Structural Ceramics for Energy Harvesting: Mechanisms and Applications

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Energy Harvesting Ceramics Background and Objectives

Structural ceramics have emerged as a significant frontier in energy harvesting technologies, representing a convergence of materials science and sustainable energy solutions. The evolution of these materials spans several decades, beginning with basic piezoelectric ceramics in the mid-20th century and advancing through various generations of increasingly sophisticated compositions and structures. Recent developments have focused on enhancing efficiency, durability, and versatility across diverse operating conditions.

The technological trajectory of energy harvesting ceramics has been characterized by progressive improvements in conversion efficiency, with contemporary materials achieving substantial advances over their predecessors. This evolution has been driven by fundamental research into crystal structures, dopant effects, and manufacturing techniques that optimize energy capture from mechanical, thermal, and electromagnetic sources.

Current research emphasizes multifunctional ceramic systems capable of harvesting energy from multiple environmental inputs simultaneously. These advanced materials represent a significant departure from traditional single-mode energy harvesters, offering more consistent energy generation across variable conditions. The integration of nanoscale engineering and composite structures has further expanded the functional capabilities of these materials.

The primary technical objectives in this field include achieving higher energy conversion efficiencies, developing more robust and reliable systems for harsh environments, and creating scalable manufacturing processes for cost-effective production. Particular emphasis is placed on materials that can operate effectively at lower activation thresholds, thereby expanding potential application scenarios.

Another critical goal involves the development of self-powered systems that can sustain operation without external power sources, particularly for remote sensing, IoT devices, and autonomous systems. This objective necessitates ceramics capable of generating sufficient power from ambient environmental conditions while maintaining long-term stability and performance.

The field is also moving toward bio-compatible ceramic harvesters for medical implants and wearable technologies, requiring materials that combine energy harvesting capabilities with biocompatibility and flexibility. This represents a significant technical challenge that demands innovative approaches to materials design and fabrication.

Looking forward, the technical trajectory points toward integrated energy harvesting systems that combine structural ceramics with complementary technologies such as energy storage components and intelligent power management. The ultimate objective is to develop autonomous energy systems that can power a wide range of devices and applications using only ambient energy sources, thereby reducing dependence on conventional power infrastructure and contributing to more sustainable technological ecosystems.

The technological trajectory of energy harvesting ceramics has been characterized by progressive improvements in conversion efficiency, with contemporary materials achieving substantial advances over their predecessors. This evolution has been driven by fundamental research into crystal structures, dopant effects, and manufacturing techniques that optimize energy capture from mechanical, thermal, and electromagnetic sources.

Current research emphasizes multifunctional ceramic systems capable of harvesting energy from multiple environmental inputs simultaneously. These advanced materials represent a significant departure from traditional single-mode energy harvesters, offering more consistent energy generation across variable conditions. The integration of nanoscale engineering and composite structures has further expanded the functional capabilities of these materials.

The primary technical objectives in this field include achieving higher energy conversion efficiencies, developing more robust and reliable systems for harsh environments, and creating scalable manufacturing processes for cost-effective production. Particular emphasis is placed on materials that can operate effectively at lower activation thresholds, thereby expanding potential application scenarios.

Another critical goal involves the development of self-powered systems that can sustain operation without external power sources, particularly for remote sensing, IoT devices, and autonomous systems. This objective necessitates ceramics capable of generating sufficient power from ambient environmental conditions while maintaining long-term stability and performance.

The field is also moving toward bio-compatible ceramic harvesters for medical implants and wearable technologies, requiring materials that combine energy harvesting capabilities with biocompatibility and flexibility. This represents a significant technical challenge that demands innovative approaches to materials design and fabrication.

Looking forward, the technical trajectory points toward integrated energy harvesting systems that combine structural ceramics with complementary technologies such as energy storage components and intelligent power management. The ultimate objective is to develop autonomous energy systems that can power a wide range of devices and applications using only ambient energy sources, thereby reducing dependence on conventional power infrastructure and contributing to more sustainable technological ecosystems.

Market Analysis for Structural Ceramic Energy Harvesters

The global market for structural ceramic energy harvesters is experiencing significant growth, driven by increasing demand for sustainable energy solutions and advancements in materials science. Current market valuations indicate that the energy harvesting devices market reached approximately 460 million USD in 2022, with structural ceramics representing a growing segment within this space. Industry forecasts project a compound annual growth rate (CAGR) of 8.4% through 2030, with piezoelectric ceramic harvesters leading this expansion.

