Understanding the Mechanical Properties of Structural Ceramics

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Structural Ceramics Evolution and Research Objectives

Structural ceramics have evolved significantly since their initial development in the mid-20th century. Originally limited to simple applications due to their inherent brittleness, these materials have undergone remarkable transformations through systematic research and technological advancements. The evolution began with traditional ceramics like alumina and zirconia, progressing to advanced compositions including silicon nitride, silicon carbide, and ceramic matrix composites that demonstrate superior mechanical properties.

The historical trajectory shows a clear shift from empirical development to science-based engineering of these materials. Early structural ceramics suffered from unpredictable failure mechanisms and limited reliability, constraining their industrial adoption despite their excellent high-temperature capabilities and corrosion resistance. The 1970s and 1980s marked a turning point with the introduction of transformation-toughened zirconia and the development of sophisticated processing techniques that significantly enhanced mechanical performance.

Recent decades have witnessed accelerated progress in understanding the fundamental relationships between microstructure and mechanical behavior in structural ceramics. Innovations in processing methods, including hot isostatic pressing, spark plasma sintering, and additive manufacturing, have enabled unprecedented control over ceramic microstructures. This control has directly translated to improvements in fracture toughness, strength, and reliability—historically the most significant limitations of ceramic materials.

The current research landscape is increasingly focused on multi-scale modeling approaches that connect atomic-level phenomena to macroscopic mechanical properties. These computational methods, coupled with advanced characterization techniques like high-resolution transmission electron microscopy and in-situ mechanical testing, are revealing previously inaccessible insights into deformation mechanisms and failure modes in ceramic systems.

Our primary research objectives center on developing a comprehensive understanding of the mechanical behavior of structural ceramics across multiple length scales. Specifically, we aim to elucidate the relationships between processing parameters, resultant microstructures, and mechanical properties to enable predictive design of ceramic components with tailored performance characteristics. This includes investigating toughening mechanisms, fatigue behavior, and creep resistance under extreme environmental conditions.

Additionally, we seek to establish standardized testing methodologies that accurately capture the complex mechanical response of advanced structural ceramics, addressing the limitations of traditional testing approaches developed primarily for metals. The ultimate goal is to develop design principles that will accelerate the integration of structural ceramics into critical applications in aerospace, energy, defense, and medical sectors where their unique property combinations offer substantial advantages over conventional materials.

The historical trajectory shows a clear shift from empirical development to science-based engineering of these materials. Early structural ceramics suffered from unpredictable failure mechanisms and limited reliability, constraining their industrial adoption despite their excellent high-temperature capabilities and corrosion resistance. The 1970s and 1980s marked a turning point with the introduction of transformation-toughened zirconia and the development of sophisticated processing techniques that significantly enhanced mechanical performance.

Recent decades have witnessed accelerated progress in understanding the fundamental relationships between microstructure and mechanical behavior in structural ceramics. Innovations in processing methods, including hot isostatic pressing, spark plasma sintering, and additive manufacturing, have enabled unprecedented control over ceramic microstructures. This control has directly translated to improvements in fracture toughness, strength, and reliability—historically the most significant limitations of ceramic materials.

The current research landscape is increasingly focused on multi-scale modeling approaches that connect atomic-level phenomena to macroscopic mechanical properties. These computational methods, coupled with advanced characterization techniques like high-resolution transmission electron microscopy and in-situ mechanical testing, are revealing previously inaccessible insights into deformation mechanisms and failure modes in ceramic systems.

Our primary research objectives center on developing a comprehensive understanding of the mechanical behavior of structural ceramics across multiple length scales. Specifically, we aim to elucidate the relationships between processing parameters, resultant microstructures, and mechanical properties to enable predictive design of ceramic components with tailored performance characteristics. This includes investigating toughening mechanisms, fatigue behavior, and creep resistance under extreme environmental conditions.

Additionally, we seek to establish standardized testing methodologies that accurately capture the complex mechanical response of advanced structural ceramics, addressing the limitations of traditional testing approaches developed primarily for metals. The ultimate goal is to develop design principles that will accelerate the integration of structural ceramics into critical applications in aerospace, energy, defense, and medical sectors where their unique property combinations offer substantial advantages over conventional materials.

