Comparison of Thermal Stability: Structural Ceramics vs Polymers

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Stability Background and Research Objectives

Thermal stability, the ability of materials to maintain their structural integrity and properties at elevated temperatures, has been a critical area of materials science research since the mid-20th century. The evolution of high-temperature applications in aerospace, energy generation, and manufacturing sectors has driven continuous innovation in thermally stable materials. Structural ceramics emerged as prominent high-temperature materials in the 1960s, while high-performance polymers gained significant attention from the 1970s onward as potential alternatives for less extreme thermal environments.

The fundamental difference in thermal stability between these material classes stems from their bonding mechanisms. Ceramics, with their predominantly ionic and covalent bonds, demonstrate superior resistance to thermal degradation compared to polymers, which rely on weaker intermolecular forces and covalent backbone structures. This distinction has historically relegated polymers to lower-temperature applications, though recent advances have begun to narrow this performance gap.

Recent technological developments have pushed the boundaries of both material classes. Advanced structural ceramics such as silicon nitride, silicon carbide, and zirconia have achieved operational temperatures exceeding 1500°C with minimal degradation. Concurrently, high-performance polymers like polyimides, PEEK (polyether ether ketone), and liquid crystal polymers have extended polymer thermal stability to the 300-400°C range, representing a significant improvement over conventional polymers.

The research landscape has evolved from focusing solely on maximum temperature resistance to a more nuanced understanding of thermal stability factors including thermal shock resistance, thermal cycling behavior, and long-term thermal aging effects. This shift reflects the growing complexity of modern applications where materials must withstand not just high temperatures but dynamic thermal conditions.

Our technical research objectives are threefold: First, to comprehensively analyze and quantify the thermal stability mechanisms and limitations of current-generation structural ceramics and high-performance polymers. Second, to identify potential hybrid or composite approaches that might leverage the complementary properties of both material classes. Third, to forecast technological trajectories and breakthrough opportunities that could fundamentally alter the thermal stability paradigm for either material class over the next decade.

This research aims to provide actionable insights for materials selection and development strategies across multiple industries, particularly focusing on emerging applications in renewable energy systems, next-generation aerospace components, and advanced manufacturing processes where thermal stability requirements continue to become more demanding and complex.

The fundamental difference in thermal stability between these material classes stems from their bonding mechanisms. Ceramics, with their predominantly ionic and covalent bonds, demonstrate superior resistance to thermal degradation compared to polymers, which rely on weaker intermolecular forces and covalent backbone structures. This distinction has historically relegated polymers to lower-temperature applications, though recent advances have begun to narrow this performance gap.

Recent technological developments have pushed the boundaries of both material classes. Advanced structural ceramics such as silicon nitride, silicon carbide, and zirconia have achieved operational temperatures exceeding 1500°C with minimal degradation. Concurrently, high-performance polymers like polyimides, PEEK (polyether ether ketone), and liquid crystal polymers have extended polymer thermal stability to the 300-400°C range, representing a significant improvement over conventional polymers.

The research landscape has evolved from focusing solely on maximum temperature resistance to a more nuanced understanding of thermal stability factors including thermal shock resistance, thermal cycling behavior, and long-term thermal aging effects. This shift reflects the growing complexity of modern applications where materials must withstand not just high temperatures but dynamic thermal conditions.

Our technical research objectives are threefold: First, to comprehensively analyze and quantify the thermal stability mechanisms and limitations of current-generation structural ceramics and high-performance polymers. Second, to identify potential hybrid or composite approaches that might leverage the complementary properties of both material classes. Third, to forecast technological trajectories and breakthrough opportunities that could fundamentally alter the thermal stability paradigm for either material class over the next decade.

This research aims to provide actionable insights for materials selection and development strategies across multiple industries, particularly focusing on emerging applications in renewable energy systems, next-generation aerospace components, and advanced manufacturing processes where thermal stability requirements continue to become more demanding and complex.

Market Analysis for High-Temperature Materials

The high-temperature materials market has experienced significant growth in recent years, driven primarily by increasing demand from aerospace, automotive, and industrial sectors. The global market for high-temperature materials was valued at approximately $10.3 billion in 2022 and is projected to reach $15.7 billion by 2028, representing a compound annual growth rate (CAGR) of 7.3% during the forecast period.

