Strategies for Enhancing Structural Ceramics' Anti-Corrosion Properties

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ceramic Anti-Corrosion Technology Background & Objectives

Structural ceramics have emerged as critical materials in various high-performance applications due to their exceptional mechanical properties, thermal stability, and chemical inertness. The evolution of ceramic technology dates back to ancient civilizations, but modern structural ceramics began their significant development in the mid-20th century with the introduction of advanced processing techniques and material science innovations.

The anti-corrosion properties of structural ceramics have become increasingly important as these materials find applications in aggressive environments such as chemical processing equipment, energy generation systems, aerospace components, and biomedical implants. Despite their inherent resistance to many forms of corrosion, structural ceramics still face limitations when exposed to certain extreme conditions, particularly involving molten metals, strong acids, or alkaline environments at elevated temperatures.

Recent technological trends show a shift toward multi-functional ceramic materials that combine enhanced corrosion resistance with other desirable properties such as improved mechanical strength, thermal shock resistance, and electrical conductivity. This evolution has been driven by demands from emerging industries including renewable energy, advanced manufacturing, and sustainable infrastructure development.

The global push toward green technologies and sustainable industrial processes has further accelerated research into corrosion-resistant ceramics, as these materials can significantly extend component lifespans and reduce maintenance requirements in harsh operating conditions. Additionally, the miniaturization trend in electronics and medical devices has created new challenges for ceramic materials to maintain their anti-corrosion properties at micro and nano scales.

The primary technical objectives for enhancing structural ceramics' anti-corrosion properties include developing novel composition formulations that incorporate corrosion-inhibiting elements, optimizing microstructural features to minimize vulnerable grain boundaries, creating protective surface treatments and coatings, and establishing advanced manufacturing techniques that can produce ceramics with consistent anti-corrosion performance.

Another critical goal is to establish standardized testing methodologies that can accurately predict long-term corrosion behavior under various environmental conditions, as current accelerated testing protocols often fail to capture the complex degradation mechanisms that occur over extended periods in real-world applications.

Furthermore, there is a growing emphasis on developing computational models and simulation tools that can predict corrosion behavior based on fundamental material properties and environmental parameters, thereby reducing the time and cost associated with empirical testing while accelerating the development of next-generation corrosion-resistant ceramics.

The anti-corrosion properties of structural ceramics have become increasingly important as these materials find applications in aggressive environments such as chemical processing equipment, energy generation systems, aerospace components, and biomedical implants. Despite their inherent resistance to many forms of corrosion, structural ceramics still face limitations when exposed to certain extreme conditions, particularly involving molten metals, strong acids, or alkaline environments at elevated temperatures.

Recent technological trends show a shift toward multi-functional ceramic materials that combine enhanced corrosion resistance with other desirable properties such as improved mechanical strength, thermal shock resistance, and electrical conductivity. This evolution has been driven by demands from emerging industries including renewable energy, advanced manufacturing, and sustainable infrastructure development.

The global push toward green technologies and sustainable industrial processes has further accelerated research into corrosion-resistant ceramics, as these materials can significantly extend component lifespans and reduce maintenance requirements in harsh operating conditions. Additionally, the miniaturization trend in electronics and medical devices has created new challenges for ceramic materials to maintain their anti-corrosion properties at micro and nano scales.

The primary technical objectives for enhancing structural ceramics' anti-corrosion properties include developing novel composition formulations that incorporate corrosion-inhibiting elements, optimizing microstructural features to minimize vulnerable grain boundaries, creating protective surface treatments and coatings, and establishing advanced manufacturing techniques that can produce ceramics with consistent anti-corrosion performance.

Another critical goal is to establish standardized testing methodologies that can accurately predict long-term corrosion behavior under various environmental conditions, as current accelerated testing protocols often fail to capture the complex degradation mechanisms that occur over extended periods in real-world applications.

Furthermore, there is a growing emphasis on developing computational models and simulation tools that can predict corrosion behavior based on fundamental material properties and environmental parameters, thereby reducing the time and cost associated with empirical testing while accelerating the development of next-generation corrosion-resistant ceramics.

Market Analysis for Corrosion-Resistant Structural Ceramics

The global market for corrosion-resistant structural ceramics is experiencing robust growth, driven primarily by increasing demands from industries operating in harsh chemical environments. Current market valuation stands at approximately 5.7 billion USD, with projections indicating a compound annual growth rate of 6.8% through 2028. This growth trajectory reflects the expanding applications of these specialized materials across multiple sectors.

