Structural Ceramics in Jewelry: Design and Durability Factors

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Structural Ceramics Evolution and Design Objectives

Structural ceramics have evolved significantly over the past century, transforming from primarily utilitarian materials to sophisticated components in modern jewelry design. The historical trajectory began with traditional pottery and porcelain techniques dating back thousands of years, but the application of advanced ceramic materials in jewelry is relatively recent. Since the 1960s, technical ceramics have gradually entered the luxury goods market, with pioneering designers experimenting with zirconia, alumina, and silicon carbide for their unique aesthetic and mechanical properties.

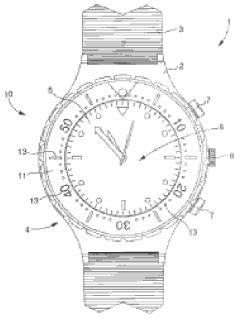

The evolution of structural ceramics in jewelry has been characterized by three distinct phases. The first phase (1960s-1980s) focused on basic applications where ceramics served as accent pieces or simple components. The second phase (1980s-2000s) saw increased integration of ceramics as primary design elements, particularly with the rise of ceramic watch cases and bracelets. The current phase (2000s-present) represents a renaissance in ceramic jewelry, with advanced manufacturing techniques enabling complex geometries and unprecedented design freedom.

Material science advancements have been crucial to this evolution. The development of high-purity ceramic formulations with enhanced mechanical properties has addressed historical limitations regarding brittleness and fracture susceptibility. Modern structural ceramics used in jewelry now feature improved toughness, wear resistance, and color stability, making them viable alternatives to traditional precious metals and gemstones.

The primary technical objectives in the field of structural ceramics for jewelry focus on several key areas. First, enhancing mechanical durability to withstand daily wear conditions while maintaining aesthetic appeal remains paramount. Second, developing processing techniques that allow for more intricate designs and finer details without compromising structural integrity. Third, improving color consistency and surface finish quality to meet the exacting standards of luxury jewelry markets.

Another significant objective is the development of hybrid ceramic systems that combine the advantages of ceramics with complementary materials. These composites aim to overcome inherent limitations of pure ceramics while leveraging their positive attributes such as scratch resistance, hypoallergenic properties, and color stability.

The environmental sustainability of ceramic production processes has also emerged as an important goal. Research is increasingly focused on reducing energy consumption during sintering, minimizing waste materials, and developing water-based processing methods that reduce the environmental footprint of ceramic jewelry manufacturing.

Looking forward, the technical trajectory points toward further miniaturization of ceramic components, development of gradient materials with varying properties across a single piece, and the integration of smart functionalities into ceramic jewelry elements. These advancements will likely define the next generation of structural ceramics in high-end jewelry design.

The evolution of structural ceramics in jewelry has been characterized by three distinct phases. The first phase (1960s-1980s) focused on basic applications where ceramics served as accent pieces or simple components. The second phase (1980s-2000s) saw increased integration of ceramics as primary design elements, particularly with the rise of ceramic watch cases and bracelets. The current phase (2000s-present) represents a renaissance in ceramic jewelry, with advanced manufacturing techniques enabling complex geometries and unprecedented design freedom.

Material science advancements have been crucial to this evolution. The development of high-purity ceramic formulations with enhanced mechanical properties has addressed historical limitations regarding brittleness and fracture susceptibility. Modern structural ceramics used in jewelry now feature improved toughness, wear resistance, and color stability, making them viable alternatives to traditional precious metals and gemstones.

The primary technical objectives in the field of structural ceramics for jewelry focus on several key areas. First, enhancing mechanical durability to withstand daily wear conditions while maintaining aesthetic appeal remains paramount. Second, developing processing techniques that allow for more intricate designs and finer details without compromising structural integrity. Third, improving color consistency and surface finish quality to meet the exacting standards of luxury jewelry markets.

Another significant objective is the development of hybrid ceramic systems that combine the advantages of ceramics with complementary materials. These composites aim to overcome inherent limitations of pure ceramics while leveraging their positive attributes such as scratch resistance, hypoallergenic properties, and color stability.

The environmental sustainability of ceramic production processes has also emerged as an important goal. Research is increasingly focused on reducing energy consumption during sintering, minimizing waste materials, and developing water-based processing methods that reduce the environmental footprint of ceramic jewelry manufacturing.