Structural ceramics dominate the high-temperature materials segment, accounting for roughly 42% of the market share. Their exceptional thermal stability at temperatures exceeding 1500°C has made them indispensable in applications requiring extreme heat resistance. The aerospace industry remains the largest consumer of structural ceramics, utilizing these materials in jet engines, thermal protection systems, and various critical components.

Polymers with high-temperature capabilities, though representing a smaller market share at 28%, are witnessing faster growth rates of approximately 9.2% annually. This accelerated growth is attributed to ongoing innovations in polymer chemistry and the development of high-performance thermoplastics and thermosets that can withstand temperatures up to 350-400°C. These advanced polymers are increasingly replacing metals in automotive and electronics applications due to their lighter weight and processing advantages.

Regional analysis reveals that Asia-Pacific currently leads the high-temperature materials market with 38% share, followed by North America (29%) and Europe (24%). China and India are experiencing the most rapid market expansion, driven by robust growth in manufacturing sectors and increasing investments in aerospace and defense industries.

Customer segmentation shows distinct preferences between ceramics and polymers. Industries requiring materials to withstand extreme temperatures (above 1000°C) predominantly favor structural ceramics despite their higher costs and processing challenges. Meanwhile, sectors where temperatures remain below 400°C increasingly opt for high-performance polymers due to their cost-effectiveness, design flexibility, and easier processing characteristics.

Price sensitivity varies significantly across application sectors. The aerospace and defense industries demonstrate lower price sensitivity when sourcing high-temperature materials due to stringent performance requirements and safety regulations. Conversely, consumer electronics and automotive sectors exhibit greater price consciousness, creating opportunities for high-temperature polymers to gain market share through competitive pricing strategies.

Future market trends indicate growing demand for hybrid and composite materials that combine the thermal stability advantages of ceramics with the processing benefits of polymers. Additionally, sustainability concerns are driving research into bio-based high-temperature polymers, potentially creating new market segments within the next decade.

Structural ceramics dominate the high-temperature materials segment, accounting for roughly 42% of the market share. Their exceptional thermal stability at temperatures exceeding 1500°C has made them indispensable in applications requiring extreme heat resistance. The aerospace industry remains the largest consumer of structural ceramics, utilizing these materials in jet engines, thermal protection systems, and various critical components.

Polymers with high-temperature capabilities, though representing a smaller market share at 28%, are witnessing faster growth rates of approximately 9.2% annually. This accelerated growth is attributed to ongoing innovations in polymer chemistry and the development of high-performance thermoplastics and thermosets that can withstand temperatures up to 350-400°C. These advanced polymers are increasingly replacing metals in automotive and electronics applications due to their lighter weight and processing advantages.

Regional analysis reveals that Asia-Pacific currently leads the high-temperature materials market with 38% share, followed by North America (29%) and Europe (24%). China and India are experiencing the most rapid market expansion, driven by robust growth in manufacturing sectors and increasing investments in aerospace and defense industries.

Customer segmentation shows distinct preferences between ceramics and polymers. Industries requiring materials to withstand extreme temperatures (above 1000°C) predominantly favor structural ceramics despite their higher costs and processing challenges. Meanwhile, sectors where temperatures remain below 400°C increasingly opt for high-performance polymers due to their cost-effectiveness, design flexibility, and easier processing characteristics.

Price sensitivity varies significantly across application sectors. The aerospace and defense industries demonstrate lower price sensitivity when sourcing high-temperature materials due to stringent performance requirements and safety regulations. Conversely, consumer electronics and automotive sectors exhibit greater price consciousness, creating opportunities for high-temperature polymers to gain market share through competitive pricing strategies.

Future market trends indicate growing demand for hybrid and composite materials that combine the thermal stability advantages of ceramics with the processing benefits of polymers. Additionally, sustainability concerns are driving research into bio-based high-temperature polymers, potentially creating new market segments within the next decade.

Current Challenges in Thermal Stability Research

Despite significant advancements in thermal stability research, several critical challenges persist in comparing and enhancing the thermal properties of structural ceramics and polymers. The fundamental challenge lies in the inherent trade-off between thermal stability and other desirable material properties. For ceramics, while they exhibit exceptional thermal resistance, they often suffer from brittleness and poor fracture toughness, limiting their application in environments requiring mechanical resilience alongside thermal stability.

The development of accurate and standardized testing methodologies presents another significant hurdle. Current thermal characterization techniques often yield inconsistent results when applied across different material classes, making direct comparisons between ceramics and polymers particularly problematic. The diverse degradation mechanisms exhibited by these materials further complicate the establishment of universal testing protocols.