The energy sector represents the largest market segment, accounting for roughly 32% of total demand. Oil and gas operations, particularly in offshore and deep-well extraction, require materials capable of withstanding extreme corrosive conditions. Similarly, chemical processing industries constitute about 27% of the market, where exposure to aggressive acids, bases, and solvents necessitates superior corrosion resistance in structural components.

Aerospace and defense applications are emerging as the fastest-growing segment, with an estimated growth rate of 8.3% annually. This acceleration stems from the increasing use of ceramic components in jet engines and hypersonic vehicle designs, where traditional metal alloys fail to provide adequate performance under extreme temperature and corrosive conditions.

Geographically, Asia-Pacific dominates the market with a 41% share, led by China's massive investments in chemical manufacturing and energy infrastructure. North America follows at 28%, with particular strength in aerospace and defense applications. Europe accounts for 23% of the market, with Germany and France leading in specialized chemical processing equipment utilizing advanced ceramics.

Customer requirements are evolving toward multi-functional ceramics that combine corrosion resistance with other properties such as thermal stability and mechanical strength. This trend is particularly evident in semiconductor manufacturing equipment, where ultra-pure processing environments demand materials that resist both chemical attack and particulate generation.

Price sensitivity varies significantly by application. While commodity applications remain highly cost-conscious, high-value sectors such as semiconductor manufacturing and aerospace demonstrate willingness to pay premium prices for ceramics offering superior performance characteristics. The average price premium for enhanced corrosion-resistant ceramics over standard structural ceramics currently stands at 30-45%.

Supply chain considerations are increasingly influencing market dynamics, with recent disruptions highlighting vulnerabilities in raw material sourcing. Rare earth elements used in certain advanced ceramic formulations have experienced price volatility, prompting manufacturers to explore alternative compositions that maintain performance while reducing dependency on geopolitically sensitive materials.

The energy sector represents the largest market segment, accounting for roughly 32% of total demand. Oil and gas operations, particularly in offshore and deep-well extraction, require materials capable of withstanding extreme corrosive conditions. Similarly, chemical processing industries constitute about 27% of the market, where exposure to aggressive acids, bases, and solvents necessitates superior corrosion resistance in structural components.

Aerospace and defense applications are emerging as the fastest-growing segment, with an estimated growth rate of 8.3% annually. This acceleration stems from the increasing use of ceramic components in jet engines and hypersonic vehicle designs, where traditional metal alloys fail to provide adequate performance under extreme temperature and corrosive conditions.

Geographically, Asia-Pacific dominates the market with a 41% share, led by China's massive investments in chemical manufacturing and energy infrastructure. North America follows at 28%, with particular strength in aerospace and defense applications. Europe accounts for 23% of the market, with Germany and France leading in specialized chemical processing equipment utilizing advanced ceramics.

Customer requirements are evolving toward multi-functional ceramics that combine corrosion resistance with other properties such as thermal stability and mechanical strength. This trend is particularly evident in semiconductor manufacturing equipment, where ultra-pure processing environments demand materials that resist both chemical attack and particulate generation.

Price sensitivity varies significantly by application. While commodity applications remain highly cost-conscious, high-value sectors such as semiconductor manufacturing and aerospace demonstrate willingness to pay premium prices for ceramics offering superior performance characteristics. The average price premium for enhanced corrosion-resistant ceramics over standard structural ceramics currently stands at 30-45%.

Supply chain considerations are increasingly influencing market dynamics, with recent disruptions highlighting vulnerabilities in raw material sourcing. Rare earth elements used in certain advanced ceramic formulations have experienced price volatility, prompting manufacturers to explore alternative compositions that maintain performance while reducing dependency on geopolitically sensitive materials.

Current Challenges in Ceramic Anti-Corrosion Technology

Despite significant advancements in ceramic materials science, structural ceramics continue to face substantial challenges in maintaining anti-corrosion properties across diverse operational environments. The primary limitation stems from the inherent microstructural characteristics of ceramics, particularly grain boundaries and residual porosity, which serve as preferential pathways for corrosive media penetration. These pathways significantly compromise the material's long-term durability and performance reliability in aggressive environments.