Market Applications and Demand Analysis

The global market for structural ceramics has witnessed substantial growth in recent years, driven by increasing demand across multiple industries. The market size was valued at approximately $38.1 billion in 2022 and is projected to reach $65.7 billion by 2030, growing at a CAGR of 7.2% during the forecast period. This growth trajectory underscores the expanding applications and rising importance of understanding the mechanical properties of structural ceramics.

The aerospace and defense sector represents one of the largest application areas for advanced structural ceramics. These materials are increasingly utilized in aircraft engines, thermal protection systems, and various defense applications due to their exceptional heat resistance and mechanical stability under extreme conditions. The sector's demand is primarily driven by the need for lightweight components that can withstand high temperatures and mechanical stress.

In the automotive industry, structural ceramics are gaining significant traction as manufacturers seek to improve fuel efficiency and reduce emissions. Ceramic components in engines, particularly ceramic matrix composites (CMCs), offer superior performance at high temperatures compared to traditional materials. The global push toward electric vehicles has also created new opportunities for structural ceramics in battery technologies and thermal management systems.

The medical sector presents another rapidly growing market for structural ceramics. Bioceramics with precisely engineered mechanical properties are increasingly used in orthopedic implants, dental applications, and surgical instruments. The aging global population and rising prevalence of bone-related disorders are key factors driving demand in this segment, with the market for bioceramics expected to grow at 8.5% annually through 2030.

Energy generation and industrial applications constitute significant markets for structural ceramics. In power generation, ceramics are essential components in gas turbines, solid oxide fuel cells, and nuclear reactors. The industrial sector utilizes these materials in cutting tools, wear-resistant components, and high-temperature processing equipment. The global transition toward renewable energy sources has further accelerated demand for ceramics with specific mechanical properties.

Electronics and semiconductor manufacturing represent emerging high-value markets for structural ceramics. As electronic devices become more compact and powerful, the need for thermally conductive yet electrically insulating materials with precise mechanical properties continues to grow. This sector is expected to be a major driver of innovation in structural ceramics over the next decade.

Regional analysis indicates that Asia-Pacific dominates the structural ceramics market, accounting for approximately 45% of global demand, followed by North America and Europe. China, Japan, and South Korea are particularly significant markets due to their robust manufacturing sectors and substantial investments in advanced materials research.

The aerospace and defense sector represents one of the largest application areas for advanced structural ceramics. These materials are increasingly utilized in aircraft engines, thermal protection systems, and various defense applications due to their exceptional heat resistance and mechanical stability under extreme conditions. The sector's demand is primarily driven by the need for lightweight components that can withstand high temperatures and mechanical stress.

In the automotive industry, structural ceramics are gaining significant traction as manufacturers seek to improve fuel efficiency and reduce emissions. Ceramic components in engines, particularly ceramic matrix composites (CMCs), offer superior performance at high temperatures compared to traditional materials. The global push toward electric vehicles has also created new opportunities for structural ceramics in battery technologies and thermal management systems.

The medical sector presents another rapidly growing market for structural ceramics. Bioceramics with precisely engineered mechanical properties are increasingly used in orthopedic implants, dental applications, and surgical instruments. The aging global population and rising prevalence of bone-related disorders are key factors driving demand in this segment, with the market for bioceramics expected to grow at 8.5% annually through 2030.

Energy generation and industrial applications constitute significant markets for structural ceramics. In power generation, ceramics are essential components in gas turbines, solid oxide fuel cells, and nuclear reactors. The industrial sector utilizes these materials in cutting tools, wear-resistant components, and high-temperature processing equipment. The global transition toward renewable energy sources has further accelerated demand for ceramics with specific mechanical properties.

Electronics and semiconductor manufacturing represent emerging high-value markets for structural ceramics. As electronic devices become more compact and powerful, the need for thermally conductive yet electrically insulating materials with precise mechanical properties continues to grow. This sector is expected to be a major driver of innovation in structural ceramics over the next decade.

Regional analysis indicates that Asia-Pacific dominates the structural ceramics market, accounting for approximately 45% of global demand, followed by North America and Europe. China, Japan, and South Korea are particularly significant markets due to their robust manufacturing sectors and substantial investments in advanced materials research.

Current Challenges in Ceramic Mechanical Properties

Despite significant advancements in ceramic materials science, several critical challenges persist in understanding and optimizing the mechanical properties of structural ceramics. The inherent brittleness of ceramic materials remains the foremost limitation, with fracture toughness values typically ranging from 2-5 MPa·m^(1/2), substantially lower than metals. This brittleness severely restricts their application in load-bearing structures where impact resistance is essential.