For polymer materials specifically, researchers struggle with the complex relationship between molecular structure and thermal degradation pathways. The incorporation of fillers and additives, while potentially enhancing thermal stability, introduces unpredictable interactions that can accelerate degradation under certain conditions. This complexity makes predictive modeling exceptionally difficult.

Ceramics face different challenges, primarily related to processing limitations. Advanced ceramic compositions with superior thermal properties often require extreme processing conditions, including ultra-high temperatures and pressures, making large-scale production economically prohibitive. Additionally, the interface stability in ceramic composites remains problematic, with thermal cycling frequently leading to delamination and structural failure.

The growing demand for materials suitable for extreme environments has intensified research into hybrid ceramic-polymer systems. However, these efforts encounter significant compatibility issues at material interfaces, where thermal expansion mismatches create stress concentrations that compromise overall stability.

Environmental considerations add another layer of complexity. Traditional thermal stabilizers for polymers often contain environmentally harmful compounds, while ceramic processing typically involves high energy consumption. Developing thermally stable materials that meet increasingly stringent environmental regulations represents a mounting challenge for researchers.

Perhaps most critically, there exists a substantial gap between laboratory research and industrial implementation. Many promising thermally stable materials demonstrate excellent properties in controlled laboratory settings but fail to maintain these advantages when scaled to industrial production or when subjected to the complex, multi-factor stresses of real-world applications.

The development of accurate and standardized testing methodologies presents another significant hurdle. Current thermal characterization techniques often yield inconsistent results when applied across different material classes, making direct comparisons between ceramics and polymers particularly problematic. The diverse degradation mechanisms exhibited by these materials further complicate the establishment of universal testing protocols.

For polymer materials specifically, researchers struggle with the complex relationship between molecular structure and thermal degradation pathways. The incorporation of fillers and additives, while potentially enhancing thermal stability, introduces unpredictable interactions that can accelerate degradation under certain conditions. This complexity makes predictive modeling exceptionally difficult.

Ceramics face different challenges, primarily related to processing limitations. Advanced ceramic compositions with superior thermal properties often require extreme processing conditions, including ultra-high temperatures and pressures, making large-scale production economically prohibitive. Additionally, the interface stability in ceramic composites remains problematic, with thermal cycling frequently leading to delamination and structural failure.

The growing demand for materials suitable for extreme environments has intensified research into hybrid ceramic-polymer systems. However, these efforts encounter significant compatibility issues at material interfaces, where thermal expansion mismatches create stress concentrations that compromise overall stability.

Environmental considerations add another layer of complexity. Traditional thermal stabilizers for polymers often contain environmentally harmful compounds, while ceramic processing typically involves high energy consumption. Developing thermally stable materials that meet increasingly stringent environmental regulations represents a mounting challenge for researchers.

Perhaps most critically, there exists a substantial gap between laboratory research and industrial implementation. Many promising thermally stable materials demonstrate excellent properties in controlled laboratory settings but fail to maintain these advantages when scaled to industrial production or when subjected to the complex, multi-factor stresses of real-world applications.