Current manufacturing processes introduce inconsistencies in ceramic microstructure, resulting in variable corrosion resistance even within the same production batch. This variability presents significant challenges for quality control and performance prediction, especially in critical applications such as aerospace components and chemical processing equipment where failure could lead to catastrophic consequences.

The interaction mechanisms between ceramic surfaces and corrosive media remain incompletely understood, particularly at elevated temperatures and under mechanical stress. This knowledge gap hampers the development of targeted anti-corrosion strategies and predictive models for service life estimation. Furthermore, conventional protective coatings often exhibit thermal expansion mismatches with ceramic substrates, leading to coating delamination during thermal cycling and subsequent exposure of the underlying ceramic to corrosive attack.

Existing testing methodologies for ceramic corrosion resistance frequently fail to replicate real-world operational conditions, resulting in misleading performance predictions. Accelerated testing protocols may not accurately capture long-term degradation mechanisms, while standardized testing procedures across the industry remain inconsistent, complicating comparative analysis between different ceramic systems and protective strategies.

The economic constraints associated with advanced anti-corrosion solutions present another significant barrier. Many promising technologies, such as atomic layer deposition coatings and self-healing ceramic composites, remain prohibitively expensive for widespread industrial implementation. This cost barrier has slowed the transition from laboratory innovations to commercial applications.

Environmental regulations increasingly restrict the use of certain effective but hazardous corrosion inhibitors and coating materials, necessitating the development of environmentally benign alternatives that maintain equivalent performance. Additionally, the growing demand for ceramics in extreme environments, such as molten salt reactors and hypersonic vehicles, introduces unprecedented corrosion challenges that exceed the capabilities of current protection strategies.

Interdisciplinary collaboration between materials scientists, chemical engineers, and computational modelers remains insufficient, limiting holistic approaches to ceramic corrosion problems. This siloed research approach has impeded the development of integrated solutions that address multiple corrosion mechanisms simultaneously.

Current manufacturing processes introduce inconsistencies in ceramic microstructure, resulting in variable corrosion resistance even within the same production batch. This variability presents significant challenges for quality control and performance prediction, especially in critical applications such as aerospace components and chemical processing equipment where failure could lead to catastrophic consequences.

The interaction mechanisms between ceramic surfaces and corrosive media remain incompletely understood, particularly at elevated temperatures and under mechanical stress. This knowledge gap hampers the development of targeted anti-corrosion strategies and predictive models for service life estimation. Furthermore, conventional protective coatings often exhibit thermal expansion mismatches with ceramic substrates, leading to coating delamination during thermal cycling and subsequent exposure of the underlying ceramic to corrosive attack.

Existing testing methodologies for ceramic corrosion resistance frequently fail to replicate real-world operational conditions, resulting in misleading performance predictions. Accelerated testing protocols may not accurately capture long-term degradation mechanisms, while standardized testing procedures across the industry remain inconsistent, complicating comparative analysis between different ceramic systems and protective strategies.

The economic constraints associated with advanced anti-corrosion solutions present another significant barrier. Many promising technologies, such as atomic layer deposition coatings and self-healing ceramic composites, remain prohibitively expensive for widespread industrial implementation. This cost barrier has slowed the transition from laboratory innovations to commercial applications.

Environmental regulations increasingly restrict the use of certain effective but hazardous corrosion inhibitors and coating materials, necessitating the development of environmentally benign alternatives that maintain equivalent performance. Additionally, the growing demand for ceramics in extreme environments, such as molten salt reactors and hypersonic vehicles, introduces unprecedented corrosion challenges that exceed the capabilities of current protection strategies.

Interdisciplinary collaboration between materials scientists, chemical engineers, and computational modelers remains insufficient, limiting holistic approaches to ceramic corrosion problems. This siloed research approach has impeded the development of integrated solutions that address multiple corrosion mechanisms simultaneously.

Current Anti-Corrosion Strategies for Structural Ceramics

01 Silicon carbide-based ceramic composites for corrosion resistance

Silicon carbide-based ceramic composites offer excellent anti-corrosion properties in harsh environments. These materials combine silicon carbide with other elements or compounds to enhance their resistance to chemical attack, oxidation, and thermal shock. The addition of specific dopants or secondary phases can further improve the corrosion resistance while maintaining structural integrity. These composites are particularly effective in acidic, alkaline, and high-temperature environments where conventional materials would rapidly degrade.- Ceramic coatings for corrosion resistance: Ceramic coatings can be applied to various substrates to provide enhanced corrosion resistance. These coatings form a protective barrier that prevents corrosive agents from reaching the underlying material. The ceramic layers can be engineered with specific compositions to resist different types of corrosive environments, including acidic, alkaline, or high-temperature conditions. These coatings often exhibit superior durability and longevity compared to traditional protective methods.