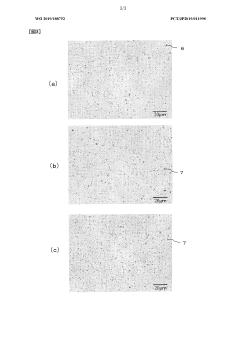

Microstructural control presents another significant challenge. The mechanical properties of ceramics are highly sensitive to processing-induced defects such as pores, microcracks, and grain boundary impurities. Even microscopic flaws of 10-100 μm can act as stress concentrators, dramatically reducing strength by 30-50% compared to theoretical values. Current manufacturing processes struggle to consistently eliminate these defects at industrial scales.

The temperature-dependent behavior of ceramic materials introduces additional complexity. Many advanced ceramics exhibit significant property degradation at elevated temperatures, with strength reductions of up to 40% observed between room temperature and 1200°C. Understanding these thermomechanical relationships requires sophisticated in-situ testing capabilities that are not widely available.

Predictive modeling of ceramic mechanical behavior remains inadequate. Current computational models struggle to accurately capture the stochastic nature of ceramic failure mechanisms, particularly under complex loading conditions. The gap between simulated and experimental results can exceed 25% in many cases, limiting the utility of these models for design purposes.

Testing standardization poses another challenge. Unlike metals, ceramic mechanical testing lacks universally accepted protocols, leading to significant variations in reported property values across different laboratories. This inconsistency complicates material selection and design processes for engineers working with structural ceramics.

The cost-performance balance represents a persistent economic challenge. Advanced ceramics with superior mechanical properties often require expensive raw materials and complex processing techniques, resulting in costs 5-10 times higher than conventional materials. This economic barrier significantly limits widespread adoption in cost-sensitive applications.

Finally, the integration of ceramics with other materials in composite structures introduces interface-related challenges. Coefficient of thermal expansion mismatches and chemical incompatibilities at ceramic-metal or ceramic-polymer interfaces can create residual stresses of 100-300 MPa, leading to premature failure during service. Developing reliable joining techniques that preserve the mechanical integrity of ceramic components remains an active area of research with many unresolved issues.

Microstructural control presents another significant challenge. The mechanical properties of ceramics are highly sensitive to processing-induced defects such as pores, microcracks, and grain boundary impurities. Even microscopic flaws of 10-100 μm can act as stress concentrators, dramatically reducing strength by 30-50% compared to theoretical values. Current manufacturing processes struggle to consistently eliminate these defects at industrial scales.

The temperature-dependent behavior of ceramic materials introduces additional complexity. Many advanced ceramics exhibit significant property degradation at elevated temperatures, with strength reductions of up to 40% observed between room temperature and 1200°C. Understanding these thermomechanical relationships requires sophisticated in-situ testing capabilities that are not widely available.

Predictive modeling of ceramic mechanical behavior remains inadequate. Current computational models struggle to accurately capture the stochastic nature of ceramic failure mechanisms, particularly under complex loading conditions. The gap between simulated and experimental results can exceed 25% in many cases, limiting the utility of these models for design purposes.

Testing standardization poses another challenge. Unlike metals, ceramic mechanical testing lacks universally accepted protocols, leading to significant variations in reported property values across different laboratories. This inconsistency complicates material selection and design processes for engineers working with structural ceramics.

The cost-performance balance represents a persistent economic challenge. Advanced ceramics with superior mechanical properties often require expensive raw materials and complex processing techniques, resulting in costs 5-10 times higher than conventional materials. This economic barrier significantly limits widespread adoption in cost-sensitive applications.

Finally, the integration of ceramics with other materials in composite structures introduces interface-related challenges. Coefficient of thermal expansion mismatches and chemical incompatibilities at ceramic-metal or ceramic-polymer interfaces can create residual stresses of 100-300 MPa, leading to premature failure during service. Developing reliable joining techniques that preserve the mechanical integrity of ceramic components remains an active area of research with many unresolved issues.