Contemporary Thermal Stability Enhancement Methods

01 High-temperature resistant ceramic-polymer composites

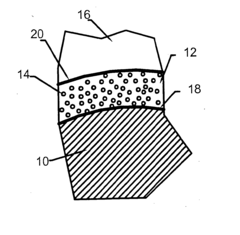

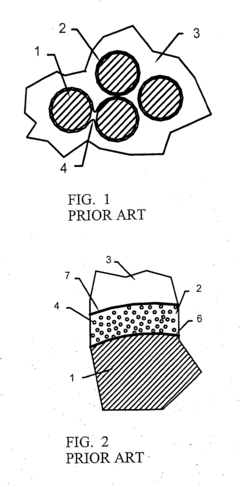

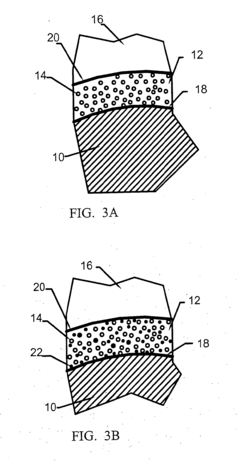

Ceramic-polymer composites can be engineered to withstand high temperatures by incorporating thermally stable ceramic particles into polymer matrices. These composites combine the thermal resistance of ceramics with the processability of polymers, resulting in materials with enhanced thermal stability. The ceramic components typically include silicon carbide, alumina, or zirconia, which provide structural integrity at elevated temperatures while the polymer matrix is modified with heat-resistant additives to prevent degradation.- High-temperature resistant ceramic-polymer composites: Ceramic-polymer composites can be engineered to withstand high temperatures by incorporating thermally stable ceramic particles into polymer matrices. These composites combine the thermal resistance of ceramics with the processability of polymers. The ceramic components typically include silicon carbide, alumina, or zirconia, which enhance the overall thermal stability of the composite material while maintaining structural integrity at elevated temperatures.

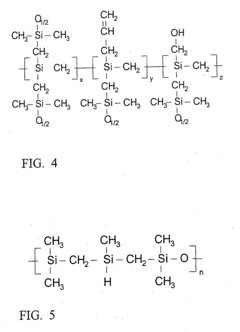

- Polymer modifications for enhanced thermal stability: Various chemical modifications can be applied to polymers to improve their thermal stability. These include cross-linking, incorporation of aromatic structures, and addition of heat-resistant functional groups. Modified polymers can maintain their structural properties at higher temperatures, making them suitable for applications requiring thermal resistance. Techniques such as copolymerization with heat-resistant monomers and the addition of stabilizing additives can significantly increase the temperature threshold at which polymers maintain their mechanical properties.

- Ceramic processing techniques for thermal stability: Advanced processing techniques for ceramics can enhance their thermal stability properties. These include controlled sintering processes, grain boundary engineering, and phase transformation toughening. By optimizing the microstructure of ceramic materials, their resistance to thermal shock and high-temperature degradation can be significantly improved. The resulting ceramics maintain structural integrity under extreme thermal conditions, making them suitable for high-temperature applications in various industries.

- Nanostructured materials for thermal applications: Nanostructured ceramics and polymer-based materials offer enhanced thermal stability compared to their conventional counterparts. The nanoscale features create unique interfaces and structural arrangements that can better withstand thermal stresses. These materials include nanocomposites, materials with nanoporous structures, and those incorporating nanoparticles. The reduced dimensions at the nanoscale allow for more efficient heat dissipation and resistance to thermal degradation, while maintaining or improving mechanical properties.

- Interface engineering in ceramic-polymer systems: The interface between ceramic and polymer components plays a crucial role in determining the thermal stability of composite materials. Engineering these interfaces through surface treatments, coupling agents, or gradient structures can enhance thermal performance. Improved adhesion between the ceramic and polymer phases prevents delamination during thermal cycling and allows for better stress transfer. This approach results in composite materials that maintain their structural integrity across a wider temperature range than would be possible with either component alone.

02 Thermally stable polymer structures for high-temperature applications

Specialized polymers can be formulated to maintain structural integrity at elevated temperatures through molecular design and cross-linking strategies. These thermally stable polymers often contain aromatic rings, heterocyclic structures, or silicon-based components that resist thermal degradation. Techniques such as controlled cross-linking, incorporation of heat-resistant monomers, and addition of thermal stabilizers can significantly improve the temperature resistance of polymeric materials, allowing them to function in environments where conventional polymers would fail.Expand Specific Solutions03 Ceramic coatings for thermal protection of polymer substrates

Applying ceramic coatings to polymer surfaces can dramatically improve their thermal stability and protect the underlying material from heat damage. These coatings create a thermal barrier that shields the polymer from direct heat exposure, preventing degradation and maintaining structural integrity. Various deposition techniques including sol-gel processing, plasma spraying, and chemical vapor deposition can be used to create ceramic layers with controlled thickness and composition, optimized for specific temperature ranges and environmental conditions.Expand Specific Solutions04 Nanostructured ceramics for enhanced thermal stability

Nanostructured ceramic materials exhibit superior thermal stability compared to their conventional counterparts due to their unique grain boundaries and structural characteristics. By controlling the grain size at the nanoscale, these advanced ceramics demonstrate improved resistance to thermal shock, reduced thermal expansion, and enhanced mechanical properties at high temperatures. The incorporation of nanoparticles, nanofibers, or nanolayers into ceramic structures creates materials with exceptional thermal stability for applications in extreme environments.Expand Specific Solutions05 Interface engineering for ceramic-polymer thermal stability