The market segmentation reveals distinct application sectors for structural ceramic energy harvesters. The automotive industry represents the largest market share at 28%, implementing these technologies in tire pressure monitoring systems, vibration dampening, and kinetic energy recovery. The industrial sector follows at 24%, utilizing ceramic harvesters for condition monitoring in manufacturing equipment and infrastructure. Consumer electronics accounts for 21%, aerospace and defense 15%, with healthcare and building automation comprising the remaining 12%.

Regional analysis shows North America currently dominating the market with 35% share, attributed to substantial R&D investments and early technology adoption. Asia-Pacific follows closely at 32% and is expected to demonstrate the fastest growth rate due to expanding manufacturing capabilities in China, Japan, and South Korea. Europe holds 26% of the market, with particular strength in automotive applications.

Key market drivers include the growing emphasis on energy efficiency across industries, increasing deployment of wireless sensor networks requiring autonomous power sources, and stringent environmental regulations promoting green technologies. The miniaturization trend in electronics has further accelerated demand for compact energy harvesting solutions where structural ceramics offer significant advantages.

Market challenges persist, primarily centered around production costs and scalability issues. The manufacturing of high-performance structural ceramics requires specialized equipment and processes, resulting in higher unit costs compared to conventional alternatives. Additionally, performance consistency across varying environmental conditions remains a technical hurdle affecting market penetration in certain applications.

Customer adoption analysis reveals that early adopters primarily come from high-value industries where reliability outweighs cost considerations. The technology adoption curve indicates that structural ceramic energy harvesters are transitioning from early adopter to early majority phase, suggesting significant market expansion potential in the coming years.

Pricing trends show gradual cost reduction as manufacturing processes mature and economies of scale take effect. Current price points range from 0.5-2.5 USD per watt for basic ceramic harvesters to 3.0-8.0 USD per watt for advanced multi-functional systems, with projections indicating a 15-20% cost reduction over the next five years as production volumes increase.

The market segmentation reveals distinct application sectors for structural ceramic energy harvesters. The automotive industry represents the largest market share at 28%, implementing these technologies in tire pressure monitoring systems, vibration dampening, and kinetic energy recovery. The industrial sector follows at 24%, utilizing ceramic harvesters for condition monitoring in manufacturing equipment and infrastructure. Consumer electronics accounts for 21%, aerospace and defense 15%, with healthcare and building automation comprising the remaining 12%.

Regional analysis shows North America currently dominating the market with 35% share, attributed to substantial R&D investments and early technology adoption. Asia-Pacific follows closely at 32% and is expected to demonstrate the fastest growth rate due to expanding manufacturing capabilities in China, Japan, and South Korea. Europe holds 26% of the market, with particular strength in automotive applications.

Key market drivers include the growing emphasis on energy efficiency across industries, increasing deployment of wireless sensor networks requiring autonomous power sources, and stringent environmental regulations promoting green technologies. The miniaturization trend in electronics has further accelerated demand for compact energy harvesting solutions where structural ceramics offer significant advantages.

Market challenges persist, primarily centered around production costs and scalability issues. The manufacturing of high-performance structural ceramics requires specialized equipment and processes, resulting in higher unit costs compared to conventional alternatives. Additionally, performance consistency across varying environmental conditions remains a technical hurdle affecting market penetration in certain applications.

Customer adoption analysis reveals that early adopters primarily come from high-value industries where reliability outweighs cost considerations. The technology adoption curve indicates that structural ceramic energy harvesters are transitioning from early adopter to early majority phase, suggesting significant market expansion potential in the coming years.

Pricing trends show gradual cost reduction as manufacturing processes mature and economies of scale take effect. Current price points range from 0.5-2.5 USD per watt for basic ceramic harvesters to 3.0-8.0 USD per watt for advanced multi-functional systems, with projections indicating a 15-20% cost reduction over the next five years as production volumes increase.

Current Challenges in Ceramic Energy Harvesting Technologies

Despite significant advancements in ceramic energy harvesting technologies, several critical challenges continue to impede widespread implementation and optimal performance. Material limitations represent a primary obstacle, as current piezoelectric ceramics like PZT and BaTiO3 exhibit inherent brittleness and poor mechanical flexibility, restricting their application in environments requiring durability or conformability. Additionally, these materials often contain toxic elements such as lead, prompting regulatory concerns and driving the need for environmentally friendly alternatives.