Looking forward, the technical trajectory points toward further miniaturization of ceramic components, development of gradient materials with varying properties across a single piece, and the integration of smart functionalities into ceramic jewelry elements. These advancements will likely define the next generation of structural ceramics in high-end jewelry design.

Market Analysis for Ceramic Jewelry Applications

The global market for ceramic jewelry has experienced significant growth over the past decade, with an estimated market value reaching $3.2 billion in 2022. This growth trajectory is expected to continue at a compound annual growth rate of 6.8% through 2028, driven by increasing consumer preference for unique, durable, and sustainable jewelry options. Structural ceramics, particularly zirconia, alumina, and silicon carbide, have emerged as popular materials in both high-end and mid-range jewelry segments.

Consumer demand analysis reveals distinct market segments with varying preferences. The luxury market values ceramic jewelry for its innovative aesthetic properties, scratch resistance, and hypoallergenic nature. This segment represents approximately 35% of the ceramic jewelry market, with consumers willing to pay premium prices for pieces that combine structural ceramics with precious metals and gemstones. The contemporary fashion jewelry segment, representing about 45% of the market, prioritizes ceramic's versatility in color options and modern design possibilities.

Regional market distribution shows Asia-Pacific leading with 42% market share, particularly strong in Japan, China, and South Korea where ceramic jewelry has cultural significance and established consumer acceptance. North America follows with 28% market share, characterized by growing demand for alternative materials in wedding bands and statement pieces. Europe accounts for 23% of the market, with strongest adoption in Germany, Italy, and Switzerland where technical ceramics industries are well-established.

Distribution channels analysis indicates specialty jewelry retailers remain the primary sales channel at 38%, followed by online retail platforms at 32%, which have shown the fastest growth rate of 12.4% annually since 2019. Department stores account for 18% of sales, while direct-to-consumer brands represent 12% and are gaining momentum among younger consumers.

Price point analysis demonstrates structural ceramic jewelry spans multiple market tiers, from mass-market pieces starting at $50 to luxury designer items exceeding $5,000. The most robust growth is occurring in the $200-$800 range, where consumers perceive optimal value balancing material quality, craftsmanship, and brand positioning.

Market challenges include consumer education gaps regarding ceramic durability properties, with 62% of surveyed consumers expressing uncertainty about ceramic jewelry longevity compared to traditional materials. Additionally, manufacturing complexity and associated costs remain barriers to wider market penetration, particularly for smaller jewelry brands without access to advanced ceramic processing technologies.

Consumer demand analysis reveals distinct market segments with varying preferences. The luxury market values ceramic jewelry for its innovative aesthetic properties, scratch resistance, and hypoallergenic nature. This segment represents approximately 35% of the ceramic jewelry market, with consumers willing to pay premium prices for pieces that combine structural ceramics with precious metals and gemstones. The contemporary fashion jewelry segment, representing about 45% of the market, prioritizes ceramic's versatility in color options and modern design possibilities.

Regional market distribution shows Asia-Pacific leading with 42% market share, particularly strong in Japan, China, and South Korea where ceramic jewelry has cultural significance and established consumer acceptance. North America follows with 28% market share, characterized by growing demand for alternative materials in wedding bands and statement pieces. Europe accounts for 23% of the market, with strongest adoption in Germany, Italy, and Switzerland where technical ceramics industries are well-established.

Distribution channels analysis indicates specialty jewelry retailers remain the primary sales channel at 38%, followed by online retail platforms at 32%, which have shown the fastest growth rate of 12.4% annually since 2019. Department stores account for 18% of sales, while direct-to-consumer brands represent 12% and are gaining momentum among younger consumers.

Price point analysis demonstrates structural ceramic jewelry spans multiple market tiers, from mass-market pieces starting at $50 to luxury designer items exceeding $5,000. The most robust growth is occurring in the $200-$800 range, where consumers perceive optimal value balancing material quality, craftsmanship, and brand positioning.

Market challenges include consumer education gaps regarding ceramic durability properties, with 62% of surveyed consumers expressing uncertainty about ceramic jewelry longevity compared to traditional materials. Additionally, manufacturing complexity and associated costs remain barriers to wider market penetration, particularly for smaller jewelry brands without access to advanced ceramic processing technologies.