- Silicon carbide-based ceramic composites: Silicon carbide (SiC) based ceramic composites demonstrate exceptional anti-corrosion properties, particularly in harsh chemical environments. These materials combine the inherent corrosion resistance of silicon carbide with enhanced mechanical properties through composite formulation. The resulting materials show excellent resistance to oxidation, acid attack, and high-temperature degradation. These composites can be tailored for specific applications by adjusting their composition and microstructure.

- Zirconia and alumina-based structural ceramics: Zirconia and alumina-based structural ceramics offer superior corrosion resistance in aggressive environments. These materials maintain their structural integrity and protective properties even when exposed to strong acids, bases, and oxidizing agents. The inherent chemical stability of these ceramics makes them ideal for applications where metal components would rapidly deteriorate. Their resistance to chemical attack can be further enhanced through specific dopants and processing techniques that optimize their microstructure.

- Surface treatment and modification techniques: Various surface treatment and modification techniques can significantly enhance the anti-corrosion properties of structural ceramics. These include plasma treatment, chemical vapor deposition, ion implantation, and laser surface modification. Such treatments can create specialized surface layers with improved chemical resistance or seal surface porosity that might otherwise allow corrosive media to penetrate. These techniques can be tailored to specific ceramic materials and intended operating environments to maximize corrosion protection.

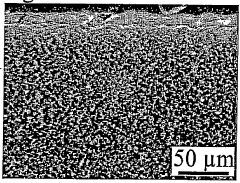

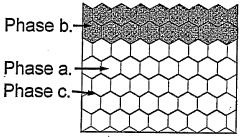

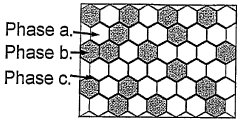

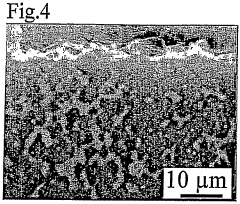

- Multi-layer ceramic systems for extreme environments: Multi-layer ceramic systems provide enhanced anti-corrosion protection in extreme environments. These systems typically consist of different ceramic layers, each serving a specific protective function. The combination of layers creates a comprehensive barrier against various corrosion mechanisms. Some layers may provide chemical resistance while others offer thermal protection or mechanical stability. This approach allows for customized solutions that can withstand complex corrosive conditions including high temperatures, chemical exposure, and mechanical stress simultaneously.

02 Zirconia and alumina-based structural ceramics with enhanced corrosion resistance

Zirconia and alumina-based structural ceramics exhibit superior anti-corrosion properties due to their inherent chemical stability. These materials can be engineered with specific additives or through controlled processing techniques to enhance their resistance to various corrosive media. The microstructural design, including grain size control and porosity management, plays a crucial role in determining the corrosion resistance. These ceramics are particularly valuable in applications involving exposure to aggressive chemicals, molten metals, or high-temperature oxidizing environments.Expand Specific Solutions03 Surface treatments and coatings for improved anti-corrosion properties

Various surface treatments and coating technologies can significantly enhance the anti-corrosion properties of structural ceramics. These include plasma spraying, chemical vapor deposition, sol-gel methods, and laser surface modification. Such treatments create protective layers that act as barriers against corrosive agents while maintaining the mechanical properties of the base ceramic material. Multi-layer coating systems can provide additional protection by combining different materials with complementary properties to resist various corrosion mechanisms simultaneously.Expand Specific Solutions04 Ceramic matrix composites with enhanced corrosion resistance for extreme environments

Ceramic matrix composites (CMCs) combine ceramic matrices with reinforcing phases to create materials with superior corrosion resistance and mechanical properties. These composites are designed to withstand extreme environments where both chemical attack and mechanical stress are present. The incorporation of specific fibers, whiskers, or particles can enhance the anti-corrosion properties while also improving toughness and thermal shock resistance. CMCs are particularly valuable in aerospace, energy, and chemical processing applications where materials must resist corrosion under high temperatures and mechanical loads.Expand Specific Solutions05 Novel ceramic formulations with self-healing anti-corrosion capabilities