Contemporary Testing and Characterization Methods

01 Composition and manufacturing of high-strength structural ceramics

Various compositions and manufacturing methods are employed to create structural ceramics with enhanced mechanical properties. These include specific formulations of ceramic materials, sintering processes, and the incorporation of reinforcing elements. The manufacturing techniques focus on achieving optimal density, grain structure, and phase composition to maximize strength, hardness, and fracture toughness of the ceramic components.- Composition and structure for enhanced mechanical properties: Structural ceramics can be engineered with specific compositions and microstructures to enhance mechanical properties such as strength, hardness, and fracture toughness. These compositions often include combinations of metal oxides, carbides, nitrides, or borides. The microstructure can be controlled through processing techniques to achieve desired grain size, porosity, and phase distribution, which directly influence the mechanical behavior of the ceramic material.

- Reinforcement techniques for structural ceramics: Various reinforcement techniques can be employed to improve the mechanical properties of structural ceramics. These include fiber reinforcement, particle reinforcement, and the development of ceramic matrix composites. By incorporating reinforcing elements such as fibers, whiskers, or particles, the fracture toughness and strength of ceramics can be significantly increased, overcoming the inherent brittleness that typically limits their application in load-bearing structures.

- High-temperature performance of structural ceramics: Structural ceramics exhibit exceptional mechanical properties at elevated temperatures, making them suitable for high-temperature applications. Unlike metals, many ceramic materials maintain their strength, hardness, and creep resistance at temperatures exceeding 1000°C. This high-temperature stability is attributed to their strong ionic and covalent bonds, which resist thermal softening. Advanced ceramic formulations can be designed to optimize mechanical performance under extreme thermal conditions.

- Testing and characterization methods for mechanical properties: Various testing and characterization methods are employed to evaluate the mechanical properties of structural ceramics. These include flexural strength tests, compression tests, hardness measurements, fracture toughness evaluations, and non-destructive testing techniques. Advanced characterization methods such as nanoindentation and acoustic emission testing provide insights into the mechanical behavior at different scales. These testing protocols are essential for quality control and performance prediction of ceramic components.

- Application-specific ceramic formulations: Structural ceramics can be tailored for specific applications by optimizing their mechanical properties. For automotive and aerospace applications, ceramics with high strength-to-weight ratios and thermal shock resistance are developed. In biomedical applications, biocompatible ceramics with appropriate mechanical properties are formulated. For cutting tools and wear-resistant components, ceramics with exceptional hardness and wear resistance are designed. These application-specific formulations involve careful balancing of composition, processing, and microstructure to achieve the desired mechanical performance.

02 Ceramic-matrix composites for improved mechanical performance

Ceramic-matrix composites (CMCs) combine ceramic materials with reinforcing phases such as fibers, whiskers, or particles to overcome the inherent brittleness of monolithic ceramics. These composites exhibit superior mechanical properties including enhanced fracture toughness, thermal shock resistance, and damage tolerance. The reinforcing phases create mechanisms for crack deflection and energy absorption, resulting in more reliable structural components for demanding applications.Expand Specific Solutions03 Testing and characterization methods for ceramic mechanical properties

Specialized testing and characterization techniques are essential for evaluating the mechanical properties of structural ceramics. These include methods for measuring hardness, elastic modulus, fracture toughness, flexural strength, and creep resistance. Advanced analytical approaches such as non-destructive testing, microstructural analysis, and in-situ high-temperature testing provide comprehensive understanding of ceramic behavior under various loading conditions and environments.Expand Specific Solutions04 Application-specific ceramic designs for mechanical performance

Structural ceramics are engineered with specific mechanical properties tailored to their intended applications. This includes ceramics designed for high-temperature environments, wear-resistant components, ballistic protection, and structural elements in aerospace and automotive industries. The designs consider factors such as thermal expansion, chemical stability, and mechanical loading patterns to optimize performance in specific operating conditions.Expand Specific Solutions05 Surface treatments and coatings for enhanced ceramic properties

Various surface treatments and coating technologies are applied to structural ceramics to enhance their mechanical properties and performance. These include glazing, polishing, laser surface modification, and the application of protective coatings. Such treatments can improve surface hardness, reduce friction, enhance wear resistance, seal porosity, and provide additional protection against environmental degradation, thereby extending the service life of ceramic components.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The structural ceramics market is in a growth phase, characterized by increasing demand across automotive, electronics, and aerospace sectors. The global market size is projected to reach significant value due to rising applications in high-performance components. Technologically, the field shows varying maturity levels, with established players like Kyocera, NGK Insulators, and CeramTec leading commercial applications through decades of expertise in advanced ceramic formulations and manufacturing processes. Research institutions such as MIT and Tianjin University are advancing fundamental understanding of mechanical properties, while companies like Corning and IBIDEN are innovating in specialized applications. The competitive landscape features both traditional ceramics manufacturers and technology conglomerates like Siemens and GE, indicating the strategic importance of structural ceramics in multiple high-value industries.