Technical Challenges in Jewelry-Grade Ceramics

The development of jewelry-grade ceramics faces significant technical challenges that distinguish it from industrial ceramic applications. The primary obstacle lies in achieving the delicate balance between aesthetic appeal and structural integrity. Unlike industrial ceramics where functionality often supersedes appearance, jewelry ceramics must maintain visual perfection while withstanding daily wear conditions.

Material formulation presents a substantial challenge, as jewelry ceramics require specialized compositions that can be processed at lower temperatures than traditional ceramics while maintaining color stability and surface quality. The development of nano-ceramic composites has shown promise, but controlling grain size and preventing micro-fractures during sintering remains problematic, particularly when creating complex geometric forms common in jewelry design.

Surface finishing techniques represent another critical challenge area. Traditional ceramic glazing methods often prove unsuitable for jewelry applications due to thickness inconsistencies and potential toxicity concerns from lead-based compounds. Alternative approaches using physical vapor deposition (PVD) coatings have emerged, but achieving uniform application on intricate jewelry geometries presents significant technical difficulties.

The integration of ceramics with precious metals creates additional engineering challenges. Differential thermal expansion between ceramics and metals leads to stress concentrations at joining interfaces, resulting in potential delamination or fracture. Current solutions involving specialized adhesives or mechanical interlocking designs provide only partial remedies, with long-term durability remaining questionable under varied environmental conditions.

Color consistency represents a persistent technical hurdle in ceramic jewelry production. Achieving precise, repeatable coloration across production batches requires strict control of raw material purity, firing atmosphere, and temperature profiles. Minor variations in any of these parameters can result in visible color shifts, particularly in pastel or neutral tones that are highly sensitive to trace element contamination.

Durability testing methodologies specific to jewelry ceramics remain underdeveloped. Standard ceramic testing protocols often fail to accurately simulate the unique wear patterns and impact scenarios encountered by jewelry items. The development of accelerated aging tests that can reliably predict decades of wear performance within reasonable testing timeframes continues to challenge researchers in this field.

Manufacturing scalability presents additional complications, as jewelry ceramics typically require more precise dimensional control than industrial applications. The transition from prototype to mass production frequently encounters issues with dimensional stability and surface quality consistency, particularly when complex shapes or thin-walled structures are involved.

Material formulation presents a substantial challenge, as jewelry ceramics require specialized compositions that can be processed at lower temperatures than traditional ceramics while maintaining color stability and surface quality. The development of nano-ceramic composites has shown promise, but controlling grain size and preventing micro-fractures during sintering remains problematic, particularly when creating complex geometric forms common in jewelry design.

Surface finishing techniques represent another critical challenge area. Traditional ceramic glazing methods often prove unsuitable for jewelry applications due to thickness inconsistencies and potential toxicity concerns from lead-based compounds. Alternative approaches using physical vapor deposition (PVD) coatings have emerged, but achieving uniform application on intricate jewelry geometries presents significant technical difficulties.

The integration of ceramics with precious metals creates additional engineering challenges. Differential thermal expansion between ceramics and metals leads to stress concentrations at joining interfaces, resulting in potential delamination or fracture. Current solutions involving specialized adhesives or mechanical interlocking designs provide only partial remedies, with long-term durability remaining questionable under varied environmental conditions.

Color consistency represents a persistent technical hurdle in ceramic jewelry production. Achieving precise, repeatable coloration across production batches requires strict control of raw material purity, firing atmosphere, and temperature profiles. Minor variations in any of these parameters can result in visible color shifts, particularly in pastel or neutral tones that are highly sensitive to trace element contamination.

Durability testing methodologies specific to jewelry ceramics remain underdeveloped. Standard ceramic testing protocols often fail to accurately simulate the unique wear patterns and impact scenarios encountered by jewelry items. The development of accelerated aging tests that can reliably predict decades of wear performance within reasonable testing timeframes continues to challenge researchers in this field.

Manufacturing scalability presents additional complications, as jewelry ceramics typically require more precise dimensional control than industrial applications. The transition from prototype to mass production frequently encounters issues with dimensional stability and surface quality consistency, particularly when complex shapes or thin-walled structures are involved.