Efficiency constraints pose another significant challenge, with most ceramic-based energy harvesters demonstrating conversion efficiencies below 10%. This limitation stems from energy losses through various mechanisms including mechanical-electrical coupling inefficiencies, internal resistance, and thermal dissipation. The performance gap becomes particularly evident when comparing laboratory results with real-world applications, where variable and unpredictable energy sources significantly reduce harvesting capabilities.

Manufacturing complexities further hinder advancement, as high-quality piezoelectric ceramics typically require specialized processing conditions including precise temperature control during sintering (often exceeding 1000°C) and careful poling procedures. These requirements increase production costs and limit scalability, particularly for complex geometries or integrated systems. The miniaturization of ceramic energy harvesters for micro-electromechanical systems (MEMS) applications introduces additional fabrication challenges related to maintaining piezoelectric properties at reduced dimensions.

Integration issues represent a persistent technical barrier, as ceramic energy harvesters must effectively interface with electronic components for energy storage and power management. The impedance matching between high-impedance ceramic generators and low-impedance electronic circuits remains problematic, often necessitating complex interface electronics that consume power and reduce overall system efficiency.

Temperature sensitivity constitutes another significant limitation, with most piezoelectric ceramics exhibiting performance degradation at temperatures approaching their Curie point. This thermal constraint restricts their application in high-temperature environments such as industrial processes or automotive applications. Additionally, many ceramic materials demonstrate performance hysteresis and aging effects, resulting in output degradation over time.

Bandwidth limitations further restrict energy capture capabilities, as conventional ceramic harvesters typically operate efficiently only within narrow frequency ranges. This characteristic severely limits their effectiveness in environments with variable or broadband vibration sources, necessitating complex mechanical solutions or arrays of harvesters tuned to different frequencies.

Efficiency constraints pose another significant challenge, with most ceramic-based energy harvesters demonstrating conversion efficiencies below 10%. This limitation stems from energy losses through various mechanisms including mechanical-electrical coupling inefficiencies, internal resistance, and thermal dissipation. The performance gap becomes particularly evident when comparing laboratory results with real-world applications, where variable and unpredictable energy sources significantly reduce harvesting capabilities.

Manufacturing complexities further hinder advancement, as high-quality piezoelectric ceramics typically require specialized processing conditions including precise temperature control during sintering (often exceeding 1000°C) and careful poling procedures. These requirements increase production costs and limit scalability, particularly for complex geometries or integrated systems. The miniaturization of ceramic energy harvesters for micro-electromechanical systems (MEMS) applications introduces additional fabrication challenges related to maintaining piezoelectric properties at reduced dimensions.

Integration issues represent a persistent technical barrier, as ceramic energy harvesters must effectively interface with electronic components for energy storage and power management. The impedance matching between high-impedance ceramic generators and low-impedance electronic circuits remains problematic, often necessitating complex interface electronics that consume power and reduce overall system efficiency.

Temperature sensitivity constitutes another significant limitation, with most piezoelectric ceramics exhibiting performance degradation at temperatures approaching their Curie point. This thermal constraint restricts their application in high-temperature environments such as industrial processes or automotive applications. Additionally, many ceramic materials demonstrate performance hysteresis and aging effects, resulting in output degradation over time.

Bandwidth limitations further restrict energy capture capabilities, as conventional ceramic harvesters typically operate efficiently only within narrow frequency ranges. This characteristic severely limits their effectiveness in environments with variable or broadband vibration sources, necessitating complex mechanical solutions or arrays of harvesters tuned to different frequencies.

Current Mechanisms and Solutions in Ceramic Energy Harvesting

01 Piezoelectric ceramic materials for energy harvesting

Piezoelectric ceramic materials are used in energy harvesting devices to convert mechanical energy into electrical energy. These materials generate an electric charge when subjected to mechanical stress or vibration. The structural properties of these ceramics, such as their crystalline structure and composition, significantly affect their energy harvesting efficiency. Advanced piezoelectric ceramics can be optimized for specific applications by adjusting their composition and manufacturing processes.- Piezoelectric ceramic materials for energy harvesting: Piezoelectric ceramic materials are used in energy harvesting devices to convert mechanical energy into electrical energy. These materials generate an electric charge in response to mechanical stress, making them ideal for harvesting energy from vibrations, pressure, and movement. Advanced structural ceramics with enhanced piezoelectric properties can significantly improve energy conversion efficiency in various applications including sensors, actuators, and power generation systems.