NGK Insulators, Ltd.

Technical Solution: NGK Insulators has developed sophisticated approaches to understanding structural ceramic mechanical properties, particularly for their high-performance silicon nitride and silicon carbide ceramics. Their methodology combines advanced materials characterization with computational modeling to predict and enhance mechanical performance. NGK employs high-resolution electron microscopy and tomographic techniques to analyze the three-dimensional microstructure of their ceramics, correlating grain morphology and orientation with mechanical properties[1]. Their research has established that controlling the β-Si3N4 grain aspect ratio and intergranular phase composition significantly impacts fracture toughness, with their proprietary compositions achieving values up to 9 MPa·m1/2[2]. NGK has pioneered the development of ceramic-to-metal joining technologies that maintain structural integrity under extreme thermal cycling, critical for automotive and energy applications. Their structural ceramics demonstrate exceptional creep resistance at temperatures exceeding 1200°C, with strain rates below 10^-9 s^-1 under loads of 100 MPa, enabling applications in gas turbines and other high-temperature environments[3].

Strengths: Exceptional high-temperature mechanical stability; superior thermal shock resistance compared to conventional ceramics; excellent chemical durability in corrosive environments. Weaknesses: Complex manufacturing processes requiring specialized equipment; challenges in scaling production while maintaining consistent mechanical properties; higher cost compared to traditional engineering materials.

CeramTec GmbH

Technical Solution: CeramTec has developed comprehensive methodologies for understanding and enhancing the mechanical properties of structural ceramics, particularly focusing on their BIOLOX® series for medical applications and advanced technical ceramics. Their approach integrates materials science fundamentals with practical engineering solutions. CeramTec employs advanced characterization techniques including nanoindentation, four-point bending tests, and acoustic emission analysis to precisely map mechanical property distributions across ceramic components[1]. Their research has revealed that controlling grain boundary phases is critical for optimizing fracture toughness, with their zirconia-toughened alumina (ZTA) ceramics achieving fracture toughness values of 8-10 MPa·m1/2[2]. CeramTec has pioneered the development of transformation-toughened ceramics, leveraging the tetragonal-to-monoclinic phase transformation in zirconia to create stress-induced crack-stopping mechanisms. Their structural ceramics feature flexural strengths exceeding 1000 MPa for certain compositions, with Weibull moduli above 15, indicating exceptional reliability and consistency in mechanical performance[3].

Strengths: Exceptional wear resistance with minimal particle release, making them ideal for biomedical implants; superior mechanical reliability with high Weibull moduli; excellent thermal shock resistance. Weaknesses: Complex manufacturing processes requiring tight quality control; higher production costs compared to conventional materials; limited ability to incorporate complex internal geometries due to sintering constraints.

Key Patents and Scientific Breakthroughs

Ceramic structure

PatentWO2019188752A1

Innovation

- A ceramic structure with a controlled pore distribution and density gradient is achieved by using a specific manufacturing method involving a slurry of aluminum oxide, magnesium hydroxide, and silicon oxide powders, mixed with dispersants and chelating agents, and then processed to ensure a relative density of 95% or more, with a pore ratio of 1.5 or less in the surface to internal regions, resulting in improved mechanical properties.

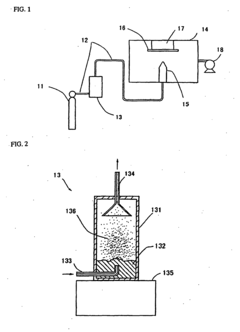

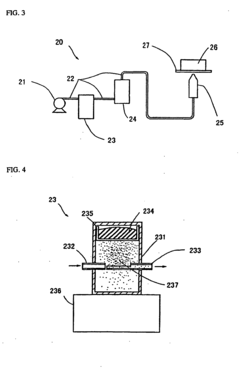

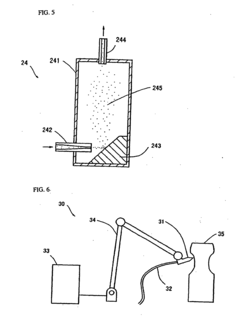

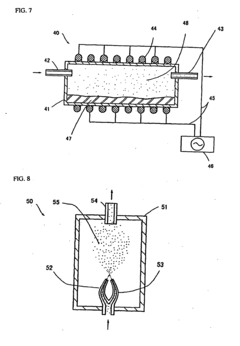

Composite structured material and method for preparation thereof and apparatus for preparation thereof