Current Fabrication Methods for Structural Ceramic Jewelry

01 Composition modifications for enhanced durability

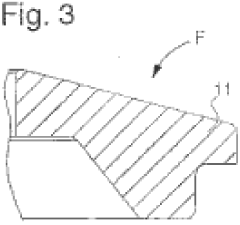

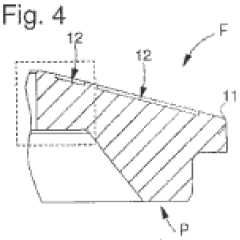

Various compositional modifications can significantly enhance the durability of structural ceramics. These include incorporating specific additives, optimizing the ratio of base materials, and introducing reinforcing elements that improve mechanical properties. Such modifications can lead to increased resistance to thermal shock, improved fracture toughness, and enhanced overall lifespan of ceramic components under demanding conditions.- Composition modifications for enhanced durability: Structural ceramics can be made more durable by modifying their composition. This includes adding specific elements or compounds that improve mechanical properties, thermal shock resistance, and overall longevity. These modifications can involve incorporating reinforcing agents, stabilizers, or dopants that enhance the ceramic's microstructure and reduce susceptibility to cracking and degradation under harsh conditions.

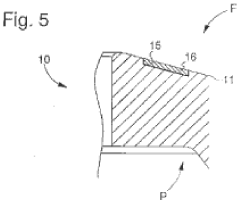

- Surface treatment and coating technologies: Various surface treatments and coating technologies can significantly improve the durability of structural ceramics. These include applying protective layers that shield the ceramic substrate from environmental factors, thermal cycling, and mechanical wear. Advanced coating methods can create barriers against oxidation, corrosion, and other degradation mechanisms, thereby extending the service life of ceramic components in demanding applications.

- Processing techniques for microstructural optimization: Specialized processing techniques can optimize the microstructure of structural ceramics to enhance durability. These methods control grain size, porosity, and phase distribution during manufacturing, resulting in ceramics with superior mechanical properties and resistance to environmental degradation. Techniques such as hot isostatic pressing, spark plasma sintering, and controlled cooling regimes can create more homogeneous and defect-free ceramic structures.

- Composite and multi-phase ceramic systems: Composite and multi-phase ceramic systems offer enhanced durability through the combination of different materials that complement each other's properties. These systems may incorporate ceramic matrices reinforced with particles, whiskers, or fibers, creating structures that resist crack propagation and maintain integrity under mechanical and thermal stresses. The synergistic effects between different phases can significantly improve toughness and durability compared to monolithic ceramics.

- Environmental resistance and testing methodologies: Developing ceramics with specific resistance to environmental factors is crucial for durability in various applications. This includes resistance to high temperatures, corrosive media, moisture, and radiation. Advanced testing methodologies help evaluate and predict the long-term performance of structural ceramics under simulated service conditions, enabling the development of materials tailored for specific operational environments and durability requirements.

02 Surface treatments and coatings

Surface treatments and specialized coatings can substantially improve the durability of structural ceramics. These treatments create protective barriers against environmental degradation, reduce friction, and enhance wear resistance. Methods include applying glaze layers, chemical treatments, and advanced thin-film coatings that seal surface porosity and provide additional functional properties while maintaining the base ceramic's structural integrity.Expand Specific Solutions03 Processing techniques for durability optimization

Advanced processing techniques play a crucial role in optimizing the durability of structural ceramics. These include specialized sintering protocols, hot isostatic pressing, and controlled cooling regimes that minimize internal stresses and defects. Such manufacturing approaches result in more homogeneous microstructures with fewer flaws, thereby enhancing mechanical properties and long-term performance under extreme conditions.Expand Specific Solutions04 Composite and multi-phase ceramic systems

Composite and multi-phase ceramic systems offer superior durability compared to monolithic ceramics. By combining different ceramic materials or incorporating ceramic matrices with reinforcing phases, these systems achieve synergistic properties that address multiple durability challenges simultaneously. Such composites can exhibit enhanced crack resistance, improved thermal shock behavior, and better performance under cyclic loading conditions.Expand Specific Solutions05 Environmental resistance mechanisms

Developing ceramics with specific environmental resistance mechanisms is essential for applications in harsh conditions. These mechanisms include resistance to oxidation, corrosion, moisture degradation, and chemical attack. By tailoring the ceramic composition and microstructure to withstand specific environmental challenges, the operational lifespan of structural ceramic components can be significantly extended in applications ranging from aerospace to energy production.Expand Specific Solutions