- Multilayer ceramic structures for improved energy harvesting: Multilayer ceramic structures are designed to enhance energy harvesting capabilities by optimizing the arrangement of piezoelectric elements. These structures can include alternating layers of different ceramic materials or electrodes to maximize power output. The multilayer approach allows for better utilization of mechanical energy and improved electrical output, making these structures particularly effective for applications requiring higher power density or efficiency.

- Ceramic composites with enhanced mechanical and electrical properties: Ceramic composites combine different materials to achieve superior mechanical strength and electrical performance for energy harvesting applications. These composites often incorporate reinforcing elements or secondary phases to improve toughness and durability while maintaining excellent piezoelectric properties. The integration of various materials allows for customization of properties to meet specific application requirements, such as flexibility, temperature resistance, or power output.

- Nanostructured ceramics for energy harvesting: Nanostructured ceramic materials offer enhanced energy harvesting performance due to their unique properties at the nanoscale. These materials feature controlled grain size, porosity, and surface area that can significantly improve piezoelectric response and energy conversion efficiency. Nanoscale engineering of ceramic structures enables the development of highly sensitive energy harvesters that can operate effectively even with minimal mechanical input, making them suitable for self-powered electronic devices and sensors.

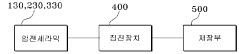

- Integration of structural ceramics in energy harvesting systems: Structural ceramics are integrated into complete energy harvesting systems that include energy collection, storage, and management components. These systems are designed to efficiently capture ambient energy, convert it to electrical power, and deliver it to the application. The integration approach considers the mechanical mounting, electrical connections, and protective enclosures to ensure optimal performance in real-world environments. Advanced system designs may incorporate adaptive circuits that optimize energy extraction across varying operating conditions.

02 Multilayer ceramic structures for enhanced energy harvesting

Multilayer ceramic structures can significantly improve energy harvesting capabilities. These structures consist of alternating layers of ceramic materials with different properties, creating interfaces that enhance the conversion of mechanical or thermal energy into electrical energy. The layered design allows for better control of energy flow and improved efficiency. These structures can be engineered to harvest energy from various sources, including vibration, temperature gradients, and electromagnetic radiation.Expand Specific Solutions03 Ceramic composites with enhanced thermal energy harvesting

Ceramic composites designed for thermal energy harvesting combine different ceramic materials to optimize thermoelectric properties. These composites can efficiently convert temperature differences into electrical energy. By incorporating specific dopants or creating nanostructured ceramics, the thermal conductivity and electrical properties can be tailored to maximize energy conversion efficiency. These materials are particularly useful in applications where waste heat can be recovered and converted into usable electrical energy.Expand Specific Solutions04 Structural ceramics with integrated energy storage capabilities

Advanced structural ceramics can be designed with integrated energy storage capabilities, creating multifunctional materials that both harvest and store energy. These ceramics combine mechanical strength with electrochemical properties, allowing them to function as both structural components and energy storage devices. By integrating energy harvesting and storage functions into a single material, these ceramics enable more compact and efficient energy systems for various applications, from building materials to aerospace components.Expand Specific Solutions05 Smart ceramic systems with adaptive energy harvesting

Smart ceramic systems incorporate sensors and adaptive mechanisms to optimize energy harvesting under varying conditions. These systems can adjust their properties or configuration in response to changes in the environment or energy source. By integrating ceramic materials with smart electronics and control systems, these devices can maximize energy harvesting efficiency across a wide range of operating conditions. Applications include self-powered sensors, IoT devices, and autonomous systems that require sustainable energy sources.Expand Specific Solutions

Leading Companies and Research Institutions in Ceramic Energy Harvesting

The structural ceramics for energy harvesting market is currently in a growth phase, characterized by increasing research activities and commercial applications. The global market size is expanding, driven by rising demand for sustainable energy solutions and advanced materials. Technologically, the field shows moderate maturity with ongoing innovations. Leading players include established corporations like NGK Insulators, Corning, and Kyocera, which leverage their extensive ceramics expertise, alongside research powerhouses such as Beijing University of Technology and Shanghai Institute of Ceramics. Academic institutions like Central South University and Southeast University are advancing fundamental research, while companies like Face International and IBIDEN are developing specialized applications. The competitive landscape features collaboration between industry and academia, with companies like Boeing and Lockheed Martin exploring high-performance applications in aerospace and defense sectors.