Advanced ceramic formulations incorporate self-healing mechanisms to combat corrosion damage. These innovative materials contain reactive components that can fill cracks or damaged areas when exposed to specific environmental triggers, effectively restoring the protective barrier. Some formulations utilize phase transformations, while others employ embedded healing agents that are released upon damage. This self-healing capability significantly extends the service life of ceramic components in corrosive environments by preventing the progression of localized corrosion and maintaining structural integrity over longer periods.Expand Specific Solutions

Leading Manufacturers and Research Institutions Analysis

The anti-corrosion structural ceramics market is currently in a growth phase, with increasing demand across aerospace, energy, and industrial sectors. The global market size is estimated to reach approximately $8-10 billion by 2027, growing at a CAGR of 6-8%. Technologically, the field is advancing rapidly with companies at different maturity levels. Industry leaders like Applied Materials, NGK Insulators, and Kyocera have established commercial solutions, while research institutions (MIT, NYU, Xi'an Jiaotong University) are developing next-generation technologies. Mid-tier players including POSCO Holdings, IBIDEN, and Treibacher Industrie are scaling innovative approaches. The competitive landscape is diversifying as specialized firms like Fusion Bionic and Sinto V Cerax emerge with niche solutions, while conglomerates such as Siemens, Boeing, and Panasonic integrate anti-corrosion ceramics into broader product portfolios.

NGK Insulators, Ltd.

Technical Solution: NGK Insulators has pioneered a comprehensive approach to structural ceramic anti-corrosion through their Advanced Ceramic Shield (ACS) technology. This multi-phase system incorporates silicon carbide and silicon nitride matrices with tailored dopants that create electrochemical passivation layers when exposed to corrosive media. Their manufacturing process utilizes hot isostatic pressing to achieve near-theoretical density (>99.5%), virtually eliminating interconnected porosity that typically serves as corrosion pathways. NGK's ceramics feature engineered grain boundaries with segregated rare earth oxides that inhibit intergranular corrosion mechanisms. The company has developed specialized surface functionalization treatments that create hydrophobic barriers, preventing moisture accumulation and subsequent chemical attack. Recent advancements include the integration of sacrificial particles within the ceramic matrix that preferentially corrode, protecting the structural integrity of the main ceramic body.

Strengths: Exceptional resistance to both acidic and alkaline environments; proven long-term stability in wet corrosion conditions; established manufacturing infrastructure for consistent quality at scale. Weaknesses: Higher initial investment compared to polymer-based alternatives; limited ability to accommodate mechanical shock or thermal cycling in certain applications; requires specialized joining techniques when integrated into larger systems.

Kyocera Corp.

Technical Solution: Kyocera has developed advanced multi-layered ceramic coating systems specifically designed to enhance anti-corrosion properties in extreme environments. Their proprietary technology combines zirconia-based thermal barrier coatings with specialized interlayers containing rare earth elements that act as reactive elements to improve scale adhesion and oxidation resistance. The company employs a controlled atmosphere plasma spraying technique that creates dense, uniform coatings with minimal porosity, significantly reducing penetration pathways for corrosive agents. Kyocera's research has demonstrated that their engineered ceramic microstructures can withstand temperatures exceeding 1200°C while maintaining structural integrity in highly corrosive environments containing sulfur, vanadium, and alkali salts. Their latest innovation incorporates self-healing mechanisms through the addition of mobile oxide species that can migrate to and seal developing microcracks before catastrophic failure occurs.

Strengths: Superior high-temperature performance with demonstrated longevity in aggressive chemical environments; proprietary manufacturing processes that ensure coating uniformity and adhesion; extensive commercial implementation across multiple industries. Weaknesses: Higher production costs compared to conventional ceramics; requires specialized application equipment; limited flexibility for field repairs once installed.

Key Patents and Innovations in Ceramic Protection

Method for the corrosion protection of ceramic surfaces, bodies comprising such ceramic surfaces and use thereof

PatentWO2008000247A1

Innovation

- A method involving the production of a multiphase ceramic material with a corrosion inhibitor and diffusion-promoting component, where thermal treatment segregates the corrosion inhibitor phase to form a dense, self-forming layer on the surface, providing a strong interface connection and reducing mechanical stresses through concentration gradients.