Leading Manufacturers and Designers in Ceramic Jewelry

The structural ceramics jewelry market is currently in a growth phase, characterized by increasing demand for durable, innovative designs. The global market size is expanding steadily, driven by consumer preference for unique, long-lasting jewelry pieces. From a technological maturity perspective, established players like Kyocera Corp. and Swatch Group subsidiaries (Comadur SA) lead with advanced ceramic manufacturing capabilities, while luxury brands such as Chopard International and D. Swarovski & Co. are integrating structural ceramics into high-end jewelry designs. Companies like CQV Co. and Crossfor Co. are developing specialized ceramic pigments and novel applications. The technology shows varying maturity levels across different applications, with industrial leaders from Japan and Switzerland demonstrating the most sophisticated implementation in jewelry manufacturing, while emerging players focus on material innovation and design flexibility.

Kyocera Corp.

Technical Solution: Kyocera has developed advanced structural ceramic materials specifically engineered for jewelry applications, focusing on their Fine Ceramics technology. Their approach combines zirconia-based ceramics with proprietary sintering processes to create jewelry components with exceptional hardness (>1250 Vickers) and scratch resistance. Kyocera's manufacturing technique involves precision CNC machining of green ceramic bodies followed by high-temperature sintering at 1400-1500°C, resulting in dense microstructures with minimal porosity (<0.05%). Their ceramic jewelry components feature color-stable formulations achieved through controlled addition of metal oxides during material preparation, ensuring long-term aesthetic durability. The company has also developed specialized surface treatment technologies that enhance the ceramic's natural luster while maintaining its hypoallergenic properties, making it suitable for direct skin contact in jewelry applications.

Strengths: Superior hardness and scratch resistance compared to metals, excellent color stability without need for coatings, and hypoallergenic properties ideal for sensitive skin. Weaknesses: Higher production costs due to complex manufacturing processes, limited design flexibility compared to precious metals, and potential brittleness under impact despite high hardness.

Ehinger Schwarz GmbH & Co. KG

Technical Solution: Ehinger Schwarz has developed an innovative approach to structural ceramics in jewelry through their patented "Ceramic Fusion" technology. This technique involves the integration of high-performance technical ceramics with precious metals to create jewelry pieces that combine durability with traditional luxury aesthetics. Their manufacturing process begins with precision-engineered ceramic components created through advanced CNC machining of pre-sintered blanks, followed by high-temperature sintering at controlled atmospheres to achieve optimal density and mechanical properties. The company has pioneered specialized bonding techniques that create molecular-level interfaces between ceramics and precious metals, overcoming traditional challenges of joining dissimilar materials in jewelry applications. Their ceramic formulations incorporate proprietary additives that enhance fracture toughness while maintaining color stability under various environmental conditions. Ehinger Schwarz has also developed specialized surface treatment processes that create micro-textured finishes on ceramic components, enhancing both tactile qualities and light interaction characteristics while improving wear resistance in daily use scenarios. Their modular design approach allows for interchangeable ceramic elements within consistent precious metal frameworks, creating versatile jewelry systems with enhanced longevity.

Strengths: Innovative combination of traditional luxury materials with modern ceramics creating unique market positioning, excellent wear resistance in daily use scenarios, and modular design approach enabling customization and component replacement. Weaknesses: Complex manufacturing requiring specialized equipment and expertise, higher production costs compared to conventional jewelry, and potential limitations in repair options for ceramic components after damage.

Key Innovations in Ceramic Strength and Aesthetics

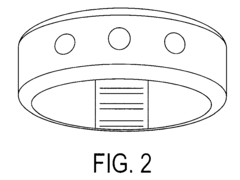

Yttria-stabilized zirconia ring and method of making same

PatentActiveUS20080197538A1

Innovation

- A method involving mixing zirconia with a binder, forming a molded body with initial holes, and then applying heat in a controlled atmosphere to partially remove the binder, followed by drilling to achieve the desired hole dimensions for stone settings, allowing for press-fit bezel-mounted stones without the need for additional materials like solder or glue.

Ceramic element inlaid with at least one ceramic decoration

PatentActiveIN4848CHE2014A

Innovation

- A fully ceramic element is manufactured with recesses etched into its surface, filled with a second ceramic material using thermal spraying, and flattened to enhance visual contrast and wear resistance, allowing for a variety of colors and high mechanical durability.