NGK Insulators, Ltd.

Technical Solution: NGK Insulators has developed advanced structural ceramic technologies for energy harvesting based on their expertise in fine ceramics manufacturing. Their approach centers on specialized piezoelectric ceramic compositions with optimized crystal structures for maximum energy conversion efficiency. NGK's proprietary manufacturing process involves precise control of grain size (typically 0.5-5 μm) and orientation to enhance piezoelectric properties. Their energy harvesting ceramics feature multilayer structures with internal electrodes, allowing for voltage output customization based on layer configuration. These devices can generate significant power from mechanical vibrations in the 10-100 Hz range, making them suitable for industrial applications. NGK has also developed composite ceramic structures that combine piezoelectric elements with structural support materials to withstand harsh operating conditions while maintaining energy harvesting capabilities. Their recent innovations include temperature-resistant formulations that can operate effectively up to 400°C, enabling energy harvesting in high-temperature industrial environments where conventional piezoelectric materials would fail.

Strengths: Exceptional durability and reliability in harsh environments; high-temperature operation capability; precise manufacturing control resulting in consistent performance. Weaknesses: Higher production costs compared to polymer-based alternatives; limited flexibility can restrict application in environments with irregular vibration patterns; relatively heavy compared to polymer-based energy harvesters.

Shanghai Institute of Ceramics, Chinese Academy of Sciences

Technical Solution: The Shanghai Institute of Ceramics has developed advanced piezoelectric ceramic materials specifically engineered for energy harvesting applications. Their technology focuses on lead-free piezoelectric ceramics based on potassium sodium niobate (KNN) and bismuth sodium titanate (BNT) systems with enhanced piezoelectric properties. These materials demonstrate high piezoelectric coefficients (d33 > 300 pC/N) and coupling factors (kp > 0.45) while maintaining good temperature stability up to 200°C. The institute has pioneered innovative microstructural design approaches, including domain engineering and grain orientation techniques, to optimize energy conversion efficiency. Their structural ceramics incorporate hierarchical architectures with controlled porosity to enhance mechanical flexibility while maintaining electrical output. Recent developments include composite structures that combine piezoelectric ceramics with flexible polymers to harvest energy from low-frequency vibrations in ambient environments.

Strengths: Superior piezoelectric performance in lead-free compositions, addressing environmental concerns; excellent temperature stability suitable for harsh environment applications; advanced microstructural control enabling tailored properties. Weaknesses: Manufacturing complexity increases production costs; some compositions still show lower performance compared to lead-based alternatives; mechanical durability challenges under prolonged cyclic loading.

Key Patents and Technical Innovations in Piezoelectric Ceramics

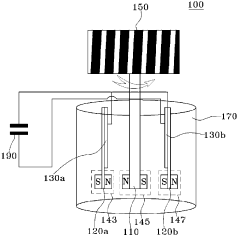

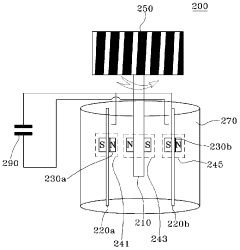

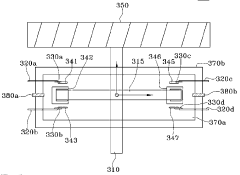

Energy harvesting device employing a piezoelectric ceramic and magnets

PatentWO2011059129A1

Innovation

- An energy harvesting device utilizing piezoelectric ceramics and magnets, where the rotation of a venturator driven by wind power induces bending in the ceramics, generating voltage through attractive and repulsive forces between magnets, which is then stored or used as an independent power source.

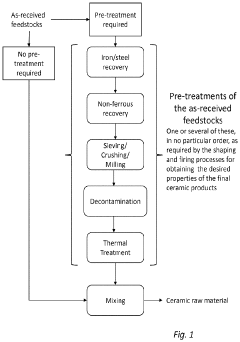

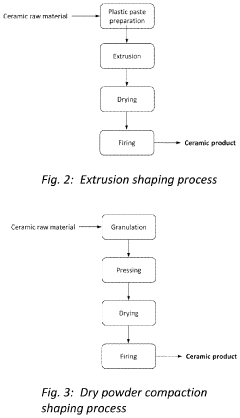

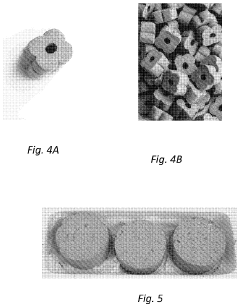

Elaboration of ceramic materials made from refractory waste for high-temperature thermal energy storage applications

PatentPendingUS20240010571A1

Innovation

- A method for producing thermal energy storage ceramics using recycled refractory waste, involving pretreatment, mixing with clay-like materials, and firing at high temperatures to create ceramic products suitable for packed bed or structured bed systems, capable of storing heat up to 1400°C.