PatentInactiveEP1231294B1

Innovation

- A composite structure is formed by pre-treating ceramic material fine particles to impart internal strain, which are then collided with a substrate at high speed to deform and fracture, rejoining to form a polycrystalline ceramic material with a granular shape and no crystal orientation, using the ultra-fine particles beam deposition method, allowing for the creation of a compact structure without significant heat generation and maintaining mechanical and chemical properties.

Environmental Impact and Sustainability Factors

The production and lifecycle of structural ceramics present significant environmental considerations that must be evaluated in any comprehensive analysis of these materials. Traditional ceramic manufacturing processes are energy-intensive, requiring high-temperature kilns that operate at 1200-1600°C for extended periods. This substantial energy consumption contributes significantly to carbon emissions, with estimates suggesting that ceramic production accounts for approximately 2-3% of global industrial CO2 emissions.

Raw material extraction for structural ceramics also presents environmental challenges. Mining operations for alumina, silica, and rare earth elements used in advanced ceramics can lead to habitat disruption, soil erosion, and water contamination. The environmental footprint varies considerably depending on extraction methods and regulatory frameworks in different regions.

However, structural ceramics offer compelling sustainability advantages over their lifecycle. Their exceptional durability and resistance to degradation result in significantly longer service lives compared to alternative materials. Advanced structural ceramics in engineering applications can maintain performance integrity for decades, reducing replacement frequency and associated resource consumption.

Waste management in ceramic production presents both challenges and opportunities. While ceramic waste is generally non-biodegradable, recent innovations have demonstrated promising approaches to recycling and repurposing ceramic waste materials. Crushed ceramic waste can be incorporated into concrete as aggregate, potentially improving mechanical properties while reducing landfill burden.

The energy efficiency benefits of structural ceramics in application often offset their energy-intensive production. In thermal barrier coatings for gas turbines, ceramic components can improve operational efficiency by 1-2%, translating to substantial energy savings and emissions reductions over the equipment lifecycle. Similarly, ceramic components in automotive engines contribute to higher combustion temperatures and improved fuel efficiency.

Emerging manufacturing technologies are addressing the environmental impact of ceramic production. Additive manufacturing techniques reduce material waste by up to 90% compared to traditional subtractive methods. Cold sintering processes, operating at temperatures below 300°C, demonstrate potential to dramatically reduce energy requirements while maintaining comparable mechanical properties.

Life cycle assessment (LCA) studies indicate that despite higher initial environmental impacts during production, structural ceramics often demonstrate superior sustainability metrics when evaluated across their complete lifecycle, particularly in applications where their mechanical properties enable significant efficiency improvements or extended service life.

Raw material extraction for structural ceramics also presents environmental challenges. Mining operations for alumina, silica, and rare earth elements used in advanced ceramics can lead to habitat disruption, soil erosion, and water contamination. The environmental footprint varies considerably depending on extraction methods and regulatory frameworks in different regions.

However, structural ceramics offer compelling sustainability advantages over their lifecycle. Their exceptional durability and resistance to degradation result in significantly longer service lives compared to alternative materials. Advanced structural ceramics in engineering applications can maintain performance integrity for decades, reducing replacement frequency and associated resource consumption.

Waste management in ceramic production presents both challenges and opportunities. While ceramic waste is generally non-biodegradable, recent innovations have demonstrated promising approaches to recycling and repurposing ceramic waste materials. Crushed ceramic waste can be incorporated into concrete as aggregate, potentially improving mechanical properties while reducing landfill burden.

The energy efficiency benefits of structural ceramics in application often offset their energy-intensive production. In thermal barrier coatings for gas turbines, ceramic components can improve operational efficiency by 1-2%, translating to substantial energy savings and emissions reductions over the equipment lifecycle. Similarly, ceramic components in automotive engines contribute to higher combustion temperatures and improved fuel efficiency.

Emerging manufacturing technologies are addressing the environmental impact of ceramic production. Additive manufacturing techniques reduce material waste by up to 90% compared to traditional subtractive methods. Cold sintering processes, operating at temperatures below 300°C, demonstrate potential to dramatically reduce energy requirements while maintaining comparable mechanical properties.