The interface between ceramic and polymer components plays a crucial role in determining the overall thermal stability of composite materials. By engineering this interface through surface treatments, coupling agents, or gradient structures, the thermal mismatch between the dissimilar materials can be minimized, preventing delamination or cracking during thermal cycling. Advanced interface engineering techniques include chemical functionalization of surfaces, creation of interpenetrating networks, and development of graded transition zones that distribute thermal stresses more effectively.Expand Specific Solutions

Leading Organizations in Advanced Materials Research

The thermal stability comparison between structural ceramics and polymers is currently in a mature development phase, with a growing market driven by high-temperature applications in aerospace, automotive, and electronics industries. Ceramics demonstrate superior thermal stability (up to 2000°C) compared to polymers (typically below 350°C), creating distinct application niches. Companies like NGK Insulators and Rauschert Holding lead in advanced ceramics development, while polymer thermal stability innovations are spearheaded by DuPont, Toray Industries, and Arkema France. The integration of ceramic-polymer composites represents an emerging trend, with 3M and Saint-Gobain developing hybrid materials that combine the thermal resistance of ceramics with the processability of polymers, addressing the performance gap between these material classes.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced high-temperature polymers like Vespel® polyimide that maintain structural integrity at temperatures up to 300°C continuously and intermittently up to 480°C. Their proprietary cross-linking technology enhances thermal stability by creating additional bonds between polymer chains when exposed to elevated temperatures. DuPont's research has shown that their specialized fluoropolymers (such as Teflon® PFA) exhibit less than 0.5% weight loss at 371°C for 100 hours, demonstrating exceptional thermal resistance compared to conventional polymers. Their engineered polymers incorporate stabilizing additives and modified molecular structures that resist chain scission and oxidation at high temperatures, allowing for prolonged service life in demanding thermal environments. DuPont has also pioneered hybrid materials that combine polymer flexibility with ceramic-like thermal stability through nano-scale ceramic particle incorporation.

Strengths: Superior processing flexibility compared to ceramics, allowing complex shapes to be formed more easily; excellent chemical resistance combined with thermal stability; lower weight than ceramic alternatives. Weaknesses: Still cannot match the absolute temperature resistance of structural ceramics (which can withstand >1000°C); higher thermal expansion coefficients than ceramics; mechanical properties degrade more significantly near upper temperature limits.

3M Innovative Properties Co.

Technical Solution: 3M has developed a comprehensive portfolio of thermally stable materials that bridge the gap between conventional polymers and ceramics. Their fluoropolymer technologies, particularly PTFE and PFA variants, incorporate proprietary stabilizers that prevent depolymerization at elevated temperatures, maintaining structural integrity up to 260°C continuously. 3M's ceramic-filled polymer composites utilize nano-scale ceramic particles (typically aluminum oxide or silicon carbide) uniformly dispersed within high-temperature polymer matrices, creating materials with thermal stability approaching 350°C while retaining polymer-like processability. Their research has demonstrated that these hybrid materials exhibit thermal expansion coefficients approximately 40% lower than unfilled polymers, reducing thermal stress during temperature cycling. 3M has pioneered specialized fluoroelastomer formulations that maintain flexibility and sealing properties at temperatures up to 325°C, significantly outperforming conventional elastomers that typically fail above 150°C. Their thermal interface materials combine ceramic fillers with specialized polymer binders to create thermally conductive yet compliant materials that maintain performance through thousands of thermal cycles between -40°C and 200°C.

Strengths: Excellent balance between thermal stability and processability; ability to create complex shapes more easily than with pure ceramics; good chemical resistance across a wide temperature range; lower density than ceramic alternatives resulting in weight savings. Weaknesses: Cannot match the absolute temperature resistance of structural ceramics; higher thermal expansion than ceramics leading to potential dimensional issues in extreme environments; mechanical properties degrade more significantly as temperature approaches upper limits.

Critical Patents in Ceramic and Polymer Thermal Properties

Ceramic-forming polymer material

PatentInactiveUS20080093185A1

Innovation

- Development of non-cyclic ceramic-forming polymers with specific ratios of carbon, silicon, oxygen, and hydrogen, which upon pyrolysis, form ceramics primarily composed of stoichiometric SiC, offering improved oxidation resistance and thermal stability by controlling the elemental composition and pyrolysis conditions.

