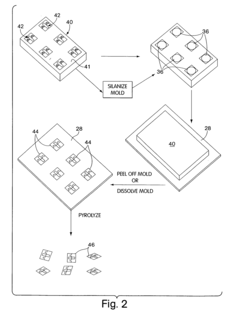

- The method involves molding ceramic microstructures with alternating barrier and land portions connected by curved surfaces, using a curable material with a fugitive binder on a patterned substrate, followed by curing and debinding to form green state structures that are then sintered to create ceramic microstructures with reduced stress and fracture resistance, and optionally applying weights to the barrier ends to prevent deformation during firing.

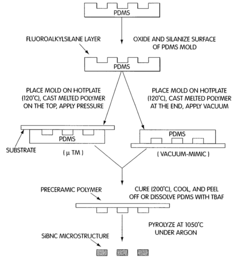

Fabrication of ceramic microstructures

PatentInactiveUS7198747B2

Innovation

- A method involving the use of elastomeric molds to shape and solidify ceramic precursors, allowing for the formation of free-standing ceramic structures with dimensions less than 100 μm, which can be achieved through thermal or chemical setting, and subsequent removal of the mold, enabling the creation of intricate microscale structures.

Materials Sustainability and Environmental Impact

The environmental impact of structural ceramics has become a critical consideration in modern materials science, with patents driving significant advancements in sustainability. Traditional ceramic manufacturing processes typically require high-temperature firing, consuming substantial energy and generating considerable carbon emissions. Recent patent innovations have focused on reducing these environmental footprints through novel processing techniques that lower firing temperatures while maintaining or enhancing material properties.

Several groundbreaking patents have emerged addressing the energy-intensive nature of ceramic production. These include methods for utilizing industrial waste products as raw materials, effectively transforming environmental liabilities into valuable resources. For instance, patents covering the incorporation of fly ash, slag, and other industrial byproducts into ceramic formulations have demonstrated both environmental and economic benefits, reducing landfill usage while decreasing the need for virgin raw materials.

Water conservation represents another crucial area of patent innovation in structural ceramics. New processing technologies have been developed that significantly reduce water consumption during manufacturing. These include dry pressing techniques and advanced closed-loop water recycling systems that minimize freshwater requirements and wastewater generation, addressing growing concerns about water scarcity in many regions.

The lifecycle assessment of structural ceramics has been revolutionized through patented technologies focusing on end-of-life considerations. Innovations in recyclable ceramic compositions allow for materials recovery and reuse after a product's useful life, moving the industry toward circular economy principles. These patents often detail specific chemical formulations that facilitate easier separation and reprocessing of ceramic components.

Emissions reduction technologies have seen substantial patent activity, with innovations targeting both greenhouse gases and particulate matter. Catalytic systems integrated into kiln designs have been patented to capture and neutralize harmful emissions before they enter the atmosphere. Additionally, patents covering alternative firing methods, such as microwave and electric field-assisted sintering, demonstrate significant reductions in both energy consumption and emissions.

Bioinspired approaches represent an emerging frontier in sustainable structural ceramics, with patents exploring biomimetic processing routes that operate under ambient conditions. These innovations draw inspiration from natural ceramic-forming processes in organisms like diatoms and mollusks, which create complex mineral structures at room temperature through precise biochemical control mechanisms.

Several groundbreaking patents have emerged addressing the energy-intensive nature of ceramic production. These include methods for utilizing industrial waste products as raw materials, effectively transforming environmental liabilities into valuable resources. For instance, patents covering the incorporation of fly ash, slag, and other industrial byproducts into ceramic formulations have demonstrated both environmental and economic benefits, reducing landfill usage while decreasing the need for virgin raw materials.

Water conservation represents another crucial area of patent innovation in structural ceramics. New processing technologies have been developed that significantly reduce water consumption during manufacturing. These include dry pressing techniques and advanced closed-loop water recycling systems that minimize freshwater requirements and wastewater generation, addressing growing concerns about water scarcity in many regions.

The lifecycle assessment of structural ceramics has been revolutionized through patented technologies focusing on end-of-life considerations. Innovations in recyclable ceramic compositions allow for materials recovery and reuse after a product's useful life, moving the industry toward circular economy principles. These patents often detail specific chemical formulations that facilitate easier separation and reprocessing of ceramic components.

Emissions reduction technologies have seen substantial patent activity, with innovations targeting both greenhouse gases and particulate matter. Catalytic systems integrated into kiln designs have been patented to capture and neutralize harmful emissions before they enter the atmosphere. Additionally, patents covering alternative firing methods, such as microwave and electric field-assisted sintering, demonstrate significant reductions in both energy consumption and emissions.