Life cycle assessment (LCA) studies indicate that despite higher initial environmental impacts during production, structural ceramics often demonstrate superior sustainability metrics when evaluated across their complete lifecycle, particularly in applications where their mechanical properties enable significant efficiency improvements or extended service life.

Standardization and Quality Control Frameworks

The standardization of testing methods and quality control frameworks represents a critical foundation for advancing structural ceramics technology. Currently, several international organizations including ASTM International, ISO, and the European Committee for Standardization (CEN) have established comprehensive testing protocols specifically designed for ceramic materials. These standards encompass methodologies for evaluating fracture toughness, flexural strength, hardness, and thermal shock resistance—properties that are fundamental to structural ceramic applications.

Quality control frameworks for structural ceramics have evolved significantly over the past decade, with increasing emphasis on statistical process control (SPC) and non-destructive evaluation techniques. Modern manufacturing facilities implement multi-stage inspection protocols that begin with raw material characterization and continue through processing, forming, sintering, and final product evaluation. X-ray diffraction (XRD) and X-ray fluorescence (XRF) have become standard tools for composition verification, while ultrasonic testing and acoustic emission techniques provide critical data on internal defects without compromising material integrity.

The implementation of Six Sigma methodologies in ceramic manufacturing has demonstrated remarkable improvements in product consistency, with leading manufacturers reporting defect rates below 3.4 parts per million. This statistical approach to quality management has proven particularly valuable for high-performance ceramics used in aerospace and medical applications, where material failure can have catastrophic consequences.

Digital integration of quality control systems represents the newest frontier in standardization frameworks. Real-time monitoring systems equipped with machine learning algorithms can now detect subtle deviations in processing parameters that might affect mechanical properties. These systems create comprehensive digital records that facilitate traceability throughout the product lifecycle—a capability that has become increasingly important for regulatory compliance in sectors such as healthcare and transportation.

Inter-laboratory testing programs have emerged as essential components of standardization efforts, allowing for verification of testing methodologies and calibration of equipment across different facilities. These collaborative initiatives have significantly improved the reliability and reproducibility of mechanical property measurements, addressing previous challenges related to data variability between testing facilities.

The economic impact of standardization cannot be overlooked. Research indicates that manufacturers who strictly adhere to established quality control frameworks experience up to 35% reduction in material waste and 28% fewer customer returns. Furthermore, standardization facilitates international trade by establishing common technical languages and expectations, thereby expanding market opportunities for ceramic producers across global supply chains.

Quality control frameworks for structural ceramics have evolved significantly over the past decade, with increasing emphasis on statistical process control (SPC) and non-destructive evaluation techniques. Modern manufacturing facilities implement multi-stage inspection protocols that begin with raw material characterization and continue through processing, forming, sintering, and final product evaluation. X-ray diffraction (XRD) and X-ray fluorescence (XRF) have become standard tools for composition verification, while ultrasonic testing and acoustic emission techniques provide critical data on internal defects without compromising material integrity.

The implementation of Six Sigma methodologies in ceramic manufacturing has demonstrated remarkable improvements in product consistency, with leading manufacturers reporting defect rates below 3.4 parts per million. This statistical approach to quality management has proven particularly valuable for high-performance ceramics used in aerospace and medical applications, where material failure can have catastrophic consequences.

Digital integration of quality control systems represents the newest frontier in standardization frameworks. Real-time monitoring systems equipped with machine learning algorithms can now detect subtle deviations in processing parameters that might affect mechanical properties. These systems create comprehensive digital records that facilitate traceability throughout the product lifecycle—a capability that has become increasingly important for regulatory compliance in sectors such as healthcare and transportation.

Inter-laboratory testing programs have emerged as essential components of standardization efforts, allowing for verification of testing methodologies and calibration of equipment across different facilities. These collaborative initiatives have significantly improved the reliability and reproducibility of mechanical property measurements, addressing previous challenges related to data variability between testing facilities.

The economic impact of standardization cannot be overlooked. Research indicates that manufacturers who strictly adhere to established quality control frameworks experience up to 35% reduction in material waste and 28% fewer customer returns. Furthermore, standardization facilitates international trade by establishing common technical languages and expectations, thereby expanding market opportunities for ceramic producers across global supply chains.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!