Ceramic material and electroceramic component comprising said ceramic material

PatentActiveEP2118037A2

Innovation

- A ceramic material with a perovskite crystal structure, formulated as {(SE111, SE211)1-x (M111, M211)x} (Cr, Mn, Me)O3, where SE are rare earth metals, M are redox-stable trivalent cations, and Cr, Mn can be trivalent or tetravalent, allowing for adjustable resistance and reduced charge transport through polaron conduction, forming a phase-homogeneous perovskite mixed-crystal system to enhance thermal stability.

Material Testing Standards and Methodologies

The evaluation of thermal stability in structural ceramics and polymers requires adherence to standardized testing protocols to ensure reliable and comparable results. ASTM International has developed several key standards specifically for high-temperature material characterization, including ASTM C1171 for quantitative measurement of thermal stability in ceramics and ASTM D3850 for polymeric materials' thermal transitions.

ISO standards complement these with ISO 11357 series for differential scanning calorimetry (DSC) of polymers and ISO 20504 for ceramic materials' high-temperature testing. These standards establish precise methodologies for sample preparation, instrument calibration, and data interpretation, creating a framework for consistent thermal stability assessment across different laboratories.

Thermogravimetric Analysis (TGA) represents a fundamental methodology for evaluating weight changes in materials as a function of temperature. For ceramics, testing typically extends to 1600°C or higher, while polymer testing generally remains below 800°C due to their inherent thermal limitations. The heating rate significantly impacts results, with standard rates ranging from 5-20°C/min depending on the material class and specific investigation objectives.

Dynamic Mechanical Analysis (DMA) provides critical insights into viscoelastic properties as materials undergo thermal transitions. This technique is particularly valuable for polymers, revealing glass transition temperatures and other phase changes that directly correlate with thermal stability. For ceramics, high-temperature mechanical spectroscopy adaptations of DMA principles allow evaluation of internal friction and elastic modulus changes at elevated temperatures.

Dilatometry measures dimensional changes during heating, offering direct observation of thermal expansion behavior—a critical parameter for both material classes. Modern dilatometers can operate at temperatures exceeding 2000°C for ceramics, while specialized instruments for polymers typically operate up to 600°C with enhanced sensitivity to detect subtle transitions.

Laser flash analysis has emerged as the preferred method for thermal diffusivity measurement, following standards like ASTM E1461. This technique, applicable to both ceramics and polymers, enables calculation of thermal conductivity when combined with specific heat capacity data, providing crucial information about heat transfer capabilities under thermal stress conditions.

Environmental chambers coupled with mechanical testing equipment allow simulation of real-world thermal conditions while simultaneously measuring mechanical performance. These integrated systems enable determination of temperature-dependent properties like strength retention, creep resistance, and fatigue behavior—parameters essential for predicting long-term thermal stability in practical applications.

ISO standards complement these with ISO 11357 series for differential scanning calorimetry (DSC) of polymers and ISO 20504 for ceramic materials' high-temperature testing. These standards establish precise methodologies for sample preparation, instrument calibration, and data interpretation, creating a framework for consistent thermal stability assessment across different laboratories.

Thermogravimetric Analysis (TGA) represents a fundamental methodology for evaluating weight changes in materials as a function of temperature. For ceramics, testing typically extends to 1600°C or higher, while polymer testing generally remains below 800°C due to their inherent thermal limitations. The heating rate significantly impacts results, with standard rates ranging from 5-20°C/min depending on the material class and specific investigation objectives.

Dynamic Mechanical Analysis (DMA) provides critical insights into viscoelastic properties as materials undergo thermal transitions. This technique is particularly valuable for polymers, revealing glass transition temperatures and other phase changes that directly correlate with thermal stability. For ceramics, high-temperature mechanical spectroscopy adaptations of DMA principles allow evaluation of internal friction and elastic modulus changes at elevated temperatures.

Dilatometry measures dimensional changes during heating, offering direct observation of thermal expansion behavior—a critical parameter for both material classes. Modern dilatometers can operate at temperatures exceeding 2000°C for ceramics, while specialized instruments for polymers typically operate up to 600°C with enhanced sensitivity to detect subtle transitions.

Laser flash analysis has emerged as the preferred method for thermal diffusivity measurement, following standards like ASTM E1461. This technique, applicable to both ceramics and polymers, enables calculation of thermal conductivity when combined with specific heat capacity data, providing crucial information about heat transfer capabilities under thermal stress conditions.