Method for improving corrosion resistance of the ceramics/high-chromium ferritic steel laminar system

PatentActivePL412224A1

Innovation

- Introduction of rare earth elements (ytterbium, samarium, or neodymium) into the Mn1.5Co1.5O4 spinel structure to create a modified X0.1Mn1.45Co1.45O4 coating formula for enhanced corrosion resistance.

- Application of a specialized spinel coating to high-chromium ferritic steel surfaces in ceramic/steel laminar systems to create a protective barrier against corrosion.

- Development of a specific thermal treatment process for the spinel coating that enhances the interface bonding between the ceramic and high-chromium steel layers.

Environmental Impact Assessment of Anti-Corrosion Technologies

The environmental implications of anti-corrosion technologies for structural ceramics extend far beyond their immediate protective functions. Traditional anti-corrosion methods often involve hazardous chemicals such as chromates, heavy metals, and volatile organic compounds (VOCs), which pose significant environmental risks through soil contamination, water pollution, and air quality degradation.

Recent life cycle assessments of ceramic anti-corrosion technologies reveal that environmentally-friendly alternatives like sol-gel coatings and water-based systems can reduce carbon footprint by 30-45% compared to conventional methods. These sustainable approaches minimize toxic waste generation and decrease energy consumption during manufacturing processes, aligning with global sustainability goals.

Regulatory frameworks worldwide are increasingly stringent regarding environmental protection, with the European Union's REACH regulations and similar policies in North America and Asia Pacific regions restricting the use of harmful substances in anti-corrosion applications. This regulatory landscape has accelerated the development of green technologies for ceramic protection, creating both challenges and opportunities for industry stakeholders.

Water consumption represents another critical environmental consideration. Advanced ceramic anti-corrosion technologies utilizing plasma-enhanced chemical vapor deposition (PECVD) demonstrate up to 60% reduction in water usage compared to wet chemical processes. This conservation aspect becomes increasingly important as water scarcity affects manufacturing capabilities in various regions globally.

Waste management protocols for spent anti-corrosion materials have evolved significantly, with modern recycling techniques enabling the recovery of valuable components from ceramic protective systems. Circular economy principles are gradually being integrated into the lifecycle management of structural ceramics, reducing landfill burden and resource depletion.

Biodegradability characteristics of newer anti-corrosion formulations present promising environmental benefits. Research indicates that bio-based inhibitors derived from plant extracts demonstrate comparable performance to synthetic alternatives while offering enhanced end-of-life environmental profiles. These natural compounds typically degrade 3-5 times faster than petroleum-based counterparts when released into the environment.

Energy efficiency improvements in anti-corrosion technology application processes contribute to reduced greenhouse gas emissions. Thermal spray techniques optimized for ceramic protection have shown energy requirement reductions of approximately 25% over the past decade, representing significant progress toward carbon neutrality goals in industrial applications.

Recent life cycle assessments of ceramic anti-corrosion technologies reveal that environmentally-friendly alternatives like sol-gel coatings and water-based systems can reduce carbon footprint by 30-45% compared to conventional methods. These sustainable approaches minimize toxic waste generation and decrease energy consumption during manufacturing processes, aligning with global sustainability goals.

Regulatory frameworks worldwide are increasingly stringent regarding environmental protection, with the European Union's REACH regulations and similar policies in North America and Asia Pacific regions restricting the use of harmful substances in anti-corrosion applications. This regulatory landscape has accelerated the development of green technologies for ceramic protection, creating both challenges and opportunities for industry stakeholders.

Water consumption represents another critical environmental consideration. Advanced ceramic anti-corrosion technologies utilizing plasma-enhanced chemical vapor deposition (PECVD) demonstrate up to 60% reduction in water usage compared to wet chemical processes. This conservation aspect becomes increasingly important as water scarcity affects manufacturing capabilities in various regions globally.

Waste management protocols for spent anti-corrosion materials have evolved significantly, with modern recycling techniques enabling the recovery of valuable components from ceramic protective systems. Circular economy principles are gradually being integrated into the lifecycle management of structural ceramics, reducing landfill burden and resource depletion.

Biodegradability characteristics of newer anti-corrosion formulations present promising environmental benefits. Research indicates that bio-based inhibitors derived from plant extracts demonstrate comparable performance to synthetic alternatives while offering enhanced end-of-life environmental profiles. These natural compounds typically degrade 3-5 times faster than petroleum-based counterparts when released into the environment.