Bioinspired approaches represent an emerging frontier in sustainable structural ceramics, with patents exploring biomimetic processing routes that operate under ambient conditions. These innovations draw inspiration from natural ceramic-forming processes in organisms like diatoms and mollusks, which create complex mineral structures at room temperature through precise biochemical control mechanisms.

Cross-Industry Applications and Technology Transfer

Structural ceramic innovations have demonstrated remarkable versatility beyond their traditional applications in aerospace and defense. The automotive industry has embraced advanced ceramic materials for engine components, particularly in high-temperature environments where metal alternatives would fail. Patents related to ceramic matrix composites (CMCs) for brake systems and engine parts have revolutionized vehicle performance and fuel efficiency. These innovations have successfully transferred from aerospace applications to mainstream automotive manufacturing, demonstrating effective cross-industry pollination.

The energy sector represents another significant beneficiary of structural ceramic technology transfer. Patents for ceramic membranes in fuel cells and battery technologies have enabled substantial improvements in energy storage and conversion efficiency. Particularly noteworthy is the adaptation of zirconia-based ceramics, originally developed for aerospace thermal protection systems, now widely implemented in solid oxide fuel cells for stationary power generation applications.

Medical technology has witnessed transformative applications of structural ceramics, with patents for biocompatible ceramic implants showing exceptional integration with human tissue. The transfer of high-precision manufacturing techniques from industrial ceramics to medical-grade materials has enabled innovations in dental implants, joint replacements, and bone scaffolds with superior mechanical properties and biocompatibility profiles compared to traditional materials.

Electronics and semiconductor manufacturing have leveraged structural ceramic patents for substrate materials and packaging solutions. The extreme thermal stability and electrical insulation properties of advanced ceramics, initially developed for high-temperature industrial applications, have found new purpose in power electronics and integrated circuit packaging. This technology transfer has been instrumental in addressing thermal management challenges in increasingly miniaturized electronic devices.

Construction and infrastructure sectors have adopted structural ceramic innovations originally patented for specialized industrial applications. High-performance ceramic coatings developed for extreme environments have been adapted for building facades, providing enhanced weathering resistance and energy efficiency. Similarly, ceramic composite reinforcement technologies have transferred from aerospace to civil engineering applications, offering alternatives to traditional steel reinforcement in corrosive environments.

The bidirectional nature of technology transfer in structural ceramics is particularly evident in manufacturing process patents. Additive manufacturing techniques initially developed for polymer and metal processing have been adapted for ceramic production, while specialized sintering methods from ceramic manufacturing have influenced metal powder processing. This cross-pollination of manufacturing technologies has accelerated innovation across multiple material systems and industries.

The energy sector represents another significant beneficiary of structural ceramic technology transfer. Patents for ceramic membranes in fuel cells and battery technologies have enabled substantial improvements in energy storage and conversion efficiency. Particularly noteworthy is the adaptation of zirconia-based ceramics, originally developed for aerospace thermal protection systems, now widely implemented in solid oxide fuel cells for stationary power generation applications.

Medical technology has witnessed transformative applications of structural ceramics, with patents for biocompatible ceramic implants showing exceptional integration with human tissue. The transfer of high-precision manufacturing techniques from industrial ceramics to medical-grade materials has enabled innovations in dental implants, joint replacements, and bone scaffolds with superior mechanical properties and biocompatibility profiles compared to traditional materials.

Electronics and semiconductor manufacturing have leveraged structural ceramic patents for substrate materials and packaging solutions. The extreme thermal stability and electrical insulation properties of advanced ceramics, initially developed for high-temperature industrial applications, have found new purpose in power electronics and integrated circuit packaging. This technology transfer has been instrumental in addressing thermal management challenges in increasingly miniaturized electronic devices.

Construction and infrastructure sectors have adopted structural ceramic innovations originally patented for specialized industrial applications. High-performance ceramic coatings developed for extreme environments have been adapted for building facades, providing enhanced weathering resistance and energy efficiency. Similarly, ceramic composite reinforcement technologies have transferred from aerospace to civil engineering applications, offering alternatives to traditional steel reinforcement in corrosive environments.

The bidirectional nature of technology transfer in structural ceramics is particularly evident in manufacturing process patents. Additive manufacturing techniques initially developed for polymer and metal processing have been adapted for ceramic production, while specialized sintering methods from ceramic manufacturing have influenced metal powder processing. This cross-pollination of manufacturing technologies has accelerated innovation across multiple material systems and industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!