Environmental Impact and Sustainability of Ceramic Energy Harvesters

The environmental impact of ceramic energy harvesters represents a critical consideration in their development and deployment. Unlike traditional energy generation methods that rely on fossil fuels, ceramic-based energy harvesting technologies offer significantly reduced carbon emissions during operation. These systems convert ambient energy sources such as vibration, heat, and pressure into usable electricity without combustion processes, thereby eliminating direct greenhouse gas emissions during energy production.

Manufacturing processes for structural ceramics, however, do present environmental challenges. The production of advanced ceramics typically requires high-temperature sintering (often exceeding 1000°C), consuming substantial energy and generating associated carbon emissions. Additionally, some specialized ceramic compositions incorporate rare earth elements or other materials with environmentally intensive extraction processes. These factors contribute to the embodied carbon footprint of ceramic energy harvesting devices.

Life cycle assessments of ceramic energy harvesters reveal a complex sustainability profile. While their operational phase demonstrates excellent environmental performance with zero direct emissions, the manufacturing and end-of-life phases require careful management. The durability of ceramics presents both advantages and challenges—their long service life reduces replacement frequency and associated resource consumption, but their chemical stability can complicate recycling efforts.

Recent innovations are addressing these sustainability concerns through several approaches. Materials scientists are developing lower-temperature processing techniques that reduce energy requirements during manufacturing. Alternative ceramic formulations that minimize or eliminate environmentally problematic elements while maintaining performance characteristics are emerging. Additionally, design strategies that facilitate component recovery and material separation at end-of-life are gaining traction.

The sustainability advantages of ceramic energy harvesters become particularly evident in remote or inaccessible deployment scenarios. By eliminating battery replacement needs in wireless sensor networks, structural health monitoring systems, and remote environmental monitoring stations, these technologies reduce maintenance requirements and associated transportation emissions. This aspect is especially valuable in applications where frequent component replacement would otherwise necessitate resource-intensive field operations.

Looking forward, the environmental profile of ceramic energy harvesters will likely improve as manufacturing processes evolve and circular economy principles are increasingly incorporated into their design. The net environmental benefit of these technologies depends significantly on application context, with greatest advantages realized in scenarios where they displace high-maintenance conventional power sources or enable new energy-autonomous systems that would otherwise require frequent battery replacement.

Manufacturing processes for structural ceramics, however, do present environmental challenges. The production of advanced ceramics typically requires high-temperature sintering (often exceeding 1000°C), consuming substantial energy and generating associated carbon emissions. Additionally, some specialized ceramic compositions incorporate rare earth elements or other materials with environmentally intensive extraction processes. These factors contribute to the embodied carbon footprint of ceramic energy harvesting devices.

Life cycle assessments of ceramic energy harvesters reveal a complex sustainability profile. While their operational phase demonstrates excellent environmental performance with zero direct emissions, the manufacturing and end-of-life phases require careful management. The durability of ceramics presents both advantages and challenges—their long service life reduces replacement frequency and associated resource consumption, but their chemical stability can complicate recycling efforts.

Recent innovations are addressing these sustainability concerns through several approaches. Materials scientists are developing lower-temperature processing techniques that reduce energy requirements during manufacturing. Alternative ceramic formulations that minimize or eliminate environmentally problematic elements while maintaining performance characteristics are emerging. Additionally, design strategies that facilitate component recovery and material separation at end-of-life are gaining traction.

The sustainability advantages of ceramic energy harvesters become particularly evident in remote or inaccessible deployment scenarios. By eliminating battery replacement needs in wireless sensor networks, structural health monitoring systems, and remote environmental monitoring stations, these technologies reduce maintenance requirements and associated transportation emissions. This aspect is especially valuable in applications where frequent component replacement would otherwise necessitate resource-intensive field operations.

Looking forward, the environmental profile of ceramic energy harvesters will likely improve as manufacturing processes evolve and circular economy principles are increasingly incorporated into their design. The net environmental benefit of these technologies depends significantly on application context, with greatest advantages realized in scenarios where they displace high-maintenance conventional power sources or enable new energy-autonomous systems that would otherwise require frequent battery replacement.