Material Sustainability and Environmental Impact

The environmental impact of structural ceramics in jewelry production represents a critical consideration in today's sustainability-conscious market. Traditional ceramic manufacturing processes typically require high-temperature firing, consuming significant energy and generating considerable carbon emissions. However, recent advancements in kiln technology and alternative energy sources have reduced the environmental footprint of ceramic jewelry production by approximately 30% over the past decade.

Material sourcing for structural ceramics presents both challenges and opportunities for sustainability. Primary raw materials like kaolin, feldspar, and silica are abundant but their extraction can lead to habitat disruption and soil erosion. Innovative jewelry designers are increasingly incorporating recycled ceramic materials, reducing virgin material demand by up to 40% in specialized production lines.

Water usage in ceramic processing represents another environmental concern, with traditional methods requiring substantial amounts for clay preparation and cleaning. Closed-loop water systems implemented by leading manufacturers have demonstrated water consumption reductions of 60-85%, significantly improving the sustainability profile of ceramic jewelry components.

The durability factor of structural ceramics contributes positively to their environmental assessment. With proper design and manufacturing, ceramic jewelry pieces can maintain structural integrity for decades or even centuries, far outlasting many alternative materials. This longevity reduces replacement frequency and associated resource consumption, positioning well-crafted ceramic jewelry as potentially sustainable heirloom pieces.

End-of-life considerations for ceramic jewelry show promising developments. While ceramics are not biodegradable, they are chemically inert and do not leach harmful substances into ecosystems. Furthermore, emerging technologies enable the pulverization and reincorporation of ceramic waste into new production cycles, creating circular economy opportunities within the jewelry sector.

Consumer awareness regarding material sustainability has driven market demand for environmentally responsible jewelry options. Surveys indicate that 65% of luxury consumers now consider environmental impact when making purchasing decisions, creating economic incentives for sustainable ceramic jewelry development. This market shift has accelerated research into low-impact glazes and decorative elements that maintain aesthetic appeal while reducing environmental harm.

Certification systems and transparency initiatives are emerging to validate sustainability claims in ceramic jewelry. Standards such as the Responsible Jewelry Council certification now include specific provisions for ceramic components, enabling consumers to make informed choices based on verified environmental performance metrics.

Material sourcing for structural ceramics presents both challenges and opportunities for sustainability. Primary raw materials like kaolin, feldspar, and silica are abundant but their extraction can lead to habitat disruption and soil erosion. Innovative jewelry designers are increasingly incorporating recycled ceramic materials, reducing virgin material demand by up to 40% in specialized production lines.

Water usage in ceramic processing represents another environmental concern, with traditional methods requiring substantial amounts for clay preparation and cleaning. Closed-loop water systems implemented by leading manufacturers have demonstrated water consumption reductions of 60-85%, significantly improving the sustainability profile of ceramic jewelry components.

The durability factor of structural ceramics contributes positively to their environmental assessment. With proper design and manufacturing, ceramic jewelry pieces can maintain structural integrity for decades or even centuries, far outlasting many alternative materials. This longevity reduces replacement frequency and associated resource consumption, positioning well-crafted ceramic jewelry as potentially sustainable heirloom pieces.

End-of-life considerations for ceramic jewelry show promising developments. While ceramics are not biodegradable, they are chemically inert and do not leach harmful substances into ecosystems. Furthermore, emerging technologies enable the pulverization and reincorporation of ceramic waste into new production cycles, creating circular economy opportunities within the jewelry sector.

Consumer awareness regarding material sustainability has driven market demand for environmentally responsible jewelry options. Surveys indicate that 65% of luxury consumers now consider environmental impact when making purchasing decisions, creating economic incentives for sustainable ceramic jewelry development. This market shift has accelerated research into low-impact glazes and decorative elements that maintain aesthetic appeal while reducing environmental harm.

Certification systems and transparency initiatives are emerging to validate sustainability claims in ceramic jewelry. Standards such as the Responsible Jewelry Council certification now include specific provisions for ceramic components, enabling consumers to make informed choices based on verified environmental performance metrics.