Environmental chambers coupled with mechanical testing equipment allow simulation of real-world thermal conditions while simultaneously measuring mechanical performance. These integrated systems enable determination of temperature-dependent properties like strength retention, creep resistance, and fatigue behavior—parameters essential for predicting long-term thermal stability in practical applications.

Environmental Impact of High-Temperature Materials

The environmental impact of high-temperature materials, particularly structural ceramics and polymers, presents significant considerations for sustainable industrial development. Structural ceramics generally demonstrate superior environmental performance during operational phases due to their exceptional thermal stability and longevity. These materials can withstand extreme temperatures without degradation, resulting in fewer replacement cycles and consequently reduced resource consumption over their lifecycle.

When examining manufacturing processes, ceramics typically require higher energy inputs during production, with kiln firing temperatures often exceeding 1400°C. This energy-intensive production contributes substantially to their initial carbon footprint. However, this environmental cost is frequently offset by their extended service life, particularly in high-temperature applications where polymers would require frequent replacement.

Polymers, while less energy-intensive to manufacture, present different environmental challenges. Their lower thermal stability leads to degradation at elevated temperatures, potentially releasing harmful volatile organic compounds (VOCs) and microplastics into the environment. This thermal decomposition not only creates air quality concerns but also contributes to persistent environmental contamination.

Waste management represents another critical environmental dimension. End-of-life ceramics are largely inert and non-toxic, though their durability makes them resistant to natural degradation. Advanced recycling technologies are emerging that can process ceramic waste into secondary raw materials for construction applications, creating circular economy opportunities.

Polymer waste management is particularly problematic for high-temperature applications, as performance-enhancing additives often include flame retardants and stabilizers with significant environmental persistence. These compounds can leach into ecosystems when improperly disposed of, creating long-term contamination issues.

Recent life cycle assessments comparing these material classes indicate that structural ceramics typically demonstrate 30-45% lower lifetime environmental impact in high-temperature applications despite their higher production energy requirements. This advantage stems primarily from their superior durability and reduced maintenance needs.

Water consumption patterns also differ significantly between these material classes. Ceramic production generally requires substantial water inputs for processing raw materials and cooling, while polymer manufacturing typically has a lower water footprint but higher chemical input requirements. Emerging water-conserving technologies in ceramic manufacturing are beginning to address this disparity through closed-loop water systems.

As industries increasingly prioritize sustainability metrics, the environmental advantages of ceramics' thermal stability are becoming more economically valuable, driving innovation in more energy-efficient ceramic processing technologies and creating new market opportunities for these materials in traditionally polymer-dominated applications.

When examining manufacturing processes, ceramics typically require higher energy inputs during production, with kiln firing temperatures often exceeding 1400°C. This energy-intensive production contributes substantially to their initial carbon footprint. However, this environmental cost is frequently offset by their extended service life, particularly in high-temperature applications where polymers would require frequent replacement.

Polymers, while less energy-intensive to manufacture, present different environmental challenges. Their lower thermal stability leads to degradation at elevated temperatures, potentially releasing harmful volatile organic compounds (VOCs) and microplastics into the environment. This thermal decomposition not only creates air quality concerns but also contributes to persistent environmental contamination.

Waste management represents another critical environmental dimension. End-of-life ceramics are largely inert and non-toxic, though their durability makes them resistant to natural degradation. Advanced recycling technologies are emerging that can process ceramic waste into secondary raw materials for construction applications, creating circular economy opportunities.

Polymer waste management is particularly problematic for high-temperature applications, as performance-enhancing additives often include flame retardants and stabilizers with significant environmental persistence. These compounds can leach into ecosystems when improperly disposed of, creating long-term contamination issues.

Recent life cycle assessments comparing these material classes indicate that structural ceramics typically demonstrate 30-45% lower lifetime environmental impact in high-temperature applications despite their higher production energy requirements. This advantage stems primarily from their superior durability and reduced maintenance needs.

Water consumption patterns also differ significantly between these material classes. Ceramic production generally requires substantial water inputs for processing raw materials and cooling, while polymer manufacturing typically has a lower water footprint but higher chemical input requirements. Emerging water-conserving technologies in ceramic manufacturing are beginning to address this disparity through closed-loop water systems.

As industries increasingly prioritize sustainability metrics, the environmental advantages of ceramics' thermal stability are becoming more economically valuable, driving innovation in more energy-efficient ceramic processing technologies and creating new market opportunities for these materials in traditionally polymer-dominated applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!