Integration Strategies with Existing Energy Systems

The integration of structural ceramics for energy harvesting into existing energy systems represents a critical pathway for practical implementation and widespread adoption. Current energy infrastructure predominantly relies on conventional generation methods, creating both challenges and opportunities for ceramic-based energy harvesting technologies.

Seamless integration requires adaptive interface designs that allow structural ceramics to complement rather than replace existing systems. This hybrid approach enables gradual technology transition while maximizing overall system efficiency. For instance, piezoelectric ceramic components can be incorporated into conventional power plants to harvest waste vibrational energy, providing supplementary power generation without disrupting primary operations.

Grid compatibility presents another significant consideration, as energy harvested from ceramic structures must be conditioned to match grid specifications. Advanced power electronics and energy management systems are essential for converting the typically intermittent, low-voltage outputs from ceramic harvesters into stable, grid-compatible power. These systems must incorporate sophisticated control algorithms to optimize energy capture across varying environmental conditions.

Energy storage integration forms a crucial component of effective deployment strategies. Since ceramic-based energy harvesting often produces variable outputs depending on external stimuli, coupling these systems with appropriate storage technologies—such as advanced batteries or supercapacitors—creates more reliable energy delivery. This pairing enables load balancing and ensures continuous power availability despite fluctuations in harvesting conditions.

Building management systems offer particularly promising integration opportunities. Structural ceramics embedded in building materials can harvest energy from daily temperature fluctuations, mechanical vibrations, and even electromagnetic radiation. When connected to smart building management systems, these materials can contribute to reduced grid dependency while providing valuable data on structural health and environmental conditions.

Industrial applications demonstrate significant potential for ceramic energy harvesting integration. Manufacturing facilities with high-temperature processes or substantial mechanical vibrations represent ideal environments for thermoelectric or piezoelectric ceramic implementations. These systems can be designed to operate in parallel with existing power systems, gradually offsetting conventional energy consumption while providing valuable redundancy.

Transportation infrastructure integration represents another frontier, with structural ceramics embedded in roadways, bridges, and railways harvesting energy from vehicular movement and environmental factors. These systems can power adjacent monitoring equipment, lighting systems, or even contribute to charging infrastructure for electric vehicles, creating self-sustaining transportation networks that reduce dependency on centralized power generation.

Seamless integration requires adaptive interface designs that allow structural ceramics to complement rather than replace existing systems. This hybrid approach enables gradual technology transition while maximizing overall system efficiency. For instance, piezoelectric ceramic components can be incorporated into conventional power plants to harvest waste vibrational energy, providing supplementary power generation without disrupting primary operations.

Grid compatibility presents another significant consideration, as energy harvested from ceramic structures must be conditioned to match grid specifications. Advanced power electronics and energy management systems are essential for converting the typically intermittent, low-voltage outputs from ceramic harvesters into stable, grid-compatible power. These systems must incorporate sophisticated control algorithms to optimize energy capture across varying environmental conditions.

Energy storage integration forms a crucial component of effective deployment strategies. Since ceramic-based energy harvesting often produces variable outputs depending on external stimuli, coupling these systems with appropriate storage technologies—such as advanced batteries or supercapacitors—creates more reliable energy delivery. This pairing enables load balancing and ensures continuous power availability despite fluctuations in harvesting conditions.

Building management systems offer particularly promising integration opportunities. Structural ceramics embedded in building materials can harvest energy from daily temperature fluctuations, mechanical vibrations, and even electromagnetic radiation. When connected to smart building management systems, these materials can contribute to reduced grid dependency while providing valuable data on structural health and environmental conditions.

Industrial applications demonstrate significant potential for ceramic energy harvesting integration. Manufacturing facilities with high-temperature processes or substantial mechanical vibrations represent ideal environments for thermoelectric or piezoelectric ceramic implementations. These systems can be designed to operate in parallel with existing power systems, gradually offsetting conventional energy consumption while providing valuable redundancy.

Transportation infrastructure integration represents another frontier, with structural ceramics embedded in roadways, bridges, and railways harvesting energy from vehicular movement and environmental factors. These systems can power adjacent monitoring equipment, lighting systems, or even contribute to charging infrastructure for electric vehicles, creating self-sustaining transportation networks that reduce dependency on centralized power generation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!