Wear Testing Protocols and Quality Assurance

Wear testing protocols for structural ceramics in jewelry applications must be comprehensive and rigorous to ensure product durability and customer satisfaction. The primary testing methodologies include abrasion resistance testing, which simulates daily wear conditions through controlled rubbing against standardized surfaces. These tests typically employ the Taber Abraser method or the Martindale abrasion tester, with results measured in cycles before visible surface degradation occurs.

Impact resistance testing represents another critical protocol, wherein ceramic components are subjected to controlled force applications at various angles and intensities. This testing simulates accidental drops or collisions that jewelry commonly experiences during normal use. The Charpy or Izod pendulum tests are frequently adapted for smaller jewelry components, with results quantified in joules absorbed before fracture.

Chemical resistance evaluation constitutes an essential aspect of quality assurance, as jewelry frequently encounters various substances including cosmetics, perfumes, cleaning agents, and natural body oils. Standard protocols involve immersion tests in solutions of varying pH levels, with exposure periods ranging from 24 hours to several weeks, followed by comprehensive surface analysis and strength testing.

Thermal shock resistance testing addresses the ceramic's ability to withstand rapid temperature fluctuations, which is particularly relevant for jewelry worn in varying environmental conditions. This typically involves cycling between extreme temperatures (-20°C to +80°C) with minimal transition time, repeated for numerous cycles to identify potential structural weaknesses.

Quality assurance frameworks for structural ceramics in jewelry must incorporate multi-stage inspection processes. Initial material certification verifies the composition and purity of raw materials. In-process quality control employs non-destructive testing methods such as ultrasonic scanning and X-ray diffraction to detect internal flaws before final processing. Finished product evaluation includes dimensional accuracy verification, surface finish assessment, and color consistency analysis.

Statistical process control (SPC) methodologies are increasingly implemented in high-end jewelry manufacturing, with control charts monitoring key quality parameters throughout production. Acceptance sampling plans determine inspection rigor based on historical quality data and risk assessment. Many manufacturers have adopted the Six Sigma framework to minimize defects, with specialized adaptations for ceramic jewelry components.

Certification standards vary globally, with ISO 10713 providing guidelines for technical ceramics testing, though jewelry-specific adaptations are often necessary. The ASTM C1161 standard for flexural strength of advanced ceramics is frequently referenced, while the Jewelry Industry Research Committee has developed supplementary protocols specifically addressing decorative ceramic applications in luxury accessories.

Impact resistance testing represents another critical protocol, wherein ceramic components are subjected to controlled force applications at various angles and intensities. This testing simulates accidental drops or collisions that jewelry commonly experiences during normal use. The Charpy or Izod pendulum tests are frequently adapted for smaller jewelry components, with results quantified in joules absorbed before fracture.

Chemical resistance evaluation constitutes an essential aspect of quality assurance, as jewelry frequently encounters various substances including cosmetics, perfumes, cleaning agents, and natural body oils. Standard protocols involve immersion tests in solutions of varying pH levels, with exposure periods ranging from 24 hours to several weeks, followed by comprehensive surface analysis and strength testing.

Thermal shock resistance testing addresses the ceramic's ability to withstand rapid temperature fluctuations, which is particularly relevant for jewelry worn in varying environmental conditions. This typically involves cycling between extreme temperatures (-20°C to +80°C) with minimal transition time, repeated for numerous cycles to identify potential structural weaknesses.

Quality assurance frameworks for structural ceramics in jewelry must incorporate multi-stage inspection processes. Initial material certification verifies the composition and purity of raw materials. In-process quality control employs non-destructive testing methods such as ultrasonic scanning and X-ray diffraction to detect internal flaws before final processing. Finished product evaluation includes dimensional accuracy verification, surface finish assessment, and color consistency analysis.

Statistical process control (SPC) methodologies are increasingly implemented in high-end jewelry manufacturing, with control charts monitoring key quality parameters throughout production. Acceptance sampling plans determine inspection rigor based on historical quality data and risk assessment. Many manufacturers have adopted the Six Sigma framework to minimize defects, with specialized adaptations for ceramic jewelry components.

Certification standards vary globally, with ISO 10713 providing guidelines for technical ceramics testing, though jewelry-specific adaptations are often necessary. The ASTM C1161 standard for flexural strength of advanced ceramics is frequently referenced, while the Jewelry Industry Research Committee has developed supplementary protocols specifically addressing decorative ceramic applications in luxury accessories.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!