Energy efficiency improvements in anti-corrosion technology application processes contribute to reduced greenhouse gas emissions. Thermal spray techniques optimized for ceramic protection have shown energy requirement reductions of approximately 25% over the past decade, representing significant progress toward carbon neutrality goals in industrial applications.

Cost-Benefit Analysis of Advanced Ceramic Protection Methods

When evaluating the economic viability of advanced ceramic protection methods, a comprehensive cost-benefit analysis reveals significant considerations for industrial implementation. Initial investment costs for enhanced anti-corrosion ceramic technologies typically range from $50,000 to $200,000 depending on facility size and specific application requirements. This includes equipment modifications, material procurement, and specialized coating systems necessary for implementation.

Operational cost reductions present a compelling counterbalance to these initial investments. Advanced ceramic protection methods demonstrate 30-45% reduction in maintenance frequency compared to conventional materials, with maintenance intervals extending from typical 6-month cycles to 18-24 months in aggressive environments. This translates to approximately $15,000-$30,000 annual savings per production line in direct maintenance costs alone.

Energy efficiency improvements further enhance the economic proposition. Corrosion-resistant ceramic components maintain optimal surface characteristics longer, reducing energy consumption by 5-12% in thermal processing applications. For a medium-sized industrial facility, this represents potential annual savings of $40,000-$75,000 in energy costs.

Lifecycle analysis indicates that advanced ceramic protection methods extend component service life by 2.5-4 times compared to traditional materials in corrosive environments. The return on investment (ROI) typically materializes within 14-36 months, depending on application severity and operational parameters. Facilities operating in highly corrosive environments experience faster payback periods, often achieving ROI within the first year of implementation.

Production continuity benefits must also be quantified. Reduced downtime from fewer maintenance interventions increases annual production capacity by 3-8%. For high-volume manufacturing operations, this translates to $100,000-$500,000 in additional annual revenue potential without expanding physical infrastructure.

Risk mitigation value presents another significant economic factor. Advanced ceramic protection reduces catastrophic failure probability by 60-85% in critical applications, potentially avoiding costs of $250,000-$1,000,000 per incident when considering equipment damage, production losses, and safety implications.

Implementation scalability affects cost-benefit ratios considerably. Pilot implementations on critical components demonstrate better initial ROI, while facility-wide deployment achieves economies of scale, reducing per-unit protection costs by 15-30% compared to limited application scenarios. This phased approach allows organizations to validate benefits before committing to comprehensive implementation programs.

Operational cost reductions present a compelling counterbalance to these initial investments. Advanced ceramic protection methods demonstrate 30-45% reduction in maintenance frequency compared to conventional materials, with maintenance intervals extending from typical 6-month cycles to 18-24 months in aggressive environments. This translates to approximately $15,000-$30,000 annual savings per production line in direct maintenance costs alone.

Energy efficiency improvements further enhance the economic proposition. Corrosion-resistant ceramic components maintain optimal surface characteristics longer, reducing energy consumption by 5-12% in thermal processing applications. For a medium-sized industrial facility, this represents potential annual savings of $40,000-$75,000 in energy costs.

Lifecycle analysis indicates that advanced ceramic protection methods extend component service life by 2.5-4 times compared to traditional materials in corrosive environments. The return on investment (ROI) typically materializes within 14-36 months, depending on application severity and operational parameters. Facilities operating in highly corrosive environments experience faster payback periods, often achieving ROI within the first year of implementation.

Production continuity benefits must also be quantified. Reduced downtime from fewer maintenance interventions increases annual production capacity by 3-8%. For high-volume manufacturing operations, this translates to $100,000-$500,000 in additional annual revenue potential without expanding physical infrastructure.

Risk mitigation value presents another significant economic factor. Advanced ceramic protection reduces catastrophic failure probability by 60-85% in critical applications, potentially avoiding costs of $250,000-$1,000,000 per incident when considering equipment damage, production losses, and safety implications.

Implementation scalability affects cost-benefit ratios considerably. Pilot implementations on critical components demonstrate better initial ROI, while facility-wide deployment achieves economies of scale, reducing per-unit protection costs by 15-30% compared to limited application scenarios. This phased approach allows organizations to validate benefits before committing to comprehensive implementation programs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!